Welding of Heat-resisting steel

Click here to load reader

-

Upload

aunginternet -

Category

Documents

-

view

225 -

download

11

description

Transcript of Welding of Heat-resisting steel

Welding of Heat-Resisting Steels

Material for May 7th 2010

Lecturer Dr. Jippei Suzuki 鈴木実平Graduate School of Engineering Mie UniversityDepartment of Mechanical EngineeringFaculty of Engineering, Mie UniversityKurima-Machiya-cho 1577, Tsu, Mie 514-8507Tel. 059-231-9372Fax. 059-231-9663E-mail [email protected]

1. Carbon steels JIS SB42, SB46, SB49

2. Molybdenum alloy steels JIS SB46M, SB49M

3. Chromium-molybdenum alloy steels JIS SCMV1-6

4. Stainless steels 18Cr-8Ni

5. Heat-resistant alloy (Superalloy) Fe-Ni base, Co base, Ni base

Tem

pera

ture

(K)

Mild steelMild steel

Mild steel

Mild steel

HRA* HRA*

BoilerPetroleumEng.

ChemicalEng. Hydrogen

HRA*: heat resistant alloy

18Cr-8Ni

Types of heat resistant steels (Fig.H1)

Service temperature for heat resistant steels

Strength of steels at elevated temperature (Fig.H2)

strain

stressRoom temp.

Elevated temp.

YT1

T2

B

C

εe

Instantaneous extension

stra

in o

r elo

ng

ati

on

timePrimary or transient creep

Secondary or steady-rate creep

Tertiary or accelerating creep

High temp.High stress

Low temp.Low stress

Creep phenomenon (Fig.H3)

Creep strength at a given temperature(Fig.H4)

Applied stress

Str

ain

rate

, L

ength

/Tim

e Creep strength at a given strain rate

Applied stressFr

act

ure

tim

e , Tim

e

Creep strengthat a given time

A

B

C

D

Str

ess

Temperature

Carbon steel

Creep strength (1%/36000ks) of steels

3600ks=1000hr=41.7days

Creep strength of heat-resisting steels(Fig.H5)

316

Carbon steel

Ni base alloy

Co base alloy

Fe-Ni base alloy

304

316: 316 stainless steel304: 304 stainless steel

5Cr-1/2Mo

2 1/4Cr-1Mo

1 1/4Cr-1/2Mo

Temperature

1000

hr c

reep

rupt

ure

stre

ngth

Creep strength of heat-resistant steels and alloy (Superalloy) (Fig.H6)

Oxidization induced by O2, H2O, CO2

Cr, Al, Si form stable oxide film at elevated temperature.

Oxide film of low melting point

Vanadium attack V2O5(m.p.963K)V2O5-Na2SO4(m.p.873K)MoO3

Attack by H2S, SO2

Resistance to oxidization (Fig.H7)

Cr2O

Fe 5%Cr 8%Cr 10%Cr 15%Cr 18%Cr 23%Cr

Fe2O3

Fe3O4

FeOFeO ・ (Cr,Fe)2O3

Type of steel Maximum allowable temperature (K)

No loading under loading

Carbon steel 838 811C-1/2Mo steel 838 8111 1/4Cr-1/2Mo steel 863 8382 1/4Cr-1Mo steel 908 8385Cr-1/2Mo steel 923 8389Cr-1Mo steel 972 838

Allowable service temperature of

low alloy steels considering to oxidization (Table H1)

Two types of hydrogen embrittlement

1. Reduction in thoughness at room temperature after long service of elevated temperature

2. Hydrogen attack occurring in service at elevated temperature

High pressurehigh temperaturehydrogen gas

Hydrogen embrittlement of low alloy heat resistant steels (Fig.H8)

Carbon containing in steel C

H

H

C + 4H CH4

Formation of methane gas

Nucleationof void

Internalstress

Grain Boundarycrack

H2

Allowable service limits of Cr-Mo steels under hydrogen of high temperature-high pressure (Nelson curve)

de-cauburization of interiorde-cauburization of surface

or

Carbon steel

Hydrogen pressure MPa

Tem

pera

ture

(K

)

Resistance to hydrogen attack (Fig.H9)(high temperature-high pressure hydrogen)

1. Hardening of HAZ and Lowering ductility

Service conditions

3. Cold crack induced hydrogen in weld metal and HAZ

4. Crack caused by PWHT (reheat crack)

2. Toughness of welds

5. Embrittlement caused by long period heating

Conditions of PWHT

Welding parameters

Influence of impurities

Influence of alloying elements

Hydrogen

Weldability and factors (Fig.H10)

Examples of Jominy curves

Hard

ness

(H

RC

)

Distance from quenched end (mm)

water

waterwater

specimen

Jominy end quenching test

Hardenability of heat resistant steels (Fig.H11)

Tem

pera

ture

Tem

pera

ture

Tem

pera

ture

TimeTime

Time

0.11C-0.77Si-0.46Mn-1.27Cr-0.50Mo 0.13C-0.31Si-0.46Mn-2.39Cr-0.97Mo

0.10C-0.27Si-0.45Mn-4.31Cr-0.59Mo

Hardening of heat affected zone (Fig.H12)

10 102 103 1040

100

200

300

400

Cooling time from A3 to 773K s

Hard

ness

V

HN

1 1/4Cr-1/2Mo

2 1/4Cr-1Mo

4.3Cr-0.6Mo

Avera

ge h

ard

ness

of

weld

meta

l(H

V)

Peak

hard

ness

in H

AZ

(HV

)

Pre-heating temperature(K) Pre-heating temperature(K)

Influence of pre-heating temperature on hardness (Fig.H13)

Pre-heating temperature

Holding time

Am

ount

of

hydro

gen

Perc

enta

ge o

f cr

ack

(%

)

Three factors of cold crack1. Hard microstructure2. Hydrogen3. Stress

Hydrogen is released at elevated temperature.

Local heating

Cast steel

Cold crack (Fig.H14)

Temperature

No cracking

Cracking

Hold

ing

tim

e (

s)

Post heating of welds is effective to prevent cold cracking.

Effect of post-weld heat treatment to prevent cold crack (Fig.H15)

about 1 hr

Crack along prior-austenite grain boundaryDuring post-weld heat treatment

Main foctors

1. Alloying elements

ΔG=(%Cr)+3.3(%Mo)+8.1(%V)-2 (for high strength steels)When ΔG>0, the crack occurs.

PSR=(%Cr)+(%Cu)+2(%Mo)+10(%V) +7(%Nb)+5(%Ti)-2

%Cr≦1.5, 0.10≦%C ≦0.25, %Cu ≦1.0, %Mo ≦2.0, %V, %Nb, %Ti ≦0.15When PSR≧0, the crack occurs.

2. Impurity P, S increase the sensitivity to crack.

3. Parameters of welding and PWHT

PWHT crack (Reheat crack) (Fig.H16)

Purposes of PWHT To reduce residual welding stress (Stress Relief annealing) To improve mechanical properties and performance to erosion (Normalizing, Quench/Temper, Solution treatment) To prevent cold cracking (Post-weld heating)

The welds are heated below Ac1 to reduce the harmful factor, such as residual stress.Then, the welds are cooled uniformly to prevent the occurrence of thermal stress.

steel HPIS JIS Z 3700 ISO/DIS 2694 ASME SecVIII

ASME SecIII BS 5500 BS2633 (tube)

ANSI B31.3 (tube)

1 Carbon steel ≧823 ≧873 823 ~ 873 ≧868 868 ~ 948 873±20 853 ~ 893903 ~ 943*

868 ~ 923

3 C-Mo ≧863 ≧873 853 ~ 893 ≧868 868 ~ 948 923 ~ 953 923 ~ 953 868 ~ 993

4 1 1/4Cr-1/2Mo ≧863*≧893

≧873 893 ~ 933 ≧868 868 ~ 948 903 ~ 943923 ~ 973

903 ~ 943 978 ~ 1018

52 1/4Cr-1Mo

≧923*≧948

≧953898 ~ 1023*

≧948 948 ~ 1033

903 ~ 943953 ~ 993983 ~ 1023

953 ~ 993973 ~ 1023

978 ~ 1033

5Cr-1/2Mo ≧948*≧973

943 ~ 1013* 983 ~ 1033 983 ~ 1033

9Cr-1Mo

9 3 1/2Ni ≧823 823 ~ 853 868 ~ 908 868 ~ 908 853 ~ 893 863 ~ 983 868 ~ 908

Standards of PWHT (unit: K)

Postweld heat treatment on heat resistant steels (Fig.H17)

Ten

sile

str

en

gth

Larson-Miller parameter

single

Temp. time

Tensile strength is decreased with increasing heating temperature and prolonging heating time.

Influence of PWHT on mechanical properties (Tensile strength) (Fig.H18)

Cree

p ru

ptur

e st

reng

th a

t 823

K(M

Pa)

SMAW bearing Ti

SMAW

Submerged arc welding

GMAW

Temperature of PWHT (K) (holing time 18ks)

Larson-Miller parameter

Temp. time

as-welded

Influence of PWHT on bond toughness of A533B steel weld (150mm)

Abso

rbed

energ

y

Influence of PWHT on mechanical properties (Creep rupture stress and Toughness) (Fig.H19)

Influence of chemical compositions on temper embrittlement in 2 1/4Cr-1Mo steels welds

(Fig.H20)

step cooling

Steel plate

Forged material

at 283K

J

Temper embrittlement is observed in low alloy steels Containing Ni, Cr, Mo. It does not occur in plain carbon steels.

Temper embrittlement is remarkable in the steels withHigh impulity contents, such as P, Sb, Sn and As.

Fracture occures along prior-austenite grain boundary.

Temper embrittlement is reversible. Ii is possible to Recover toughness, heating over the temperature range of embrittlement.

Temper embrittlement

A: as-receivedT: PWHTS: Step coolingSS: Double step coolingR: Re-tempering treatment

W.M.: weld metal

W.M. W.M. W.M.

W.M. W.M. W.M.

W.M. W.M.

Temper embrittlementof heat resisting steels

vTrs

vTrs

vTrs : Surface transition temperature(2mm V-notch Charpy test)

(Fig.21)

Welding of stainless steels - Schaeffler diagram (Fig.S1)

0 10 20 30 40

Creq=%Cr+%Mo+1.5%Si+0.5%Nb

30

20

10Ni eq

=%N

i+30

%C+

0.5%

Mn

F+M

M

A+M

A

A+M+F

M+F F

0%F(1

00%A)

5%F

10%F

25%F

40%F

80%F

100%F

0 10 20 30 40

Creq=%Cr+%Mo+1.5%Si+0.5%Nb

30

20

10Ni eq

=%N

i+30

%C+

0.5%

Mn

F+M

M

A+M

A

A+M+F

M+F

F

0%F(1

00%A) 5%

F

10%F

25%F

40%F

80%F

100%F

Cold crackingdue to martensite(pre-heating)

Hot crackingabove 1250℃

Embrittlement dueto grain coarsening

Embrittlementdue to σphaseprecipitationduringheat-treatmentor slow cooling

Welding of stainless steels 4 problems (Fig.S2)

Problems

1. Explain the dilution.

2. Estimate the Ni and Cr contents of weld metal, when the stainless steel of 18%Cr-8%Ni is welded using the electrode of 2%Ni-28%Cr, assuming that the dilution is 20%.

3. We should weld the stainless steel of 0.36%C-2.0%Si-0.4%Mn-14.0%Ni -15.0%Cr, and we want that the Ni and Cr equivalents of weld metal are 8% and 22%Cr, respectively. Determine the chemical compositions of electrode, assuming that the dilution is 20%.

4. Estimate the Ni and Cr equivalents of weld metal, when the steels of 8%Ni-18%Cr and 0.15%C-2%Cr-1%Mo are but-welded by using the electrode of 26%Cr, assuming that the dilution is 20%.

Answer 1 (Fig.S3)

1. Explain the dilution.

A; mass of melted electrode

B; mass of melted base metal plates

Mass of weld metal C = A+B

Answer 1

Dilution of base metal = =C A+B

B B

Answer 2 (Fig.S4)

2. Estimate the Ni and Cr contents of weld metal, when the stainless steel of 18%Cr-8%Ni is welded using the electrode of 2%Ni-28%Cr, assuming that the dilution is 20%.

0 10 20 30 40

Creq=%Cr+%Mo+1.5%Si+0.5%Nb

30

20

10

Ni eq

=%N

i+30

%C+

0.5%

Mn

4

1 Answer 2

3%Ni-26%Cr

Answer 33. We should weld the stainless steel of 0.36%C-2.0%Si-0.4%Mn-14.0%Ni-15.0%Cr, and we want that the Ni and Cr equivalents of weld metal are 8% and 22%Cr, respectively. Determine the chemical compositions of electrode, assuming that the dilution is 20%.

Nieq(B.M.)=%Ni+30%C+0.5%Mn=14.0+30×0.36+0.5×0.4=25.0

Creq(B.M.)=%Cr+%Mo+1.5%Si+0.5%Nb=15.0+1.5×2.0=18.0

Answer 3

Nieq(B.M.)×dilution+Nieq(El.)×(1-dilution)= Nieq(W.M)

25.0×0.2+Nieq(El.)×(1-0.2)=8

Nieq(El.)=3.75=4%

Creq(B.M.)×dilution+Creq(El.)×(1-dilution)= Creq(W.M)

18.0×0.2+Creq(El.)×(1-0.2)=22

Creq(El.)=23%

0 10 20 30 40

Creq=%Cr+%Mo+1.5%Si+0.5%Nb

30

20

10

Ni eq

=%N

i+30

%C+

0.5%

Mn

4

1

Another answer 3 (Fig.S5)

Nieq(B.M.)=%Ni+30%C+0.5%Mn=14.0+30×0.36+0.5×0.4=25.0

Creq(B.M.)=%Cr+%Mo+1.5%Si+0.5%Nb=15.0+1.5×2.0=18.0

Answer 4 (Fig.S6)

4. Estimate the Ni and Cr equivalents of weld metal, when the steels of 8%Ni-18%Cr and 0.15%C- 2%Cr-1%Mo are but-welded by using the electrode of 26%Cr, assuming that the dilution is 20%.

0 10 20 30 40

Creq=%Cr+%Mo+1.5%Si+0.5%Nb

30

20

10

Ni eq

=%N

i+30

%C+

0.5%

Mn

4

1

Nieq(0.15%C-2%Cr-1%Mo)=30×0.15=4.5Creq(0.15%C-2%Cr-1%Mo)=2+1=3

1

1

Answer 4

Nieq=about 1.5%

Creq=about 23%

Electrode 80%

8%Ni-18%Cr

0.15%C-2%Cr-1%Mo

Base Metal 1 10% Base Metal 2

10%

Shielded metal arc welding low hydrogen type electrode with similar chemical and mechanical properties to base metal plate

formation of porosity lime-titania electrode low tendency of porosity good appearance relatively low ductility

Backstep welding

Submerged arc welding lower carbon, higher chromium than that of base metal plate

Gas shielded metal arc welding

Electroslag welding

Welding process applied to heat resistant steels

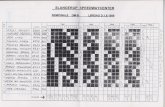

14-17 October 1985

Koreaki Tamaki and Jippei Suzuki

Department of Mechanical and Material EngineeringMie University, Kamihama-cho 1515

Tsu, Mie 514 JAPAN

Implant test machine modified for reheat cracking test

Fig.2 A set of the implant test specimen

Assessment of Reheat Cracking Sensitivity of Steels from their Chemical Compositions (Fig.J1)

Initi

al re

stra

int s

tres

s ,

MPa

Fig.4 Critical restraint stress, σAW-crit of Cr-Mo-0.02%P steels

Fig.3 Definition of critical restrain stress to produce reheat crack

Influence of chromiumon the sensitivity

to reheat cracking (Fig.J2)

Comparing the critical stress to reheat cracking index

ΔG=(%Cr)+3.3(%Mo)+8.1(%V)-2 PSR=(%Cr)+(%Cu)+2(%Mo)+10(%V)+7(%Nb)+5(%Ti)-2

For simple Cr-Mo steels, ΔG=(%Cr)+3.3(%Mo)-2=0 PSR=(%Cr)+2(%Mo)-2=0

Contour lines of critical restraint stress (Fig.J3)

Note: A;1/2Mo, B;3/4Cr-1/2Mo, C;1Cr-1/2Mo, D;1 1/4Cr-1/2Mo, E;2 1/4Cr-1Mo, F;3Cr-1Mo, G;5Cr-1Mo

Fig5 Contour lines of critical restraint stress of Cr-Mo-0.02%P shownin the Cr-Mo contents diagram

(Fig.J4)

Fig.8 Influence of phosphorus on the critical restraint stress, σAW-crit of five types of Cr-Mo steels

Initi

al re

stra

int s

tres

s, M

Pa

Initi

al re

stra

int s

tres

s, M

Pa

Influence of phosphorus on the sensitivity to reheat crack

(Fig.J5)

Manganese reduces the sensitivity, and sulfur increases the sensitivity.

Influence of manganese and sulfuron reheat cracking sensitivity of 1Cr-1/2Mo steels (Fig.J6)

Sulfur in steel=Combined sulfur as MnS + dissolved sulfur (free sulfur)

Combined influence of manganese and sulfur (Fig.J7)

Free sulfur would segregate to grain boundary, and increases the sensitivity to cracking.

Influence of vanadium (Fig.J8)

Influence of titanium (Fig.J9)

Effect of stress relaxation (Fig.J10)

Carbides precipitate during stress relief annealing. Ti+C TiC 4V+3C V4C3

Secondaryhardening

High stress at elevated temperature