multi storey buidling

-

Upload

ravi-nandan-singh -

Category

Documents

-

view

100 -

download

1

Transcript of multi storey buidling

i

A Project Report

on

DESIGN OF

MULTI-STOREY RESIDENTIAL BUILDING

Submitted for partial fulfillment of award of

BACHELOR OF TECHNOLOGY (B. Tech.)

Degree

inCIVIL ENGINEERING

By:

ABHISEK KUMAR MAURYAISHWARYA TIWARIAJIT PRAJAPATIFARHAN ALIRAVI NANDAN SINGH

Under the Guidance of Mr. NURUL HASSAN (Asst. Prof.)

Department of Civil Engineering

VISHVESHWARYA GROUP OF INSTITUTIONS[20 Kms. from Ghaziabad on Ghaziabad – Bulandshahr G.T. Road]

(Near Dadri), Gautam Buddh Nagar (UP) – 203 207Visit us at: www.viet.ac.in

(May, 2015)

ii

CERTIFICATE

Certified that following students have completed the project

entitled “ DESIGN OF MULTI STORY RESIDENTIAL

BUILDING ” for the award of Bachelor of Technology , in Civil

Engineering from Vishveshwarya Institute of Technology Dadri,

(G. B. Nagar) affiliated to Gautam Buddha Technical University,

Lucknow under my supervision. The project report embodies result

of original work and studies carried out by student himself and

the contents of the report do not form the basis for the award of

any other degree to the candidate or to anybody else.

GROUP MEMBER:Sr.No. Name of Students Roll No.1. ABHISEK KUMAR MAURY (1128600001)2. AISHWARYA TIWARI (1128600004)3. AJIT PRAJAPATI ( 1128600006)4. FARHAN ALI (1128600016)5. RAVI NANDAN SINGH ( 1128600033)

MR. NURUL HUSSAN MR. ABHAY SHANKAR RAI ASST. PROFESSOR HOD, CIVIL ENG. DEPT.

DATE:

iii

ACKNOWLEDGEMENT

We would like to express our gratitude towards Mr.NURUL HUSSAN,

project supervisor for his valuable encouragement and guidance.

We would also like to thank (Mr. Abhay Shankar Rai), project

manager for his continuous support and advice throughout the entire

project of Design of Multi Storey Residential Building. We are also

thankful Mr. NURUL HUSSAN for her support and valuable guidance,

rejuvenating encouragement, positive criticism and constant supervision

all through our project session.

SUBMITTED BY: ABHISEK KUMAR MAURY

AISHWARYA TIWARI

AJIT PRAJAPATI

FARHAN ALI

RAVI NANDAN SINGH

iv

OBJECTIVEOBJECTIVE OF THE PROJECT:

• Carrying out the complete analysis and design of the main structural

elements of multi storey residential building including slab, column, shear

wall, and foundation.

• Getting real life experience with engineering practices.

v

ABBREVIATIONSUnless specified otherwise, the symbols and notations used in the report shall have the following meaning.

a0……………………………Basic Horizontal seismic coefficient

Ag…………………………...Gross area of section

Ah ………………………….. Horizontal seismic coefficient

Asc …………………………..Area of compression steel

Ast……………………………Area of tension steel

b……………………………...Width of member

C……………………………..Flexibility co-efficient

d……………………………..Effective depth of member

D……………………………..Overall depth of member

d’…………………………….Nominal cover in compression

Dia…………………………..Nominal Diameter of the bar

Fck…………………………...Characteristic compressive strength of concrete

Fy……………………………Characteristic yield strength of steel

I……………………….……..Importance factor

K……………………………..Performance factor

K1……………………………Probability factor

vi

K2……………………………Terrain, height and structure size factor

K3……………………………Topographical factor

Ld……………………………Development length

Lex……………………………Effective length of column about X-X axis

Ley……………………………Effective length of column about Y-Y axis

L0……………………………….Unsupported length of column

Mu………………………………Factored Moment

Mx………………………………Moment about X-X axis

My………………………………Moment about Y-Y axis

P/Pu……………………………..Axial load

Pc………………………………..Percentage compressive steel

Pt………………………………..Percentage tension steel

Pz………………………………..Design wind pressure at level z

T…………………………………Fundamental Time period

tc …………………………………Design shear strength of section

tv…………………………………Normal shear stress

V/Vu …………………………….Factored shear force

Vb ……………………………….Basic wind speed/ Base shear

Vz………………………………...Design wind speed at level z

W…………………………………Tidal weight of building

Z…………………………………..Height or level with respect to mean

ground level

vii

TABLE OF CONTENTS

TITLE PAGE……………………………………………………...…….iCERTIFICATE……………………………………………...………….iiACKNOWLEDGEMENT……..…..………………….……………….iiiOBJECTIVE…………………………………………………………...ivABBREVATION…………………………….…………………....v – vi

CHAPTER 1 1 - 4 1.1 Introduction

1.1.1 Salient features of the building

1.1.2 Architectural Plan of the building

CHAPTER 2 5 - 242.1 Gravity Design

2.1.1 Analysis for Gravity Loads

2.2 Manual Design of Slab Panel

2.3 Manual Design of Stair case

2.4 Manual Design of Beam

2.5 Manual Design of Column

CHAPTER 3 25 – 46 3.1 Materials required by Gravity Design method

3.2 Ductility consideration

3.2.1 Requirements for Ductility

3.3 Foundation

3.3.1 Raft Foundation

3.3.2 Raft Foundation Design

3.4 Shear Wall

viii

CHAPTER 4 47 – 54 4.4 Design of slab

CONCLUSION 55

BIBLIOGRAPHY 56

1

CHAPTER 1

INTRODUCTION

The project is to analyze and design the proposed building. The building which is to

be used as a residential building is located in the Greater Noida, U.P.The project

came under the final year project work scheme of department of Civil Engineering.

The project includes generation of floor plan in AutoCAD,design of several

component of the building viz. beams,columns,slabs,staircase,shear wall etc

manually as well as by STAAD software.this also contain the structural analysis of

the building on application of several load combination specially wind and seismic

loads.

SALIENT FEATURE OF THE BUILDING

Porpuse→Residential

No. of floors→6(G+5)

Storeys Height→3.2m

Builtup Area→859.1m2

No. of Staircase→1

No. of Lifts→2

Foundation used→Raft

2

1.1.2 ARCHITECTURAL PLAN OF THE BUILDING

It covers a plan area equal to 28.13mX30.54m, consists of a ground floor plus

eleven upper floors.

The type of the building is that of a framed structure. All the floors are similar in

plan, each floor consists of four flats and each flat consists of three rooms which are

of different dimensions.

Some open area is provided in different parts of all floors in the same vertical plane

through all the floors. This open space will facilitate enough ventilation and natural

light. It is surrounded by steel railings on all the four sides.

All the rooms are provided with a wide balcony at the back face and a wide corridor

at the front face.

3

LAYOUT PLAN

4

PLAN

5

CHAPTER 2

2.1 GRAVITY DESIGN

The basic analysis of the structure starts with the gravity load combinations

applied to the structure. This includes dead load due to weight of different

components of the buildings structure itself (beams, columns, Slabs stairs etc

)live load due to miscellaneous moveable components in the

floors( furniture, electrical appliances eetc. ). The presence of occupants also

adds to the live load of the structure.

Here we have analysed the structure for one load combination

• 1.5*(Dead load + Live load)

• (Dead Load+ Live load)

The beams and columns have been designed on the basis of responses obtained in

preliminary analysis for gravity loads using STAAD Pro Software. However

the slab panels have been designed manually for ine floor of the building a

model calculation for the slab panels and stair case has also been discussed.

2.1.1 ANALYSIS FOR GRAVITY LOADS

Dead Loads:

Self weight factor =1

Weight of Main Walls on Beams =14.72KN/m2

Weight of partition Walls on Beams =7.06KN/m2

Weight of parapet Walls on Beams =4.72KN/m2

Weight of Floor slabs =3KN/m2 (Discussed Later)

Weight of Floor finish =1.25 KN/m2

6

Live Loads:

All floors =2KN/m2

Corridors and Staircases including fire escapes and store rooms =3 KN/m2

Roof Top =1.5 KN/m2

Based on application of this loads the structure has been designed for load

combination of 1.5(DL+LL). While the slab panels and staircases have been

designed manually or by Microsoft Excel program for the above mentioned load

conditions, the beams and columns have been designed based on the responses

obtained by STAAD pro.

2.2 MANUAL DESIGN OF FLOOR SLAB PANEL:

Slab of size (3.527×4.207)

Short span, Lx=3.527m

Long span, Ly =4.207,

Depth of slab,D=120mm,

Two adjacent age discontinuous

Load Calculation:

self wt of slab =0.120*25=3.0KN/m2

D.L due to finishing =0.05*24=1.2KN/m2

L.L onb slab =2.0KN/m2

Total load on slab(W) = 6.2KN/m2

Ultimate load on slab(Wu) =1.5×6.20=9.30KN/m2

Hence design as a two way slab

ɑx+=0.045 ɑx

-=0.060

ɑy+=0.035 ɑy

-=0.047

Mux(+)=ɑx+*Wu*Lx

2

7

=0.045*9.3*3.5272 = 5.206KNm

Mux(-) =0.060*9.3*3.5272 =6.94KNm

Muy(+)=0.035*9.3*3.5272 =4.094KNm

Muy(-) =0.047*9.3*3.5272 =5.437KNm

Depth oif slab required =sqrt(Mmax/(0.138*Fck*b))

= (6.94×106)/(0.138*25*1000)

=44.85mm (<100mm)

Design of Reinforcement:

Shorter span:

Area of steel required,Ast=(0.5*Fck/Fy)*(1-sqrt(1-((4.6*Mx)/(Fck*b*d2)))

=(0.5*25/415)*(1-sqrt(1-((4.6*6.94*106)/

(25*1000*1012)))

= 198.9mm2

Minimum area of steel required,Ast min =0.12%

=(0.12*b*D)/100 =(0.12*1000*120)/100

= 144mm2 (198.9mm2>144mm2) O.K

Let us provide diameter of bar 8mm

Required spacing =(1000*50.26)/198.9

=252mm

Longer span:

Area of steel required,Ast=(0.5*Fck/Fy)*(1-sqrt(1-((4.6*My)/(Fck*b*d2)))

=(0.5*25/415)*(1-sqrt(1-((4.6*5.437*106)/

(25*1000*1002)))

=163.25mm2

Minimum area of steel required,Ast min =0.12%

=(0.12*b*D)/100 =(0.12*1000*120)/100

8

= 144mm2 (163.25mm2>144mm2) O.K

Let us provide diameter of bar 8mm

Required spacing =(1000*50.26)/163.25

=307.1mm

Maximum spacing for reinforcement

• Three times the effective depth ,3d=3*101=300mm

• 300mm

Provide 8mm dia bar @250m c/c on shorter span

Area of steel provided=(1000*50.26)/250=201mm2

Provide 8mm dia bar @200mmc/c on longer span

Area of steel provided=(1000*50.26)/250=201mm2

Check for deflection:

Pt=201/(103*102))*100=0.201

Fs=0.58*415*(198.9/201)

=238

Modification factor=2.15N/mm2

(l/d)max =20*2.15=43

(l/d)provided=4207/100=42.07(<43) O.K

Check for shear:

Average effective depth=(101+97)/2 =99mm

Vu=Wu*(0.5*Lx-d)

=9.3*(0.5*3.527-0.099)

=15.48KN/m

9

Τv=(15.48*103)/(1000*99)=0.0.156

For Pt =0.201 and Fc=25KN/m3

Tc=0.32

From above Tc>Tv O.K

SECTION A-A

Where

10

As1 =201mm2 As2 =201mm2 L1 =4.21 L2 =3.53

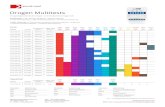

SLB No.

Slab dimension in m

Span Ratio

Design

Load Wu (kN/m^2)

Overall

Depth

Provided (mm

)

Bending moment coefficie

nts

Ultimate Bending moment (Mu) kN-

m/m

Area of

Steel Required

Area of

Steel Provided

Modification factor

Effective Dept

h Required

Dia. Of

Steel Provided

Spacing (mm)

fck =25N/m

m^2fy=415N/mm^2

S1

2.78X3.92

1.41 9.3 120

αx(-) 0 αx(-)*W

u*lx^2 0 0 201 Above 2

53.462 8 250

αx(+)

0.085

αx(+)*Wu*lx^2 6.11 172.

51 201 Above 2

53.462 8 250

αy(-) 0 αy(-)*W

u*ly^2 0 0 201 Above 2

53.462 8 250

αy(+)

,056

αy(+)*Wu*ly^2 4.02 117.

34 201 Above 2

53.462 8 250

S2

3.52X4.21

1.196 9.3 120

αx(-) 0 αx(-)*W

u*lx^2 0 0 201 Above 2

67.692 8 250

αx(+)

0.051

αx(+)*Wu*lx^2

5.87676672

165.75 201 Above

267.692 8 250

αy(-)

0.045

αy(-)*Wu*ly^2

5.1853824

152.07 201 Above

267.692 8 250

αy(+)

0.035

αy(+)*Wu*ly^2

4.0330752

117.58 201 Above

267.692 8 250

S3

1.64X4.21

2.567 9.3 120

αx(-)

0.111

αx(-)*Wu*lx^2 2.28 77.2

3 201 Above 2

31.558 8 250

αx(+) 0.1 αx(+)*W

u*lx^2 2.5 69.42 201 Above

231.558 8 250

αy(-) 0 αy(-)*W

u*ly^2 0 0 201 Above 2

31.558 8 250

αy(+) 0 αy(+)*W

u*ly^2 0 0 201 Above 2

31.558 8 250

S4

3.52X4.21

1.196 9.3 120

αx(-) 0 αx(-)*W

u*lx^2 0 0 201 Above 2

67.692 8 250

αx(+)

0.051

αx(+)*Wu*lx^2

5.87676672

165.75 201 Above

267.692 8 250

αy(-)

0.045

αy(-)*Wu*ly^2

5.1853824

152.07 201 Above

267.692 8 250

αy(+)

0.035

αy(+)*Wu*ly^2

4.0330752

117.58 201 Above

267.692 8 250

S5

3.53X4.69

1.33 9.3 120

αx(-)

0.057

αx(-)*Wu*lx^2

6.71827536

190.28 201 Above

268.462 8 250

αx(+)

0.044

αx(+)*Wu*lx^2

5.18603712

145.78 201 Above

268.462 8 250

αy(-)

0.037

αy(-)*Wu*ly^2

4.36098576

127.36 201 Above

268.462 8 250

αy(+)

0.028

αy(+)*Wu*ly^2

3.30020544 95 201 Above

268.462 8 250

S6

3.53X4.08

1.156 9.3 120

αx(-)

0.043

αx(-)*Wu*lx^2

4.98311391

139.94 201 Above

267.885 8 250

αx(+)

0.032

αx(+)*Wu*lx^2

3.70836384

103.51 201 Above

267.885 8 250

αy(-)

0.032

αy(-)*Wu*ly^2

3.70836384

107.93 201 Above

267.885 8 250

αy(+)

0.024

αy(+)*Wu*ly^2

2.78127288

80.57 201 Above

267.885 8 250

S 3.68X 1.6 9.3 120 αx 0.0 αx(-)*W 8.438 241. 251 Above 70.7 8 200

11

7 6.12 63

(-) 67 u*lx^2 26944 07 2 69αx(+)

0.051

αx(+)*Wu*lx^2

6.42316032

181.65 201 Above

270.769 8 250

αy(-)

0.037

αy(-)*Wu*ly^2

4.65993984

136.3 201 Above

270.769 8 250

αy(+)

0.028

αy(+)*Wu*ly^2

3.52644096

102.54 201 Above

270.769 8 250

S8

4.08X4.92

1.206 9.3 120

αx(-)

0.052

αx(-)*Wu*lx^2

8.05019904

229.53 251 Above

278.462 8 200

αx(+)

0.039

αx(+)*Wu*lx^2

6.03764928

170.43 201 Above

278.462 8 250

αy(-)

0.037

αy(-)*Wu*ly^2

5.72802624

168.5 201 Above

278.462 8 250

αy(+)

0.028

αy(+)*Wu*ly^2

4.33472256

126.58 201 Above

278.462 8 250

S9

3.0x4.08

1.36 9.3 120

αx(-)

0.055

αx(-)*Wu*lx^2

4.6035

129.04 201 Above

257.692 8 250

αx(+)

0.041

αx(+)*Wu*lx^2

3.4317

95.66 201 Above

257.692 8 250

αy(-)

0.037

αy(-)*Wu*ly^2

3.0969

89.85 201 Above

257.692 8 250

αy(+)

0.028

αy(+)*Wu*ly^2

2.3436

67.74 201 Above

257.692 8 250

S10

2.33x7.36

3.16 9.3 120

αx(-)

0.111

αx(-)*Wu*lx^2 9.3 269.

79 314 Above 2

57.692 10 250

αx(+) 0.1 αx(+)*W

u*lx^2 8.37 241.63 314 Above

257.692 10 250

αy(-) 0 αy(-)*W

u*ly^2 0 0 314 Above 2

57.692 10 250

αy(+) 0 αy(+)*W

u*ly^2 0 0 314 Above 2

57.692 10 250

2.4 DESIGN OF BEAM

All beams have been designed as rectangular section, of different sizes as per optimum requirement.

The general design considerations are taken from IS: 456 -2000

Effective depth – is the distance from the centre of the tensile reinforcement to the outermost compression fibers.

Control of deflection – the vertical deflection limit may generally assumed to be satisfied provided that the span to depth ratios are not greater than the values obtained as below :

a) Span to effective depth ratio for span up to 10m

Cantilever 7 Simply supported 20 Continuous 26

12

b) Depending upon the area and stress of steel for tension reinforcement, values in (a) shall be modifying by multiplying with modification factor obtained as per fig 5 (IS: 456-2000).

c) Depending upon the area of compression reinforcement, the value of span to depth ratio is further modified by multiplying with the modification factor obtained as per fig 5 (IS : 456-2000 ).

Development stresses in reinforcement Ld is taken directly from SP 16 (table 65), for deform bars conforming to IS: 1786 these values shall be increased by 60% for bars in compression, the values of bond stress for bar in tension shall be increased by 25%.

Curtailment of tension reinforcement shall extend beyond the point at which it is no longer required to resist flexure for distance equal to the effective depth of the member or 12 times the bar diameter, whichever is greater except at simple support or end of cantilever.

Positive moment reinforcement: – at least 1/3 +ve moment reinforcement in simple member and ¼ +ve reinforcement in continuous member shall extend along the same face of the member into the support , to length equal to Ld/3.

Spacing of reinforcement: - min. distance b/w the individual bar not be greater than the dia. of bar if dia. are equal or dia. of larger bar if dia. are of different size and 5mm more than the nominal maximum size of course aggregate.Maximum distance should not be exceeded than 180mm for Fe – 415 from table – IS: 456-2000. Min. reinforcement should not be less than As =0.85bd/fy

Maximum reinforcement both in tension and compression shall not exceed 0.04bD.

Maximum spacing of shear reinforcement shall not exceed 0.75d for vertical stirrups and d for inclined stirrups and in no case shall the spacing exceed 300mm and minimum reinforcement provided as per this formula

= Asv/bsv > (0.4 /0.87fy).

The maximum spacing of shear stirrups has been kept at 200mm, subjected to detailing consideration with respect to earthquake detailing.

At least two bars have been provided continuous over the entire span of beam.

At external joints bars with columns, top and bottom bars have been provided with anchorage length of Ld in tension + 10 dia. of bar.

At internal joints bars have been taken continuous through the column.

13

The tension steel ratio on any section is not less than (0.24 fck0.5)/fy and not greater than 0.025Mpa.

Provision for laps has been provided wherever required. Hooks shall be provided wherever lap occurs at spacing not greater than 150mm. Further it has been taken care not to be provided any laps in the joint within distance of 2d from any face and within quarter length of any member. Also not more than 50% bars have been curtailed at a section.

MANUAL DESIGN OF BEAM

LIVE LOAD ON BEAM No. 2779

DEAD LOAD ON BEAM No. 2779

1.5(DL+LL) ON BEAM No. 2779

1.5(DL+LL) ON BEAM No. 2779

On STAAD Pro Analysis of the whole structure ,we get the follwing responses.

14

S.F.D

B.M.D

Sample Design Calculation for Beam No: 2779

Steel Reinforcement for=Tor grade 415 Concrete =M25 Grade B=400 D=600 mm Effective L =6.12 Determination of area of steel reinforcement: Maximum Positive Moment=206 KN-m Maximum Negative Moment=133 KN-m Top Reinforcement Tor 16 mm @ 150 C/C Bottom Reinforcement Tor 10mm@ 90 mm C/C

Check for shear:

= 190 KN = 0.47 From Is Code 456- Table-19 3.1 Since << shear reinforcement is required =190-0.47*400*575=81.9 KN

Provide 8 mm, 2-legged stirrups@220 mm c/c Strength of shear reinforcement ==94.8 KN > 81.9 KN OK

15

Development length ==825 mm Provide (8*16mm=128mm) anchorage length and provide a 90 degree bend in the 16 mm bars.

16

B E A M N O. 2779 D E S I G N R E S U L T S

M25 Fe415 (Main) Fe415 (Sec.)

LENGTH: 6117.5 mm SIZE: 400.0 mm X 600.0 mm COVER: 25.0 mm

SUMMARY OF REINF. AREA (Sq.mm)---------------------------------------------------------------- SECTION 0.0 mm 1529.4 mm 3058.7 mm 4588.1 mm 6117.5 mm---------------------------------------------------------------- TOP 718.66 0.00 0.00 0.00 1002.68 REINF. (Sq. mm) (Sq. mm) (Sq. mm) (Sq. mm) (Sq. mm)

BOTTOM 0.00 462.89 619.86 462.89 0.00 REINF. (Sq. mm) (Sq. mm) (Sq. mm) (Sq. mm) (Sq. mm)----------------------------------------------------------------

SUMMARY OF PROVIDED REINF. AREA---------------------------------------------------------------- SECTION 0.0 mm 1529.4 mm 3058.7 mm 4588.1 mm 6117.5 mm---------------------------------------------------------------- TOP 4-16í 2-16í 2-16í 2-16í 5-16í REINF. 1 layer(s) 1 layer(s) 1 layer(s) 1 layer(s) 1 layer(s)

BOTTOM 2-20í 3-20í 3-20í 3-20í 2-20í REINF. 1 layer(s) 1 layer(s) 1 layer(s) 1 layer(s) 1 layer(s)

SHEAR 2 legged 8í 2 legged 8í 2 legged 8í 2 legged 8í 2 legged 8í REINF. @ 220 mm c/c @ 220 mm c/c @ 220 mm c/c @ 220 mm c/c @ 220 mm c/c----------------------------------------------------------------

SHEAR DESIGN RESULTS AT DISTANCE d (EFFECTIVE DEPTH) FROM FACE OF THE SUPPORT

SHEAR DESIGN RESULTS AT 915.0 mm AWAY FROM START SUPPORT

17

VY = 118.75 MX = -1.50 LD= 207 Provide 2 Legged 10í @ 220 mm c/c

SHEAR DESIGN RESULTS AT 915.0 mm AWAY FROM END SUPPORT VY = -138.43 MX = -1.50 LD= 207 Provide 2 Legged 8í @ 220 mm c/c

2.5 DESIGN OF COLUMNS

The columns of proposed structure have been designed as short columns with axial

load and bi axial moments. All columns have been designed using method outlined

in SP 16, (Design Aids to IS: 456-2000) using the columns interaction diagrams

with all the reinforcement distributed equally on all sides.

DESIGN APPROACH

As mentioned, all columns have been designed as short columns along both axes in

accordance with clause 25.1.1 of IS: 456-2000.

A column is said to be short when the slenderness ratio as given by the expression is

less than 12

Slenderness ratio along X-X axes

Lex /b and

Slenderness ratio along Y-Y axes

Ley/D

Where:

Lex = Effective length of column along X-X axis

Ley = Effective length of column along Y-Y axis

B=width of column along X-X axis

D=Depth of the column along Y-Y axis

18

UNSUPPORTED LENGTH

The length of column ,LO was taken as the clear distance b/w the floor and the

underside of the shallower beam framing into the columns in each direction at the

next higher floor level in accordance with clause 25.1.3 of IS : 456-2000

The limit to slenderness, in accordance with clause 25.3.1 of IS: 456-2000 was also

taken into consideration.

EFFECTIVE LENGTH OF COLUMNS

The columns being restrained along both axes the effective length of columns was

taken as 0.65 Lo in accordance with table – 28 of IS: 456-2000

All columns have been designed for the following forces:-

• Axial load

• Moment about X-X axis

• Moment about Y-Y axis

• Moment due to minimum eccentricity as mentioned in clause 25.4 of

IS: 456-2000

• Shear force analysis (see article below), and

• Torsion shear due to seismic forces.

19

DESIGN OF COLUMNS FOR SHEAR

As mentioned above, all columns have been designed for greater of the two.

• Factored shear force from analysis

• Shear given by the expression in IS: 13920 -1993.

In all the cases that were encountered, the factored shear force from analysis was

found greater and thus the columns designed for the same.

Design for shear was done in accordance with clause 40.1 of IS: 456-2000

by calculating the nominal shear stress given by the expression

Tv = Vu/bd

Where

Vu = Design shear force

b = Width of member

d = effective depth

Depending upon the area of tensile reinforcement and grade of the concrete used,

the design shear strength of concrete was obtained from modified given in clause

40.2.2 of IS: 456-2000

NOTE: - While calculating the design shear strength 50% area of steel was taken

into consideration by assuming that half of the steel would be in compression and

the total steel is distributed equally on all sides.

DETAILING OF REINFORCEMENT

• The cross-section of longitudinal reinforcement was kept b/w 0.8% to 4% in

accordance with clause 26.5.3.1 of IS : 456-2000

• All bars used for longitudinal reinforcement are greater than 12mm.

20

• Spacing of bars along periphery of column has been kept less than 300mm.

• All transverse reinforcement provided is of greater than ¼ of the largest

longitudinal bar and not exceeding the 16mm.

• The pitch of ties should not exceed 300mm.

• All transverse reinforcement has been arranged in accordance with clause

26.5.3.2 of IS : 456-2000

Apart from these considerations, following provision of IS 13920-1993 has been

conformed to

• The least lateral dimension of the column is greater than 300mm.

• The ratio of the least lateral dimension to the perpendicular dimension is

more than 0.4.

• Lap splices wherever they occur have been proposed in the central half of

the member. Hoop with a pitch not exceeding 150mm c/c have been

provided over entire splice length.

• The transverse reinforcement consists of square hoops having 135 degree

with a 10 dia. extended at each end confined in the core.

• The parallel edges of hoops are not spaced greater than 300mm as far as

possible. A cross tie or a pair of overlapping hoops have provided engaging

all peripheral bars.

MANUAL DESIGN OF COLUMN

Unsupported Length=3200, Pu=2303KN,

Mux=11.2KNm Muy=18.67KNm ,

As the moment in X and Y direction are very small compared to axial load. We

shall design the column as axially loaded only.

Let us assume a trial section (400*700)mm2

21

Fck=25N/ mm2 F y=415N/mm2

Check 1:

Effective Lenth=0.65*L=0.65*3200=2080mm,

Effective Lenth/Least Lateral dimension=2080mm/400mm=5.20(>3)

Check 2 :

Effective Length/Depth(D)=2080mm/700mm=2.97(<12)

Effective Lenth/Width(B)=2080mm/400mm=5.20(<12)

It is a short axially loaded column

Check 3:

Minimum Eccentricity

(1)Emin=Unsupported Lenth/500+lateral dimension/30

3200/500+400/30=20.73

(2) Emin=20mm => Emin=20.73

Design the member as short axially loaded column

Longitudanal Reinforcement:

We have

Pu=0.4*25*(Ag-Asc)+0.67*Fy*Asc

Pu=0.4*Fck*Ag+(0.67*Fy-0.4Fck)*Asc

Area of steel required,

Asc=(Pu-0.4*Fck*Ag)/(0.67Fy-0.4Fck)

Asc=(2303000-0.4*25*400*700)/(0.67*415-0.4*25)

Asc=1854.13mm2

22

Providing 12mm diameter bar

No. of bar =1844.13/(π*82)

=15.83=16 bar

Providing 8mm dia lateral ties

The spacing of the column should not exceed

• Least dimension of the column=400mm

• Sixteen times the dia of longitudinal bar=12*16=196mm

• 300mm

Provide 8mm lateral ties at 190mm c/c spacing

23

24

CHAPTER 3

This chapter deals with the miscellaneous topics. First of all we provide a

comparative study of the economy involved in the design with and without seismic

design. Then we move to ductile design of the building. Some theories and codal

provision have been discussed. A special mention of the reinforcement in the beam,

column and joints according to the provision of IS:13920 have been discussed. A

discussion about the type of foundation used and its design has also been given.

3.1 MATERIAL REQUIRED BY GRAVITY LOAD DESIGN METHOD

3.2 DUCTILITY CONSIDERATION

25

The basic approach of earthquake resistant design should be based on lateral

strength as well as deformability and ductile capacity of the structure with

limited damage but no collapse. The IS 13920:1993 is based on this

approach .Ductility of the structure is one of the most important factor

affecting its seismic performance. The gap between the actual and lateral

force is narrowed down by providing ductility in the structure. Ductility in

the structure will arise from inelastic material behaviour and detailing of

reinforcement in such a manner that brittle failure is avoided and ductile

behaviour is induced by allowing steel to yield.

3.2.1 REQUIREMENT FOR DUCTILITY

In order to achieve a ductile structure we must give stress on three key area

during the design process. Firstly, the overall design concept of the building

configuration must be sound. Secondly, individual member must be designed

for ductility, and finally connection and other detail need careful attention

CONSTRUCTION MATERIAL

3.1 Concrete

Concrete is a stone like hard material obtained by mixing cement, sand and

aggregate in some specific proportion and water to harden and give workability to

fill in the form of shape and dimensions desired for a structure. The chemical

interaction between cement and water binds the aggregate into a solid mass.

Concrete possesses high compressive strength but is weak in tension. This

short coming is offset by providing steel bars at appropriate location at the time of

casting the member to take up the stresses, and the compressive stresses if required.

Thus, the concrete is strengthened (i.e. reinforced) by steel and the resultant

composite mass is known as reinforced cement concrete(RCC),

3.1.1 Constituent materials:

The main constituent materials of concrete are –

Aggregates,

26

Cement ,and

Water

Aggregates: The aggregates occupy approximately more than 75 percent of

the volume of concrete and, their properties have definite influence on the

strength of hardened concrete. Hence, the aggregate used for concrete should

be durable, strong, good resistance to weathering action and effects economy

in cost, of concrete.

Cement: cement is a material to having property of binding minerals

fragments into a solid mass on its chemical combination with water. Since

binding and hardening actions are due to presence of water, such cements are

called as hydraulic cement. The cement used for construction is known as

Portland cement.

Water: water plays an active role in the chemical process of hydraulic and

incurring concrete. It is, therefore, necessary that what are used for fixing

and curing should be clean and free from injurious materials like oils, acids,

alkalis, salts, sugar, organic materials or other substances that may be

deleterious to concrete and steel. Drinking water is generally considered

satisfactory for mixing concrete.

3.1.2 Concrete mix proportioning:

In reinforced concrete construction, the concrete is known by its grade and

is designated as M20, M25 in which letter M refers to mix a\and the number to its

characteristic strength in axial compression at 28 days on 150mm cube, expressed in

N/mm², grades normally used in R.C construction are M20 and M25.

The structural designers specify is the required strength and properties of

concrete to achieve this, various ingredients of concrete are proportioned so that the

resulting concrete has desired strength, proper workability for placing and namely,

the cement, aggregate and water to attain the required strength is done in the

following ways:

By designing the concrete mix: such concrete is called as ‘design mix

concrete’.

27

By adopting nominal mix, such concrete is called ‘nominal mix concrete’.

3.2 Reinforcement steel:

Reinforcement steel consists of bars, usually circular in cross-section. These

are at present available in different grades ways. Fe250, Fe415, Fe500, where ‘Fe’

refers to Ferrous metals and the number refers to a specified guaranteed yield stress

in N/mm².

3.2.1 Types of reinforcement:

Based on the physical and mechanical properties namely ductility, yield

strength, the following two types of steel reinforcements are mainly used in

reinforced concrete construction:

Plain round bars of mild steel.

Deformed bars of high-grade steel.

Plain round bars of mild steel: They are usually of mild steel (grade

Fe250) conforming to IS: 432-1982. It has a well-defined yield point giving

yield stress of 250N/mm² and excellent ductility.

Deformed bars of high-grade steel: These bars are usually of steel and do

not possess a well-defined yield point. The characteristics strength is given

by 0.2 percent proof stress. These bars have low ductility and low bend

ability ribs, lugs, or deformations on their surface with the result that their

bond characteristics is improved.

Detail consideration

1. GENERAL

The design and construction of reinforced concrete buildings shall be

governed by the provisions of IS 456 : 2000, except as modified by

the provisions of this code.

For all buildings which are more than 3 storeys in height, the

minimum grade of concrete shall be M20 ( fck = 20 MPa ).

28

The concerned structure is G+13 storied, that’s why we have

used M25 grade of concrete.

Steel reinforcements of grade Fe 415 or less only shall be used.

2. FLEXURAL MEMBERS

2.1 General

• The factored axial stress on the member under earthquake loading shall not

exceed 0.1 fck.

• The member shall preferably have a width-to-depth ratio of more than 0.3.

• The width of the member shall not be less than 200 mm.

• The depth D of the member shall preferably be not more than 1/4 of the clear

span.

2.2 Longitudinal Reinforcement

• The top as well as bottom reinforcement shall consist of at leasttwo bars

throughout the member length.

• The tension steel ratio on any face, at any section, shall not be less than ρmin

= 0.24(fck/fy) ; where fck and fy are in MPa.

• The maximum steel ratio on any face at any section, shall not exceed ρmax =

0.025.

• The positive steel at a joint face must be at least equal to half the negative

steel at that face.

• In an external joint, both the top and the bottom bars of the beam shall be

provided with anchorage length, beyond the inner face of the column, equal

to the development length in tension plus 10 times the bar diameter minus

the allowance for 90 degree bend(s) ( see Fig. 1 ). In an internal joint, both

face bars of the beam shall be taken continuously through the column.

• The longitudinal bars shall be spliced, only if hoops are provided over the

entire splice length, at a spacing not exceeding 150 mm.The lap length shall

29

not be less than the bar development length in tension. Lap splices shall not

be provided (a) within a joint, (b) within a distance of 2d from joint face, and

(c) within a quarter lengh of the member where flexural yielding may

generally occur under the effect of earthquake forces. Not more than 50

percent of the bars shall be spliced at one section.

Use of welded splices and mechanical connections may also be made, as per

25.2.5.2 of IS 456 : 1978. However, not more than half the reinforcement shall be

spliced at a section where flexural yielding may take place

30

LAP SPLICES IN BEAM2.3 Web Reinforcement

• Web reinforcement shall consist of vertical hoops. A vertical hoop is a

closed stirrup having a 135° hook with a 10 diameter extension (but not < 75

mm) at each end that is embedded In confined core.

• The minimum diameter of the bar forming a hoop shall be 6 mm. However,

inbeams with clear span exceeding 5 m, the minimum bar diameter shall be

8 mm.

• The shear force to be resisted by the vertical hoops shall be the maximum of

a) calculated factored shear force as per analysis, and

b) shear force due to formation of plastic hinges at both ends of the beam

plus the factored gravity load on the span.

31

• The contribution of bent up bars and inclined hoops to shear resistance of

the section shall not be considered.

• The spacing of hoops over a length of 2d at either end of a beam shall not

exceed (a) d/4,and (b) 8 times the diameter of the smallest longitudinal bar;

however, it need not be less than 100 mm.

32

CALCULATION OF DESIGN SHEAR FORCE ON BEAM

BEAM REINFORCEMENT

33

3. Compression Member:

3.1General

• These requirements apply to frame members which have a factored axial

stress in excess of 0.1 fck under the effect of earthquake forces.

• The minimum dimension of the member shall not be less than 200 mm.

However, in frames which have beams with centre to centre span exceeding

5 m or columns of unsupported length exceeding 4 m, the shortest

dimension of the column shall not be less than 300 mm.

• The ratio of the shortest cross sectional dimension to the perpendicular

dimension shall preferably not be less than 0.4.

3.2Longitudinal Reinforcement

Any area of the column that extends more than 100mm beyond the confined

core due to architectural requirement shall be detailed as in diagram.

34

3.3 Transverse Requirement

The detailing of the transverse reinforcement should be done in the diagram below

Transverse Reinforcement in Column

• Special Confining reinforcements

35

Special confining reinforcement shall be provided over a legth lo from each

joint face, towards midspan, and on either side of anysection, where flexural

yielding may accur under the effect of earth quake forces. The length ‘lo’

shall not be less than :

• Larger dimension of the member at the section where yielding accur,

• 1/6 of clear span of member, and

• 450mm

When a column terminate into a footing or mat, special confining

reinforcement shall extend atleast 300mm into the footing or mat.

COLUMN AND JOINT DETAILING

36

PROVISION OF SPECIAL CONFINING REINFORCEMENT IN FOOTING

3.3 FOUNDATION

3.3.1 RAFT OR MAT FOOTING

A raft or mat is a combined footing that covers the entire area beneath a structure

and supports all the wall and columns . When the allowable soil pressure is low ,or

the building loads are heavy, the use of spread footing Would cover more than one-

half of the area and it may prove more economical to use mat or raft

foundation .They are also used where the soil Mass contains compressible lenses or

the soil is sufficiently erratic so that the differential settlement would be difficult to

control .The raft tends to bridge over the erratic deposits and eliminates the

differential settlement. Raft foundation is also used to reduce settlement above

highly compressible soil , by making the weight of structure and raft approximately

equal to the weight of soil excavated.

Ordinarily, raft are designed as reinforced concrete flat slabs .If the C.G of loads

coincide with the centroid of the raft ,the upward load is regarded as uniform

pressure equal to the downward load divided by the area of the raft .The weight of

raft is not considered in structural design because it is assumed to be carried directly

by the subsoil .

37

3.3.2 Design of RAFT Foundation

Total weight of columns =90516 KN

Assume self weight of foundation equal to 1.1 times of the total columns load

=+1.1X 90516=99567.6 KN

Area of foundation =99567/100=996

Let us provide =34.5X32=1104 ok

Net upward intensity = = 90.18 KN/

Net upward reaction/m=90.18X16=1442.88 KN/m

Maximum longitudinal bending moment =34.5X3335=116620 KNm

Factor moment= Mu =0.8X116620=93296 KNm

Equating Mu,lim to Mu

Mu,lim = 0.138fCKb

We found d=906

d = 950mm, provide 50 mm cover

D= 950+ 50 = 1000 mm

Mu/b = (93296×106)/ (34500×9502) =2.99

=0.99 % (obtained from page -49 of SP 16)

= 9405 mm2

Maximum shear force=7438.52KN

Factored shear, vu= 4867.9*0.8=3894.32KN

38

τv = = 0.22 N/

But τc = 0.63 N/ (obtained from Is 456: 2000 table 19)

τv < τc . Hence OK

For =.99 %, =9405mm2

Provide 32mm dia. bars @ 80mm c/c

TRANSVERSE BENDING

Sum of all loads in outer strip =15073KN

Sum of all loads in inner strip = 7966KN

Soil pressure acting under entire width =90.18.62*32 =2885 KN/m

Maximum transverse bending moment=62046 KNm

Factored moment =0.8*62046 =49638 KNm

Equating Mu,lim to Mu

2458.6 =0.138fckb

Here we have: b=32000mm, fck = 25 N/

Hence, d is coming =599 mm

But available effective depth =1000-50-32-16=900

= =1.19

Hence = 0.343% (obtained from page -49 of SP 16)

Therefore Ast = =3037

Provide 25mm dia. bars @150mm c/c

Maximum transverse shear =0.8x3848.8 =3079 kN

Nominal shear stress (τv )= =.109 N/

and τc = 0.38 N/ (obtained from table 19 of IS 456 : 2000)

since τv < τc . ok

Using 25 mm dia. of 2 –legged vertical stirrups

A sv = 2x =981.75

Spacing =30 mm c/c

Transverse bottom steel = 0.189% b d

= x17000 x468

= 15036.8

39

Provide 25 mm dia. Bars @ 80mm c/c

Longitudinal bottom steel = 0.12% of gross area

=

= 10800

Provide 25 mm dia. Bars @ 150 mm c/c

Two way punching shear force

Size of the column = 0.7mx0.4m

Depth (d) =1000mm

Critical section at d/2 = 0.5 m

Width of critical plane =0.7m

τ'c = τc

= (0.5+)

= (obtained from IS 456 : 2000 cl. 31.6.31 )

= 0.57

Hence take

Now = (0.5+0.57) (not greater than 1)

Thus, = 1.

τ'c = τc

=1x0.25 =1.25 N/> 0.34 N/.

Thus, OK.

Development of reinforcement

Development length in 25 mm dia. bars

=

= (obtained from IS 456: 2000 cl. 26.2.1.1 )

=65 x dia.

Therefore,

M.O.R = 0.87(d-0.42 x0.48xd)

= 6207.48 KNm

= 1.3 M/V + -------> here = 12 x dia.

= 694mm < Hence okay.

40

3.4 SHEAR WALL

Shear walls are a type of structural system that provides lateral resistance to a

building or structure. They resist "in-plane" loads that are applied along its height.

The applied load is generally transferred to the wall by a diaphragm or collector

or drag member. They are built in wood, concrete, and CMU (masonry).

Plywood is the conventional material used in the construction of Shear Walls, but

with advances in technology and modern building methods, there are other

prefabricated options, such as Hardipanel and Simpson Strong Wall, which have

made it possible to inject shear assemblies into narrow walls that fall at either side of

an opening in a shear wall. Sheet steel and steel-backed shear panels (i.e. Sure-

Board) in the place of structural plywood in shear walls has proved to be far

stronger in seismic resistance.

41

SHEAR WALL DESIGN

Detail of shear wall consideration

Lenth of the wall,lw=4950m Thickness of the wall =230mm

Height of the wall,H=39.4m Ag=113.85*103mm2

Iy=2.325*1012

42

SHEAR WALL CONSIDERATIONData collected from STADD Pro Analysis

Load case Moment(KN-m)

Shear

(KN)

Axial

force KN

Axial load on boundary element(KN

)

1.5(DL+LL) 1561.4 1010 5860 39701.2(DL+LL+EQZ

)4000 2025 4420 3040

I.2(DL+LL-EQZ) 1500 410 4950 33101.5(DL+EQZ) 4832 2425 4890 33501.5(DL-EQZ) 2044 618 5550 3690

(0.9DL+1.5EQZ) 4274 2063 2800 1940(0.9DL-1.5EQZ) 2600 980 3460 2280

Shear strength Requirement:

tv=Vu/(b*d) Vu=2425/2=1212.5KN

tw=230mm

dw0.8*lw = 0.8*4950=3960mm Effective depth of wall of the section

Now,tv=(1212.5*103)/(230*3960)=1.3312N/mm2

Table-19 IS-456 gives for pt =0.25,tc=0.36N/mm2

Table 20 IS:456 gives tc max =3.1N/mm2

Since tc<tv<tc max ,shear reinforcement is required.

Now 0.25*sqrt(fck) =0.25*sqrt(25)=1.25(tv>0.25*sqrt(25))

Also tw >200mm

SHEAR REINFORCEMENT IS REQUIRED IN TWO CURTAINS

43

Area of horizontal shear reinforcement is given by:

Vus =0.87*fy*Ah*dw/Sw

Ah =Horizontal shear reinforcement area

Sv= Vertical spacing

Vus=vu-tc*tw*dw

=(tv-tc)*tw*dw

=(1.3312-0.36)*230*3960N

= 884568.9N

Spacing required for two legged 8f TOR bars

Sv=0.87*415*100.53*3960/884568.9

Sv=162.49mm

This gives the ratio As/Sv =100.53/162.49=0.64

Minimum horizontal reinforcement =0.0025*230

=0.575<0.64 (O.K)

Provide 8mm bar @150mm c-c in two curtain in horizontal reinforcement

Provide 8mm bar @150mm c-c in two curtain in vertical reinforcement

Spacing should not exceed in either direction

1.lw/s=4950/5=990mm

2. 3*tw=3*230=690mm

3. 450mm

Provide spacing 150mm . Hence O.K

Flexural strength

The moment of resistance Muv ,of the wall section shall be calculated as for column

subjected to combined axial load and uniaxial bending.The moment of resitance that

is provided by uniformly distributed vertical reinforcement in a slender rectangular

wall section,may be calculated as follows:

44

Muv/(fck*tw*lw2)=f[(1+?/f)*(0.5-0.416*xu/lw)-( xu/lw)2*(0.168+

β2/3)]

When xu/lw<=( xu*/lw)

xu/lw=(f+?)/(2f+0.36) xu*/lw=0.0035*Es/(0.0035Es+0.87*fy)

f=(0.87*fy*?)/fck ?=pu/( fck*tw*lw)

where ,

?=Vertical reinforcement ratio

Ast=As*lw/sv=0.64/230=0.003

f=0.87*415*0.003/25=0.044

?=2930*103/25*230*4950=0.102

pu=5860/2=2930KN

xu/lw=0.044+0.102/(2*0.044+0.36)=0.31

xu*/lw=(0.0035*2*105)/(0.0035*2*105+0.36)=0.66

xu/lw< xu*/lw HENCE O.K

β=0.87*415/(0.0035*2*105)=0.516

Muv/(fck*tw*lw2)= 0.044[(1+0.102/0.044)*(0.5-0.416*0.31)-( 0.31)2*(0.168+

0.5162/3)]=0.0530

MUV=0.0530*25*230*49502

=7468KNm

The remaining moment Mu-Muv=24160-7468

=16692KNm

This much moment has to be resisted by boundary element

Pboundary element=16692/4.95=3372.2KN

fc=Pu/Ag+(Mu*lw/2)/Iy

=(2930*103)/(113.85*103)+((24160*1064950/2)/(2.325*1012)

45

=25.73+25.72=51.45N/mm2 >0.2*fck

Provide boundary element

Dimension of boundary elements=(600*500)mm2

Ag =30*106mm2

Let us assume 2% longitudinal reinforcement

As=0.02*600*500=5000mm2

Axial load capacity of the boundary element

Pu =0.4*25*30*104+(0.67*415-0.4*25)6000

=4608300N

=4608.30KN >3970KN o.k

>3372.2KN O.K

Provide 12 No. of 25mm dia bar

Splicing of vertical reinforcement may be done at higher larger of

1.lw=4950mm

2.H/6=39400/6=6567mm

Splicing may be done at a height 7m above the base.

46

CHAPTER – 4

DESIGN APPROACH

4.1 Working Stress Method

This has been the traditional method used for the reinforced concrete design

where it has been assumed that concrete is elastic, steel and concrete act together

elastically, and the relationship between loads and stresses is linear right up to the

collapse of the structure. The basis of the method is that the permissible stress for

steel and concrete are not exceeded anywhere in the structure when it is subjected to

the worst combination of working loads and the design is in accordance with hook’s

law.

4.2 Ultimate Load Method

In the ultimate load method, the working loads are increased by suitable

factors to obtain ultimate loads. These factors are called load factors. The structure is

then designed to resist the desired ultimate loads. This factor takes into account the

non-linear stress-strain behavior of concrete.

4.3 Limit State Method (LSM)

The discussions of the earlier two method clearly shows that the working stress

method, though ensures satisfactory performance at working loads, is unrealistic and

a rational at ultimate state and hence does not give a true margin of safety, while the

ultimate load method, though provides realistic assessment of degree of safety in

confirming with the actual behavior of the structure at or near the ultimate state, it

does not guarantee the satisfactory performance of the structure at service loads.

Undoubtedly, the ideal approach to design a structure is one which recognizes

and take into consideration all the states, like uncracked, cracked, elastic and

ultimate state through which a structure or its element and its material pass from

service loads to ultimate load, and ensures that neither the safety at the ultimate state

47

nor the serviceability at the service condition is in jeopardy(danger) rendering the

structure to perform its function satisfactorily during unfit is called the limit state

philosophy of design.

4.3.1 Types and classification of limit state –

The various limit states required to be considered in structural design are

conveniently group into three major categories, namely

Limit state of collapse ,

Limit state of serviceability ,

Limit state of durability ,

4.3.1.1 Limit state of collapse:

It is the limit state on attainment of which the structure is likely to collapse

it related to stability and ultimate strength of the structure. Design to this limit state

safely of structure from collapse.

The structure failure can be any of the following types:-

Collapse of one or more members uttering as a result of force coming on the

member exceeding its strength {types (a) and (b) given below} ;

Displacement of the structure body due to lack of equilibrium between the

external forces or displacement and the resisting reactions {type (c),(d),(e)

given below}.

The various condition leading to structural failures are as follows –

(a) Failure, bright age and hence division into segment of one or more members

of the structure either due to material failure (as in case of columns) or on

account of formation of mechanism by development of plastic images at one

or more critical sections due to yielding of steel and concrete (as in case of

slabs and beams):

48

(b) Elastic or plastic instability;

(c) Overturning,

(d) Sinking

This limit state is attained by providing resistance (or resisting reaction)

greater than the force coming on it and keeping a margin of safety through safety

factors.

Some of the codes consider each of the above the states as independent

limit states instead of a single limit state of collapse and prescribe different safety

factor for each of them. I S. code prescribe different safety factors for overturning

and sliding without giving any special status to sinking and buckling.

The limit state under discussion is critical in case of column and

foundations on particular and in case of a normal structure as a whole.

4.3.1.2 Limit state of serviceability:

Limit state of serviceability related to performance of behavior of structure

at working loads and based on causes effecting serviceability if the structure. They

are subdivided into following three categories:

Limit state of deflection,

Limit state of resistance to chemical and environmental actions, and

Limit state of resistance to accidental or catastrophic collapse.

49

4.4 DESIGN OF SLABS

SLAB TYPE 1

Slab name S1

Condition interior panel

+αx +αy

-αx -αy

Ly, length of longer span = 4.315m

Lx, lengh of shorter span = 3.705m

Lx/Ly < 1.16 which is less than 2

Hence, design as two way slab.

Leff,whichever is less Leff = 3.705m

L/D = 26

D =3705/26 =142.5mm =150mm (say)

d = 120mm

Load calculation

Superimposed dead load =4.5KN/m2

Sumperimposed live load = 2kN

Total load = 6.5KN/m2

Edge condition

For Lx/Ly = 1.16

+αx = 0.030 +αy = 0.024

-αx = 0.040 -αy = 0.032

50

Since (pt)reqrd/100 = (Ast)reqrd/bd = fck[1-sqrt(1- 4.59*Mu/(fckbd2)]/2fy

Grade of concrete fck 25

Grade of steel fy 415

Width b 1000

Depth of slab d 120

Take diameter of bar,Ф= 8mm

Coeff

W (kN/m2)

Lx(m)

M(KN-m

Mu(KN-m

Mu/bd2

pt Ast(mm2)

spacing

Ast prov

pt

0.030

6.5 3.705

2.67 4.00

0.278 0.078

93.6 300 94.23 0.0785

0.040

6.5 3.705

3.569

5.35

0.371 0.104

124.8 225 125.6 0.1047

0.032

6.5 3.705

2.855

4.28

0.297 0.083

99.6 280 100.96

0.084

0.024

6.5 3.705

2.14 3.21

0.223 0.062

74.4 375 75.3 0.062

Check for deflection

fs = 0.58*fy[(Ast) reqrd/(Ast)provided ]

fs = 239.16

Refer IS:456-2000 PAGE 38 (FIG4)

Modification factor , mft=2

Depth required = (4.315*1000)/(23*2) = 93.8mm < 100mm

Hence okay

51

SLAB TYPE S2

8mm@300mm8mm @300mm c/c

120mm150mm

8mm @280mm

3.705m

SLAB TYPE S3

Slab name S3

Condition one long edge discontinuous

+αx +αy

-αx -αy

Ly, length of longer span = 4.925m

Lx, lengh of shorter span = 3.705m

Lx/Ly < 1.329 which is less than 2

Hence, design as two way slab.

Leff,whichever is less Leff = 3.705m

Assumed thickness = 120mm

Effective thickness = 100mm

Load calculation

Superimposed dead load =4.5KN/m2

Sumperimposed live load = 2kN

Total load = 6.5KN/m2

Factored load = 6.5×1.5

=9.75KN/m2

52

Edge condition

For Lx/Ly = 1.329

+αx = 0.0448 +αy = 0.028

-αx = 0.058 -αy = 0.037

Since (pt)reqrd/100 = (Ast)reqrd/bd = fck[1-sqrt(1- 4.59*Mu/(fckbd2)]/2fy

Grade of concrete fck 25

Grade of steel fy 415

Width b 1000

Depth of slab d 100

Mx(+) = αx*w*Lx2

Mx(+) = 5.995 KN-m

Mx(-) = 7.762 KN-m

My(+) =3.747 KN-m

My(-) = 4.952KN-m

Required depth = sqrt( Mmax/2.76b)

= 53.03mm < 100mm

Area of main reinforcement

Ast = (0.36× fck × b × 0.48 × d)/( 0.87×fy)

= ((0.36× 25 × 1000 × 0.48 × 53.03)/( 0.87×415)

=634.15mm2

Take 12mm bars

Spacing = (113.09×1000)/634.15

= 178.34mm (say 160mm)

Ast provided = (113.09 × 1000)/160

= 706.81mm2

Distribution steel

4.592×10(pow 6) = 0.87×415×Ay [43.03 –[(415 × Ay)/25×1000]]

0.0166×Ay2 - 43.03 Ay + 13715.55 =0

Ay = 372.18mm2

Use 8mm dia bars

Spacing = 135.05mm (say 130mm)

Actual area of steel = 386.615mm2

53

Check for deflection

fs = 0.58 ×fy×Ast(reqrd)/Ast(provided)

= 231.713

Refer IS:456-2000 PAGE 38 (FIG4)

Modification factor , mft=1.38

Depth required = (4.925*1000)/(23*1.38) = 155.16mm (say 160mm)

Overall depth =160 +6 +6 =172mm (say 175mm)

Overall depth = 175 mm

SLAB TYPE S3

12mm @160mm c/c

160mm

175mm

8mm @130mm

3.705mm

54

CONCLUSION

• We have practiced real life engineering .

• We can conclude that there is difference between the theoretical and

practical work done. As the scope of understanding will be much more

when practical work is done. As we get more knowledge in such a

situation where we have great experience doing the practical work.

• At this point, we would like to thanks all the instructors,

engineers, consultant offices for their grate support.

55

BIBLIOGRAPHY

• CONSTRUCTION SITE OF GREATER NOIDA U.P .

• I.S CODE 456:2000.

• I.S CODE 800:2007.

• I.S CODE 875 (PART 3) 1987

• I.S CODE 1893:2002

• FACULTY ‘S INSTRUCTIONS.

• BOOK REFERENCES:

• B.C PUNMIA

• A.K JAIN

• S. RAMAMURTHAM