cleaning validation Chengdu ne · 2011-04-18 · 1 When chromatography column xxx is opened for...

Transcript of cleaning validation Chengdu ne · 2011-04-18 · 1 When chromatography column xxx is opened for...

1 /GE /

Process Chromatography

Cleaning and Cleaning Validation

Validation of Chromatography Media Lifetime

隋礼丽

Fast Trak China

GE Life Science

Process Chromatography

Cleaning and Cleaning Validation

col val 2008 gs 3

It is a customer requirement - it ensures the safety and purity of the product.

It is a regulatory requirement in Active Pharmaceutical Ingredient product manufacture.

It also assures from an internal control and compliance point of view the quality of the process.

The objective of cleaning validation

col val 2008 gs 4

第一百四十三条 清洁方法应当经过验证,证实其清洁的

效果,以有效防止污染和交叉污染。清洁验证应当综合考虑设备使用情况、所使用的清洁剂和消毒剂、取样方法和位置以及相应的取样回收率、残留物的性质和限度、残留物检验方法的

灵敏度等因素。

药品生产质量管理规范(2010年修订)(卫生部令第79号)

Where is cleaning validation required?

col val 2008 gs 5

Contamination and Cross Contamination

Precursors to the Active Pharmaceutical Ingredient

By-products and/or degradation products of the Active Pharmaceutical Ingredient

The previous product

Solvents and other materials employed during the manufacturing process.

Micro-organisms: This is particularly the case where microbial growth may be sustained by the product.

Cleaning agents themselves and lubricants

col val 2008 gs 6

The objective of cleaning validation

Safety of product :– Prevent bio-burden and carry-over, e.g, prevent possible

contamination and cross-contamination

– Minimize deterioration of resin affecting product quality and yield

Process economy:– Re-use of resins is instrumental to good process economy

2 /GE /

col val 2008 gs 7

Where is cleaning validation required?

Normally cleaning validation needed for critical cleaning, e.g.

–between manufacturing of one product and another

–contact surfaces (products, drug products and API).

col val 2008 gs 8

When to Perform Cleaning Validation

“Companies studying sterile drugs, especially biotech products, should probably begin cleaning validation in Phase 2 clinical trials.”

Validation Times, September 2002

Validation of Cleaning Procedures

Optimize & Define Cleaning Procedures

Evaluation of Cleaning Efficacy

Which physical parameters shall be evaluated?

What analytical tests are utilized?

How much residual will be permitted?

Written SOP's detailing the cleaning processes used for various pieces of equipment and columns.

Validation protocol: how cleaning processes will be validated.

Who is responsible for performing and approving the validation study

When shall cleaning validation be performed?

Three consecutive batches and evaluation to meet pre-set standards

Final validation report approved by management and which states whether or not the cleaning process is valid

col val 2008 gs 10

Optimize & Define Cleaning Procedures

Cleaning reagents• Type, concentration, preparation methods

Contact time

Temperature

Frequency

Holding time prior to and after cleaning

Storage conditions • May give added cleaning effect

col val 2008 gs 11

Cleaning Chromatography Resins

Keep in mind• Each feedstream is unique• Interactions with both functional groups and resin

backbone are often poorly understood

Follow suppliers’ recommendations• Exceeding suppliers’ data will require extra validation

work

Obtain Regulatory Support Files (RSF)

col val 2008 gs 12

Cleaning Reagents

• Must be compatible with ALL in-line equipment – e.g. O-rings, filters

• Must have assay for demonstrating removal• Consider disposal issues• Consider worker safety• Address facility issues

– e.g. need for explosion proof area for ethanol

3 /GE /

col val 2008 gs 13

Retention Time, minWeeks in 1 M NaOH

A B C D0 8.50 23.80 37.40 51.653 8.40 23.08 37.13 51.484 8.44 23.26 36.84 51.47Weeks in 0.1 M HCl0 8.45 22.34 35.14 50.304 8.34 20.85 33.28 48.91Pooled S.D.(n=9) 0.12 0.36 0.17 0.08A: Cytochrome C; B: Ribonuclease A; C: Lysozyme; D: Chymotrypsinogen

Resin: Butyl Sepharose® 4 Fast Flow Berggrund, A., et al. Poster Presentation. Engineering Foundation. Sept. 1992, Interlaken,

Switzerland

Functional Stability after CIP with Acid or Base

Always evaluate your own processcol val 2008 gs 14

Sampling

Clean as soon as possible after use• especially topical products, suspensions and bulk

drug or• where the drying of residues will directly affect

the efficiency of a cleaning procedure

Two methods of sampling:• direct surface sampling • rinse samples

Combination of the two - most desirable

col val 2008 gs 15

Direct surface sampling

Most commonly used method

Use “swabs” (inert material) - type of sampling material should not interfere with the test

Factors to be considered include:• supplier of the swab,• area swabbed, number of swabs used, whether they

are wet or dry swabs,• swab handling and swabbing technique

col val 2008 gs 16

Rinse samples

Allows sampling of:• a large surface • areas that are inaccessible or that cannot be

routinely disassembled

Provides an "overall picture"

Useful for checking for residues of cleaning agents

In combination with other sampling methods such as surface sampling

col val 2008 gs 17

Rinse samples

The manufacturer has to provide evidence that samples are accurately recovered

What is considered acceptable in terms of recovery?

col val 2008 gs 18

1: inlet valve2: column gasket3: base gasket4: outlet valve

4

1

2

3

Equipment: Columns & Skids

4 /GE /

col val 2008 gs 19

ÄKTApilot Sampling Points

col val 2008 gs 20

Protocol for Sampling Resin for Cleaning Validation

PURPOSE: To demonstrate chromatography resin through direct sampling and testing.

SCOPE: This protocol applies to the sampling and testing of resin only.

PROCEDURE:

1 When chromatography column xxx is opened for planned or unplanned reslurry, before resin is slurried, take the following 15 mL samples:

1.1 Four samples, one each separated by 90º from each other (samples 1-4).

1.2 Two samples from the center (samples 5 & 6)

1.3 One sample from any region that appears to have a darker or different color from the rest of the column. Indicate the location of these samples on

attachment I (samples 7a-7x).

2 After the resin is slurried, take six 15 mL samples. Take three samples (samples 8-10) in polypropylene tubes, and three in polystyrene (samples 11-13).

3 Testing

3.1 Test samples according to the following table:

Courtesy of S. Rudge

col val 2008 gs 21

Sampling Resin for Cleaning Validation

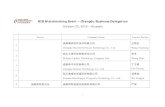

Sample No Bioburden Endotoxin Small ion capacity

Product sensitive

1-4 X X 5 X 6 X X 7 X X X 8 X 9 X 10 X X 11 X 12 X 13 X X

Courtesy of S. Rudgecol val 2008 gs 22

Validation: Use of Coupons

Contaminate with known amounts of contaminants

Let dry

Swab

Extract

TOC

col val 2008 gs 23

Validation

Recovery

> 80% is considered good

col val 2008 gs 24

Validation

Recovery

> 80% is considered good > 50% is considered

reasonable

5 /GE /

col val 2008 gs 25

Validation

Recovery

< 50% is consideredquestionable

> 80% is considered good > 50% is considered

reasonable

col val 2008 gs 26

Evaluation of Cleaning Efficacy

A combination of small scale models and production runs

Bio-burden control

Blank (sham, mock) run analysis•UV, TOC, total protein assays, SDS-PAGE, product-specific assays

Stress media (small scale only)•Longer contact times with cleaning agent•Higher concentration of cleaning agent

Removal of specific, potentially problematic impurities•Dependent on feedstream (Mass Balance)

col val 2008 gs 27

Bio-Burden control: Microbiology

Prevent microbial growth and remove contaminationDocumented evidence

• routine cleaning• storage of equipment

The period and conditions• storage of unclean equipment before cleaning• between cleaning and equipment reuse

Equipment stored in a dry condition after cleaning (no stagnant water)

Control of bioburden important: <10CFU/ml

col val 2008 gs 28

VALIDATED ASSAYS ARE REQUIRED

Specific*, sensitive

Broad spectrum

TEST METHODS

Rinse fluids

Swab testing (equipment)

Coupons (equipment)

Visual inspection

“TOC can be an acceptable method for monitoring residues routinely and for cleaning validation.” U.S. FDA www.fda.gov/cder/guidance/cGMPs/equipment.htm#TOC

Analytical methods

col val 2008 gs 29

Analytical methods

Validated analytical methods – able to detect residuals or contaminants:

• specific for the substance(s) being assayed• at an appropriate level of cleanliness (sensitivity)

Sensitive and specific - may include:• chromatographic methods (e.g. high pressure liquid

chromotography (HPLC), gas chromotography (GC), and high pressure thin-layer chromatography (HPTLC)). Others include (alone or in combination), e.g. total organic carbon (TOC), pH, conductivity, ultraviolet (UV) spectroscopy, and ELISA.

col val 2008 gs 30

Analytical methods

Validation of the analytical method should include, e.g.• precision, linearity and selectivity (the latter if

specific analytes are targeted);• limit of detection (LOD);• limit of quantitation (LOQ);• recovery, by spiking with the analyte; and• reproducibility

Detection limit (sufficiently sensitive) to detect the established acceptable level of residue / contaminants

6 /GE /

col val 2008 gs 31

1: inlet valve2: column gasket3: base gasket4: outlet valve

4

1

2

3

Equipment: Columns & Skids

col val 2008 gs 32

TOC Results

col val 2008 gs 33

Fraction Tested µg DNA % of Total DNA

Starting material 699.75 100Buffer A wash 0.79 0.11100% B eluate 253.80 36.27Acid wash 0.64 0.091 M NaOH/1M NaCl wash 449.60 64.25Water wash 3.92 0.56

Total DNA eluted from column 708.75 101.2

Dasarathy, Y., BIOPHARM, Volume 9, Number 10, 1996

Mass Balance of Calf Thymus DNA Clearance from Q SepharoseTM Fast Flow

col val 2008 gs 34

Establishing acceptable limits

Limits: Practical, achievable and verifiable

Rationale: Logical, based on knowledge of materials

Each situation assessed individually

Principal reactant and other chemical variations

Screening (thin-layer chromatography) in addition to chemical analyses where necessary

col val 2008 gs 35

Establishing acceptable limits

The limit-setting approach can:• be product-specific• group products into families and choose a worst

case product• group products into groups according to risk, e.g.

very soluble products, products with similar potency, highly toxic, or difficult to detect products

• use different safety factors for different dosage forms based on physiological response (this method is essential for potent materials)

col val 2008 gs 36

Establishing acceptable limits

Limits may be expressed as:• a concentration in a subsequent product (ppm), • limit per surface area (mcg/cm2), or • in rinse water as ppm.

Limits for carry-over of product residues should meet defined criteria.

7 /GE /

col val 2008 gs 37

Establishing acceptable limits

The three most commonly used criteria are:

• Visually clean No residue visible on equipment after cleaning. Spiking studies to determine the concentration at which most active ingredients are visible. (May not be suitable for high potency, low-dosage drugs.)

• No more than 10 ppm of one product will appear in another product

• No more than 0.1% of the normal therapeutic dose of one product will appear in the maximum daily dose of a subsequent product.

col val 2008 gs 38

Visual Inspection

Subjective assessment

Performed by two observers

Experiences with CIP Validation in a Multiproduct Biopharmaceutical Manufacturing Facility, D. Sherwood, Celltech Biologics PLC

col val 2008 gs 39

Visual Inspection

Is a discolored column unacceptable?

Is there really a “Grey Sepharose”?

col val 2008 gs 40

AKTApilot Sanitization

Protocol:

1. Infection with solutions containing 3 bacterial strains and 1 yeast

2. Sterile water rinse followed by 1 M NaOH, approx. 1.5 h

YeastGS 115P. pastoris*

Gram positive bacteriaATCC 6538S. aureus

Gram negative bacteriaATCC 9027P. aeruginosa

Gram negative bacteriaATCC 8739E. coli

* Selected instead of USP XXV recommended yeast, C. albicans as it is more frequently used in production

col val 2008 gs 41

ÄKTApilot Sanitization Procedure

25 min10 LSterile physiological saline solution

pH neutralization

75 min4 L w/ circulation

1 M NaOHSanitization

12.5 min5 L1 M NaOHRinsing

12.5 min5 LSterile waterRinsing

TimeVolumeSolutionFunction

col val 2008 gs 42

ÄKTApilot Sampling Points

8 /GE /

col val 2008 gs 43

ÄKTApilot Sanitization Study Summary

0000Post-sanitization effluent

6.7 x 1061.2 x 1072.0 x 1081.2 x 108Pre-sanitization flow through

0.2 x 1061.6 x 1061.8 x 1068.8 x 105Post-infection flow through

0.8 x 1064.1 x 1062.1 x 1061.5 x 106Inoculum

P. pastorisS. aureusP. aeruginosaE. coliViable Count, CFU/mL

Results: A Reduction of at least 106

col val 2008 gs 44

Establishing acceptable limits

The most stringent of three options should be used

Certain allergenic ingredients and highly potent material should be undetectable by the best available analytical methods

• e.g. penicillins and cephalosporins• e.g. anovulent steroids, potent steroids and

cytotoxics

Dedicated manufacturing facilities needed

col val 2008 gs 45

Cleaning validation protocols

Approved by QC or QA and to cover, e.g.• disassembly of system;• pre-cleaning;• cleaning agent, concentration, solution volume, water

quality;• time and temperature;• flow rate, pressure and rinsing;• complexity and design of the equipment;• training of operators; and• size of the system.

WHO Cleaning validation guideline

col val 2008 gs 46

Cleaning validation protocols

The cleaning validation protocol should include objectives, responsible people; –description of the equipment including the make, model, serial number or other unique code; –time intervals; bioburden; cleaning procedures; –equipment used for routine monitoring (e.g. conductivity meters, pH meters and total organic carbon analysers);–number of cleaning cycles; sampling procedures (e.g. direct sampling, rinse sampling, in process monitoring and sampling locations) and the rationale for their use

col val 2008 gs 47

Bracketing:

Very similar cleaning procedures for products and processes - no need for individual validation. “Worst case”may be acceptable and should be justified.

Consider type of products and equipment; allowed only where products are similar in nature or property and processed on the same equipment; and identical cleaning procedures used.

Cleaning validation protocols

WHO Cleaning validation guideline

col val 2008 gs 48

Bracketing:

Representative product - most difficult to clean.

Equipment - only when it is similar or the same equipment in different sizes (e.g. 300 l, 500 l and 1000 l tanks).

–Alternative approach may be to validate the smallest and the largest sizes separately.

Cleaning validation protocols

WHO Cleaning validation guideline

9 /GE /

col val 2008 gs 49

The cleaning validation protocol should include –data on recovery studies (efficiency of the recovery of the sampling technique should be established); –analytical methods; –acceptance criteria (with rationale for setting the specific limits) including a margin for error and for sampling efficiency;–cleaning agent to be used;–revalidation requirements.

Cleaning validation protocols

col val 2008 gs 50

Resin Reuse and Carryover: FDA 483s

• Protein carryover from previous purifications not characterized*

• Impact of carryover proteins not evaluated

• Cleaning validation not performed for removal of urea, primatone and media*

• No periodic monitoring of chromatography columns following cleaning

• Cleaning validation not performed on some multiuse equipment

* 483 of the past

col val 2008 gs 51

FDA Form 483 - Equipment Issues

Equipment Cleaning• Not all equipment has time limits on how much time

may lapse between use and cleaning

col val 2008 gs 52

Inspection Issues: Cleaning/Sanitization

No product specific or other validated test methods for cleaning of multipurpose equipmentNo study to demonstrate removal of residual … from final purification columnColumn, UF/DF skids hold time after cleaning/sanitization has not been validatedNo routine monitoring following cleaning of dedicated product contact parts and equipmentNo data to support lack of expiration dating on sanitizer

FDA Form 483s from 2005Compiled by BioQuality www.i2icorp.com

Validation of Chromatography Media Lifetime

Process Chromatography

col val 2008 gs 54

Validation of Lifetime Studies

• Missing validation of resin reuse lifetime studies• Validation study did not include evaluation that the

scale down version was representative of the manufacturing process

Barry Cherney, Process Validation: A Product Reviewer’s Perspective, WCBP, 2005

10 /GE /

col val 2008 gs 55

Decisions

Lifetime studies or disposables

When to initiate lifetime studies

How to implement lifetime studies

col val 2008 gs 56

Lifetime Studies or Disposables

• Availability/feasibility of disposables• Cost ($ and environment)• Regulatory issues

• Expedite approval by avoiding safety issues e.g. viral clearance and resin reuse

• Scale up challenges• Extractables

col val 2008 gs 57

Cost of Resin Reuse Studies

0.40.7900.21530

0.211310

Approximate Validation Cost ($M)

Approximate Savings ($M/Year)

Lot #

Table adapted from Rathore & Sofer, Lifespan Studies for Chromatography Media In Process Validation in Manufacturing of Biopharmaceuticals, 2005, Rathore and Sofer, Eds, CRC Press

col val 2008 gs 58

When to Initiate Lifetime Studies?

• Too soonProcess conditions not definedData not relevant

• Too lateDelayed regulatory approval

• After process finalized • Using production samples

col val 2008 gs 59

How to Implement Lifetime Studies: Topics

• Concurrent vs. Prospective• Measurable parameters to determine lifetime• Resin lifetime and viral clearance• Case studies

col val 2008 gs 60

Lifespan Studies: Concurrent

Concurrent

Prospective?

11 /GE /

col val 2008 gs 61

FDA Therapeutic Compliance Guide Program Guide 7341.001

“There should be an estimated life span for each column type, i.e., number of cycles. Laboratory studies are useful even necessary to establish life span of columns. There are situations where concurrent validation at the manufacturing scale may be more appropriate. Continued use may be based upon routine monitoring against predetermined criteria.”

col val 2008 gs 62

Is Concurrent Validation of Lifespan Practical?

Provides real data on performance with repeated use (like PAT)

Are assays sufficiently sensitive to determine process consistency?

Are you willing to take the risk of a failed batch?

Is viral clearance claimed on a purification step?

col val 2008 gs 63

Critical aspects of a resin lifetime study

•Development and qualification of a scale down model

•Equipment Qualification:IQ/OQ/PQ

•Column packing qualification

•Column repacking frequency and qualification

•Column critical operating parameters

•Cleaning and Sanitization protocol

•Column Storage

•Carryover Studies

•Raw materials and Feedstream

•Measurable performance of column

•Acceptance criteria

col val 2008 gs 64

Measurable Parameters to Determine Lifetime: Chromatography Resins

Product purity

Impurities profile

Changes in flow rate/pressure

Changes in elution profile• Shift in retention volume or time• Peak heights

Changes in regeneration/reequilibration profile • pH, conductivity, UV

Decreasing product yields

Appearance

Bed height

Column packing• HETP• Asymmetry

Capacity• Product, total protein

Leachables

Others

col val 2008 gs 65

Which Parameters are Most Meaningful?

• It’s a Case by Case Decision• Is appearance informative in a 2meter dia column?

col val 2008 gs 66

One Firm’s Observations on Column Failure and Manufacturing Surveillance

Protein A• Dynamic capacity decay

Anion exchange• Removal of key contaminants decrease

Cation exchange• No identifiable sources of column failure• Study included cleaning, capacity, contaminant removal,

yield, purity

Data presented by Cindy Oliver, Medimmune, PDA/FDA Viral Clearance Forum, Oct. 2001

12 /GE /

col val 2008 gs 67

Case Studies

I. Humanized IgG1 from CHO culture on Protein A column

II. E. coli extract on capture anion exchange column

col val 2008 gs 68

Case Study: IgG1 Purification on Protein A Column

Dynamic binding capacity after CIP

Yield of IgG1

Residual HCP

col val 2008 gs 69

Dynamic Binding Capacity of Humanized IgG1

Dynamic binding capacity for MabSelect SuRe after purification cycles and CIP in 0.1 M NaOH

0

10

20

30

40

0 25 50 75 100 125 150 175

Purification / CIP cycles

10%

bre

akth

roug

h ca

paci

ty (m

g/m

l) fo

r IgG

1

CIP: 0.1 M NaOH, 15 min. 150 purification cycles on MabSelect SuRe™col val 2008 gs 70

Yield of IgG1 up to 149 Cycles

9414999130941119480995098101001Yield, %CIP Cycle No.

Average yield > 95% of initial value over 149 cyclesResin: MabSelect SuRe

col val 2008 gs 71

Host Cell Proteins and Carryover

• HCP levels in bound fraction eluates of humanized IgG1

1000 ppm (ng HCP/mg humanized IgG1)• Carryover levels

less than 10 ng/mL after 150 cycles

col val 2008 gs 72

Case Study I: Summary

Clarified CHO cell culture, 0.8g/ml, Humanized IgG1

Load 28 mg/ml (80 % of initial DBC)150 cycles, CIP every cycle, 15 minutes 0.1 M NaOHConstant yield, 95-100%Consistent purity, (1000-1500 ppm HCP)

No detectable carry-over, < 10 ng/mlResin appearance: naïve and used were sameDBC approx 85 % of initial value after 150 cycles

13 /GE /

col val 2008 gs 73

Case Study 2: Clarified E. coli Homogenate Purified by Capture Anion Exchange Step

Column packing

Column backpressure

Dynamic binding capacity of BSA at 10% breakthrough

Endotoxin content in eluates

Carryover runs at 79 cycles:

CIP: 4 h, 1 M NaOH

Column performance

capacity, endotoxin content, discoloration

Ionic capacity and amino acid content of resin

col val 2008 gs 74

Column Packing and Performance

1.123180791.093328691.103126591.103139501.093155391.143186291.123146201.113134111.0629860

AsymmetryN/mCycle no.

Resin: Capto Q™

col val 2008 gs 75

Backpressure over 80 Cycles

MPa at 30.0 mL

0

0,5

1

1,5

2

0 10 20 30 40 50 60 70 80

Cycle no.

MPa

col val 2008 gs 76

Dynamic Binding Capacity

Decrease of ca. 10% after 316 CIP h

Decrease of 2.6%

104105109108113116115116120116

QB10%(mg/mL Capto Q)

796959503929201110

Cycle no

col val 2008 gs 77

Endotoxin in Blank Runs

0.5Blank

11Cycle 79307*Cycle 69

20Cycle 5972Cycle 506.5Cycle 3920Cycle 2936Cycle 2090Cycle 119.6Cycle 1

21Cycle 0≈2.5x106Clarified E. coli homogenate

Endotoxin (EU/mL)Sample

* Thought to be due to contaminationcol val 2008 gs 78

Carryover Studies: “Blank” Runs

• Blank runs periodically during 79 cycles

• No peak detected in blank runs

Equilibration

Sample or equilibration buffer

Wash

Elute

14 /GE /

col val 2008 gs 79

Other Parameters Measured in Case Study II

Ionic capacity

Unused resin: 0.19 mmol Cl‒/mL

After last cycle: 0.17 mmol Cl‒/mL

Discoloration

None observed

col val 2008 gs 80

Thanks

col val 2008 gs 81

隋礼丽021 [email protected] Trak China LeaderGE Life Science

![[WeGO e-Government Program]City Paper Presentation : Chengdu(China)](https://static.fdocument.pub/doc/165x107/55cb2400bb61eb09318b46eb/wego-e-government-programcity-paper-presentation-chengduchina.jpg)