UOP SELEXOL Process for Acid Gas Removal (AGR) UOP ......3rd Coal to SNG China 2012 2012...

Transcript of UOP SELEXOL Process for Acid Gas Removal (AGR) UOP ......3rd Coal to SNG China 2012 2012...

UOP SELEXOL™ Process

for Acid Gas Removal (AGR)

UOP 脱酸气 SELEXOL™ 工艺

Dr. Lubo Zhou

周麓波博士

UOP LLC

A Honeywell Company

© 2011 UOP LLC. All rights reserved. UOP 5254-01

3rd Coal to SNG China 2012 2012中国第三届煤制合成天然气会议

Beijing, China 中国, 北京

January 9-10th, 2012 2012年1月9-10日

OUTLINE 演讲大纲

Introduction to UOP and UOP’s Gas Process Technology

UOP和UOP气体处理技术介绍

UOP Selexol Process

UOP Selexol 工艺过程

Global UOP Selexol Process Applications

Selexol 工艺过程应用实例

Advantages of UOP Selexol Process

Selexol 工艺过程优势

Summary

综述

34%

15%

36%

15%

• Founded in 1886

创立于1886年

• 118,000 employees in nearly 100 countries

在大约100个国家拥有118000个雇员

• Global leader in advanced technology products, services and solutions

先进技术产品,服务和解决方案世界领先

• UOP is part of Honeywell family

UOP是Honeywell的全资子公司

UOP

Technology Company, Financially Strong and Global

Honeywell Company Profile 霍尼韦尔公司介绍

航空航天 Aerospace

Automation & Control自动化控制

Performance Materials & Technology

Transportation & Power Systems

运输和电力系统

特性材料和技术

UOP Company Summary UOP公司介绍

Profile

Employees: 2,891

Location: HQ: Des Plaines, Illinois (suburban Chicago), USA

Business Units:

Process Technology & Equipment (PT&E)

Catalysts, Adsorbents & Specialties (CA&S)

Renewable Energy and Chemicals (RE&C)

Offering:

Process Technology & Services to Refining, Petrochemicals, and Gas Processing industries

Supplier of catalysts to the process industry

Supplier of molecular sieve adsorbents to process & Mfg. Industries

Significant Brand Equity

Global Market Coverage

UOP Facilities

UOP Footprint

Licensing 14%

Products 46%

Services 13%

Equipment 25%

Revenue Distribution

Business Geographic Breakdown

20 Offices

17 Countries

11 Manufacturing Facilities

4 Engineering Centers

UOP Offices

UOP Manufacturing sites

Business Segment Breakdown

Middle

East, 15%

Americas,

25%

Asia, 24%

India, 7%

China,

10%

Europe,

19%

UOP Process Engineering Technology UOP 工艺工程技术

Technology Delivery

Complete Technology Delivery Package 全面的技术交付包

Planning & Consulting Studies

计划和咨询研究

Engineering Services

工程服务

Basic Engineering Design

基础设计

Advanced Process Control

先进过程控制

UOP delivers Technology in Engineering,

Equipment and Services

UOP Process Engineering Technology UOP 工艺工程技术

Technology Delivery

Complete Technology Delivery Package 全面的技术交付包

Equipment 设备

– Modular Construction

模块制造

– 160 projects since 1987

从1987年开始160个项目

Catalyst, Adsorbent, Chemicals

催化剂、吸附剂、化学品

Training 培训

Start-up Assistance 开工指导

Ongoing Services & Inspection

服务和检查

UOP delivers Technology in Engineering,

Equipment and Services

National Medal of Technology Citation 美国国家技术奖

“over 85 years of sustained technical leadership and innovation for the worldwide petroleum refining and petrochemical

industries, and for commercialization of

adsorbents, catalysts, process plants and process technology that have strengthened America’s global competitiveness

and benefited quality of life throughout the world.”

UOP 4638NC-25

UOP has been named a Thomson Reuters 2011 Top 100 Global Innovator

Amine MolSivTM

ADS Mercury

RU Selexol

Tech Separex

Tech Ortloff NGL

Ortloff Sulfur

Merox Tech

Gas Plant (on-shore)

X X X X X X X X

LNG (on-shore) X X X X X X X X

Platform X X X

FPSO X X X X X

FLNG X X X X X X

1000

100

10

1.0

0.1

Scavengers

MolSiv™ Ads

PSA

Selexol™ Process

Amine Guard™ FS Process

Separex™ Membrane

Tech

Benfield™ Process

Pa

rtia

l Pre

ssu

re A

cid

Ga

s in

Fe

ed

, p

sia

Partial Pressure Acid Gas in Product, psia 0.001 0.01 0.1 1.0 10 100

1000

100

10

1.0

0.1

UOP’s Acid Gas Removal Technologies UOP脱除酸气技术

Market

Segments

Product

Lines

Proven/Reliable/Leading

Process Technology #Units

Molecular Sieves >3,000

Membranes 250

Amine Guard 550

Ortloff NGL 94

Ortloff SRU 92

Selexol 60

PSA 800

Benfield 650

Merox 1,700

What is the SELEXOL Process?

什么是SELEXOL工艺 ?

Absorption/regeneration process for selective removal of H2S, COS, & CO2 选择脱除H2S,COS,CO2的吸收/再生工艺

– Uses a physical solvent 使用物理溶剂

– Uses a typical solvent-extraction flow-scheme 使用典型的溶剂抽提流程

– Loading proportional to partial pressure 负荷与分压成比例

Physical vs Chemical物理溶剂 VS化学溶剂

Partial Pressure 分压

So

lven

t L

oad

ing

溶剂

负荷

Chemical Solvent 化学溶剂

Physical Solvent 物理溶剂

High Pressure is advantageous

高压有利吸收

Acid Gas

Feed Gas

Treated Gas 净化气

酸气

进料气

Typical

Gasification

Application

典型的气化应用

Selexol Solvent Characteristics Selexol 溶剂特性

Solvent details

– Dimethyl Ether of Polyethylene Glycol

多乙二醇二甲醚

– A clear fluid that looks like tinted water

透明的液体,看起来像镀了色的水

Energy efficient regeneration of CO2 by changing pressure

过改变压力,温度或使用气提的节能的再生

– Enhanced recovery of CO2 in flash drums 在闪蒸罐中CO2提高回收率 Relative Selectivity 相对选择性

Methane甲烷 Hydrogen氢气 – H2S ~ 135 ~ 680 – CH3SH ~ 340 ~1700 – CO2 ~ 9 ~45 – CO ~0.43 ~2.2 – COS ~35 ~175

UOP 5241F-04

Selexol Solvent Characteristics Selexol 溶剂特性

– High selectivity of H2S over CO2 - selective absorption of H2S in the

Absorber

由于 H2S比CO2具有更高的选择性, Selexol可以在吸收塔选择吸收硫化氢

• Lower the downstream SRU cost

降低硫回收装置的费用

High Selectivity for CO2 over H2

对CO2有比 H2更高的选择性

– Supports separate CO2 production

支持单独的 CO2生产

– Minimizes downstream H2 purification

把下游氢气净化的要求降到最低

UOP 5241F-04

Selexol in Syngas Applications 合成气的应用

Coal or PetCoke, Biomass

煤或石油焦,生物气

O2

Treated Syngas

净化合成气

Sulfur 硫磺

H2S

Raw Syngas

粗合成气

CO2

Gasifier

气化器

Sour Shift

水煤汽反应

Air Separation

空分

Tail Gas 尾气

Selexol Unit Selexol装置

Sulfur Recovery

硫回收

No Shift, Full Shift or Partial Shift

Typical Raw Syngas

典型的粗合成气

H2 30 - 50%

CO 30 - 50%

Ar 0.5 - 1%

N2 0.7 - 1.5%

CO2 5 - 19%

H2S 0.5 - 2%

COS 200-1000 ppmv

Ni & Fe Carbonyls 羰基镍和铁

HCN, NH3 ...

Applications: 应用

Power 发电

SNG 合成气

Chemicals 化学品

Hydrogen 制氢

Liquid Fuels 液体燃料

Etc

Typical Gasification Complex 典型的气化系统

无水煤汽反应 全水煤汽反应或 部分水煤汽反应

UOP 5632B_Bejing-12

Process Flow Schemes Selexol for Sulfur Removal Only 仅脱硫的Selexol流程

Power applications typically require sulfur removal only to 10 to 20 ppmv. Less than 1 ppmv can be achieved

ONLY TWO COLUMNS REQUIRED – One solvent absorber with solvent regeneration

Adjustable acid gas composition

Low CAPEX and OPEX

Sulfur Absorber

Reflux Pump

Stripper Reboiler

汽提再沸器

H2S Concentrator

Packinox Exchanger 板式换热器

Lean Solution Filter

H2S Stripper 汽提塔

Reflux Accumulator

回流罐

Acid Gas 酸气

Export Water 排出水

Feed Gas

进料气

Treated Gas

Makeup Water 补充水

发电应用通常仅脱硫至10-20ppmv Selexol可实现小于1ppmv硫。

只有两个塔:溶剂吸收塔和再生塔 可调节酸气组成

低的投资和操作费用

净化气

硫吸收塔

贫液过滤器

回流泵 H2S

提浓器

UOP 5632B_Bejing-13

Sulfur Absorber 硫吸收塔

Reflux Pump

Stripper Reboiler

汽提再沸器

H2S Concentrator

Packinox Exchanger 板式换热器

Lean Solution Filter

Stripper 汽提塔

Reflux Accumulator

回流罐

Acid Gas 酸气

Export Water 排出水

Makeup Water 补充水

CO2 Absorber

CO2吸收塔

CO2

Treated Gas

CO in the CO2 stream is ~500 ppmv CO2中的CO到500ppmv CO2 purity as high as 99.7 mol% CO2纯度高达99.7mol% Sulfur in treated gas to less than 1 ppmv 净化气中硫小于1ppmv CO2 in treated gas below 1% is achievable 可实现净化气中CO2低于1% Sulfur in CO2 as low as 2 ppmv CO2中硫含量低至2ppmv Adjustable acid gas composition 可调的酸气组成

Selexol Flow Schemes Sulfur Removal & CO2 Capture—Conventional

Feed Gas 进料气

脱硫和CO2捕集常规流程 净化气

贫液过滤器

H2S 提浓器

UOP 5632B_Bejing-14

SELEXOL® Solvent Experience Selexol ® 溶剂经验

Synthesis Gas 天然气 Natural Gas 合成气 Landfill Gas 垃圾场气 Over 110 Operating Units

with SELEXOL solvent

全球有110套装置用到了Selexol溶剂 UOP 5670-15

UOP SelexolTM Applications Worldwide UOP SelexolTM在世界范围的应用

Recent Selexol Applications in Operation 近期运行的Selexol

Sarlux: IGCC power and H2 IGCC 发电和制氢

API: IGCC power IGCC发电

Coffeyville Energy Resources: H2 and CO2 capture for Ammonia/Urea Production 合成氨/尿素制氢和CO2捕集

SandRidge: Natural gas CO2 removal for EOR 改进的油回收天然气脱除CO2

Nexen: H2, fuel and future CO2 capture 制氢、燃料和未来CO2捕集

Projects in Construction 建设中的项目

Duke Energy: IGCC power and future CO2 capture (Plant start up in March 2012)

IGCC 发电和未来CO2 捕集(装置2012年3月开工)

Southern Company: IGCC power and CO2 capture (Plant start up in 2014)

IGCC 发电和CO2捕集(装置2014年开工)

Projects in Engineering 设计中的项目

DKRW: Coal to Liquids and CO2 capture (USA) 煤制油和CO2捕集

U.S. Transcarbon: H2 and CO2 capture (USA) 制氢和CO2捕集

Erora Project: IGCC power and SNG production (USA) IGCC发电和SNG生产

Don Valley Power: IGCC power and CO2 capture (UK) IGCC发电和CO2捕集

J-Power: IGCC power and CO2 capture (JAPAN) IGCC发电和CO2捕集

Jindal Steel & Power Limited: DRI Reduction Gas (INDIA) DRI还原气 UOP 5670-16

UOP Selexol Applications: Three Examples 三个实例

Coffeyville Resources 合成气制胺和尿素

–Gasification and Ammonia-Fertilizer Complex 气化和合成氨化肥厂

Erora Cash Creek Project 项目

– IGCC + SNG Complex 合成气制替代天然气和发电联合装置

DKRW Advanced Fuels

–Coal to Liquids Complex

煤制油

Coffeyville Resources Coffeyville, Kansas, USA

Gasification Ammonia Complex Coffeyville气化合成氨厂

UOP 5632B_Bejing-18

Coffeyville Resources Ammonia Fertilizer Complex 合成氨厂

Feedstock进料: 45 MT/H petroleum coke

EPC Contractor承包商: Black & Veatch Pritchard

Commercial Operation商业运行: July 2000

Process Licensors

Gasification气化工艺: ChevronTexaco

Gas Purification Block 气体提纯工段:

- Acid Gas Removal 酸性气脱除: Selexol - UOP

- H2 Purification 变压吸附氢气提纯: Polybed PSA - UOP

Sulfur 硫磺: Black & Veatch Pritchard

Air Separation 空分: BOC

Ammonia / UAN 氨/尿素: Ammonia Casale / Weatherly

UOP 5632B_Bejing-19

Coffeyville Design Basis

设计基础

Feed Stream Specifications 进料指标

Feed Flowrate 流量 169,000 Nm3/hr (151 MM SCFD)

Pressure 压力 36.9 bar-a (535 psia)

Temperature 温度 38 ºC (100 ºF)

Component 组份 Mole %

H2 > 56

CO ~ 1.2

CO2 ~ 41

H2S and COS ~ 0.6

CH4, Ar, & N2 ~ 1

H2O Saturated 饱和

UOP 5632B_Bejing-20

Coffeyville Block Flow Diagram

简易流程图

Air Separation

Unit 空分

Ammonia Synthesis 合成氨

N2

Polybed PSA 变压吸附

UAN Plant 尿素装置

NH3 Product 氨产品

UAN

Product 尿素产品

O2 High Purity Hydrogen

高纯氢气 Purified CO2 净化的CO2

Quench

Gasification 急冷气化

Syngas Scrubbing 合成气洗涤

CO Shift & Gas Cooling 变换和气体冷却

Selexol 2-stage

2-级 Selexol

Petroleum Coke 石油焦

Air

Claus Plant 克劳斯装置

Acid Gas 酸气

Raw CO2

粗CO2

CO2 Purification

净化

CO2 Vent 排放 Raw H2

粗氢

UOP Technologies UOP技术

Tail Gas 尾气

UOP 5632B_Bejing-21

Coffeyville 2-Stage Selexol Unit

2-级 Selexol 单元

Product Stream Specifications 产品指标 Raw H2 Product 粗H2产品

Flowrate 流量 101,900 Nm3/hr (90 MM SCFD)

Product Purity 产品纯度 93 mole % H2 (minimum)

Raw CO2 Product 粗 CO2 产品\

Flowrate 流量 11,900 Nm3/hr (10.6 MM SCFD)

Product Purity 产品纯度 95 mole % CO2 (minimum)

CO2 Removed 脱除的CO2 ~ 94 %

Acid Gas 酸性气

Product Purity产品纯度 44 mole % H2S (minimum)

Commercial Selexol Process

商业化的Selexol工艺

Coffeyville Actual Operations

实际操作参数

Operating Results操作结果 Design设计 Actual实际

Raw H2 to PSA 粗氢到PSA

– H2, % 93 > 93

– CO2, % NA < 5

– H2S, ppm NA < 1

– COS, ppm NA < 1

Raw CO2 to UAN 粗CO2到UAN

– CO2, % 95 > 95

– H2S, ppm NA < 1

– COS, ppm NA < 10

Units met all process requirements

装置满足了所有的工艺指标要求 UOP 5632B_Bejing-23

SNC-Lavalin DKRW Coal to Liquid Fuel Project

DKRW煤气化制液体燃料项目

DKRW Advanced Fuels Coal to Liquids Complex 煤气化制液体燃料项目 Feedstock进料: 4,422 TPD coal

Products 产品 : 10,624 BPD gasoline

6,320 TPD CO2

1,529 BPD LPG

30 TPD Sulfur

EPC Contractor承包商: Kvaerner

Commercial Operation预计开工: May 2015

Process Licensors工艺商

Gasification气化: GE

Acid Gas Removal酸性气脱除: UOP Selexol

Methanol Synthesis 甲醇合成 : Davy

Methanol to Gasoline 甲醇制油 : ExxonMobil

UOP 5241F-21

DKRW Advanced Fuels Design Basis 设计基础

Sour Syngas Feed – 635,700 Nm3/hr (570 MM SCFD)

合成气原料

Treated Gas Specifications 合成气产品要求

– CO2 content: <0.35 mol%

– Total Sulfur: <1 ppmv

CO2 Product Specifications CO2气产品要求

– Total Sulfur: 10 ppmv

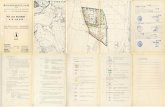

DKRW Selexol Process Selexol工艺

Makeup/

Purge

Water

H2S

Stripper

Reflux

Drum

Stripper

ReboilerLP Lean

Solvent

Pump

Lean/Rich

Exchanger

Reflux

Condenser

Stripped

Gas

Cooler

Treated

Syngas

CO2

Absorber

Reflux

Pump

Loaded

Solvent

Chiller

Loaded

Solvent

Pump

CO2

Vacuum

Drum

Acid Gas to

Sulfur

Recovery

Unit

H2S

Absorber

CO2

Recycle

Compr.

Semi-Lean

Solvent Pump

Semi-Lean

Solvent Chiller

H2S

Concentrator

Rich

Flash

Drum

Rich

Flash

Gas

Comp.

Flash

Gas

KO

DrumFlash

Gas

Cooler 1Sour

Syngas

SELEXOL PROCESS FOR SNC-LAVALIN (DKRW) PROJECT

CO2 Recycle

Flash Drum

CO2

Recycle

Cooler

Stripping

Gas

Compr.

CO2

Vent

Drum

Vacuum

Comp.

CO2

Vent

CO2

from

Vacuum

Compr.

Flash Gas

Cooler 2

Lean

Solvent

Chiller

Cond

.

Lean

Solvent

Cooler

HP Lean

Solvent

Pump

Steam

DKRW Project Status 项目状况

March 2011 – Signed Major Contract for Sale of CO2 for use in local EOR applications

2011年3月— 签用于改进的油回收的CO2销售合同

December 2011 – Signed Major Gasoline Contract

2011年11月-签汽油合同

Front End Engineering Design (FEED) completed

前期工程设计完成

Finalizing construction and procurement plan

建设和采购计划完成

Construction to begin in 2012

2012年开始施工

Anticipated startup – May 1, 2015

预计开工— 2015年5月

Erora Cash Creek Gasification IGCC + SNG Project

Erora Cash Creek煤气化制替代天然气

和发电混合装置项目

Erora Cash Creek Project IGCC + SNG Complex 煤气化制替代天然气和发电混合装置项目 Feedstock进料: 7,670 TPD coal

Products产品: CO2 to pipeline

SNG to pipeline

FEED Contractor承包商: Burns & McDonnell

Commercial Operation预计开工: May 2015

Process Licensors工艺商

Gasification气化: GE

Acid Gas Removal酸性气脱除: UOP Selexol

Sulfur 硫磺工厂 : Ortloff

Methanation 甲烷化 : Unknown UOP 5241F-21

Erora Cash Creek Design Basis 设计基础

Sour Syngas Feed – 694,200 Nm3/hr (622 MM SCFD) 合成气进料量

Methanation Recycle – 127,250 Nm3/hr (114 MM SCFD) 甲烷化装置的循环气量

Treated Gas Specifications /处理气要求

– CO2 content: <1 mol%

– Total Sulfur: <10 ppmv

CO2 Product Specifications /CO2气产品规格

– H2S: 10 ppmv

– Total Sulfur: 30 ppmv

– CO: <1 mol%

Methane Product Stream甲烷产品气要求

– 90% CO2 removal

– Total Sulfur: 20 grains / 100 SCF

Erora Cash Creek Block Flow Diagram

简易流程图

Erora Cash Creek Project Status 项目状况 Schedule A of acid gas removal unit was issued by

UOP to the customer

UOP提供脱除酸气装置的工艺包给客户

Engineering package for the Ortloff sulfur plant was issued by UOP to the customer

UOP提供Ortloff 硫磺回收装置的工艺包给客户

Project is on hold now 目前项目暂停

– Still awaiting approval of air and water permit applications

仍在等空气和水许可证批准

• Water permit requirements are changing due to revisions to Clean Water Act

由于清洁水法,水许可证要求改变

• Air permit requirements are changing due to revision to Clean Air Act

由于清洁空气法,水许可证要求改变

Enhancements include:

改进包括:

– Power recovery systems 能量回收系统

– CO2 Pumparound Scheme CO2 回流流程

– New Selexol offering by DOW 由陶氏提供新的Selexol

– High efficiency equipment 高效设备

•Packinox Heat Exchangers 板式换热器

•Column Internals / Packing

塔内件/填料

Solvent & Flow Scheme Improvements & Complex Optimization 溶剂和工艺流程改进和系统优化

UOP 5254-15

Areas of Optimization

优化的部分

– Detailed study on the impact of Acid Gas H2S% on the Selexol Unit and SRU unit

详细研究酸气中H2S含量对Selexol和硫回收装置的影响

– CO shift location

– Tail gas recycle streams 尾气循环

• Eliminates a portion of Claus Tail Gas Treatment (TGTU)

减少一部分克劳斯硫回收装置的单元

尾气处理

• Maximize CO2 capture

CO2捕集最大化

Solvent & Flow Scheme Improvements & Complex Optimization 溶剂和工艺流程改进和系统优化

UOP 5254-15

UOP Syngas Purification Complex Optimization 合成气净化和反应最优化

Sulfur Product

Syngas

UOP works with our partners (other technology suppliers) optimizing the process

to assure Capex and Opex are minimized while achieving the project goals

H2 Product

SNG Product

CO2 Product

Technology Partners

UOP/Ortloff UOP

PSA Tailgas

SRU Tailgas

Acid Gas

FT Liquids

Methanol

UOP 5254-17

Selexol Unit

PolybedTM PSA CO Shift/COS

Hydrolysis SG

TGCU

SRU

Methanation

FT Reactor

Methanol Unit

IGCC Power

UOP与合作伙伴一起对整个工艺流程进行优化从而达到设备投资和运行费用的最小化

Selexol Process Advantages Selexol 工艺优势

Ambient Temperatures or mild chilling ( 5°C )

环境温度或缓和冷冻(5℃)

– Simple refrigeration system based on propane is adequate

基于丙烷的简单冷冻系统就足够了

Simple flow schemes & limited number of equipment

流程简单和有限数量的设备 – Much less equipment counts compared to competing technology

与其他技术相比设备更少

Low Vapor Pressure

低蒸汽压 – Significantly lower solvent loss (much less environmental

concerns)

更低的溶剂损失(环境问题更少)

Selexol Process Advantages Selexol 工艺优势

100% Organic – non-toxic

100%有机溶剂-无毒

Mostly Carbon Steel Construction

大多数碳钢设备 – Lower CAPEX

更低的投资

Removes metal carbonyls if present

脱除羰基金属

Absorbs NH3, HCN and other trace contaminants, without the need for additional equipment

不需要增加设备,吸收NH3,HCN和其他微量杂质。

Selexol Process Advantages (cont.) Selexol 工艺 优势(续)

Provides high product quality 产品质量高

– Total sulfur to <1.0 ppmv (ppb guarantee with guard bed)

总硫<1.0 ppmv(使用保护床 保证总硫在ppb级)

– CO2 less than 1 mol% CO2 小于1mol%

Design and operational flexibility 设计和操作灵活性

– Adjustable Acid Gas Composition 可调节的酸气组成

– Can be designed for a range of CO2 capture levels

捕捉一系列浓度CO2

– Operate with moderate refrigeration 使用缓和冷冻操作

– Stable operation at turndown 低负荷时,操作稳定

Simplicity of design设计简洁

– >99% availability Selexol正常运行率 >99%

UOP 5670-39

Reliability / Availability/ Maintainability 可靠性/可用性/可维护性

>99% plus availability

Selexol正常运行率 >99%

Operators follow availability of gasification complex

操作人员根据气化装置的正常运行率运行Selexol

– Typically report 80 to 90%

典型的报道80-90%

Reliability / Availability/ Maintainability 可靠性/可用性/可维护性

Selexol operators report that plant can be brought on-line within 2 to 3 hours

Selexol 操作者报告装置在2-3小时内即可投入运行

Nothing in Selexol which requires special treatment or reliability needs during normal operation

正常操作期间,在Selexol装置内不需要特别的处理或可靠性需求

Selexol plant can still be operated with loss of refrigeration at ~50% reduced capacity

在~50% 冷冻负荷损失情况下,Selexol装置仍能操作

Summary of SELEXOL Process?

Selexol 工艺综述

Proven technology, High reliability 已被多年工业装置验证的工艺,高的可靠性

Simple flow schemes & limited number of equipment 简单的工艺流程和数量不多的设备

Safe Operation and Maintenance 安全的操作和维护

Treated gas with very low sulfur (<1 ppm) – suited for SNG and other chemical applications (with guard bed)

处理气含硫极低(<1 ppm),很适合替代天然气合成和其他化学物合成工艺(加保护床)

Refrigeration is not critical to meet specification 冷冻装置不是满足工艺指标的关键

Selexol unit can operate even with loss of refrigeration at reduced capacity Selexol 单元可以在冷冻装置不能工作的情况下降低负荷操作

Efficient and high overall sulfur recovery 高效和高硫回收率

Unit can be customized to meet your processing goals 设计装置可特别定制以满足您的工艺目标

Facilitates CO2 capture (available at high pressure) 很好结合 CO2 捕集(可提供高压CO2 )

Multi-purpose (acid gas removal, dehydration, dew point depression) 多种功能(脱酸气,脱水,降低露点)

Treat gases that other technologies cannot tolerate 处理其他技术不能处理的气体

World-Class Technical Support from UOP and Dow Oil & Gas 来自世界一流的UOP 和陶氏化学油气部门的支持

. . . . lowest total cost option for gasification 对气化过程, 是一种最低总费用的选择

Summary of SELEXOL Process?

Selexol 工艺综述