Centrifugle Bugle Autumn 2016

-

Upload

alasdair-carstairs -

Category

Documents

-

view

91 -

download

1

Transcript of Centrifugle Bugle Autumn 2016

tec

hno

log

ies

Autumn 2016Centrifuges Un-limited Newsletter

Featuring our NEW Innovative Products

www.centrifuges-unlimited.co.uk

A Centrifuges Un-Limited Product

SuperCulA Centrifuges Un-Limited Product

AutoCul

Smaller design mud coolerCompact

Performance Unit

Superior performance mud cooler - half the

size of dual unit

Automated mud cooling system

A Centrifuges Un-Limited Product

BopSepBOP Fluids Clean Up

NEWfunction

A Centrifuges Un-Limited Product

EcoCul

CENTRIFUGLE BUGLE | ISSUE 04 | AUTUMN 2016

Our Heat Transfer Division has developed 3 new products which are ready to market, with 1 more in the pipeline for onshore land cooling. Our Mechanical Separation division are also continuing to innovate, with the new BopSep system, a purposely built solution for BOP (Blow Out Preventer) fluids cleaning.

Jim Shiach MANAGING DIRECTOR

MANAGING DIRECTOR’S MESSAGE

Welcome to this edition of the Centrifugle Bugle. We will focus on Innovation and highlight some of the advancers we are developing to give the customer more flexible and cost effective solutions.

Customer Issue Drilling contractors looking at how they can reduce operating costs and drive up efficiencies.Currently costs $30,000 - $50,000 to change out BOP fluid; $300k+ per year spend. Also takes 2 days +/- to clean with filtration so reduces NPT.

Filters being used continuously, corrosion of equipment and internal lines causing failures of operating system are also issues experienced.

Background to Mud Cooling

Our SolutionCustomers required a cost effective solution that would allow them to reuse the fluid as opposed to buying more.

We received a sample of contaminated fluid and processed it in our facility.

Results were sent back to the manufacturer of the fluid who confirmed that fluid was class 7 and “as new fluid”.

The BopSep system reduces operating cost, increases uptime and reduces environmental impact.

NEW PRODUCT LAUNCHCentrifuges Un-Limited have launched innovative products and services which offer more efficient and cost effective ways of mechanical separation and heat transfer.

We were well ahead of our closest competitors but without resting on our laurels, CUL were already investing in R&D to further develop and enhance our state of the art MUD 500. Testimonials from our customers were “you have produced a tool that outperforms anything that is in the market” but we again asked the question to our customers…. “what does the industry require now”?….We were now tasked to produce a Mud Cooler with

similar performance but with a smaller footprint, “plug and play”, and having the option and capability of controlling automatically the temperature performance of the Mud Cooler. Our objective and mission was clear…. “keep the high temperature performance of the MUD 500 but reduce the footprint by 50% and have an automated system”. This lead CUL to develop AutoCul, SuperCul and EcoCul.

We developed and introduced the Dual MUD 500 with GEA Plate Heat Exchangers 6 years ago. The market at that time was looking for a high performance top of the range Mud Cooler for HPHT drilling operations. Centrifuges Un-Limited (CUL) had developed a third-generation Mud Cooler system that took the market by storm and outperformed anything that was on the marketplace.

A Centrifuges Un-Limited Product

BopSep

CENTRIFUGLE BUGLE | ISSUE 05 | AUTUMN 2016

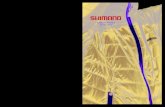

This map shows where our equipment is currently on contract in the world.

Customer Issue Overcooling of drilling mud can be detrimental to wellbore and formation properties.AutoCul was designed to eliminate the potential for over cooling but also to give complete control to the drilling engineer for mud temperature control. The client came to us looking to maintain a return to well.

Our SolutionThe next challenge was to develop the AutoCul unit. The task was to design a small footprint, “bolt on plug and play” module, with an electronic touch screen setting to automatically control the required mud temperature drop and is easily adjustable depending on downhole temperature requirement. The AutoCul unit would also have the option of having remote operational screens within the drilling office and the drillers “dog house”.

Benefits: removed risk of over cooling, increased performance of well fluids due to working at optimum temperatures, reduced operator interface for data recording, increased accuracy of performance results, reduced risk of fluid temperatures going above safe limits, increased safety.

A major offshore operator was approached and asked if they would assist in testing SuperCul and AutoCul on one of the hottest HPHT wells ever drilled in the North Sea. Testing Started in November 2015 and instantly the performance and flexibility of the enhanced SuperCul/AutoCul system was noticeable.

Falkland IslandsSurinameEgyptAbu DhabiDubaiBakuIvory CoastTrinidad & TobagoSaudi ArabiaNorth SeaStanlow, Cheshire

Where are we now?

Customer Issue Client was looking for dual mudcooler performance but did not have the space requirements for installation due to large HPHT spread on the jack-up.

Customer Issue Although CUL are the market leaders in Mud Cooler technologies, aiming at the high value end of the market, there are also opportunities to develop and compete direct against our competitors in the lower value end for Mud Coolers.

Our SolutionThe SuperCul was developed through 2 years of R&D with our OEM plate heat exchanger provider. A new chevron plate and design was tested for better performance but with a 50% smaller footprint than the Dual MUD 500.

The new generation plate design third less titanium plates were required but offering 65% more Thermal Surface Area than the Single MUD 500.

Benefits: reduced footprint, increased efficiency, shorter installation time

Our SolutionEcoCul is a smaller, less expensive version of SuperCul. Although still giving very good temperature performance with high quality, it is a “fit for purpose” offer for different regions and for market competiveness.

This now also gives our customers a price choice with different types/sizes of Mud Coolers. We will still be offering very high quality product but prices to suit the customer’s and regional requirements.

A Centrifuges Un-Limited Product

SuperCul

A Centrifuges Un-Limited Product

AutoCul

A Centrifuges Un-Limited Product

EcoCul

www.centrifuges-unlimited.co.uk

Centrifuges Un-limited Centrifuge HouseHowe Moss TerraceKirkhill Industrial Estate DyceAberdeen AB21 0GR

contactt +44 (0) 1224 772918f +44 (0) 1224 772193 e [email protected]

Business is going well in the Middle East and ahead of initial expectations. However the market is challenging and we are doing what we can to reduce clients’ downtime and increase their efficiencies. We recently won an order to provide heat exchangers for a major global drilling contractor. Centrifuges Middle East faced stiff competition from long term providers, however due to our proactive approach in going beyond client expectations, we were able to secure the order for 2 rigs. We will have our first BopSep and Fuel Treatment separators for rent

arriving in Dubai next month and these will be available to support our ongoing growth in the region from November. We have also just completed our first mud cooling project in Abu Dhabi with very positive feedback from the client. Centrifuges Un-Limited are continuing to increase awareness of our capabilities in the region and look to build on the good foundations already laid. A lot of hard work and teamwork has been put in and support from our UK head office will be crucial in continuing to expand our global presence.

Nick Slater GENERAL MANAGER MIDDLE EAST

IADC

Centrifuges Middle East FZE

Centrifuges Un-Limitedare now verified by FPAL.

Centrifuges Unlimited MENA were invited to conduct a presentation on cost saving solutions at the IADC Southern Arabian Peninsula Chapter Technical Meeting on the 22nd Sept 2016 in Dubai. We were fortunate to have the opportunity to illustrate our Mechanical Separation and Thermal Plate Heat Exchanger Technologies which can minimise operating costs on both onshore and offshore rigs.

Two issues were broached during the discussions: BOP Fluid Management and Thermal Technology Mud Coolers.

Nick introduced Centrifuge Un-Limited’s BopSep Fluid Clean up System; a 3 Phase Mechanical Separator which separates oil, water and particulate on a continuous basis. This minimises water in the system and bacterial growth, whilst maintaining the BOP Fluid at NACE level recommended by the BOP manufacturers.

Nick then discussed the need for Drilling Contractors to extend the life cycle of all Elastomers in the BOP, Mud Pit System and Mud Pump Liners. Since 2002, Centrifuges Unlimited

have been providing mud coolers to the majority of oilfield operators throughout North Sea, Africa, Middle East and South America regions on onshore and offshore installations. These have predominately been installed on rigs drilling HTHP wells with downhole temperatures of up to 400°F, using downhole tools such as MWD/LWD/VPWD which have a maximum temperature range to operate efficiently.

Over the past 6 months, drilling contractors within the MENA region have shown an interest in using our mud cooling solutions in the belief that they will improve the rigs readiness of drilling and reduce the operating cost of elastomers which are exposed to increased mud temperatures.

May we take this opportunity to thank the IADC Southern Arabian Peninsula Chapter for the opportunity to present at the technical forum and also a special thank you to Penny LeBaron, Mike Simpson of Cansco Well Control and Mike McTavish of Ensco who assisted in overviewing the presentation prior to the technical meeting.

Come and see us at ADIPEC 2016!We are exhibiting in Hall 1, within the Scotland Pavilion on stand 1210 and would love to see you there.

Over the past 6 months Centrifuges Middle East FZE has increased it’s focus in the Dubai MENA Region, where Onshore and Offshore Drilling Contractors have asked how our technology can assist them in reducing operating costs.