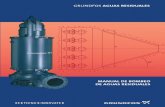

sewage pump amacan

-

Upload

iwangic4639 -

Category

Documents

-

view

649 -

download

5

Transcript of sewage pump amacan

DesignationAmacan K 800-380 / 64 U

XG6

Pump typeChannel type impellerDN of discharge pipe [mm]Impeller diameter [mm]Motor power P2 in kW

(only correct for U motor designs)

Number of poles in the motor

Motor design U/U1/U2 = product temperature 30 �CX/X1/X2 = flameproof, product temperature 40�C

Material codeG = grey cast iron

G1= grey cast iron with variantsG3= sea water design

Automation products available:

� PumpExpert� Hyamaster� hyatronic

Baureihenheft Amacan K1579.5/3--10

ApplicationsSewage pumps, mixed water pumps and activated sludgepumps in sewage treatment plants, irrigation and drainagepumping stations. Storm water pumps for flood protection,water pollution control and industrial refuse tip effluents, forpumping all pre--screened or pre--settled media not liable totwist.

Operating dataHeads H up to 30 mCapacity-- standard programme : Q up to 1000 l/s-- custom--made programme : Q up to 2000 l/sMotor power P2 up to 320 kWProduct temperature: up to 40 �Cmax. submersion level: 20 m

DesignWet installed, close--coupledpumpwith channel--type impeller,single--stage, single--entry, for installation in discharge pipes.

DriveThree-phase asynchronous motor, winding acc. to IEC 38 for400/690V supply voltage (also suitable for 380 V and 415 Vmains), enclosure type 58 to IEC 34-5/IP 68 to DIN 40050,motor design to VDE 0530 part 1/IEC 34--1, insulation class F,for flameproof units also VDE 0171/5.78 parts 1 and 5/EN 50014/EN 50018, protection type EEx d IIB T3.

Bearings-- up to motor sizes 646, 548 :

grease lubricated, maintenance--freeanti--friction bearings

-- up to motor sizes 806, 678, 4310 :grease lubricated anti--friction bearings,re--lubrication without dismantling the pumpset.

Shaft sealingShaft sealing is effected by means of two elastomer bellowsmechanical seals in tandem arrangement, independent of thedirection of rotation. A liquid chamber filled withenvironment--friendly non--toxic paraffin oil between the sealsensures cooling and lubrication.

Submersible motor pump withchannel-type impeller for

installation in discharge pipes

OW 380 092-00

MaterialsPump casing GG-25Motor housing GG-25Pump shaft C 45 NShaft prot. sleeve 1.4021.05Impeller GG-25/Noridur �

Nuts and bolts A 4/1.4462Casing wear ring GG-25/VG 434Cathodic corrosion protection available

Q [l/s]

Q [m3/h]

Standard programme

Custom--made programme

H [m]

Amacan K

2

Selection chart 50 Hz

H [m]

Q [l/s]

Q [m3/h]

Amacan K

3

Range chart 60 Hz

Amacan K

4

Product advantages to the benefit of our customers

Two- or three-channelimpeller with largefree passage

The illustration shown corresponds to Amacan K 1000--420

Especially designed lug for receivingcrane hook allows installation andremoval even when inlet chamber isflooded.(No need to enter the pit!)

The cable entry is completely watertight withinsulation at several points:1. Long rubber gland2. Cable embedded in cast resin3. Conductors embedded in cast resin4. Soldered strandsEven in the event of damage to thecable and core insulation there is nopossibility of moisture entering themotor chamber along the strands dueto capillary action.

Increased efficiency thanks to motorshaft made of ferromagnetic steel

Cable mounted with strain relief.

Operationally safe, dry, three-phaseasynchronous motor, surface cooled,in acc. with VDE regulations (from theKSB submersible pump range)

Motor housing with statorremovable after loosening the flangeconnections(simple visual inspection of the motor)

Patented, standard moisturesensor as additional safetydevice.

Early fault detection by means ofbearing temperature monitoring(from motor /286 and /258 onwards)

Inspection ports for separatefunctional test of mechanical seals

Shaft sleeve protects the pumpshaft against corrosion

Mechanical seals in tandemarrangement, trouble-freeoperation guaranteed for manyyears due to a common liquidfeed with large air cushion forexpansion and high quality, wear--resistant sealing materials.

Mechanical seal monitored bymeans of float switchin the leakage chamber

Thermal protection prevents motorfrom overheating

Self-centering positioning ofthe pump in the dischargecolumn by its own weight.Sealing ensured by an O-ring.No additional anchoring orrotational protection required.Fast installation and removalof pump as disconnection ofpipes and cables is notnecessary.

High operational safety dueto protected sealing chamber.

Renewable casing wear ringprotects casing against wear

OW 380 109-00

Amacan K

5

Table of Contents

Programme and scope of supply, order data, general comments Page 6

Table of pumped media, impeller types Page 7

Modes of installation Page 8

Technical data, warranty, testing and quality assurance, operation withfrequency converter, materials, coating Pages 9 -- 12

Connection of monitoring equipment Pages 13

General drawings Pages 14 -- 17

Mechanical seal -- detail Pages 18 -- 19

Dimension tables -- pump/discharge pipe Pages 20 -- 23

Installation plans Pages 24 -- 29

Pump with suspension wire and turnbuckle in discharge pipe, dischargepipe cover with cable entry Pages 30 -- 32

Selection table -- example Page 33

Characteristic curves Pages 34 -- 55

For further motor datarefer to motor documentation: Amarex KRT Reference-No. 2553.53/...-90

Amacan K

6

ProgrammeStandard pump programme : pumpsets up to sizes 1200-540, n = 980 1/min as described in this brochure

Custom-made programme : pumpsets from size 1200-540 on, n = 980 1/min, motor power P2 > 200 kW with various drives.Hydraulic data on request.

Scope of supplyBasic version : pump unit complete and ready for installation, 400 V / 50 Hz, supplied with10 m power cable,

without performance test(deviations from the basic version will result in extra charges and longer delivery period).

Accessories available / required:-- steel discharge pipes in various designs-- lifting rope complete with cable protection

(obligatory from 3.5 m of free cable length in the discharge pipe onwards)-- monitoring unit

General commentsOur pump units comply with enclosure type IP 68 in accordance with DIN 40050 and therefore include the lesserrequirements of IP 58 of IEC 34--5 valid since April 1, 1988.During production the pumps and motors are subjected to functional tests both independently and as a unit.Head and power rating apply only to pumped liquids with a density of ρ = 1 kg/dm3 and kinematic viscosityν up to 20 mm2/s.

Motor ratings P2 should have a safety factor which is adequate for a particular pumping application(see selection example on page 33).To facilitate transportation the electrical cabling will be supplied separately from cross--sectional area 4x50 mm2 upwards.Applicable drawing numbers are indicated below the drawings.

Order data-- Designation of pump unit according to ”Designation” / ”Selection of pump”-- Capacity Q-- Total head H (Hgeo and plant losses)-- Liquid handled and liquid temperature-- Voltage, frequency, starting method, length of cable-- Accessories required -- (for discharge pipes, please indicate installation mode and relevant levels)-- Quantity and language of operating instructions

Closed channel--type impeller (K impeller)for contaminated non--gaseous liquidscontaining solids, not liable to twist

Note:K-impellers are trimmed to meet the exact duty point.

Amacan K

7

List of liquids handledThe application of submersible pumps is versatile and subject to local conditions which are distinct from case to case.The following list serves as recommendation only!For profound counselling in all questions of planning, consult your nearest KSB sales agency or our technical divisions.

Liquid handled 1)

The end user should decide whetherflameproof motors are necessary

Indication, recommendation

Dirty waterRiver water free impeller passage, larger than solids occuringRain water

free impeller passage, larger than solids occuringprescreened or pre--settled if necessary

Sewagep esc ee ed o p e se ed ecessa y

Activated sludge max. 3% dry substance content

Sea water material combination G3, tmax = 30 �C,anode check every 6 months

Industrial effluent, contaminated with ...-- paint suspension free of solvents, refer to operator’s instructions!-- varnish suspension free of solvents, for silicon--free version consult KSB-- fibrous material short fibres, not liable to twist-- abrasive material variant ”G1” 3) - 0.5 g/l max. solids content

Industrial effluent, slightly acid ph-Wert � 6variant ”G1” 3) plus INERTOL POXITAR coating

Chemically neutral waste water-- ammonia water-- ammonia hydroxide 5% NH4OH-- urea 25% (NH2)2-CO-- potassium hydroxide 10% KOH-- calcium hydroxide 5% Ca(OH)2-- sodium hydroxide 5% NaOH-- sodium carbonate 30% Na2CO3

Chemically neutral waste water contaminatedwith ...

-- aliphatic hydrocarbonse.g. oils, petrol, butane, methane

with polyamide cable sheath or Tefzel cable 2)

-- aromatic hydrocarbonse.g. benzene, styrene

FPM(VITON)O-rings andTEFZEL cable 2)

-- chlorinated hydrocarbonse.g. trichlorethylene, ethylene chloride,

chloroform, methylene chloride

FPM(VITON)O-rings andTEFZEL cable 2)

1) Liquids not mentioned here require in most of the cases upgraded materials. Please consult KSB.2) Modified fluoropolymer ETFE, standard variant (page 10 und 11) to be ordered separately3) Standard variant (page 12) to be ordered separately

Impeller type

Amacan K

8

Types of installation

Steel discharge pipewith underfloor discharge

CU

DU Steel discharge pipewith floor-mounted dischargenozzle

Steel discharge pipeoverflow design

BU

CS Design variant of installationmode CU, under installationcover in floor, foot--mounted(on request)

OW 380 086--00 OW 380 088--00

OW 380 089--00 OW 380 087--00

Inclined installation on request.

Amacan K

9

Technical data

Size Pipe dia. req.[mm]

n[1/min]

Impellerno. of blades

Free passage[mm]

Standard programme

700-330 700 735 3 70x92

700-330 700 980 3 70x92

700-321 700 735 2 105x115

700-321 700 980 2 105x115

700-324 700 735 3 70

700-324 700 980 3 70

800-370 800 980 3 75

800-380 800 735 3 115x95

800-381 800 735 2 145x135

800-380 800 980 3 115x95

800-381 800 980 2 145x135

1000-420 1000 735 3 126x100

1000-421 1000 735 2 140x150

1000-420 1000 980 3 126x100

1000-421 1000 980 2 140x150

1000-500 1000/1300 * 980 3 145x110

1200-540 1200 590 3 133x150

1200-540 1200/1300 * 735 3 133x150

1200-540 1300 980 3 133x150

Custom--made programme

1200-540 1400 980 3 133x150

1300-520 1300 590 3 145

1300-520 1300/1400 * 735 3 145

1300-750 1400 490 3 180

1300-750 1300/1400 590 3 180

*) depending on the motor size (see page 21)

mechanical

elektrical

= special version---- = not available

= standard

= standard design variant

Amacan K

10

Technical data -- Pumpset

K 700-330K 700-324/321

K 800-370

Pump sizes K 800-380/381

K 1000-420/421

K 1000-500

K 1200-540K 1300-520

Characteristics K 1300-750

Motor versions : 6 - pole 20 6 26 6 28 6 ... 64 6 80 6 ... 120 6 138 6 ... 200 6 260 6 ... 320 6

U = non-flameproof 8 - pole 10 8; 17 8 21 8 25 8 ... 54 8 67 8 ... 107 8 126 8 ... 180 8 225 8 ... 280 8

X = flameproof 10 - pole 43 10 ... 84 10 107 10 ... 170 10 215 10 ... 270 10

12 - pole 132 12 ... 200 12

Typical sectional drawing / motorsize DKN

p.14161; 181

p.15225

p.16280

p.17315

----355

Shaft sealingpump -- motor 2 bellows mech. seals, independent of direction of rotation, in tandem arrangement

Anti-friction bearing withre-lubrication facility ----

Typical mech. seal detail p. .18/19 ill. 1 OW 309 124-00 ill. 2 OW 309 110-00

Elastomers in Viton(for O-Rings and mech. seal)

Enclosure Pressure-tight enclosure IP 58 to IEC 34-5/IP 68 to DIN 40050

Explosionprotection

VDE 0171/1.690171/5.78EN50014/50018

----protection (Ex) dll G3

VDE 0171/1.69 ----

Insulation class F

Windings for 400V/50 Hz mains(suitable for 380 ... 415 V) 400 V delta ; 690 V star

230 V with special winding ----

Windings for500 V with special winding star connectedWindings for

mainsvoltage

690 V with standard winding star connectedvoltageother voltages

Starting mode d.o.l. or star--delta

Motor cooling by surrounding pumped liquid, S 1 operation

Cable length 10 m

Cable length > 10 m (> 50m )

Cable entry U ; X resin filled cable gland

Polyamide cable sheath (for cross sectional area 4 x 35 mm2) ----TEFZEL 1) cable(waterproof over full length)

Operated with frequencyinverter 2) (flameproof version )

1) modified fluoropolymer ETFE2) see page 11

Monitoringpage13

Operatinglim

its

Amacan K

11

Technical data -- Pumpset

K 700-330K 700-324/321

K 800-370

Pump sizes K 800-380/381

K 1000-420/421

K 1000-500

K 1200-540K 1300-520

Characteristics K 1300-750

Motor versions : 6 - pole 20 6 26 6 28 6 ... 64 6 80 6 ... 120 6 138 6 ... 200 6 260 6 ... 320 6

U = non-flameproof 8 - pole 10 8; 17 8 21 8 25 8 ... 54 8 67 8 ... 107 8 126 8 ... 180 8 225 8 ... 280 8

X = flameproof 10 - pole 43 10 ... 84 10 107 10 ... 170 10 215 10 ... 270 10

12 - pole 132 12 ... 200 12

max.permissible

U 25 mpermissiblesubmersionlevel

X 20 m

Pumpedliquid

U 30 �Cliquidtemperature X 40 �C

U automatic on/off when permissible winding temp. has been reached (control circuit)

temperaturecontrol ofthe winding

X 2 separate control circuits -- automatic on/off control when permissible winding temp.has been reached (control circuit)

-- trip control when the flameproof temperature limit hasbeen reached (limitation circuit)

Temp. control of pump-sideanti--friction bearings (PT 100) ----Moisture electrode in the motorhousing

Float switch in the leakagechamber to monitor mech. seal ----

= special version---- = not available

= standard

= standard design variant

Warranty, tests and quality assuranceEvery pump is subjected to a functional test. We grant a warranty for pump performance(non--witnessed) in line withISO 9906/A or similar/equivalent international standards.

Witnessed performance test in acc. with ISO or equivalent standards possible.

The high quality of our pumps is ensured by constant quality checks.

Frequency inverter operationOnly 95 % of the motor power P2 must be utilized.For flameproof units, only thermistor tripping devices with PTB approval must be used.Observe the exception on page 13 (ill. 1).

Amacan K

12

Materials

Material combinations G G1 G3 1)

(Sea water version)

Part No. Designation Materials

101 Pump casing GG-25

113 Intermediate casing GG-25

138 Inlet nozzle 2) GG-25

163 Discharge cover 3) GG-25

230 Impeller GG-25 9.4460 4) 9.4460 4)

350 Bearing housing GG-25

360 Bearing cover GG-25

412 O--ring NBR NBR 5) Viton 6) Viton 6)

421 Shaft seal ring NBR NBR 5)

433.01 Mechanical seal Carbon / cast chrome

433.02 Mechanical seal Silicon carbide / silicon carbide

502 Casing wear ring GG-25 VG 434 VG 434

524 Shaft protecting sleeve 1.4021.05

571 Lifting lug ST 37 7)

811 Motor housing GG-25

812 Motor housing cover GG-25

818 Shaft (rotor): up tomotor DKN 161/181 1.4021.05 1.4057

Shaft (rotor): from motor DKN 225 on C 45 N 8)

834.1/.2 Cable entry GG

div. Bolts 1.4462 / 1.4571

99-16 Anode ---- Zn

818 Shaft (rotor) C 45 N

1) Pump units with cathodic protection: check anode every 6 months2) for pump sizes 1300--520 and 1300--7503) for pump size 700--3304) Noridur5) Nitrile (Perbunan)6) Fluororubber FPM7) Lifting lug in 1.44628) dry shaft in the pump area (shaft-protecting sleeve in chromium steel)

Standard surface coatingStandard: Primer and final coat

Surface treatment: SA 2 1/2 (SIS 055900) AN 1865Corrosion prevention to AA 0080-06-01Primer: iron oxide (dipped) 0.035 mm to 0.040 0.0mTop coat: KSB standard coating, approx.0.070 mm (RAL 5002)

Standard design variant: -- sea water version:Primer and INERTOL POXITARSurface treatment see standardPrimer: see standard + wash primerTop coat: INERTOL POXITAR, approx. 0.250 mm (2-component epoxy-tar coating)

Special surface treatmentAvailable at extra charge and longer delivery periods

10 1120 21

10 11 Connected via thermistortripping device withmanual reset 1)

20 21 Connected directly intothe control circuit of themotor contactor 2)

20 21

10 11

Flameproof ”X”Non-flameproof ”U”

Connected via thermis-tor tripping device withautomatic reset

PTCbi-metal

PT100

15 16 3 4

floatswitch

9

moisturesensor

Thermal monitoring ofpump-side ball bearing

Moisture detection probe inmotor housing

Mechanical seal monitoringvia float switch

Connected via PT100tripping relay e.g. makeKriwantype PT100--2AV

9 Connected to earthleakage circuit breaker,nominal currentleakage 30--50 mA

3 4 Connected for alarm,i.e. switch off

Not required, if suppliedconnect to blank terminal

Ill 2

Ill 5Ill 4Ill 3

Thermal motor monitoring for all other Amacan K sizes

15 16

2120 = identity of conductor

Bi-Metall / PTC = temperature sensor in the winding

PTC

10 1121 22

10 11

21 2221 22

10 11

Thermal motor monitoring for range of capacity > 4 kW to 30 kW

bi-metal

Motor version ”U” and ”W”(non-flameproof)

Motor version ”X” and ”Y”(flameproof)

Connected directlyinto the control circuitof motor contactor

Connected directlyinto the control circuitof motor contactor

Not required, if suppliedconnect to dummyterminal

Connected via thermistortripping with manual reset

Ill 1

Amacan K

13

Connection of monitoring equipment

1) For inverter operation with flameproof requirements, PTB--approved tripping devices are required, e.g. make Siemens type3UN6 with manual reset.

2) KSB tripping device available with both functions

571

914.26920.26550.26

529

322

932.01

421.01

811/81-59

818

834

914.04

412.07

81-17

900.28

81-56

81-44.28

81-18

99-17

902.01920.01

412.04

113

433.01433.02

260 914.10 940.03 101 502 230

412.20

932.03

321.02

914.02

412.02

441

412.03

330

932.02

903

411.03

903.15

0W 383650-00

Amacan K

14

Sectional drawingtypical for sizes < 4 kW to 30 kW

Part No. Part Designation Part No. Part Designation Part No. Part Designation

101 Pump casing 421 Lip seal 818 Rotor

113 Intermediate casing 433 Mechanical seal 834 Cable duct

230 Impeller 502 Casing wear ring 900 Bolt

260 Impeller hub cap 529 Bearing sleeve 902 Stud

321 Radial ball bearing 550 Disc 903 Screw plug

322 Radial roller bearing 571 Lug 914 Socket head cap screw

330 Bearing bracket 81-17 Cable crimp 920 Nut

411 Joint ring 81-18 Cable socket 932 Circlip

412 O-ring 81-56 Moisture protection of motor 99-17 Desiccant

OW 380 103-00

571

550.25

920.25

68-3.2

901.25

550.25

81-97.259-71

914.01

500.04

322932.01

81-22

81-56

81-45

411.26

99-17

914.02

412.09

914.06

421.02500.02

350

903.5411.05

412.04902.01920.01

113411.06

412.20412.06

550.23

901.21

931.01

940.03 260 502 230 101

321901.01550.02

932.02412.02

433.01433.02903.03

412.05

903.04

901.26

412.01

812

421.01500.0180-1

818360

411.04

411.03

550.01

Amacan K

15

General arrangement drawingAmacan K 800-370 to 1000-420/421 , motors 28 6 to 54 8

Part No. Part Designation Part No. Part Designation Part No. Part Designation Part No. Part Designation

101 Pump casing 421 Lip seal 81-56 Moisture protection of motor 931 Lock washer

113 Intermediate casing 433 Mechanical seal 81-97 Cable protector 932 Circlip

230 Impeller 500 Ring 812 Motor casing cover 940 Key

260 Impeller hub cap 502 Casing wear ring 818 Rotor 99-17 Desiccant

321 Radial ball bearing 550 Disc 834 Cable duct

322 Radial roller bearing 571 Lug 901 Hexagon bolt

350 Bearing housing 68-3 Cover plate 902 Stud

360 Bearing cover 80-1 Semi-finished motor 903 Screw plug

411 Joint ring 81-22 Terminal box cover 914 Socket head cap screw

412 O-ring 81-45 Float switch 920 Nut

OW 380 104-00

571

901.26

812914.01

412.01

500.04322

932.01

421.01

412.09

81-22

421.03

500.05

81-56

914.06

412.02914.02

99-17

412.03

81-45

411.26421.02

903.05411.05902.01920.01412.04

412.05

113

411.06

433.01433.02

412.20

412.06

550.23 901.21

931.01940.03

260

502230 101

903.01411.01636.01

500.01520.0180-1

818

360500.03

647

320

901.01550.02932.02

550.01

500.02

350

903.03411.03636.02903.02411.02903.04411.04

A -- A550.25

920.25

68-32

901.25

550.25

81-97.2

59-71

Amacan K

16

General arrangement drawingAmacan K 1000-420/421 to 1300-520 , motors 80 6 to 84 10

Amacan K 1300-520 with inlet nozzle (Part No. 138)

Part No. Part Designation Part No. Part Designation Part No. Part Designation Part No. Part Designation

101 Pump casing 421 Lip seal 80-1 Semi-finished motor 914 Socket head capscrew113 Intermediate casing 433 Mechanical seal 81-22 Terminal box cover

9 S pscrew

230 Impeller 500 Ring 81-45 Float switch 920 Nut260 Impeller hub cap 502 Casing wear ring 81-56 Moisture protection of motor 931 Lock washer320 Anti--friction bearing 520 Sleeve 81-97 Cable protector 932 Circlip322 Radial roller bearing 550 Disc 812 Motor casing cover 940 Key350 Bearing housing 571 Lug 818 Rotor 99-17 Desiccant360 Bearing cover 636 Grease nipple 901 Hexagon bolt411 Joint ring 647 Grease regulator 902 Stud412 O-ring 68-3 Cover plate 903 Screw plug

OW 380 105-00

571

901.26

901.04

914.01

412.01

812

80-1

818

834.01834.03

412.12

69-6

81-56

411.26

902.03920.03

412.02

99-17

914.02

903.05411.05

902.01920.01

81-45

412.04

412.05

113

433.01433.02

940.03 260 931.01 230 101550.23 901.21 412.06 502 412.20

500.04322

932.01903.01411.01

636.01500.01

360

421.03

320

550.01

901.01550.02

421.02

350

903.02411.02

421.01520.01

500.03

647

500.05

932.02

500.02

412.03

903.03411.03

636.02903.04411.04

916.02

914.03

411.06

916.03

Amacan K

17

General arrangement drawingAmacan K 1000-500 to 1300-520 , motors 138 6 to 170 10(Standard programme)Amacan K 1300-520 with inlet nozzle (Part No. 138)

Part No. Part Designation Part No. Part Designation Part No. Part Designation Part No. Part Designation

101 Pump casing 421 Lip seal 80-1 Semi-finished motor 916 Plug113 Intermediate casing 433 Mechanical seal 81-45 Float switch 920 Nut230 Impeller 500 Ring 81-56 Moisture protection of motor 931 Lock washer260 Impeller hub cap 502 Casing wear ring 812 Motor casing cover 932 Circlip320 Anti--friction bearing 520 Sleeve 818 Rotor 940 Key322 Radial roller bearing 550 Disc 834 Cable duct 99-17 Desiccant350 Bearing housing 571 Lug 901 Hexagon bolt360 Bearing cover 636 Grease nipple 902 Stud411 Joint ring 647 Grease regulator 903 Screw plug412 O-ring 69-6 Temperature sensor 914 Socket head cap screw

OW 309 124-00

figure 1

Seal variants for different pump types see table on p.10

433.01

551.01

932.03

433.02

524

562.13

412.17

Amacan K

18

Mechanical seal detail

Part No. Part designation Part No. Part designation

433.01 Mechanical seal 551.01 Spacer sleeve433.02 Mechanical seal 562.13 Parallel pin412.17 O-ring 932.03 Circlip524 Shaft protection sleeve

OW 309 110-00

figure 2

Seal variants for different pump types see table on p.10

433.01

550.03

932.03500.06

914.07

433.02

524

412.17

940.13

Amacan K

19

Mechanical seal detail

Part No. Part designation Part No. Part designation

433.01 Mechanical seal 550.03 Disc433.02 Mechanical seal 914.07 Socket head cap screw412.17 O-ring 932.03 Circlip500.06 Ring 940.13 Key524 Shaft protection sleeve

OW 380 111-00

OW 380 085-00

d7

b20

Amacan K

20

Dimension tables for pump and support ring

Amacan K

21

Pump and support ring all dim. in mm, standard programme up to 1200-540/10710 2, custom--made progr. from 1200-540/2606 upwards

Amacan K . . . - . . . / . . .U/X . h1 h2 d1 d2 b c D d7 b20 h20 f20700-330 / 206 1195 1000

/ 266 1170 975670 556 250 130 711 570 691 60 5/ 108 1195 1000 670 556 250 130 711 570 691 60 5

/ 178 1195 1000

700-324/321 / 206 1195 1000/ 266 1170 975

670 556 250 130 711 570 691 60 5/ 108 1195 1000 670 556 250 130 711 570 691 60 5

/ 178 1195 1000

800-370 / 206 1155 960 250 130/ 266 1130 935 250 130/ 286 1400 1080 760 640 369 232 813 656 793 60 2/ 376 1400 1080 369 232/ 456 1400 1080 369 232

800-380/381 / 266 1225 930 250 130/ 286 2 1495 1175 369 232/ 376 1495 1175 369 232/ 456 1495 1175 369 232/ 646 1600 1280 770 640 369 232 813 656 793 60 2/ 178 1250 1055 250 130/ 218 1225 930 250 130/ 258 1 1495 1175 369 232/ 338 1 1495 1175 369 232

1000-420/421 / 376 1 1575 1255 369 232/ 456 1 1575 1255 369 232/ 646 1 1680 1360 369 232/ 806 1 1695 1345 449 232/ 1026 1695 1345 469 232/ 1206 1695 1345 970 840 469 232 1016 856 992 70 8/ 258 2 1575 1255 369 232/ 338 2 1575 1255 369 232/ 438 2 1680 1360 369 232/ 548 1680 1360 369 232

1000-500 / 806 1 1700 1350 449 232/ 1026 1900 1550 469 232 1016 992/ 1206 1900 1550 469 232

(1300-500) / 1386 2150 1770 970 820 577 382 856 70 8/ 1656 2150 1770 577 382 1320 1292/ 2006 2150 1770 577 382

(1300-540) / 1656 2205 1825 577 3821320 1292(1300-540) / 2006 2205 1825 577 382 1320 1292

1200-540 / 848 1955 1605 469 2321220 11921200-540 / 1078 2 1955 1605 469 232 1220 1192

(1300-540) / 1268 2 2205 1825 577 382(1300-540) / 1508 2 2205 1825 1140 960 577 382 1320 1015 1292 70 2(1300-540) / 1808 2 2205 1825 577 382

1320 1292

1200-540 / 4310 1 1765 1415 449 2321200-540 / 5410 2 1955 1605 469 232

1220 11921200-540 / 6710 2 1955 1605 469 232 1220 1192

1200-540 / 8410 2 1955 1605 469 232(1300-540) /10710 2 2205 1825 577 382 1320 1292

(1400-540) / 26062700 1935 1140 960 1420 1015 1192 70 2(1400-540) / 3206 2700 1935 1140 960 -- -- 1420 1015 1192 70 2

1300-520 / 1268 11300-520 / 1508 1 2600

2135577 382 1320 1292

1300-520 / 1808 1 2135

(1400-520) / 2258 1 2900 622 494 1420 13921300-520 / 6710 1

2440 19701250 1100

469 2321155 60 5

1300-520 / 8410 1 2440 1970 469 2321320 12921300-520 / 10710 1

2600 2135 577 3821320 1292

1300-520 / 12610 1 2600 2135 577 382

1300-750 / 17010 2 2585 1920 577 382 1320 1292(1400-750) / 21510 2(1400-750) / 23510 2 2900 2135(1400-750) / 27010 2

1260 920 622 494 1420 1170 1392 60 5(1400-750) / 11012 1260 920 622 494 1420 1170 1392 60 5

(1400-750) / 13012 2585 1920(1400-750) / 15512

2585 1920

(1400-750) / 18012 2900 2135

Steel discharge pipes

Overflow design B Underfloor discharge C

Floor-mounted discharge D Floor-mounted discharge Dpressure--tight

� � to suit � � to suit

OW 380 113-00 OW 380 115-00

OW 380 117-00OW 380 119-00

Amacan K

22

Dimension table, discharge pipes

Amacan K

23

Main dimensions -- discharge pipes all dimensions in mm

Pump sizes D pipe dia. A DN2 min DN2 max H1 min H3 min H1,H3 max H2 min H0 max

700-330 711 700 650 300 600 1900 2570 670 7820

700-324/321 711 700 650 300 600 1900 2570 670 7820

800-370 813 800 700 400 700 2080 2850 10000 770 7580

800-380/381 813 800 700 400 700 2250 302010000

770 7410

1000-420/421 1016 1000 810 600 900 2520 3490 (dischargepipes longer

925 7040

1000-500 1016 1000 810 600 900 2730 3700pipes longer

than 925 6830

1320 1300 960 1000 1300 3280 4660than

10,000 mmon request)

1130 6080

1200-540 1220 1200 910 900 1200 2930 4200on request)

1080 6480

1320 1300 960 1000 1300 3280 4660 1130 6080

1420 1400 1010 1100 1400 3640 5000 1180 5660

1300-520 1320 1300 960 1000 1300 3110 4500 1130 6240

1420 1400 1010 1100 1400 3380 4800 1180 5920

1300-750 1320 1300 960 1000 1300 3420 4800 1130 5930

Pump sizes D H4 M1 M2 M3 M4 N1 N2 N3 N4

700-330 711 500 800 1150 1160 1080 1160 910 455 695

700-324/321 711 500 800 1150 1160 1080 1160 910 455 695

800-370 813 550 900 1250 1260 1250 1260 1010 505 745

800-380/381 813 550 900 1250 1260 1250 1260 1010 505 745

1000-420/421 1016 650 1120 1460 1460 1450 1460 1210 605 855

1000-500 1016 650 1120 1460 1460 1450 1460 1210 605 855

1320 1000 1450 1760 1760 1700 1900 1510 755 1005

1200-540 1220 930 1350 1670 1670 1600 1800 1410 710 960

1320 1000 1450 1760 1760 1700 1900 1510 755 1005

1420 1050 1550 1870 1870 1900 2040 1610 810 1060

1300-520 1320 1000 1450 1760 1760 1700 1900 1510 755 1005

1420 1050 1550 1870 1870 1900 2040 1610 810 1060

1300-750 1320 1000 1450 1760 1760 1700 1900 1510 755 1005

Wall thickness against dia. D:-- up to size 800-380/381: 8 mm-- sizes 1000-420/421, 1000-500 with pipe diameter 1000 mm: 10 mm-- sizes 1000-500 with pipe diameter 1300 mm, 1200-540: 12 mm

Discharge flanges to ISO 7005/2 / DIN 2501, PN 6

Admissible deviations for dimensions without tolerance indication:-- flange dimensions: ISO 2768 medium-- welding constructions: B/F to DIN EN ISO 13920

Subject to technical modifications

OW 380 120--00

View Y

0-45�

Y

Section A -- A

100

350

d7

h üh a

X

t 1Hgeo

t 3

t 4t 2

e1

D

s 1/2min

s 1min

s 1min

p2

p 2100

p 1

Foundation holes

View X(without pump)

Foundation holes

Support plate-- discharge pipes

A

A

Minimumwater level

Recommendedinflow direction

Amacan K

24

Installation planInstallation example Installation mode BU

Head loss diagram

H = Hgeo + hü + v2/2g

Allowances for sumpdimensions to DIN 18202,part 4, group B

v as a function of DA

Diagram for minimumwater level t1

Amacan K 1300-750

OW

380110--00

700--324/321

Overflow head hü

hü [m]

Q [m3/s]

Overflow head ”hü” dependent on Q and the design of outletdiam. DA. The characteristic curves only apply for dischargeunobstructed on all sides; otherwise to be regarded as anapproximation.

Amacan K

25

Main dimensions of discharge pipe and pump sump all dimensions in mm

Pump sizes D*) t2 t3 t4 min t4 max d7 e1700-330 711 330 200 1900 570 430700-324/321 711 330 200 1900 570 430800-370 813 330 200 2080 656 480800-380/381 813 410 250 2250

10000656 480

1000-420/421 1016 435 250 252010000

856 6001000-500 1016 480 300 2730 (discharge

pipes856 600

1320 480 300 3280

( gpipes

longer than 856 7501200-540 1220 585 350 2930

longer than10,000 mmon request)

1015 7001320 585 350 3280

,on request) 1015 750

1300-520 1320 1025 400 3570 1155 7501420 1025 400 3670 1155 800

1300-750 1320 940 480 3740 1170 750

Pump sizes D*) s1 min p1 p2 ha700-330 711 1000 900 640 100700-324/321 711 1150 900 640 100800-370 813 1150 1000 740 100800-380/381 813 1400 1000 740 100

1000-420/421 1016 1600 1220 960 1001000-500 1016 1800 1220 960 100

1320 1800 1550 1260 1001200-540 1220 2250 1450 1160 100

1320 2250 1550 1260 1001300-520 1320 2250 1550 1260 100

1420 2250 1650 1360 1001300-750 1320 2700 1550 1260 100

*) from size 1000-500 onwards, D depends on motor size, see page 21

Subject to technical modifications

OW 380 121-00

DN2 can be chosen with regard to the desired outlet speed.See table DN2min/DN2max and head loss diagram.

1

s 1/2min

s 1min

s 1min

Recommendedinflow direction

0-45�

e

Y

X

t 1Hgeo

Minimumwater level

t 3

t 4t 2

D

Vent pipe

t 5

DN2

a

A

A

View Y

Section A -- A

d7

250

300

200

Foundation holes

p2

a 2200

p1

a 1

a 3

200

View X(without discharge pipe cover,

without pump)

Foundation holes

Support plate-- discharge pipe

Amacan K

26

Installation planInstallation example Installation mode CU

Head loss diagramAllowances for sumpdimensions to DIN 18202,part 4, group B

H = Hgeo + HV ges

HV ges includes:

-- elbow-- disch. pipe length = 5xDN2-- check valve-- outlet loss v2/2g

OW

380110--00

Diagram for minimumwater level t1

Amacan K 1300-750

700--324/321

HV ges [m]

Q [m3/s]

Amacan K

27

Main dimensions of discharge pipe and pump sump all dimensions in mm

Pump sizes D*) t2 t3 t4 min t4 max d7 e1 s1 min700-330 711 330 200 2570 570 430 1000700-324/321 711 330 200 2570 570 430 1150800-370 813 330 200 2850 656 480 1150800-380/381 813 410 250 3020 10000 656 480 1400

1000-420/421 1016 435 250 349010000

856 600 16001000-500 1016 480 300 3700 (discharge

pipes856 600 1800

1320 480 300 4660 pipeslonger than 856 750 1800

1200-540 1220 585 350 4200longer than10,000 mm 1015 700 2250

1320 585 350 466010,000 mmon request) 1015 750 2250

1300-520 1320 1025 400 5350

q )

1155 750 22501420 1025 400 5550 1155 800 2250

1300-750 1320 940 480 5520 1170 750 2700

Pump sizes D*) p1 p2 DN2 min DN2 max a a1 a2 a3 t5 min700-330 711 860 960 300 600 650 1100 850 430 670700-324/321 711 860 960 300 600 650 1100 850 430 670800-370 813 960 1060 400 700 700 1200 950 480 770800-380/381 813 960 1060 400 700 700 1200 950 480 770

1000-420/421 1016 1160 1260 600 900 810 1410 1160 580 9251000-500 1016 1160 1260 600 900 810 1410 1160 580 925

1320 1600 1700 1000 1300 960 1710 1460 730 11301200-540 1220 1500 1600 900 1200 910 1620 1370 685 1080

1320 1600 1700 1000 1300 960 1710 1460 730 11301300-520 1320 1600 1700 1000 1300 960 1710 1460 730 1130

1420 1740 1840 1100 1400 1010 1820 1570 785 11801300-750 1320 1600 1700 1000 1300 960 1710 1460 730 1130

*) from size 1000-500 onwards, D depends on motor size, see page 21

Subject to technical modifications

OW 380 122-00

DN2 can be chosen with regard to the desired outlet speed.See table DN2min/DN2max and head loss diagram.

1

s 1/2min

s 1min

s 1min

e

Recommendedinflow direction

0-45�

Y

t 1

Minimumwater level

Vent pipe

A

A

X

DN2

a

Dt7

t 3

H4

t 6t 4

t 2

d7

250

300

200

Section A -- A

View Y

p2

a 2200

p1

a 1

200

Foundation holes(without pump)

Foundationholes

Support plate-- discharge pipe

View X

Amacan K

28

Installation planInstallation example Installation mode DU

-- not pressure sealed

Head loss diagram Allowances for sumpdimensions to DIN 18202,part 4, group BH =

Hgeo + hV Kr + HV Anl

Except for hV Krall losses must be calculatedwith a view to plant conditions

OW

380110--00

Diagram for minimumwater level t1 Amacan K 1300--750

700--324/321

hV Kr [m]

Q [m3/s]

Amacan K

29

Main dimensions of discharge pipe and pump sump all dimensions in mm

Pump sizes D*) t2 t3 t4 min t4 max d7 e1 s1 min p1 p2700-330 711 330 200 1250 8680 570 430 1000 860 960700-324/321 711 330 200 1250 8680 570 430 1150 860 960800-370 813 330 200 1430 8580 656 480 1150 960 1060800-380/381 813 410 250 1600 8580 656 480 1400 960 1060

1000-420/421 1016 435 250 1765 8275 856 600 1600 1160 12601000-500 1016 480 300 1975 8275 856 600 1800 1160 1260

1320 480 300 2180 7520 856 750 1800 1460 15601200-540 1220 585 350 1860 7660 1015 700 2250 1360 1460

1320 585 350 2180 7520 1015 750 2250 1460 15601300-520 1320 1025 400 2740 7520 1155 750 2250 1460 1560

1420 1025 400 2840 7420 1155 800 2250 1560 16601300-750 1320 940 480 2910 7520 1170 750 2700 1460 1560

Pump sizes D*) DN2 min DN2 max a a1 a2 t6 min t6 max H4 t7 max700-330 711 300 600 650 860 610 820 8250 500700-324/321 711 300 600 650 860 610 820 8250 500800-370 813 400 700 700 960 710 870 8020 550800-380/381 813 400 700 700 960 710 870 7850 550

100001000-420/421 1016 600 900 810 1160 910 1075 7585 650

10000

1000-500 1016 600 900 810 1160 910 1075 7375 650 (dischargepipes1320 1000 1300 960 1460 1210 1480 6820 1000

( gpipes

longer than1200-540 1220 900 1200 910 1360 1110 1410 7210 930

longer than10,000 mmon request)1320 1000 1300 960 1460 1210 1480 6820 1000,

on request)

1300-520 1320 1000 1300 960 1460 1210 1460 6260 10001420 1100 1400 1010 1560 1310 1530 6110 1050

1300-750 1320 1000 1300 960 1460 1210 1480 6090 1000*) from size 1000-500 onwards, D depends onmotor size, see page 21

OW 380 090-00

Part list

Cross-section of carrier cable arrangement(Where free cable length in discharge pipe exceeds 3.5 m,this arrangement is absolutely necessary)

Cable length in discharge pipe exceeding 3.5 m:Mounting of tensioning device 59-8-- closed discharge pipe: on the discharge pipe cover

(see ill. above)-- open discharge pipe of installation mode BU on a

girder above water level, to be supplied on site

Cable length in discharge pipe under 3.5 m:On open discharge pipe: electrical cables must bemounted on a girder above water level (to be supplied on site)to avoid damages by the swirl of the water.

Plastic hose for clamp

Clamp

Control cable Power supply cable

Carrier cable59-24

SpacerOW 380 091-00

59-8

59-17.2

59-47

59-24

59-17.2

Part No. Part designation Material

59-8 Turnbuckle 1.457159-17.2 Shackle 1.457159-47 Carrier cable 1.475159-24 Carrier cable to DIN 3088,

form PK 1.4401720 Spacer EPDM

Amacan K

30

Pump with suspension wire and tensioning device in discharge pipe turnbuckle

Top view

Section A -- A

OW 380 836-00

1 Discharge pipe cover2 Cover3 Welding sleeve with input bushing acc. to DIN 22 419 with strain relief, protection against buckling and torsion4 Bracket for fixing turnbuckle (cable)5 Gasket, rubber reinforced with fabric

Note: Versions with split cover are possible, too.

12

3

45 5

A

A

Amacan K

31

Discharge pipe cover with cable ductDesign variant: with welding sleeve

Section A -- A

A

A

81 65 4 7

OW 380 861-00

3

2

1 Discharge pipe cover2 Cable gland, type RGP (cable gland)3 Tecron modules (packing and filling)4 Cover segment with cable duct5 Sealing of the cover division with closed cell profile gasket, which may be pre-stressed by inserting an O-ring.6 Division guard7 Holding brackets for cover segment with cable glands8 Gasket, rubber reinforced with fabric

Note: Versions with split cover are possible, too.

Top view

View X

X

Amacan K

32

Discharge pipe cover with cable ductDesign variant: with cable gland

The following steps lead toa correct selection ofpump:

Given data:Capacity Q=400 l/sHead H = 6 mLiquid temp. t=30 �CNon-flameproofMaterial type G

Q [ l/s ]H [m]

Impellerdiameter

With available QH data,the impeller diam. D2A isapprox. 400 mm and thusPduty can be found.

A

B

P2 min

C

Motor size

Motor size is to be se-lected by considering tem-perature and flameproof/non-flameproof designs.

The maximum value ofthe characteristic curve Pthrough Pduty is the mini-mum motor power P2 min

Amacan K 800-381 980 1/min

Pduty

Minimummotor power

P2 min

Nr. : D2A / D2I[mm]

4 : 408 / 3783 398 / 3442 : 384 / 3171 : 367 / 295

H [m]

P [kW]

FörderhöheHead

Hauteur

LeistungsbedarfPower Input

Puiss. hyd. abs.

Förderstrom/Rate of Flow/Débit

LaufradformImpeller type

Forme de roue

freier Durchgangfree passage

section de passage

145 x 135 mm

H [ft]

P [hp]

Amacan K

33

Selection table -- Example

400 V 50 Hz 3~ (winding 400/690 V) max. temperature of liquid handled 30/40�C

Motor Motor Amacan K Code Irated Istarting 1) cos � Electric cables NSSHöu-J Weight

design rating 800-381/... Nr. d.o.l. Power supply cable Control

U or X P2 Cross-section Outside dia cable 2)

(Flameproof) kW A A mm2 mm kg

24 .../266 U 48.5 225 0.84 1x(7x10+5x1.5) 29.5--32.9 -- 730U 28 .../286 U 60.0 250 0.78 2x4x4 16.6-18.7 A 780

tmax = 30 �C 37 .../376 U 77.0 335 0.78 2x4x6 17.8-19.8 A 870tmax = 30 C45 .../456 U 92.0 460 0.79 2x4x10 21.7-23.7 A 930

24 .../266 X 48.5 225 0.84 1x(7x10+5x1.5) 29.5--32.9 -- 730X 28 .../376 X 61.0 335 0.75 2x4x4 16.6-18.7 A 870

tmax = 40 �C 37 .../456 X 77.0 460 0.77 2x4x6 17.8-19.8 A 930tmax = 40 C45 .../646 X 106.0 600 0.69 2x4x10 21.7-23.7 A 1030

Selected: Motor version ”U”, (non--flameproof), motor with 37.0 kW, 6--pole

Designation of complete pump set: : Amacan K 800--381 / 376 U GFor further data refer to the tables on pages 34-55 and motor documentation Amarex KRT Rh.-Nr. 2553.53/. . .-90

For a flameproof machine or tmax = 40 �C, motor .../45 6 X G should be used.

Note :Impellers are trimmed to the operating point.The QH data should be clearly stated at the time of ordering, in order to define the exact impeller diameter.

Nr. : D2A / D2I[mm]

4 : 323 / 3233 : 320 / 3052 : 314 / 2801 : 305 / 251H [m]

P [kW]

H [ft]

P [hp]

Kennlinien nachISO 9906/A

Curves as perISO 9906/A.

Courbes selonISO 9906/A.

FörderhöheHead

Hauteur

LeistungsbedarfPower Input

Puiss. hyd. abs.

Förderstrom/Rate of Flow/Débit

LaufradformImpeller type

Forme de roue

freier Durchgangfree passage

section de passage

105 x 115 mm

Amacan K

34

Amacan K 700-321 980 1/min

400 V 50 Hz 3~ (winding 400/690 V) max. temperature of liquid handled 30/40�C

Motor Motor Amacan K Code Irated Istarting 1) cos � Electric cables NSSHöu-J Weight

design rating 700-321/... Nr. d.o.l. Power supply cable Control

U or X P2 Cross-section Outsidedia.

cable

(Flameproof) kW A A mm2 mm kg

U 18 .../206 U 35.5 160 0.85 1x(7x4+5x1.5) 26.9--28.8 -- 430

tmax = 30 �C 24 .../266 U 48.5 225 0.84 1x(7x10+5x1.5) 29.5--32.9 -- 470

X 18 .../206 X 35.5 160 0.85 1x(7x4+5x1.5) 26.9--28.8 -- 430

tmax = 40 �C 24 .../266 X 48.5 225 0.84 1x(7x10+5x1.5) 29.5--32.9 -- 470

Data applies to a density of 1 kg/dm3 and a kinematic viscosity of up to max. 20 mm2/sWarranty acc. to ISO 9906/A1) further starting modes on request

Nr. : D2A / D2I[mm]

4 : 323 / 3233 : 320 / 3052 : 314 / 2801 : 305 / 251

H [m]

P [kW]

H [ft]

P [hp]

Kennlinien nachISO 9906/A

Curves as perISO 9906/A.

Courbes selonISO 9906/A.

FörderhöheHead

Hauteur

LeistungsbedarfPower Input

Puiss. hyd. abs.

Förderstrom/Rate of Flow/Débit

LaufradformImpeller type

Forme de roue

105 x 115 mm

freier Durchgangfree passage

section de passage

Amacan K

35

Amacan K 700-321 735 1/min

400 V 50 Hz 3~ (winding 400/690 V) max. temperature of liquid handled 30/40�C

Motor Motor Amacan K Code Irated Istarting 1) cos � Electric cables NSSHöu-J Weight

design rating 700-321/... Nr. d.o.l. Power supply cable Control

U or X P2 Cross-section Outsidedia.

cable

(Flameproof) kW A A mm2 mm kg

U 10 .../108 U 22.5 65 0.79 1x(12x2.5) 22.7--24.7 -- 410

tmax = 30 �C 16 .../178 U 36.0 115 0.79 1x(7x4+5x1.5) 26.9--28.8 -- 435

X 10 .../108 X 22.5 65 0.79 1x(12x2.5) 22.7--24.7 -- 410

tmax = 40 �C 16 .../178 X 36.0 115 0.79 1x(7x4+5x1.5) 26.9--28.8 -- 435

Data applies to a density of 1 kg/dm3 and a kinematic viscosity of up to max. 20 mm2/sWarranty acc. to ISO 9906/A1) further starting modes on request

Nr. : D2A / D2I[mm]

3 : 324 / 3242 : 309 / 2801 : 290 / 234

H [m]

P [kW]

H [ft]

P [hp]

Kennlinien nachISO 9906/A

Curves as perISO 9906/A.

Courbes selonISO 9906/A.

FörderhöheHead

Hauteur

LeistungsbedarfPower Input

Puiss. hyd. abs.

Förderstrom/Rate of Flow/Débit

LaufradformImpeller type

Forme de roue

70 x 70 mmfreier Durchgang

free passagesection de passage

Amacan K

36

Amacan K 700-324 980 1/min

400 V 50 Hz 3~ (winding 400/690 V) max. temperature of liquid handled 30/40�C

Motor Motor Amacan K Code Irated Istarting 1) cos � Electric cables NSSHöu-J Weight

design rating 700-324/... Nr. d.o.l. Power supply cable Control

U or X P2 Cross-section Outsidedia.

cable

(Flameproof) kW A A mm2 mm kg

U 18 .../206 U 35.5 160 0.85 1x(7x4+5x1.5) 26.9--28.8 -- 430

tmax = 30 �C 24 .../266 U 48.5 225 0.84 1x(7x10+5x1.5) 29.5--32.9 -- 470

X 18 .../206 X 35.5 160 0.85 1x(7x4+5x1.5) 26.9--28.8 -- 430

tmax = 40 �C 24 .../266 X 48.5 225 0.84 1x(7x10+5x1.5) 29.5--32.9 -- 470

Data applies to a density of 1 kg/dm3 and a kinematic viscosity of up to max. 20 mm2/sWarranty acc. to ISO 9906/A1) further starting modes on request

Nr. : D2A / D2I[mm]

3 : 324 / 3242 : 309 / 2801 : 290 / 234

H [m]

P [kW]

H [ft]

P [hp]

Kennlinien nachISO 9906/A

Curves as perISO 9906/A.

Courbes selonISO 9906/A.

FörderhöheHead

Hauteur

LeistungsbedarfPower Input

Puiss. hyd. abs.

Förderstrom/Rate of Flow/Débit

LaufradformImpeller type

Forme de roue

freier Durchgangfree passage

section de passage

70 x 70 mm

Amacan K

37

Amacan K 700-324 735 1/min

400 V 50 Hz 3~ (winding 400/690 V) max. temperature of liquid handled 30/40�C

Motor Motor Amacan K Code Irated Istarting 1) cos � Electric cables NSSHöu-J Weight

design rating 700-324/... Nr. d.o.l. Power supply cable Control

U or X P2 Cross-section Outsidedia.

cable

(Flameproof) kW A A mm2 mm kg

U 10 .../108 U 22.5 65 0.79 1x(12x2.5) 22.7-24.7 -- 410

tmax = 30 �C 16 .../178 U 36.0 115 0.79 1x(7x4+5x1.5) 26.9--28.8 -- 435

X 10 .../108 X 22.5 65 0.79 1x(12x2.5) 22.7-24.7 -- 410

tmax = 40 �C 16 .../178 X 36.0 115 0.79 1x(7x4+5x1.5) 26.9--28.8 -- 435

Data applies to a density of 1 kg/dm3 and a kinematic viscosity of up to max. 20 mm2/sWarranty acc. to ISO 9906/A1) further starting modes on requestt

Nr. : D2A / D2I[mm]

4 : 326 / 3263 : 300 / 2922 : 287 / 2451 : 270 / 214

H [m]

P [kW]

H [ft]

P [hp]

Kennlinien nachISO 9906/A

Curves as perISO 9906/A.

Courbes selonISO 9906/A.

FörderhöheHead

Hauteur

LeistungsbedarfPower Input

Puiss. hyd. abs.

Förderstrom/Rate of Flow/Débit

LaufradformImpeller type

Forme de roue

freier Durchgangfree passage

section de passage

70 x 92 mm

Amacan K

38

Amacan K 700-330 980 1/min

400 V 50 Hz 3~ (winding 400/690 V) max. temperature of liquid handled 30/40�C

Motor Motor Amacan K Code Irated Istarting 1) cos � Electric cables NSSHöu-J Weight

design rating 700-330/... Nr. d.o.l. Power supply cable Control

U or X P2 Cross-section Outsidedia.

cable

(Flameproof) kW A A mm2 mm kg

U 18 .../206 U 35.5 160 0.85 1x(7x4+5x1.5) 26.9--28.8 -- 430

tmax = 30 �C 24 .../266 U 48.5 225 0.84 1x(7x10+5x1.5) 29.5--32.9 -- 470

X 18 .../206 X 35.5 160 0.85 1x(7x4+5x1.5) 26.9--28.8 -- 430

tmax = 40 �C 24 .../266 X 48.5 225 0.84 1x(7x10+5x1.5) 29.5--32.9 -- 470

Data applies to a density of 1 kg/dm3 and a kinematic viscosity of up to max. 20 mm2/sWarranty acc. to ISO 9906/A1) further starting modes on request

Nr. : D2A / D2I[mm]

4 : 326 / 3263 : 310 / 3102 : 295 / 2661 : 278 / 231

H [m]

P [kW]

H [ft]

P [hp]

Kennlinien nachISO 9906/A

Curves as perISO 9906/A.

Courbes selonISO 9906/A.

FörderhöheHead

Hauteur

LeistungsbedarfPower Input

Puiss. hyd. abs.

Förderstrom/Rate of Flow/Débit

LaufradformImpeller type

Forme de roue

freier Durchgangfree passage

section de passage

70 x 92 mm

Amacan K

39

Amacan K 700-330 735 1/min

400 V 50 Hz 3~ (winding 400/690 V) max. temperature of liquid handled 30/40�C

Motor Motor Amacan K Code Irated Istarting 1) cos � Electric cables NSSHöu-J Weight

design rating 700-330/... Nr. d.o.l. Power supply cable Control

U or X P2 Cross-section Outsidedia.

cable

(Flameproof) kW A A mm2 mm kg

U 10 .../108 U 22.5 65 0.79 1x(12x2.5) 22.7-24.7 -- 410

tmax = 30 �C 16 .../178 U 36.0 115 0.79 1x(7x4+5x1.5) 26.9--28.8 -- 435

X 10 .../108 X 22.5 65 0.79 1x(12x2.5) 22.7-24.7 -- 410

tmax = 40 �C 16 .../178 X 36.0 115 0.79 1x(7x4+5x1.5) 26.9--28.8 -- 435

Data applies to a density of 1 kg/dm3 and a kinematic viscosity of up to max. 20 mm2/sWarranty acc. to ISO 9906/A1) further starting modes on request

Nr. : D2A / D2I[mm]

4 : 370 / 3703 340 / 3402 : 318 / 3031 : 300 / 278

H [m]

P [kW]

H [ft]

P [hp]

Kennlinien nachISO 9906/A

Curves as perISO 9906/A.

Courbes selonISO 9906/A.

FörderhöheHead

Hauteur

LeistungsbedarfPower Input

Puiss. hyd. abs.

Förderstrom/Rate of Flow/Débit

LaufradformImpeller type

Forme de roue

freier Durchgangfree passage

section de passage

75 mm

Amacan K

40

Amacan K 800-370 980 1/min

400 V 50 Hz 3~ (winding 400/690 V) max. temperature of liquid handled 30/40�C

Motor Motor Amacan K Code Irated Istarting 1) cos � Electric cables NSSHöu-J Weight

design rating 800-370/... Nr. d.o.l. Power supply cable Control

U or X P2 Cross-section Outsidedia.

cable 2)

(Flameproof) kW A A mm2 mm kg

18 .../206 U 35.5 160 0.85 1x(7x4+5x1.5) 26.9--28.8 -- 505

U 24 .../266 U 48,.5 225 0.84 1x(7x10+5x1.5) 29.5--32.9 -- 565

tmax = 30 �C 28 .../286 U 60.0 250 0.78 2x4x4 16.6--18.7 A 710max

37 .../376 U 77.0 335 0.78 2x4x6 17.8--19.8 A 780

18 .../206 X 35.5 160 0.85 1x(7x4+5x1.5) 26.9--28.8 -- 505

X 24 .../266 X 48.5 225 0.84 1x(7x10+5x1.5) 29.5--32.9 -- 565

tmax = 40 �C 28 .../376 X 61.0 335 0.75 2x4x4 16.6--18.7 A 780max

37 .../456 X 77.0 460 0.77 2x4x6 17.8--19.8 A 860

Data applies to a density of 1 kg/dm3 and a kinematic viscosity of up to max. 20 mm2/sWarranty acc. to ISO 9906/A1) further starting modes on request2) Control cable: A = 1x8x1.5 ; Outside: 16.5--18.7 mm ; B = 1x10x1.5 ; Outside : 18.7--20.7 mm

H [m]

P [kW]

H [ft]

P [hp]

Kennlinien nachISO 9906/A

Curves as perISO 9906/A.

Courbes selonISO 9906/A.

FörderhöheHead

Hauteur

LeistungsbedarfPower Input

Puiss. hyd. abs.

Förderstrom/Rate of Flow/Débit

LaufradformImpeller type

Forme de roue

freier Durchgangfree passage

section de passage

115 x 95 mm

Nr. : D2A / D2I[mm]

4 : 388 / 3633 376 / 3412 : 355 / 3061 : 332 / 268

Amacan K

41

Amacan K 800-380 980 1/min

400 V 50 Hz 3~ (winding 400/690 V) max. temperature of liquid handled 30/40�C

Motor Motor Amacan K Code Irated Istarting 1) cos � Electric cables NSSHöu-J Weight

design rating 800-380/... Nr. d.o.l. Power supply cable Control

U or X P2 Cross-section Outsidedia.

cable 2)

(Flameproof) kW A A mm2 mm kg

28 .../286 U 60.0 250 0.78 2x4x4 16.6--18.7 A 780

U 37 .../376 U 77.0 335 0.78 2x4x6 17.8--19.8 A 870

tmax = 30 �C 45 .../456 U 92.0 460 0.79 2x4x10 21.7--23.7 A 930max

64 .../646 U 139.0 600 0.75 2x4x16 27.1--30.1 A 1030

X28 .../376 X 61.0 335 0.75 2x4x4 16.6--18.7 A 870

X

t = 40 �C37 .../456 X 77.0 460 0.77 2x4x6 17.8--19.8 A 930

tmax = 40 �C 45 .../646 X 106.0 600 0.69 2x4x10 21.7--23.7 A 1030

Data applies to a density of 1 kg/dm3 and a kinematic viscosity of up to max. 20 mm2/sWarranty acc. to ISO 9906/A1) further starting modes on request2) Control cable: A = 1x8x1.5 ; Outside: 16.5--18.7 mm ;

Nr. : D2A / D2I[mm]

4 : 388 / 3633 376 / 3412 : 355 / 3061 : 332 / 268

H [m]

P [kW]

H [ft]

P [hp]

Kennlinien nachISO 9906/A

Curves as perISO 9906/A.

Courbes selonISO 9906/A.

FörderhöheHead

Hauteur

LeistungsbedarfPower Input

Puiss. hyd. abs.

Förderstrom/Rate of Flow/Débit

LaufradformImpeller type

Forme de roue

freier Durchgangfree passage

section de passage

115 x 95 mm

Amacan K

42

Amacan K 800-380 735 1/min

400 V 50 Hz 3~ (winding 400/690 V) max. temperature of liquid handled 30/40�C

Motor Motor Amacan K Code Irated Istarting 1) cos � Electric cables NSSHöu-J Weight

design rating 800-380/... Nr. d.o.l. Power supply cable Control

U or X P2 Cross-section Outsidedia.

cable 2)

(Flameproof) kW A A mm2 mm kg

U16 .../178 U 36.0 115 0.79 1x(7x4+5x1.5) 26.9--28.8 -- 630

U

t = 30 �C20 .../218 U 44.0 150 0.75 1x(7x10+5x1.5) 29.5--32.9 -- 700

tmax = 30 �C25 .../258 U1 57.0 230 0.73 2x4x4 16.9-18.7 A 870

X16 .../178 X 36.0 115 0.79 1x(7x4+5x1.5) 26.9--28.8 -- 630

X

t = 40 �C20 .../218 X 44.0 150 0.75 1x(7x10+5x1.5) 29.5--32.9 -- 700

tmax = 40 �C25 .../338 X1 60.0 300 0.69 2x4x4 16.6-18.7 A 930

Data applies to a density of 1 kg/dm3 and a kinematic viscosity of up to max. 20 mm2/sWarranty acc. to ISO 9906/A1) further starting modes on request2)Control cable: A = 1x8x1.5 ; Outside: 16.5--18.7 mm ; B = 1x10x1.5 ; Outside: 18.7--20.7 mm

Nr. : D2A / D2I[mm]

4 : 408 / 3783 398 / 3442 : 384 / 3171 : 367 / 295

H [m]

P [kW]

H [ft]

P [hp]

Kennlinien nachISO 9906/A

Curves as perISO 9906/A.

Courbes selonISO 9906/A.

FörderhöheHead

Hauteur

LeistungsbedarfPower Input

Puiss. hyd. abs.

Förderstrom/Rate of Flow/Débit

LaufradformImpeller type

Forme de roue

freier Durchgangfree passage

section de passage

145 x 135 mm

Amacan K

43

Amacan K 800-381 980 1/min

400 V 50 Hz 3~ (winding 400/690 V) max. temperature of liquid handled 30/40�C

Motor Motor Amacan K Code Irated Istarting 1) cos � Electric cables NSSHöu-J Weight

design rating 800-381/... Nr. d.o.l. Power supply cable Control

U or X P2 Cross-section Outsidedia.

cable 2)

(Flameproof) kW A A mm2 mm kg

24 .../266 U 48.5 225 0.84 1x(7x10+5x1.5) 29.5--32.9 -- 730

U 28 .../286 U 60.0 250 0.78 2x4x4 16.6-18.7 A 780

tmax = 30 �C 37 .../376 U 77.0 335 0.78 2x4x6 17.8-19.8 A 870max

45 .../456 U 92.0 460 0.79 2x4x10 21.7-23.7 A 930

24 .../266 X 48.5 225 0.84 1x(7x10+5x1.5) 29.5--32.9 -- 730

X 28 .../376 X 61.0 335 0.75 2x4x4 16.6-18.7 A 870

tmax = 40 �C 37 .../456 X 77.0 460 0.77 2x4x6 17.8-19.8 A 930max

45 .../646 X 106.0 600 0.69 2x4x10 21.7-23.7 A 1030

Data applies to a density of 1 kg/dm3 and a kinematic viscosity of up to max. 20 mm2/sWarranty acc. to ISO 9906/A1) further starting modes on request2) Control cable: A = 1x8x1.5 ; Outside: 16.5--18.7 mm ; B = 1x10x1.5 ; Outside: 18.7--20.7 mm

Nr. : D2A / D2I[mm]

4 : 408 / 3783 : 398 / 3442 : 384 / 3171 : 367 / 295

H [m]

P [kW]

H [ft]

P [hp]

Kennlinien nachISO 9906/A

Curves as perISO 9906/A.

Courbes selonISO 9906/A.

FörderhöheHead

Hauteur

LeistungsbedarfPower Input

Puiss. hyd. abs.

Förderstrom/Rate of Flow/Débit

LaufradformImpeller type

Forme de roue

freier Durchgangfree passage

section de passage

145 x 135 mm

Amacan K

44

Amacan K 800-381 735 1/min

400 V 50 Hz 3~ (winding 400/690 V) max. temperature of liquid handled 30/40�C

Motor Motor Amacan K Code Irated Istarting 1) cos � Electric cables NSSHöu-J Weight

design rating 800-381/... Nr. d.o.l. Power supply cable Control

U or X P2 Cross-section Outsidedia.

cable

(Flameproof) kW A A mm2 mm kg

U 16 .../178 U 36.0 115 0.79 1x(7x4+5x1.5) 26.9-28.8 -- 630

tmax = 30 �C 20 .../218 U 44.0 150 0.75 1x(7x10+5x1.5) 29.5-32.9 -- 700

X 16 .../178 X 36.0 115 0.79 1x(7x4+5x1.5) 26.9-28.8 -- 630

tmax = 40 �C 20 .../218 X 44.0 150 0.75 1x(7x10+5x1.5) 29.5-32.9 -- 700

Data applies to a density of 1 kg/dm3 and a kinematic viscosity of up to max. 20 mm2/sWarranty acc. to ISO 9906/A1) further starting modes on request

H [m]

P [kW]

H [ft]

P [hp]

Kennlinien nachISO 9906/A

Curves as perISO 9906/A.

Courbes selonISO 9906/A.

FörderhöheHead

Hauteur

LeistungsbedarfPower Input

Puiss. hyd. abs.

Förderstrom/Rate of Flow/Débit

LaufradformImpeller type

Forme de roue

freier Durchgangfree passage

section de passage

126 x 100 mm

Nr. : D2A / D2I[mm]

6 : 450 / 4205 430 / 4004 : 420 / 3703 : 403 / 3492 : 387 / 3221 : 370 / 302

Amacan K

45

Amacan K 1000-420 980 1/min

400 V 50 Hz 3~ (winding 400/690 V) max. temperature of liquid handled 30/40�C

Motor Motor Amacan K Code Irated Istarting 1) cos � Electric cables NSSHöu-J Weight

design rating 1000-420/... Nr. d.o.l. Power supply cable Control

U or X P2 Cross-section Outsidedia.

cable 2)

(Flameproof) kW A A mm2 mm kg

45 .../456 U1 92.0 460 0.79 2x4x10 21.7--23.7 A 1050

U 64 .../646 U1 139.0 600 0.74 2x4x16 27.1--30.1 A 1200

tmax = 30 �C 80 .../806 U1 158.0 740 0.81 2x4x25 32.8--35.8 A 1400max

102 .../1026 U 200.0 1140 0.82 2x4x25 32.8--35.8 A 1550

45 .../646 X1 105.0 600 0.69 2x4x10 21.7--23.7 A 1200

X 64 .../806 X1 131.0 740 0.77 2x4x16 27.1--30.1 A 1400

tmax = 40 �C 80 .../1026 X 158.0 1140 0.80 2x4x25 32.8--35.8 A 1550max

102 .../1206 X 200.0 1450 0.79 2x4x25 32.8--35.8 A 1650

Data applies to a density of 1 kg/dm3 and a kinematic viscosity of up to max. 20 mm2/sWarranty acc. to ISO 9906/A1) further starting modes on request2) Control cable : A = 1x8x1.5 ; Outside: 16.5--18.7 mm ; B = 1x10x1.5 ; Outside: 18.7--20.7 mm

H [m]

P [kW]

H [ft]

P [hp]

Kennlinien nachISO 9906/A

Curves as perISO 9906/A.

Courbes selonISO 9906/A.

FörderhöheHead

Hauteur

LeistungsbedarfPower Input

Puiss. hyd. abs.

Förderstrom/Rate of Flow/Débit

LaufradformImpeller type

Forme de roue

freier Durchgangfree passage

section de passage

126 x 100 mm

Nr. : D2A / D2I[mm]

6 : 450 / 4205 430 / 4004 : 420 / 3703 : 403 / 3492 : 387 / 3221 : 370 / 302

Amacan K

46

Amacan K 1000-420 735 1/min

400 V 50 Hz 3~ (winding 400/690 V) max. temperature of liquid handled 30/40�C

Motor Motor Amacan K Code Irated Istarting 1) cos � Electric cables NSSHöu-J Weight

design rating 1000-420/... Nr. d.o.l. Power supply cable Control

U or X P2 Cross-section Outsidedia.

cable 2)

(Flameproof) kW A A mm2 mm kg

U25 .../258 U2 57.0 230 0.73 2x4x4 16.6--18.7 A 1000

U

t = 30 �C33 .../338 U2 72.0 300 0.75 2x4x6 17.8--19.8 A 1050

tmax = 30 �C 43 .../438 U 100.0 460 0.70 2x4x10 21.7--23.7 A 1150

X25 .../338 X2 59.0 300 0.70 2x4x4 16.6--18.7 A 1050

X

t = 40 �C33 .../438 X 85.0 460 0.64 2x4x10 21.7--23.7 A 1150

tmax = 40 �C 43 .../548 X 105.0 560 0.66 2x4x10 21.7--23.7 A 1200

Data applies to a density of 1 kg/dm3 and a kinematic viscosity of up to max. 20 mm2/sWarranty acc. to ISO 9906/A1) further starting modes on request2) Control cable : A = 1x8x1.5 ; Outside : 16.5--18.7 mm ; B = 1x10x1.5 ; Outside : 18.7--20.7 mm

H [m]

P [kW]

H [ft]

P [hp]

Kennlinien nachISO 9906/A

Curves as perISO 9906/A.

Courbes selonISO 9906/A.

FörderhöheHead

Hauteur

LeistungsbedarfPower Input

Puiss. hyd. abs.

Förderstrom/Rate of Flow/Débit

LaufradformImpeller type

Forme de roue

freier Durchgangfree passage

section de passage

140 x 150 mm

Nr. : D2A / D2I[mm]

4 : 450 / 4153 434 / 3862 : 416 / 3561 : 396 / 324

Amacan K

47

Amacan K 1000-421 980 1/min

400 V 50 Hz 3~ (winding 400/690 V) max. temperature of liquid handled 30/40�C

Motor Motor Amacan K Code Irated Istarting 1) cos � Electric cables NSSHöu-J Weight

design rating 1000-421/... Nr. d.o.l. Power supply cable Control

U or X P2 Cross-section Outsidedia.

cable 2)

(Flameproof) kW A A mm2 mm kg

37 .../376 U1 77.0 335 0.78 2x4x6 17.8--19.8 A 1010

U 45 .../456 U1 92.0 460 0.79 2x4x10 21.7--23.7 A 1050

tmax = 30 �C 64 .../646 U1 139.0 600 0.74 2x4x16 27.1--30.1 A 1200max

80 .../806 U1 158.0 740 0.81 2x4x25 32.8--35.8 A 1400

X37 .../456 X1 77.0 460 0.77 2x4x6 17.8--19.8 A 1050

X

t = 40 �C45 .../646 X1 105.0 600 0.69 2x4x10 21.7--23.7 A 1200

tmax = 40 �C 64 .../806 X1 131.0 740 0.77 2x4x16 27.1--30.1 A 1400

Data applies to a density of 1 kg/dm3 and a kinematic viscosity of up to max. 20 mm2/sWarranty acc. to ISO 9906/A1) further starting modes on request2) Control cable : A = 1x8x1.5 ; Outside : 16.5--18.7 mm ; B = 1x10x1.5 ; Outside : 18.7--20.7 mm

H [m]

P [kW]

H [ft]

P [hp]

Kennlinien nachISO 9906/A

Curves as perISO 9906/A.

Courbes selonISO 9906/A.

FörderhöheHead

Hauteur

LeistungsbedarfPower Input

Puiss. hyd. abs.

Förderstrom/Rate of Flow/Débit

LaufradformImpeller type

Forme de roue

freier Durchgangfree passage

section de passage

140 x 150 mm

Nr. : D2A / D2I[mm]

4 : 450 / 4153 434 / 3862 : 416 / 3561 : 396 / 324

Amacan K

48

Amacan K 1000-421 735 1/min

400 V 50 Hz 3~ (winding 400/690 V) max. temperature of liquid handled 30/40�C

Motor Motor Amacan K Code Irated Istarting 1) cos � Electric cables NSSHöu-J Weight

design rating 1000-421/... Nr. d.o.l. Power supply cable Control

U or X P2 Cross-section Outsidedia.

cable 2)

(Flameproof) kW A A mm2 mm kg

U25 .../258 U2 57.0 230 0.73 2x4x4 16.6--18.7 A 1000

U

t = 30 �C33 .../338 U2 72.0 300 0.75 2x4x6 17.8--19.8 A 1050

tmax = 30 �C 43 .../438 U 100.0 460 0.70 2x4x10 21.7--23.7 A 1150

19 .../258 X2 46.0 230 0.68 2x4x4 16.6--18.7 A 1000

X 25 .../338 X2 59.0 300 0.70 2x4x4 16.6--18.7 A 1050

tmax = 40 �C 33 .../438 X 85.0 460 0.64 2x4x10 21.7--23.7 A 1150max

43 .../548 X 105.0 560 0.66 2x4x10 21.7--23.7 A 1200

Data applies to a density of 1 kg/dm3 and a kinematic viscosity of up to max. 20 mm2/sWarranty acc. to ISO 9906/A1) further starting modes on request2) Control cable : A = 1x8x1.5 ; Outside : 16.5--18.7 mm ; B = 1x10x1.5 ; Outside : 18.7--20.7 mm

H [m]

P [kW]

H [ft]

P [hp]

Kennlinien nachISO 9906/A

Curves as perISO 9906/A.

Courbes selonISO 9906/A.

FörderhöheHead

Hauteur

LeistungsbedarfPower Input

Puiss. hyd. abs.

Förderstrom/Rate of Flow/Débit

LaufradformImpeller type

Forme de roue

freier Durchgangfree passage

section de passage

145 x 110 mmNr. : D2A / D2I

[mm]4 : 508 / 5083 460 / 4602 : 448 / 4121 : 430 / 350

Amacan K

49

Amacan K 1000-500 (applies to Amacan K 1300-500, too) 980 1/min

400 V 50 Hz 3~ (winding 400/690 V) max. temperature of liquid handled 30/40�C

Motor Motor Amacan K Code Irated Istarting 1) cos � Electric cables NSSHöu-J Weight

design rating 1000-500/... Nr. d.o.l. Power supply cable Control

U or X P2 Cross-section Outsidedia.

cable 2)

(Flameproof) kW A A mm2 mm kg

80 .../806 U1 158.0 740 0.81 2x4x25 32.8--35.8 A 1470

102 .../1026 U 200.0 1140 0.82 2x4x25 32.8--35.8 A 1630

U 120 .../1206 U 230.0 1450 0.82 2x4x35 36.9--39.9 A 1750

tmax = 30 �C 138 .../1386 U 245.0 1750 0.87 2x4x35 36.9--39.9 B 2050tmax 30 C165 .../1656 U 285.0 1670 0.89 2x4x50 42.9--45.9 B 2200

200 .../2006 U 345.0 2400 0.91 2x3x70/35 48.4--51.4 B 2350

80 .../1026 X 158.0 1140 0.80 2x4x25 32.8--35.8 A 1630

X102 .../1206 X 200.0 1450 0.80 2x4x25 32.8--35.8 A 1750

X

t = 40 �C120 .../1386 X 215.0 1750 0.87 2x4x35 36.9--39.9 B 2050

tmax = 40 �C 138 .../1656 X 240.0 1670 0.89 2x4x35 36.9--39.9 B 2200

165 .../2006 X 258.0 2400 0.90 2x4x50 42.9--45.9 B 2350

Data applies to a density of 1 kg/dm3 and a kinematic viscosity of up to max. 20 mm2/sWarranty acc. to ISO 9906/A1) further starting modes on request2) Control cable : A = 1x8x1.5 ; Outside: 16.5--18.7 mm ; B = 1x10x1.5 ; Outside: 18.7--20.7 mm

H [m]

P [kW]

H [ft]

P [hp]

Kennlinien nachISO 9906/A

Curves as perISO 9906/A.

Courbes selonISO 9906/A.

FörderhöheHead

Hauteur

LeistungsbedarfPower Input

Puiss. hyd. abs.

Förderstrom/Rate of Flow/Débit

LaufradformImpeller type

Forme de roue

freier Durchgangfree passage

section de passage

133 x 150 mm

Nr. : D2A / D2I[mm]

5 : 582 / 5504 : 565 / 5173 : 550 / 4742 : 540 / 4421 : 520 / 380

Amacan K

50

Amacan K 1200-540 (applies to Amacan k 1300-540 and 1400-540, too) 980 1/min

400 V 50 Hz 3~ (winding 400/690 V) max. temperature of liquid handled 30/40�C

Motor Motor Amacan K Code Irated Istarting 1) cos � Electric cables NSSHöu-J Weight

design rating 1200-540/... Nr. d.o.l. Power supply cable Control

U or X P2 Cross-section Outsidedia.

cable 2)

(Flameproof) kW A A mm2 mm kg

165 .../1656 U 285.0 1670 0.89 2x4x50 42.9--45.9 B 3000

U 200 .../2006 U 345.0 2400 0.91 2x3x70/35 48.4--51.4 B 3150

tmax = 30 �C 260 .../2606 U 450.0 1920 0.89 2x3x95/50 55.0--59.0 B 3550max

320 .../3206 U 590.0 3700 0.83 4x4x50 42.9--45.9 B 3750

X165 .../2006 X 285.0 2400 0.90 2x4x50 42.9--45.9 B 3150

X

t = 40 �C200 .../2606 X 345.0 1920 0.88 2x3x70/35 48.4--51.4 B 3550

tmax = 40 �C 260 .../3206 X 470.0 3700 0.84 4x4x35 36.9--39.9 B 3750

Data applies to a density of 1 kg/dm3 and a kinematic viscosity of up to max. 20 mm2/sWarranty acc. to ISO 9906/A1) further starting modes on request2) Control cable: A = 1x8x1.5 ; Outside: 16.5--18.7 mm ; B = 1x10x1.5 ; Outside: 18.7--20.7 mm

H [m]

P [kW]

H [ft]

P [hp]

Kennlinien nachISO 9906/A

Curves as perISO 9906/A.

Courbes selonISO 9906/A.

FörderhöheHead

Hauteur

LeistungsbedarfPower Input

Puiss. hyd. abs.

Förderstrom/Rate of Flow/Débit

LaufradformImpeller type

Forme de roue

freier Durchgangfree passage

section de passage

133 x 150 mm

Nr. : D2A / D2I[mm]

5 : 582 / 5504 : 565 / 5173 : 550 / 4742 : 540 / 4421 : 520 / 380

Amacan K

51

Amacan K 1200-540 (applies to Amacan K 1300-540, too) 735 1/min

400 V 50 Hz 3~ (winding 400/690 V) max. temperature of liquid handled 30/40�C

Motor Motor Amacan K Code Irated Istarting 1) cos � Electric cables NSSHöu-J Weight

design rating 1200-540/... Nr. d.o.l. Power supply cable Control

U or X P2 Cross-section Outsidedia.

cable 2)

(Flameproof) kW A A mm2 mm kg

84 .../848 U 177.0 680 0.77 2x4x25 32.8--35.8 A 2400

U 107 .../1078 U2 225.0 1000 0.76 2x4x35 36.9--39.9 A 2500

tmax = 30 �C 126 .../1268 U2 240.0 1220 0.83 2x4x35 36.9--39.9 B 2910max

150 .../1508 U2 285.0 1400 0.82 2x4x50 42.9--45.9 B 3100

84 .../1078 X2 199.0 1000 0.67 2x4x25 32.8--35.8 A 2500

X 107 .../1268 X2 205 1220 0.82 2x4x35 36.9--39.9 B 2910

tmax = 40 �C 126 .../1508 X2 250.0 1400 0.80 2x4x50 42.9--45.9 B 3100max

150 .../1808 X2 275.0 1700 0.85 2x4x50 42.9--45.9 B 3210

Data applies to a density of 1 kg/dm3 and a kinematic viscosity of up to max. 20 mm2/sWarranty acc. to ISO 9906/A1) further starting modes on request2) Control cable : A = 1x8x1.5 ; Outside: 16.5--18.7 mm ; B = 1x10x1.5 ; Outside: 18.7--20.7 mm

H [m]

P [kW]

H [ft]

P [hp]

Kennlinien nachISO 9906/A

Curves as perISO 9906/A.

Courbes selonISO 9906/A.

FörderhöheHead

Hauteur

LeistungsbedarfPower Input

Puiss. hyd. abs.

Förderstrom/Rate of Flow/Débit

LaufradformImpeller type

Forme de roue

freier Durchgangfree passage

section de passage

133 x 150 mm

Nr. : D2A / D2I[mm]

5 : 582 / 5504 : 565 / 5173 : 550 / 4742 : 540 / 4421 : 520 / 380

Amacan K

52

Amacan K 1200-540 590 1/min

400 V 50 Hz 3~ (winding 400/690 V) max. temperature of liquid handled 30/40�C

Motor Motor Amacan K Code Irated Istarting 1) cos � Electric cables NSSHöu-J Weight

design rating 1200-540/... Nr. d.o.l. Power supply cable Control

U or X P2 Cross-section Outsidedia.

cable 2)

(Flameproof) kW A A mm2 mm kg

43 .../4310 U1 99.0 380 0.68 2x4x10 21.7--23.7 A 2250

U 54 .../5410 U2 121.0 420 0.71 2x4x16 27.1--30.1 A 2350

tmax = 30 �C 67 .../6710 U2 149.0 540 0.71 2x4x16 27.1--30.1 A 2450max

84 .../8410 U2 189.0 680 0.70 2x4x25 32.8--35.8 A 2550

43 .../5410 X2 102.0 420 0.67 2x4x10 21.7--23.7 A 2350

X 54 .../6710 X2 125.0 540 0.68 2x4x16 27.1--30.1 A 2450

tmax = 40 �C 67 .../8410 X2 159.0 680 0.66 2x4x25 32.8--35.8 A 2550max

84 .../10710 X2 185.0 980 0.70 2x4x25 32.8--35.8 B 2900

Data applies to a density of 1 kg/dm3 and a kinematic viscosity of up to max. 20 mm2/sWarranty acc. to ISO 9906/A1) further starting modes on request2) Control cable: A = 1x8x1.5 ; Outside : 16.5--18.7 mm ; B = 1x10x1.5 ; Outside : 18.7--20.7 mm

H [m]

P [kW]

H [ft]

P [hp]

Kennlinien nachISO 9906/A

Curves as perISO 9906/A.

Courbes selonISO 9906/A.

FörderhöheHead

Hauteur

LeistungsbedarfPower Input

Puiss. hyd. abs.

Förderstrom/Rate of Flow/Débit

LaufradformImpeller type

Forme de roue

freier Durchgangfree passage

section de passage

145 mm

Nr. : D2A / D2I[mm]

5 : 612 / 5324 : 600 / 5053 : 585 / 4872 : 570 / 4601 : 560 / 435

Amacan K

53

Amacan K 1300-520 (applies to Amacan K 1400-520, too) 735 1/min

400 V 50 Hz 3~ (winding 400/690 V) max. temperature of liquid handled 30/40�C

Motor Motor Amacan K Code Irated Istarting 1) cos � Electric cables NSSHöu-J Weight

design rating 1300-520/... Nr. d.o.l. Power supply cable Control

U or X P2 Cross-section Outsidedia.

cable 2)

(Flameproof) kW A A mm2 mm kg

126 .../1268 U1 235 1220 0.84 2x4x35 36.9--39.9 B 3050

U 150 .../1508 U1 290 1400 0.82 2x4x50 42.9--45.9 B 3200U

tmax = 30 �C 180 .../1808 U1 335 1700 0.84 2x3x70/35 48.4--51.4 B 3350max

225 .../2258 U1 425 2650 0.83 2x3x95/50 55.0--59.0 B 3900

126 .../1508 X1 245 1400 0.81 2x4x35 36.9--39.9 B 3200

X 150 .../1808 X1 275 1700 0.85 2x4x50 42.9--45.9 B 3350

tmax = 40 �C 180 .../2258 X1 355 2650 0.80 2x3x70/35 48.4--51.4 B 3900max

225 .../2808 X1 445 3420 0.78 2x3x95/50 55.0--59.0 B 4250

Data applies to a density of 1 kg/dm3 and a kinematic viscosity of up to max. 20 mm2/sWarranty acc. to ISO 9906/A1) further starting modes on request2) Control cable: A = 1x8x1.5 ; Outside: 16.5--18.7 mm ; B = 1x10x1.5 ; Outside: 18.7--20.7 mm

H [m]

P [kW]

H [ft]

P [hp]

Kennlinien nachISO 9906/A

Curves as perISO 9906/A.

Courbes selonISO 9906/A.

FörderhöheHead

Hauteur

LeistungsbedarfPower Input

Puiss. hyd. abs.

Förderstrom/Rate of Flow/Débit

LaufradformImpeller type

Forme de roue

freier Durchgangfree passage

section de passage

145 mm

Nr. : D2A / D2I[mm]

5 : 612 / 5324 : 600 / 5053 : 585 / 4872 : 570 / 4601 : 560 / 435

Amacan K

54

Amacan K 1300-520 590 1/min

400 V 50 Hz 3~ (winding 400/690 V) max. temperature of liquid handled 30/40�C

Motor Motor Amacan K Code Irated Istarting 1) cos � Electric cables NSSHöu-J Weight

design rating 1300-520/... Nr. d.o.l. Power supply cable Control

U or X P2 Cross-section Outsidedia.

cable 2)

(Flameproof) kW A A mm2 mm kg

U67 .../6710 U1 149 540 0.71 2x4x16 27.1--30.1 A 2650

U

t = 30 �C84 .../8410 U1 189 680 0.70 2x4x25 32.8--35.8 A 2750

tmax = 30 �C 107 .../10710 U1 220 980 0.75 2x4x35 36.9--39.9 B 3000

X67 .../8410 X2 159 680 0.66 2x4x25 32.8--35.8 A 2750

X

t = 40 �C84 .../10710 X2 185 980 0.70 2x4x25 36.9--39.9 B 3000

tmax = 40 �C 107 .../12610 X2 205 1070 0.82 2x4x35 36.9--39.9 B 3200

Data applies to a density of 1 kg/dm3 and a kinematic viscosity of up to max. 20 mm2/sWarranty acc. to ISO 9906/A1) further starting modes on request2) Control cable: A = 1x8x1.5 ; Outside: 16.5--18.7 mm ; B = 1x10x1.5 ; Outside: 18.7--20.7 mm

Amacan K

55

Hydraulic data of pump sizes -- 1300--750on request

L

suspension at the cover or with BU / BG / Aat a support

L = mm

lower edge of pit = lower edge of pump

1579.5/3--10

10/97

Subjecttomodificationwithoutnotice

KSB AktiengesellschaftP.O. Box 200743 � 06008 Halle (Saale) � Turmstraße 92 � 06110 Halle (Germany)Tel. +49 (345) 48 26 0 � Fax +49 (345) 48 26 46 99 � www.ksb.com

Amacan K

Order detail -- carrier cable lengthIn order to select the proper length of the carrier cable, it is absolutely necessary to define dimension ”L”.