tube mill

-

Upload

hilmy-muhammad -

Category

Documents

-

view

26 -

download

10

description

Transcript of tube mill

φ3.8×13m水泥磨 φ3.8×13m CEMENT MILL

安装使用维护说明书 ERECTION,OPERATION AND MAINTENANCE INSTRUCTION

K4536.00 SM

印尼南加里曼丹海螺股份有限公司

South Kalimantan Indonesia Conch Cement

Company Limited

设备编号:09A,01a.b.c

EQUIPMENT NO:09A,01a.b.c

合同号:GSB12028

ORDER NO:GSB12028

上海重型机器厂有限公司

Shanghai Heavy Machinery Plant Co.,Ltd

二 0一三 年 二 月

February,2013

公司名称:上海重型机器厂有限公司

地 址:上海市闵行区江川路 1800号

电 话:021-54721141

传 真:021-54721132

邮政编码:200245

Name of Company: Shanghai Heavy Machinery Plant Co.,Ltd

Address: NO,1800 Jiangchuan road,Minhang,Shanghai

Tel: 021-54721141

Fax: 021-54721132

Postcode: 200245

目 录 CONTENTS

1 前言 .................................................................................................................................. 1

Preface ............................................................................................................................. 1

2 主要技术参数 .................................................................................................................. 1

Main Technical Parameter ............................................................................................. 1

3 工作原理 .......................................................................................................................... 4

Working principle ............................................................................................................ 4

4 结构概述 .......................................................................................................................... 6

Configuration summarize............................................................................................... 6

5 安装要求 ........................................................................................................................ 11

Installation ..................................................................................................................... 11

6 试运转 ............................................................................................................................ 28

Commissioning.............................................................................................................. 28

7 操作、维护及检修 ........................................................................................................ 32

Operation、Maintenance& Overhaul ......................................................................... 32

附录 A 磨机筒体衬板的安装 ........................................................................................... 40

Appendix A. Installation of Coal Mill Barrel Liner .............................................................. 40

附录 B 螺栓螺母的安装要求及紧固力矩 ....................................................................... 42

Appendix B. Installation Requirement of Bolts, Nuts and Tightening Torques ................... 42

附录 C 润滑示意图及润滑剂表 ....................................................................................... 45

Appendix C. Lubrication Sketch Map and Lubricant List .................................................... 45

附录 D 附图目录 .............................................................................................................. 47

Appendix D. Attached Drawing Catalog .............................................................................. 47

附录 E 备件清单 ............................................................................................................... 48

Appendix E. Spare Parts list ................................................................................................. 48

编 制 Organized

审 核 Checked

批 准 Approved

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 1 of 48

1 前言 Preface

1.1 用户或相关责任人应仔细阅读本说明书,充分理解本说明书的安装使用维护。

The users or the responsible person should carefully read this instruction and fully

understand the installation, maintenance and usage of the instruction.

1.2 负责安装的所有人员都要经过安全培训,对他们的任务和设备本身应充分了解。

All personnel responsible for the installation should have safety training and fully

understand their tasks and the equipment as well.

1.3 本说明书详细叙述了本设备及附属设备的施工措施及工作内容,并推荐了常规的安装

顺序。

This instruction specifies detailed construction measures and job contents of the equipment

hereby and its accessories and recommends the general installation orders.

1.4 本说明书并不能完全代替我公司专业安装指导人员的现场指导工作。

The instruction should not entirely replace the on-site guidance job of our company’s

professional erecting guiders.

1.5 根据现场实际情况,我公司专业安装指导人员可以考虑修改安装步骤或者采取和本说

明书不一样的方法进行施工。

Professional erecting guiders of our company may consider modifying the installation steps

or take methods different from this specification to carry on the construction work according

to the actual conditions.

1.6 使用单位按照说明书的要求,可以结合实际情况制定设备运行、维护、管理的制度。

The user (company) should establish the system of operation, maintenance and management

for the equipment while combines the requirements of the instruction with the actual

conditions.

1.7 凡是没有达到说明书规定的值和违反本说明定的操作,所造成的后果,本公司不予负

责。

Any consequence caused by the absent achievement of the values set by the instruction or

operations against the instruction, our company shall take no responsibility.

1.8 说明书中叙述的某些方法只是推荐之一,我们强调的是结果。

Some methods described in the instruction are some of the recommendations. What we

emphasis is the result.

2 主要技术参数 Main Technical Parameter

2.1 主要参数 Main parameter

规格 Specification: φ3.8×13m

筒体有效内径 Effective Barrel Diameter: 3570mm

筒体有效长度 Effective Barrel Length: 12847mm

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 2 of 48

磨机转速 Coal Mill Rotate speed:

工作转速 Operating Rotate Speed: 16.6 r/min

盘磨转速 Disc Mill Rotate Speed: 0.178r/min

2.2 用途:粉磨水泥熟料

Purpose: to abrade the powder of cement clinker

2.3 生产特性:圈流

Production feature: closed-circuit

2.4 研磨体装载量: 180t Grinding load: 180t

2.5 生产能力:~75t/h(入磨粒度≤25mm,95%通过,成品比表面积 3600cm2/g)

Production capability:~75t/h(entry abrasive particle size≤25mm,95% passing,surface

area of finished products 3600cm2/g)

2.6 传动方式:中心传动

Driving mode: center driving

2.7 主电动机 Main Motor:

电机型号 Motor type: YRKK900-8

额定功率 Rated power: 2500KW

额定转数 Rated rotary speed: 746r/min

额定电压 Rated voltage: 10kV

2.8 主电动机油站 Main motor oil station:

型号 Type: XYZ-25G

公称流量 Nominal flow: 25L/min

供油压力 Supply pressure: 0.6MPa

供油温度 Oil temperature: 28℃

有关参数以用户所购油站说明书为准。

Relevant parameters shall be in line with instruction of oil station purchased by the user.

2.9 减速机系统 Reducer system

2.9.1 主减速机 Main reducer

型号 Type: JS130-C

传递功率 Transmission power: 2500KW

输入转速 Input rotary speed: 746r/min

输出转速 Output rotary speed: 16.6r/min

重量 Weight: 48t

2.9.2 慢速驱动装置 Slow driving motor

型号 Type: HMS660

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 3 of 48

电机功率 Motor power: 37KW

电机转速 Motor rotary speed: 740r/min

传动比 Transmission ratio: 93:1

重量 Weight: 4.5t

2.9.3 膜片联结器 Diaphragm coupling

型号 Type: JL130-C

重量 Weight: 11.5t

(减速机供货还包括连接磨机接管法兰的螺栓等紧固件和调整膜片、联接主电动机的

联轴器)

Reducer supply also includes fasteners, such as bolts connected with the mill’s pipe

connecting flanges, adjustable diaphragm and couplings linked up with main motor.

2.9.4 主减速机油站 Main reducer oil station

型号 Type: XRZ-300

公称流量 Nominal flow: 300L/min

电机功率 Motor power: 11KW

电机转速 Motor rotary speed: 1460r/min

冷却面积 Cooling area: 16m2

加热器功率 Heater power: 4x6KW

重量 Weight: 3.5t

详细参数请参阅油站说明书为准。

Please check the instruction of oil station for detailed parameters.

2.10 滑履轴承高低压油站 (每台油站的参数)

The high and low pressure oil station of Sliding shoe bearing (parameters for each oil

station)

油站型号 Oil station model: XGD-A2.5x2/80P

高压部分(双高压) High-pressure section (double high pressure):

高压油额定流量 High-pressure oil rated flow: 2.5x2L/min

高压油额定压力 High-pressure oil rated pressure: 31.5Mpa

高压泵电动机功率 High-pressure pump motor power: 2.2X2(台 set)=4.4KW

低压部分(一备一用) low-pressure section (one for use and the other for spare part)

低压油额定流量 low-pressure oil rated flow 80L/min

低压油额定压力 low-pressure oil rated pressure 0.6Mpa

低压泵电机功率 low-pressure pump motor power 2.2x2=4.4KW

有关参数以用户所购油站说明书为准。

Relevant parameters shall be in line with instruction of oil station purchased by the user.

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 4 of 48

2.11 滑履轴承电气参数(每个滑履轴承)

Sliding shoe bearing electric parameters (each sliding shoe bearing)

托瓦及滑环测温元件 Pillow and slip ring temperature measuring component:

型号 Type: WZPM-201

数量 Quantity: 3

测温范围 Temperature range: -100~150℃

分度号 Index No: Pt100

电阻值 Resistance value: 100±0.12Ω(0℃)

油箱测温元件( 以用户所购油站说明书为准) :

Oil box temperature measurement component (oil station instruction purchased by the user

shall prevail):

型号 Type: WZP-26S

数量 Quantity: 1

分度号 Index No.: Pt100

油箱电加热器( 以用户所购油站说明书为准)

Oil tank electric heater (oil station instruction purchased by the user shall prevail)

型号 Type: HRY2-220/2

数量 Quantity: 2

功率 Power: 2KW(220V)

2.12 冷却水耗量 Cooling water consumption:

主电机油站 Main motor oil station: 1.5 m3/h

减速机油站 Reducer oil station: 27m3/h

滑履轴承油站 Sliding shoe bearing oil station: 3.8x2m3/h

滑履轴承 Sliding shoe bearing: 3.5x2m3/h

3 工作原理 Working principle

3.1 主要特点 Main feature;

3.1.1 本磨机为中心传动,两端都采用滑履轴承(焊接式滑环)支撑结构,缩短了磨机跨

距,受力良好,支撑稳定,筒体厚度减薄,从而降低成本;制造简单,零件量少,

用户操作、维护方便,节省运行费用。

The driving mode of this mill is center driving with sliding shoe bearing support structure

(welding slip rings) in both sides, which helps it to shorten the mill span, well carry

burden, stably support the structure, and reduce the thickness of the barrel, thereby

reducing the cost. The simple way of manufacturing, small amount of parts, user-friendly

operation and easy maintenance save the expense of operation.

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 5 of 48

3.1.2 本磨机为圈流磨,采用了新型隔仓板和出料篦板的分级衬板结构,使物料在粉磨仓

内的研磨过程更为合理,提高了粉磨能力。

The mill is closed-circuit mill that applies the classifying liner structure of new diaphragm

plates and discharge grate plates, which enables more reasonable grinding process of the

material in the grinding chamber, consequently improving the grinding ability.

3.1.3 易损件品种少,维修方便,维修费用低。

Less variety of the wearing parts, easy maintenance and low maintenance costs.

3.1.4 进料装置采用斜进风的百叶窗式结构,可以增大磨机的通风量,减小进风阻力,使

进料更顺畅,并采用快捷方便的电动调节风门结构。

Feeding device adopts the oblique air intake shutter structure, which increases the mill

ventilation and decreases the air intake resistance in order to make the feeding smoother.

The adoption also includes shortcut and convenient dynamo-electric adjusting air door

structure.

3.2 工作原理 Working principle

本磨机采用中心传动,即主电动机通过主减速机将动力传给膜片联轴器,再由膜片联

轴器驱动磨机筒体回转。在主电动机后面还配有慢驱动装置,以备安装、检修、维护时盘

磨使用。

The mill adopts center driving mode, namely, the main motor transmits dynamic to

diaphragm couplings through the main reducer, and then mill barrel turns around driven by

diaphragm couplings. Low-speed driving system arrangement is equipped with the main motor

to prepare for the usage of drive the mill when any installation, repair and maintenance work to

be done.

物料由进料装置中的进料溜子直接喂入筒体内的粗磨仓,物料在平均直径较大的研磨

体(钢球)的冲击研磨作用下得到粉碎。被粉碎到一定粒度的物料,通过隔仓板的粗筛板

之间的缝隙,进入组合式隔仓板,而粗磨仓的研磨体则被隔仓板的粗筛板挡住。物料在组

合式隔仓板内被细筛板进一步筛析,过粗物料被筛出,并返回粗磨仓,而小于细筛板尺寸

的物料被扬料板扬起进入细磨仓,在细磨仓内被小研磨体进一步研磨。达到工艺要求的粉

状物料经出料篦板、出料圆筒进入出料装置并被排出,进入到系统中的高效选粉机进行选

粉。磨细了的研磨体残余由出料装置的排渣口排出。

Material is fed into the coarse grinding compartment inside the barrel directly from the

incoming chute in the feeding device. The great grinding impact of the grinding body (steel ball)

with longer average diameter helps to crush the material. While the material is crushed to a

certain size, it enters into combined diaphragm plates through the gap between coarse sieve

plates in diaphragm plates. At the same time, the grinding body in the coarse grinding

compartment is blocked by the coarse sieve plates of diaphragm plates. In the combined

diaphragm plates, material gets the further sieve analysis by fine sieve plates. During the

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 6 of 48

process, material of too coarse size is to be screened out and returned back to the coarse

grinding compartment and material of small size less than a fine sieve plate is raised by the

scatter plates into the fine grinding compartment and got further grinding by the small grinding

body. Powder material reached the process requirements will be discharged through the

discharge grate plate and discharge barrel into the discharge device and gets into the high

efficiency separator in the system for powder selection. Residual slag of fine grinding body

will be discharged from the discharge port out of discharge device.

4 结构概述 Structure Summarize

磨机由进料装置、滑履轴承、滑履轴承润滑装置、回转部分、出料装置、传动装置、

滑履安装工具等组成。

The mill is composed of material feeding device, sliding shoe bearing, sliding shoe bearing

lubrication device, rotating unit, discharge device, driving device and sliding shoe installation

device, etc.

4.1 进料装置 Feeding device

物料经过进料装置而喂入磨内。进料装置由进料管、进风管及支架组成。本装置采用

斜进料的百叶窗式结构,使得进料更为顺畅。进料管内铺设有可更换的衬板。并设有快捷

方便的电动调节风门机构;进风管与支架之间可垫入调节垫片,以便必要时能方便地调正

进料装置的中心高。

The material is fed into the mill through feeding device which is composed of feeding

pipes, air incoming pipes and brackets. The device adopts the oblique air intake shutter

structure, which improves the smoothness of material feeding. Changeable liners are paved in

the feeding pipes. The shortcut and convenient dynamo-electric adjusting air door structure is

also set up. Adjustable shims can be put between air incoming pipes and brackets so as to

conveniently adjust the center height of feeding device if necessary.

4.2 滑履轴承 Sliding shoe bearing

本机为双滑履轴承结构。针对磨机的实际运行工况,进料端设计为可移动的滑履轴承,

当筒体热胀冷缩时,回转部分可作轴向移动。出料端为固定式滑履轴承。

The mill’s structure is double sliding shoe bearings. The feeding end can be designed as

movable sliding shoe bearings according to the actual operating condition. When the thermal

expansion and cold contraction happen to the barrel, the rotating unit can move axially. The

discharge end is fixed sliding shoe bearings.

滑履轴承各由两个托瓦在与垂直方向成 30°的角度上支承磨机的滑环。每一个托瓦

下部都装设有凹、凸球面体结构,凸球面体座落在凹球面体的球窝内,两者之间呈球面接

触,以便磨机回转时可以自动调位。进料端滑履整个托瓦通过球面体座落在托辊上,从而

可以在筒体热胀冷缩时,托瓦能随筒体回转部分作轴向移动。出料端的滑履轴承中靠滚环

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 7 of 48

上行侧的托瓦通过球面体座落在固定的支座上,以保证靠磨机传动端的滑履轴承具有定位

的功能。这种支承结构保证托瓦与滑环之间的良好接触。

Two pillows of sliding shoe bearings support slip rings of the mill on the angle of 30 ° with

the vertical direction. Each pillow is equipped with concave and convex spherical body

structure on the bottom side. The convex spherical surface body is located within the ball and

socket of the concave spherical surface body while the spherical contact is functioned between

these bodies. In this case, it is possible to execute the automatically location adjustment when

the mill turns around. The whole sliding shoe pillow of the feeding end locate on the support

roller through the spherical surface body so that it can make axial movement with the barrel

rotating unit when thermal expansion and cold contraction happen to the barrel. The pillows of

sliding shoe bearings in the discharge end which are near the up side of rolling hoop locate in

the fixed support to ensure sliding shoe bearings in the driving end of the mill having a locating

function. This kind of support structure guarantees the good contact between pillows and the

slip rings.

托瓦体为铸件,并敷设有轴承合金内衬。为了能形成油楔,托瓦的内径应比滑环的外

径略大。其表面粗糙度要求较高,因此在加工已符合设计要求的情况下,不需要刮瓦。托

瓦瓦面上设有油囊,使高压油由此进入托瓦与滑环之间形成一高压腔,顶起筒体后进行启

动和正常运转。

The pillow body is a casting piece and lies with bearing alloy lining. The internal diameter

of the pillow should be slightly larger than the outside diameter of the slip ring so that an oil

wedge is able to form. Since the surface roughness has high requirement, it is no need to do

pillow scraping as long as the machining process meets the design requirements. The pillow

surface has oil capsule, which enables the entrance of high pressure oil into the pillow and

forms a high pressure chamber between the pillow and the slip ring, lifting the barrel and then

operating startup and normal work.

滑履轴承设置带高压启动润滑装置,每个滑履轴承设置一套。高压润滑系统用于磨机

的启动、停机和盘车检修,即用静压的方法在各自的托瓦和滑环之间形成一层油膜,减小

磨机启动、停机时的摩擦力,同时避免磨机启动和停止时由于滑环线速度太低无法形成动

压油膜而烧毁托瓦合金面。每个滑履轴承润滑装置有两套高压供油系统,分别为两个托瓦

单独供油。低压润滑系统是由低压泵将输送至滑履轴承的两个油盘,其中一个油盘放置在

滑环的下方,另一个放置在一个托瓦的前面(旋转方向的前上方),滑环能在油盘里浸到

油,磨机转动后,油就被带至滑环与托瓦之间,从而形成动压润滑。每个滑履轴承润滑装

置有两台低压泵,其中一台工作,一台备用。

Sliding shoe bearings is set with high-voltage-started lubricating device, one set for each

sliding shoe bearing. High pressure lubrication system is applied for start-up, stop and repair of

the mill, namely, use the method of static pressure to form a layer of oil film between their

respective pillows and slip rings, reducing the mill start-up and shutdown friction and avoiding

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 8 of 48

burnout of pillow alloy surface because of the linear velocity of slip rings is too slow to form a

hydrodynamic oil film, which happens at the mill start and stop period. Each sliding shoe

bearing lubrication system has two sets of high pressure oil supply systems, supplying two

pillows separately. Low pressure lubrication system is the one that using low pressure pump to

transport two oil pans, one placed in the bottom of the slip ring and the other placed in front of

the pillow (upper front of the rotating direction) , to the sliding shoe bearings. Slip rings can dip

in oil in the oil pan. When mill rotates, oil is brought to the midst of the slip ring and the pillow.

So far, the hydrodynamic lubrication is formed. Each sliding shoe bearing lubrication device

has two sets of low pressure pumps, one for work and the other for spare parts.

在滑环两端的上行侧各安装一个刮油刷,以防润滑油外流,刮油刷由拉杆上的弹簧拉

紧,安装时可作调整,以便使刮油刷与滑环两侧贴合良好。

Both sides of the slip rings should be installed with an oil scraper brush to prevent

lubrication oil outflow. The oil scraper brush is strained by the spring on the rod, which can be

adjusted by the installation so that the oil scraper brush can well stick to both sides of the slip

rings.

为了防止磨机运转中托瓦温度过高,保证磨机正常运行,托瓦用水冷却,冷却水进口

在托瓦的最低点,出水通过管子和软管接头流至安装在轴承罩外的一个排水箱,由此排走。

同时也装有测温元件,直接监测其温度,便于监控。

In order to prevent the pillow from getting over temperature during the mill operation, and

to ensure the normal operation of the mill, water cooling shall be applied to the pillow. Cooling

water inlet is at the lowest point of the pillow. The water comes out through a pipe and a hose

coupling to the drainage box installed outside the bearing cover, and drains from here.

Temperature measurement devices are also installed for the direct and convenient monitor of the

temperature.

在每个滑环的上方设置一测温装置,装有测温元件,可以在磨机运转中随时监测滑环

的温度,它与主电机连锁,一旦温度超过规定值,可发出报警信号直至主电机停止运转。

Above each slip ring there is a temperature measuring device, equipped with temperature

measurement elements, which can monitor the temperature of the slip ring at any time during the

mill operation. Linked with the main motor, the temperature measuring device can send out the

alarm signal once the temperature exceeds the set value until the main motor stops running.

滑履罩壳由钢板焊接而成,上面设有检查孔,以便日常操作、维护、检查之用。滑履

罩下壳和底板间采用橡胶垫及密封胶密封,使用中应加强维护,防止漏油。

Sliding shoe cover is made of welding sheet steel with inspection hole for daily operation,

maintenance and inspection. Rubber pads and sealants shall be used between sliding shoe bottom

cover and base plate. Maintenance shall be strengthened during the operation to prevent it from

oil leakage.

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 9 of 48

4.3 回转部分 Rotation unit

回转部份是磨机的主要部体,物料就是在回转部分的筒体内进行粉碎、研磨而成的。

回转部分由筒体、隔仓板、出料篦板、衬板、端盖衬板、进料锥等组成。

Rotation unit is the main body of the mill. The material is pulverized and grinded in the

barrel of the rotation unit which is composed of the barrel, diaphragm plates, discharge grate

plates, liners, cover liners, and feed cones, etc.

4.3.1 筒体 Barrel

筒体是回转部分的重要部件,它由钢板卷制焊接而成,筒体进、出料端采用焊接式滑

环与筒体钢板焊接,滑环是筒体的两个支点,筒体是靠进出料滑环支撑在滑履轴承上;卸

料管是卸出物料的场所,成品从卸料管的卸料孔排出,同时卸料管也是磨体与减速机连接

部位。粗磨仓与细磨仓之间设有组合式隔仓板,出料端设有出料篦板,筒体内表面装有筒

体衬板和端部衬板。一仓设有一个人孔门,二仓设有两个人孔门,以供装卸研磨体、内部

零件更换及检修时工作人员出入之用。

Barrel is an important component of the rotation unit, made of welding steel plate roll. The

inlet and outlet ends of the barrel apply the welding structure that the slip rings are welded with

the barrel steel plates. Slip rings are the two fulcrums of the barrel and the barrel relies on the

support of the feeding and discharges slip rings and stays on the sliding shoe bearings.

Discharge pipe is the place where material is discharged like the finished product is discharged

from the hole of discharge pipe, and is the position where the mill and the reducer connect with

each other. There is a combined diaphragm plate between coarse grinding storehouse and fine

grinding storehouse. Discharge grate plate is set at the discharge end. The inner surface of the

barrel is equipped with barrel liner and liner ends. One storehouse has a manhole door and two

storehouses have two manhole doors for staff passing in and out under the grinding body

loading and unloading, internal parts replacing and examining condition.

4.3.2 隔仓板 Diaphragm plates

隔仓板由粗筛板、细筛板、支撑板、中心格栅和衬板组成。各块粗筛板径向和环向之

间留有缝隙,形成粗筛。粗筛板仅让磨碎的物料通过,挡住粗磨仓的研磨体及大料,故

能避免在其后的细筛板的直接磨损。磨碎的物料,迅速进入组合式隔仓板的分离室,在

不受球料压力的条件下,由细筛板进一步筛分,细筛板由多孔薄钢板制成,实际通过面

积比普通水泥磨的隔仓板大,对提高隔仓板的通过能力极为有利。细料通过细筛板由扬

料板送至细磨仓,不能通过的粗物料,受分离室内的扬料肋条和中心格筛的中心锥的作

用返回粗磨仓继续粉磨。

The diaphragm plate is composed of coarse sieve plates, fine sieve plates, support plates,

center grilles and liners. Leave gap between radial and circumferential direction of each coarse

sieve plate to form coarse sieve. Only milled material is allowed to pass through the coarse

sieve. The coarse sieve can block the grinding body and large material in the kibble storehouse

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 10 of 48

to avoid the direct wear of the subsequent fine sieve. Milled material gets into the separation

chamber of combined diaphragm plate in the condition without ball feeding pressure and they

are screened by the fine sieve. The fine sieve is made of porous thin steel plate with the

effective passage area larger than the diaphragm plate of common cement mill, which is

extremely favorable of improving the ability of passing through the diaphragm plate. Fine

material is sent to the fine grinding storehouse through the fine sieve plate by scatter plate.

Coarse material that can not pass through return to the coarse storehouse under the function of

scatter rib bars in the separate chamber and center cone of center grizzly for continue grinding.

4.3.3 出料篦板 Discharge grate plate

出料篦板由篦板、中心筛板、支撑架等组成。篦板为耐磨合金铸钢。磨细的物料通过

篦板缝隙进入出料仓,由起扬料作用的肋板将物料扬起送至卸料体而进入出料装置。

Discharge grate plate is composed of grate plates, center sieve plates, and support frames

and so on. The grate plate is made by wear-resistant alloy cast steel. Finely ground material

enters the discharge chamber through the gap of grate plate. The ribs with lifting function lift

the material and send it to the discharge body and enter into the discharge device.

4.3.4 筒体衬板 Barrel liner

筒体粗磨仓采用环沟阶梯衬板,细磨仓采用双阶梯分级衬板。在滑环处的衬板与筒体

间装有隔热垫,以减少对滑环的热影响。

The barrel coarse grinding chamber applies the ring groove ladder liner while the fine

grinding chamber applies the double ladder grading liner. To reduce the heat impact to the slip

ring, the heat insulation pad should be installed between liner at the slip ring and the barrel.

4.3.5 传动装置 Transmission device

传动装置包括主电动机、主电动机油站、主减速机、主减速机油站、慢驱动装置、膜

片联轴器、联轴器等,其详细介绍见各自的相关技术文件。

Driving device includes main motor, main motor oil station, main reducer; main reducer

oil station, low-speed driving system, diaphragm coupling, coupling, etc. Check relevant

technical documents respectively for more detail.

4.4 滑履轴承润滑装置 Sliding shoe bearing lubrication device

为了确保滑履轴承正常工作及筒体正常运转,必须建立高、低压润滑系统,该系统

由带双高压启动和低压润滑的稀油站及管路系统组成。高压系统用于磨机启动、停车和检

修,低压系统用于磨机正常工作时润滑。

It is necessary to establish high and low pressure lubrication systems to ensure the regular

operation of sliding shoe bearing and work of the barrel. The system consists of sparse oil

station with double high pressure start-up and low pressure lubrication and pipeline system.

High pressure system is for mill start-up, parking and maintenance and low pressure system is

for mill lubrication under the normal operation.

润滑装置的高压系统设置了两个电动高压泵分别为滑履轴承的两个托瓦单独供油,

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 11 of 48

高压系统的最大供油压力为 31.5MPa,流量为 2.5x2L/min。低压系统有两台低压油泵,其

中一台工作,一台备用,低压系统的供油压力为 0.6MPa,流量为 80L/min。

High pressure system of lubrication system set two dynamoelectric high pressure pumps

for oil supply to two pillows of sliding shoe bearing respectively. The maximum oil supply

pressure is 31.5MPa with 2.5x2L/min of flow quantity. Low pressure system has two

low-pressure pumps, one for work and the other for spare parts. Supply pressure of the low

pressure system is 0.6MPa with 80L/min of flow quantity.

其详细介绍见其相关的技术文件。

Check relevant technical documents for more detail.

润滑装置和主电动机设有联锁,即高、低压系统的参数达不到设定值时,主电动机无

法启动;运行时当高、低压系统或其它元件发生故障,参数达不到设定值时要报警,主电

动机应自动停车。

The lubrication system and main motor have interlocks. In this case, the main motor is not

able to start-up if the parameters of the high and low pressure system can not reach the set value.

During the operation, if the high and low pressure system or other components go wrong, and

the parameter can not reach the set value, give an alarm and automatically stop the main motor.

4.5 出料装置 Discharge device

出料装置主要由罩壳和支架等零件组成。罩壳由支架直接支承在地基上固定。内部装

有随筒体一起旋转的筛筒,以便筛出碎铁渣等杂物。出料装置的上罩壳设有排风口,下罩

壳设有出料口,出料口旁边还设有出渣口。

Discharge device is mainly composed of parts such as covers and brackets. The covers are

fixed directly on the groundwork supporting by the brackets. The inside is equipped with screen

barrel that rotates with the barrel in order to weed out the broken iron slag and other debris. Top

hood of the discharge device has air vent and bottom hood has discharge opening. Near the

discharge opening there is taphole.

4.6 滑履安装工具 Sliding shoe installation tool

滑履安装工具帮助用于滑履轴承安装时固定找正,为滑履轴承的顺利正确安装而推荐的

方法之一。

Sliding shoe installation tool helps fixing and aligning for sliding shoe bearing installation

and is one of the recommended methods for the successful and correct installation of sliding

shoe bearings.

5 安装要求 Installation Requirement

磨机的安装应按 JCJ03《水泥机械设备安装工程施工及验收规范》进行,并符合图纸

中的有关技术要求。

The mill installation should be in accordance with JCJ103 “Construction and Acceptance

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 12 of 48

Rules of Cement Machinery Equipment Installation”, and comply with the relevant technical

requirements of the drawing.

5.1 安装前的准备工作 Preparation work before installation

5.1.1 基础验收应严格按照《水泥机械设备安装工程施工及验收规范》中有关项目规定,

验收项目见表一:

Basic acceptance should be strictly in accordance with the related requirements in

“Construction and Acceptance Rules of Cement Machinery Equipment Installation”. See

table 1 for acceptance items.

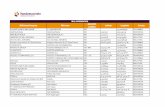

表一: 设备基础各部分的偏差

Table 1: deviation of equipment different basic parts

序号

Serial

No.

项目

Item

允差(mm)

Tolerance(mm)

1 基础座标位置(纵、横轴中心线)

Basic coordinate position ( vertical and horizontal centerline) ±20

2 基础各不同平面上的标高

Basic elevation on different planes 0

-20

3 基础上平面外型尺寸

Basic top surface shape dimension ±30

4 基础上平面的水平度

Level of basic top surface 每米 Per meter 5

全长 Total length 10

5 基础铅垂面的垂直度

Perpendicularity of basic vertical plane 每米 Per meter 5

全长 Total length 20

6 预留地脚螺栓孔

Reserved for anchor bolt hole

中心位置

Center position ±10

深度 Depth +20

0

垂直度/米

Vertical /meter 5

7 预埋地脚螺栓

Pre-buried anchor bolt

顶端标高

Top elevation +10

0

中心距

Center distance ±2

8 中心线间的距离

Distance between center lines 1

土建单位必须向安装单位和建设单位提供沉降观测点。基础验收合格后,对基础面铲

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 13 of 48

麻,以保证二次浇灌层的稳固性。

Construction party must provide settlement observation point to installation unit and

erection unit. After the basic checkout is qualified, shovel hemp the basic surface to ensure the

stability of the secondary pouring layer.

5.1.2 基础划线必须注意以下几点 Several points need attention for foundation marking:

u 设备基础放线前必须预埋中心标板,中心标板采用 10×200×100 钢板,在中心标板

上打定位基准点的记号。

Center standard plate must be pre-buried before marking equipment foundation. Center

standard plate is made of steel plate with 10 × 200 × 100. Mark the locating datum point on

the center standard plate.

u 用精密经纬仪根据定位基准点放出纵向中轴线(即磨体中心线),其精确度误差不超

过 0.5mm。

Use precision theodolite to release the longitudinal axis (namely mill centerline) according

to positioning reference point with precision tolerance less than 0.5mm.

u 按图纸尺寸(并复合实物尺寸)放出各条横向中心线。

Release all the transverse center line according to the dimension in the drawing (check the

real size of the item also).

u 基础放线测量:用水平仪核对纵向、横向定位中心标板的水平度及磨机两端支承基础

公共水平面。

Measure the foundation line. Check the level of the vertical and transverse locating center

standard plate as well as the foundation horizontal plane of supports at two ends of the mill

by a spirit level.

u 若因制造误差造成筒体进出料端滑环中心距与的理论中心距不一致时,则应以实际中

心距为准进行基础划线。

If center distance of slip ring in the discharge ends of the barrel is inconsistent with the

theoretical center distance, the actual centerline should be prevailed as the reference for

foundation marking.

5.1.3 检查筒体、滑履轴承、电动机、减速机等重要零部件的完好情况,如有损伤、变形

和尺寸误差,应在安装前采取措施进行处理合格,必要时修正相关的安装尺寸。

Check the condition of the important components such as barrel, sliding shoe bearing,

electromotor and reducer. Measures should be taken to repair any damage, deformation or

dimension error and ensure the qualified result before installation. Revise the relevant

installation dimension when necessary.

5.1.4 用清洗剂(如汽油等)将筒体滑环、筒体止口、滑履轴承、滑履轴承座及底座等零

件的重要配合表面的防锈漆及污物清洗干净,严禁携带污物进行安装。

Clean the anti-dust paint on the important cooperate surface of parts such as barrel slip

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 14 of 48

ring, barrel ended mouth, sliding bearing, sliding bearing chocks and base and dirt with a

cleaning agent (such as gasoline). No dirt should be allowed during the installation.

5.2 地脚螺栓的安装 Installation of anchor bolts

u 安装前,要除净地脚螺栓上的锈垢、油质等,检查地脚螺栓与相应的螺母配合是否良

好,并在螺纹表面涂上防锈油脂。

Clean all the dust and oil on the anchor bolts before installation. Check whether the fitting

of anchor bolts and nuts is good or not and coat anti-rust grease on the thread surface.

u 安装前地脚螺栓孔内不能有杂物,在安装过程中严防杂物掉入基础孔内。

No debris is allowed to be found in the anchor bolts before installation. Prevent debris from

falling into the foundation hole during installation.

u 安装地脚螺栓时,应使地脚螺栓垂直,其不垂直度允许误差为 1/1000。

Make the anchor bolts plump when install the anchor bolts. The tolerance out of the vertical

degree is 1/1000.

u 拧紧地脚螺栓时应对角进行,同时均匀施力,严禁拧紧一边再紧另一边的作法,在拧

紧螺母后还应复查一次,以确保所有的螺母都已拧紧。详细要求见附录 B。

Screw down the anchor bolts on the cross angle and use force evenly. The action of

tightening one side and then tightening the other side is prohibited. After screw down the

nuts, recheck once and make sure that all nuts have been tightened. Check appendix B for

more detail requirements.

5.3 滑履轴承的安装 Sliding shoe bearing installation

5.3.1 滑履轴承的安装准备 Preparation of sliding shoe bearing installation

u 对托瓦、凹凸球体、球体座等进行试组装,总的误差应在设计要求以内,并做好配对

标记。

Assemble pillow, concave and convex sphere, and the sphere seat for test. The total error

should be within the design requirements and matching mark must be made.

u 对托瓦的冷却水通道进行 0.63MPa的水压试验,时间为 20min,要求无渗漏现象。

Make water pressure test of 0.63Mpa to the cooling water channel of pillow for 20 minutes.

No leakage is allowed.

u 凹凸球体之间的接触面应均匀涂上二硫化钼;装配后要求接触良好,转动灵活,不得

有不同心的晃动。

Contact surface between the concave and convex sphere should be coated with

molybdenum disulfide. After assembly, the contact should be in good condition and flexible

rotation without eccentric shake.

u 检查轴承合金与托瓦体的铸合是否严密、牢固、不得有脱壳、裂纹、气孔等缺陷,特

别是在以油嘴为中心的 500×500mm的瓦面范围内不得有任何缺陷。

Check the casting connection between bearing alloys and pillows to see whether it is sealed

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 15 of 48

and firm without defects like shelling, crack, or pores, especially in the 500 × 500mm

range of tile surface regarding oil nozzle as the center.

5.3.2 滑履轴承底板的找正和灌浆准备

Alignment Sliding shoe bearing bottom plate and preparation of grouting

u 按图纸对轴承基础进行核对。一次基础面先只浇灌到比安装图上所示底板底面低

约 75mm处,其余的灌浆则要等到找正完成后进行。

Check the bearing foundation according to the drawing. First grouting of the foundation

surface can be grouted at about 75mm lower than underside of the base plate as shown in

the assemble drawing. The rest grouting can be carried on after the complete alignment.

u 根据滑环的实际尺寸及托瓦等的实际配对尺寸,对轴承底板的安装尺寸进行调整,必

须保证磨机中心线不变。

Adjust the assembly dimension of the bearing base plate according to the real dimension of

the slip rings and the actual fitting dimension of the pillows. The centerline of the mill must

be unchangeable.

u 开始找正时,根据磨机中心线位置检查基础图上所示的标高。

Start the alignment according to elevation shown in the inspection foundation drawing of

the mill centerline location.

u 用高标号水泥 1份、中砂 1份、适量水制作砂墩(见 JCJ03),在 20℃环境下进行 48h

加水养护后,方可进行设备安装。安装时将底板放在垫铁上。这些垫铁的布置应符合

图纸设计要求。

Use 1 share of high-grade cement, 1 share of middle sand and proper amount of water to

produce sand pier (see JCJ03). Install the equipment after watering conservation for 48

hours under the environment of 20 ° C. Put the base plate on the iron pillows during the

installation. The arrangement of these iron pillows should meet the requirements of the

design drawing.

为稳妥起见,在滑履轴承基础的 V形口中间,即两块底板的两内侧撑顶架及调节

螺钉,以防止底板下滑。

For the sake of security, support the middle of the sliding shoe bearing foundation of

the V-shaped mouth, top frames of both inner sides of two base plates, and adjust screws, to

prevent the base plate from sliding down.

进行找正,使底板中心线平行于磨机中心线,另一条中心线则垂直于磨机中心线。

用水准仪 3,直规尺 2及随磨机滑履轴承安装工具提供的 30°的测量块 1来找正,将

测量块按图一所示放在滑履轴承底板上,调整滑履轴承底板位置,保证所示的安装尺

寸偏差不大于 0.5mm。同时保证:

Carry on the alignment. Make sure that one centerline of the base plate is parallel to

the centerline of the mill, and the other centerline is perpendicular to the centerline of the

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 16 of 48

mill. Use water level 3, straight ruler 2 and 30 °measurement block 1 provided with the mill

sliding shoe bearing installation tool to find alignment. Put measurement block on the

sliding shoe bearing base plate according to Figure 1 and adjust the location of the sliding

shoe bearing base plate. Make sure the deviation of assembly dimension as shown is less

than 0.5mm. Meanwhile guarantee:

a. 滑履轴承底板在筒体轴线方向的水平度允差不大于 0.1/1000,两端底板对应点的

相对标高允差为 0.5mm,且不允许进料端低于出料端。

The tolerance of sliding shoe bearing base plate level in the barrel axes direction is no

more than 0.1/1000. The tolerance of the relative elevation of corresponding points both

ends of the base plate is 0.5 mm. No allowance of the lower feeding end than the

discharge end.

b. 两端滑履轴承底板纵向中心线不重合度不大于 0.5mm,横向中心线距离与两滑环的

实测中心距相差不大于 1mm,平行度允差不大于 0.5/1000。

The vertical centerline misalignment of the sliding shoe bearing base plates on both ends

is not more than 0.5mm. The difference of the transverse centerline distance and the

actual measured center distance of two slip rings is not more than 1 mm. The tolerance

of parallelism is not more than 0.5/1000.

最终找正后,安装连接底板与基础的双头螺柱,拧紧双头螺柱的螺母,再检查找正

情况,如无误将螺母拧紧到规定的扭矩。然后小心地对地脚螺栓进行二次灌浆,其

混凝土配料组成为 1份水泥对 2.5~3份沙子(颗粒规格 0.8mm)。

After the final alignment, install the studs connecting the base plates and the foundation.

Screw down the nuts of the studs and check the alignment condition. Tighten the nuts to

the specified torque if no error shall be found. Then carry on the secondary grouting of

anchor bolts carefully. The concrete ingredients include 1 share of cement to 2.5 to 3

share of sand (particle size 0.8mm).

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 17 of 48

图 1 Figure 1

5.3.3 滑履轴承托瓦的安装 Installation of sliding shoe bearing pillows

u 检查 Inspection

滑履轴承滑动面的内径设计成比磨机筒体外径环大,其表面粗糙度达到 Ra≤1.6

时,当达到加工要求时,一般不需要刮瓦。

The inner diameter of the sliding shoe bearing sliding surface is designed as a ring

larger than the outer diameter of the mill barrel. If the surface roughness reaches Ra ≤ 1.6,

and meets the processing requirements, generally scraping is not necessary.

将托瓦放在滑环顶上,用塞尺在托瓦两端头检查,滑环与托瓦的微小间隙约为

0.05~0.1mm(距托瓦端头边缘约 20mm),否则就需刮瓦,但只许在托瓦两端头最外边

20~50mm的区域进行,不能为增加接触面积而在其余面上刮瓦,理论上是滑环与托瓦

底线接触。

Put the pillow on the top of the slip rings. Check two ends of the pillow with plug

gauge. The slight gap between the slip rings and pillows is about 0.05 to 0.1 mm

(approximately 20mm from pillow’s end edge), otherwise scraping is needed. However, the

area of 20 to 50mm outside two ends of the pillow is allowed to do the scraping. Scrap on

the rest surface is not allowed though it can increase the contact area. In theory, the slip ring

contacts the bottom line of the pillow.

涂上薄薄一层标记色以检查在托瓦整个宽度上的良好接触。

1. Measurement block (provided with mill) 2. Ruler 3. Water level 4.iron pillow

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 18 of 48

Coat a thin layer of color markers to check the contact of the pillow in entire width.

将底板清理干净,并安装滑履罩的底盘,底盘与底板之间垫入橡胶密封垫。先涂

上进口 Aseal4803密封胶或乐泰公司的平面厌氧胶再装。

Clean the base plate and install the chassis of sliding shoe cover. Fill up the rubber

gasket between chassis and base plate. Install the items after coat the import 4803 sealant or

plane anaerobic adhesive sealant of Loctite Company.

u 安装 Installation

首先确认底板已认真清理,然后安装托辊、球体座及凹球体,安装时使用吊环螺

钉。

First, make sure the base plate has been seriously cleaned up. Then install the support

roller, the sphere seat and the concave sphere. Use swinging rings for installation.

轴承底板的十字中心线要对准中心标板,其偏差不得大于±0.5mm。

Cross centerline of the bearing base plate should be aligned to the center target plate.

The deviation should be not more than ± 0.5mm.

然后用随机提供的滑履安装工具安装已装入凸球体的托瓦。凸球体的球面必须坐

落在凹球体内,并能自由运动。用二硫化钼润滑剂来润滑球面。如是固定托瓦,则放

在滑环上行侧的固定支座上。

Then use the sliding shoe installation tool provided with the mill to install the pillows

which are installed into the convex sphere. The surface of the convex sphere must be located

in the concave sphere, and can move freely. Use molybdenum disulfide lubricant to

lubricate the sphere. If pillows are fixed, put them on the fixed support at top side of the slip

rings.

托瓦的位置及其倾斜度必须尽可能接近最终位置。用钢丝绳穿过托瓦最高端所拧

入的吊环螺钉将托瓦系住,让托瓦滑动面朝向中心。当磨机要放入滑履轴承时,在滑

环刚要与托瓦接触前,去掉系住的钢丝绳,以使磨机就位时便可进行自调。

The position and inclination of pillows must be as close to the final position as

possible. Put the steel wire rope through swinging ring screws on top end of pillows and tie

the pillows. Let sliding surfaces of pillows face towards the center. When sliding shoe

bearings get into the mill, and before slip rings touch pillows, remove the steel wire rope so

that the mill is in the right place and can be self-adjusting.

检查隔板是否能在槽内自由移位而不受制约。检查托辊是否能自由转动而无挤压

现象。

Check whether the spacer plate can shift in the tank free from any constraints. Check

whether the rollers are free to rotate without any extrusion phenomenon.

安装润滑泵站并对其进行机械和电气的连接,详见滑履轴承管路及润滑泵站供油

系统图。

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 19 of 48

Install lubricating pump station and finish its mechanical and electrical connections.

Check the drawing for sliding shoe bearing piping and the lubricating pump station fuel

supply system.

在找正期间必须能转动磨机。当转动磨机时,高压泵必须工作。因此在进行找正

前必须对润滑泵站进行试验认可。

The mill must be able to rotate during the alignment process. When the mill is

rotating, high pressure pump must work. Therefore, lubricating pump station must be tested

and proved to be qualified before the alignment.

5.3.4 筒体的找正 Barrel alignment

u 安放好筒体,使滑环进入滑履轴承,要记住松开托瓦。

Well place the barrel and let the slip rings enter into the sliding shoe bearing. Remember to

release the pillow.

u 在确认高压泵在转动磨机时已能正常工作后,再按如下步骤找正:

After confirm the high-pressure pump can work under the normal condition when the mill

rotates, take the alignment according to the following steps:

1) 在滑环上沿磨机轴向放一水准仪(0.1mm)并记录下水平偏差。

Put a spirit level (0.1mm) on slip rings along the mill axial direction and record the

horizontal deviation.

2) 将开启慢驱动使磨机转动 180°(高压泵必须在工作),再将水准仪放在滑环上,

并再次记录水平偏差。两次偏差的代数和必须为零,经确认找正数据正确无误。否

则,要再调整其滑履轴承,然后重复用水准仪测量(需再度反转磨机筒体 180°),

直到在所有的位置上得到满意的结果为止。

Open the slow drive so that the mill rotates 180 ° (high-pressure pump must be under

working condition). And then put the spirit level on the slip ring, and record the

horizontal deviation. The algebra sum of twice deviations must be zero. The alignment

data is correct through confirmation. Otherwise, further adjustment of the sliding shoe

bearings must be taken and then repeat the spirit level measurement (the mill barrel need

reverse 180 °again) until satisfied results could be found in all positions.

3) 用水平检测装置测量两个滑环上部相同部位达到同样的水平,可通过精调底板下的

斜垫铁在进行水平找正。磨机两端滑环的相对径向圆跳动公差为 0.2mm。

Use a level detection device to measure whether the same part of two slip rings can

achieve same level. Take horizontal alignment by fine-tuning oblique iron pillows under

the base plate. The relative radial circular run-out tolerance slip rings of mill both ends

are 0.2mm.

4) 检查底板定位是否正确,如果有误,必须进行重新校正。

Check whether the locating of the base plate is correct or not. If it is incorrect,

re-calibration must be done.

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 20 of 48

5) 用塞尺检查滑环与托瓦夹板之间的间隙,这个间隙必须不小于 0.15mm。

Use a feeler gauge to check the gap between slip rings and plywood of pillows. This gap

must be not less than 0.15 mm.

6) 用千分表检查滑环轴向跳动,此时磨机慢驱动在工作。如果总的轴向跳动超过测量

间隙,则有必要在托瓦侧面与夹板之间插入垫片。垫片厚度必须等于总轴向跳动加

上 0.15mm再减去测量间隙。

Check slip ring axial run-out with a dial gauge while the mill slow drive is at work. If

the total axial run-out exceeds the measuring gap, it is necessary to insert the gaskets

between the side of pillows and the plywood. Thickness of the gaskets must be equal to

the total axial run-out plus 0.15mm and then minus the measuring gap.

5.3.5 底板浇灌 Base plate pouring

u 开始进行浇灌前,清洗底板将与基础接触的部位,尤其要清洗掉油和油脂。

Clean the area where the base plate contacts the foundation before pouring, especially the

oil and grease.

u 小心地进行底板的浇灌,确保底板与一次基础之间的空穴填满水泥砂浆。用具有稳定

性能的特种水泥来浇灌,一直浇到底板周围全部下边缘以上 30~40mm处。

Carefully pour the bottom plate. Make sure that the cavity between the base plate and the

first foundation is filled with cement mortar. Use special cement with a stable performance

to pour until 30 to 40 mm above the bottom edge all around the base plate has been poured.

u 全面检查,确保无误。

Take comprehensive check to ensure nothing is wrong.

5.3.6 滑履罩及油管的安装 Sliding shoe covers and oil piping installation

u 安装油盘,利用调节螺母来找正油盘,使其边缘呈水平,并以滑环底边缘为基准校正

油盘高度,使滑环浸入油中 20mm。

Install the oil pan. Use adjusting nuts to align oil pan. Make sure the edge is horizontal, and

align the height of the oil pan according to the reference of slip ring bottom edge. Make slip

rings immerse into oil of 20mm.

u 连接至油盘和布油槽的内部循环管路,连接外油管至循环油泵,并连接冷却水管道。

Connect the internal circulation piping from the oil pan to fabric oil groove. Connect the

outside tubing to the circulation oil pump and the cooling water pipe.

u 滑履罩壳与基础底板相接触部分的安装,注意:在罩与底板之间及各罩壳段节之间的

密封垫安装时,密封垫上应涂上乐泰公司生产的震动性平面厌氧系列胶。然后清理底

板,并对滑履罩壳进行吸尘处理,并用煤油检查密封情况,注意不要用水检查。

Install the contact area of sliding shoe covers and foundation base plates. Pay attention to

the installation of the gaskets between covers and base plates and each cover section. The

gaskets should be coated with vibratility plane anaerobic adhesive sealant series produced

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 21 of 48

by Loctite Company. Then clean the base plates and clean the sliding shoe covers with the

cleaner. Check the sealing condition of the kerosene. Be careful not to use water for check.

滑履罩壳是由几个形状基本相同的罩壳段节组成,通过法兰及密封垫用螺栓相

连。

The sliding shoe cover is composed of several cover section with similar shape

connected by flanges and bolts for sealing pad.

安装滑履罩壳时,要找正好各个罩壳段节。使滑履罩壳与滑环密封面之间的径向

间距须相等。在安装滑履罩壳顶部时,应在滑环表面淋上润滑油。安装 L形密封圈,

应使密封圈与滑环在圆周上均匀接触,并在两侧涂上密封胶。固定 L形密封圈的螺钉

安装时需要涂乐泰公司的螺纹紧固剂进行防松处理。

Align each cover section when install the sliding shoe covers. The radial spacing

between the sliding shoe covers and slip ring sealing surface shall be equal to each other.

When install top of the sliding shoe cover, lubricating oil should be poured on the surface of

the slip ring. Install the L-shape sealing ring and ensure the evenly contact of seal ring and

slip ring on the circumference and coat sealing sealant on both sides. Coat thread fastening

agents of Loctite company when install the bolts for fixing L-shape sealing ring for locking

processing.

u 安装低压润滑油的管道到滑履罩壳上方某位置的接口。

Install the joint from low-pressure lubricating oil pipeline to top location of the sliding shoe

cover.

u 安装油流信号器电控部分,必须将循环油泵出故障时油流信号器发出油量不足信号或

断油的信号传送到控制室(详见其滑履轴承润滑装置的说明书)。

Install electric control part of the oil flow signal. The signal of cycle oil pump oil flow

failure and fuel shortage or oil-break signal must be emitted to the operator’s room. (Check

the sliding shoe bearing lubrication device instruction for detail).

启动高、低压泵站,将滑履轴承的油盘和布油槽注满油,同时确认托瓦上的高压

油压力正常,才能启动磨机。

Start high and low-pressure pump station. The oil pan and oil groove of sliding shoe

bearing are filled with oil. Meanwhile, confirm the high pressure oil on pillow is normal.

Then start the mill.

磨机运转后,将润滑泵站停机,检查油流信号器是否能使控制室自动停磨(检查

是否达到自锁要求)。而且保证在油流信号器发出油流正常信号后,才能重新启动磨

机电机。

After the mill operates, stop the lubrication pump station. Check the oil flow signal to

see whether it can cause automatically stop the control room from grinding (Check whether

it meet the requirements of self-locking). Make sure restart the mill motor after the oil flow

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 22 of 48

signal emits the normal signal.

5.3.7 滑履轴承的冷却系统安装 Installation of sliding shoe bearing cooling system

按照管路系统图及零部件表安装冷却水管道。将三通旋塞阀安装在进水口,以保

证在关闭通向轴承冷却水的同时,接通下水道,从而使轴承内的水可以排净,以免轴

承遭霜冻损坏。

Install the cooling water pipes according to the piping system drawing and components

and parts list. The three-way stopcock should be installed in the inlet to make sure shutting

down the bearing cooling water and at the same time connecting to the sewer so that the

water can be drained out from bearing which avoids bearing damage from frost.

5.3.8 滑履轴承的刮油刷安装 Installation of the sliding shoe bearing oil scraping brush

在滑环两托瓦上行部的旋出端两侧各安装一个刮油刷,以避免向外泄漏。将两个

刮油刷拉向滑环的弹簧必须能产生 0.4kg的拉力压在滑环的侧面上,假如不能,就必

须加以调整,以使能获得必要的拉力。

Install an oil scraping brush on both sides of revolve out ends on the pillows of two

slip rings to prevent from leaking out. Springs drawn two scraping brushes to the slip rings

must be able to generate 0.4kg tensile pressure on the side of the slip rings. If it can’t, it

must be adjusted in order to acquire the necessary tension.

5.3.9 安装时需注意的问题 Problems require attention during installation

u 滑履轴承的冷却水系统安装完毕后须进行 0.63MPa的水压测试,时间为 20min,托瓦

及管路联接处均不得有渗漏现象。润滑管路进行油循环和油压试验,压力为工作压力

的 1.25倍,时间为 15min,要求无渗漏现象。

Hydraulic pressure test of 0.63MPa shall be done after the complete installation of sliding

shoe bearing cooling water system for 20minutes. No leakage is allowed at the pipe

connection and pillows. Take the Lubricant oil circulation and hydraulic test pressure of the

lubricating pipeline. The test pressure is 1.25 times of the working pressure. The test lasts

15 minutes. No leakage is allowed.

u 组装后的高压油路必须进行不小于 32MPa的油压试验,保压时间不少于 10min。

特别提示:滑履轴承的托瓦安装时,在对高压油路试验好后(安装筒体前),须取出

托瓦高压油囊(油管封口)中的螺塞。

The oil pressure test not less than 32MPa must be carried out to the high pressure oil

pathway after the assembly. The dwell time is not less than 10min.

Special Notice: When install the pillows of sliding shoe bearing, after the test of the high

pressure (before install the barrel), the oil plug shall be moved out of the high pressure oil

capsule (tubing sealing) of the pillow.

u 轴承中刮油刷及淋油管的位置均与磨机运转方向有关,安装时请注意。另外,对与滑

环贴合的刮油刷面应修磨光滑、并使贴严。

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 23 of 48

The location of oil scraping brush and oil shower pipe in the bearing are all related with the

mill rotation direction. Please pay attention during the installation. In addition, the surface

of the oil scraping brush and slip ring should be grinded smoothly and firm.

u 轴承中的冷却水道要求畅通,不得使用未经处理的水源。

Cooling water pipeline of bearing should be expedited. The untreated water supply is not

allowed to use.

u 排水管下水位置、其余水管及水漏斗由使用单位自行配置。

Launching position of the drainpipe, the rest pipes and the water funnel are equipped by the

user. 5.4 回转部分的安装 Installation of the rotation part

5.4.1 筒体为超大超重件,安装时应特别注意起吊安全。

The barrel is a oversized parts. Pay special attention to the lifting security during

installation.

5.4.2 筒体衬板的安装要求见附录 A。

Check appendix A for installation of barrel liner.

筒体的隔仓板安装(参见隔仓板部件图及衬板布置图)

Installation of barrel diaphragm plate (Check diaphragm plate components drawing and

liner layout drawing)

5.4.3.1 隔仓板的安装准备 Preparation of diaphragm installation

彻底清扫安装部位的筒体内表面,除去灰尘、铁锈和残油。在安装操作时,用同

样的方法清洗所有的组件,注意清洗所有的接触面并除去所有的毛刺和表面疤疵。

Clean the barrel inner surface of installation part thoroughly. Remove dust, rust and

residual oil. Clean all the component parts with the same method. Pay attention to all the

contact surfaces and remove all the burs and surface scars and defects.

5.4.3.2 固定块的安装 Installation of fastening block

u 检查接触面上有无毛刺和疤疵。

Check the contact surface to see whether there are any burrs and scar defects.

u 用环氧树脂胶把橡胶板粘在固定块凸肋的一侧。

Stick rubber plate to the protruding rib side of the fastening block with epoxy resin glue.

u 用螺栓将固定块紧固到磨机筒体上,保证固定块与筒体贴合良好。

Use bolts to tighten the fastening block to the mill barrel and make sure the fastening block

has good joint with the barrel.

5.4.3.3 支撑板和前板的安装 Installation of support plate and front plate

u 清除支撑板和前板上与固定块接触面的铁锈、毛刺和疵点,以使其接触良好。

Remove rust, burrs and defects of the contact surface on the support plate and the front

plate with the fastening block to make them in good contact.

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 24 of 48

u 用八根Φ30钢棒(两端车制螺纹)穿过支承板、扇形固定块、前板,钢棒两端用螺母

固定,以防滑脱,见图二。八根Φ30钢棒圆周方向均匀分布。

Use eight Φ30 steel bars (thread cutting on both ends ) getting through the support plate,

the sector fastening block, and the front plate. Fix two ends of steel bars with nuts to

prevent of slipperiness. Check Chart 2. EightΦ30 bars distribute at the circumferential

direction evenly.

u 在各处分别装好钢棒、确保安全后,方可卸掉支撑板、前板与筒体之间的连接螺栓。

将临时固定用的固定板割去,绝对不能割到筒体,并将筒体处打磨光滑。然后把支撑

板、前板沿钢棒滑向固定块。

Install steel bars at every area and ensure safety. Then, the connecting bolts between

support plate, front plate and barrel can be dismantled. Cut the dead plate for temporary

fastness. The barrel shall absolutely not be cut into. Polish the barrel surface smoothly.

Slide the support plate and the front plate to fastening block along the steel bars.

u 用螺栓、螺母将支撑板、前板与固定块连接固定好,见图三。拆掉八根Φ30钢棒,安

装剩余的螺栓、螺母。

Fix the support plate and front plate with the fastening block by using bolts and nuts. See

Chart3. Dismantle eightΦ30 steel bars and install the rest bolts and nuts.

5.4.3.4 后板的安装 Installation of backboard

中心后板为两片式结构,拼装成圆环形,嵌入前板和支撑板的相关部位,经交叉

逐步拧紧后,再点焊死。

Center backboard is of two-piece-structure which assembled into a round circle. It is

embedded into the relevant parts of the front plate and the support plate and tightened

gradually through crossing, and then spot welded firmly.

5.4.3.5 中心架和中心筛板的安装 Installation of center frame and center sieve plate

u 中心架的安装 Installation of center frame

1) 按图纸要求,把中心筛板置于中心架和后板之间。

Front plate Sheet support

Chart 2

Fastening block

Chart 3

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 25 of 48

Put center sieve plate between center frame and backboard according to the drawing.

2) 用螺栓和螺母在中心线处,把中心架、中心筛板和后板临时固定。

Temporarily fix the center frame, the center sieve plate and the backboard with bolts and

nuts at the centerline.

3) 调整中心架、中心筛板和后板的紧固螺孔,在螺钉的螺纹上涂厌氧胶并装上弹簧垫

圈,固定中心架、中心筛板和后板。

Adjust the fastening screws of center frame, the center sieve plate and the backboard.

Coat threads on the screws with anaerobic adhesive sealant and install spring washers.

Fix center frame, center sieve plate and backboard.

4) 按图纸要求把两个半中心架焊接成一体。

Weld two half center frames into one piece according to the drawing.

u 筛板的安装 Installation of sieve plate

1) 清洗筛板,同时检查其平直度,为了确保筛板与前板的贴合,若有变形,应给予校

平整。

Clean sieve plate and check the flatness at the same time. Make sure the sieve plate is in

good contact with the front plate. If any deformation happens, proofread the flatness.

2) 用压条、压块和螺钉把筛板固定在前板上,然后检查筛板上孔能否与支撑板、前板

上连接粗筛板、扇形衬板的螺栓孔相对齐。螺钉的拧紧及放松同上。

Fix the sieve plate to the front plate with layering, briquetting and screws. And then

check whether the holes in the sieve plates are in line with bolt holes in the support plate,

the front plate connected with coarse sieve plate and sector liner. Bolt fastening and

loosening are the same as the above.

5.4.3.6 粗筛板和扇形衬板的安装 Installation of coarse sieve plate and sector liner

u 前板上的粗筛板和支撑板上的扇形衬板由贯穿螺栓连接,装后不允许倾斜、晃动。

The throughout bolt connects the coarse plate on the front plate and sector liner on the

support plate. No tilt or shake is allowed.

u 安装时,应尽量保证粗筛板、扇形衬板的环向和纵向间隔相等。

During installation, try to guarantee the gap of circumferential and longitudinal direction of

coarse plate and sector liner is equal.

u 粗筛板和扇形衬板的连接螺栓在安装时应能在孔内自由移动,并要求分别与粗筛板和

扇形衬板垂直,然后紧固螺栓,紧固时,要用锤子轻轻敲击螺栓,同时拧紧螺栓。

The connecting bolts of coarse sieve plate and sector liner should be installed in the hole

and can move freely and is perpendicular to coarse sieve plate as well as sector liner

according to the requirements. Tighten the bolts and use a hammer to gently knock the bolts

at the same time.

u 然后,螺栓按附录 A中紧固力矩表的要求拧紧到规定的值。

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 26 of 48

After that, tighten the bolts according to the requirements of tightening torque table in

Appendix A to the specified value.

5.4.3.7 重新拧紧粗筛板和扇形衬板的螺栓

Retighten bolts of the coarse sieve plate and the sector liner

u 所有连接粗筛板和扇形衬板的螺栓都需要重新拧紧。

Re-tighten all bolts connecting the coarse sieve plate and sector liner.

u 起动两小时以后进行第一次重新拧紧,然后每隔 2小时再重新拧紧一次,直到规定的

扭矩保持不变。然后将螺母和螺栓点焊死。

Retighten for the first time after start for two hours. Then tighten once every two hours until

the specified torque remains unchanged. All the nuts and bolts should be welded firmly.

5.4.3 出料篦板的安装 Installation of discharge grating plate

5.4.4.1 安装准备 Installation preparation

彻底清扫安装部位的筒体内表面,除去灰尘、铁锈和残油。在安装操作时,用同

样的方法清洗所有的组件,注意清洗所有的接触面并除去所有的毛刺和表面疤疵。

Clean the barrel inner surface of installation part thoroughly. Remove dust, rust and

residual oil. Clean all the component parts with the same method. Pay attention to all the

contact surfaces and remove all the burs and surface scars and defects.

5.4.4.2 承架的安装 Installation of bearing frame

先用回转部分中序号 27螺钉(共 12件)来作径向调整,由两圈共 18件 GB11的

螺栓连接到腹板上(并使 3圈装衬板的孔都对准)并予以固定。

First take radial adjustment with No. 27 screws (totally 12 pieces) in the rotation part.

Totally 18 pieces two rings of GB11 bolts are connected to the webs (aligning holes of three

rings liner correctly) and fixed.

5.4.4.3 扇形衬板的安装 Installation of sector liner

按 5.4.3.6和 5.4.3.7的要求进行。

Carry on according to the requirements of 5.4.3.6 and 5.4.3.7.

5.4.4 所有装在筒体内部的螺母应在负荷试车中反复拧紧后再点焊牢固,以免运转中脱落。

All nuts installed inside the barrel should be tightened repeatedly in the loading test and

spot welded firmly to avoid breaking off during the operation.

5.4.5 其余安装要求见回转部图纸及图中技术要求。

Check rotation part drawings and technical requirements for the rest installation

requirements.

5.5 进料装置的安装 Installation of feeding device

由于磨机进料端为磨体温度升高后筒体膨胀的游动端,所以进料装置安装时应保

证筒体有足够的热膨胀空间,一般可按两滑环中心距的 1.5‰考虑。

Since the mill feeding end is the travelling end of inflatable barrel after the mill

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 27 of 48

temperature rises. Therefore, it is a must to guarantee there is enough thermal expansion

space in the barrel when install the feeding device. Generally consider it according to 1.5 ‰

center distance of two slip rings.

5.6 出料装置的安装 Installation of discharge device

按附图 K4536.5.0SM出料装置中的有关要求。

Follow related requirements in attached drawing K4536.5.0SM feeding device.

5.7 润滑装置安装 Installation of lubricating device

u 所有油、水管件在安装前要求清洗干净,方法是:用 20%的硫酸或盐酸溶液进行冲洗,

在冲洗过程中应随时观查,当铁锈被清除之后,再将管子浸在 3%的石灰水溶液中 1~

2 小时使其中和,然后再用清水冲洗,并用压缩空气(不能用氧气)吹干,最后在管

子里注入润滑油,以防再次生锈,同时将管子两端堵严,以防进去脏物。上述操作应

连续进行。

Clean all oil and water pipe before installation. The method is using 20% sulfuric acid or

hydrochloric acid solution to wash. Investigate from time to time during the washing

process. When the rust has been cleaned out, immerse the pipe into 3% lime water solution

for one to two hours to neutralize, and then rinse them with water, blow to dry with

compressed air (not with oxygen), and finally fill lubricating oil into the pipes to prevent

them from getting rust again. Block both ends of pipes from the dirt. The operation should

be carried out continuously.

u 各润滑油站应在其润滑点附近就近安装,其管路系统,应按现场和油站实际情况进行

配置,为保证回油通畅,回油管斜度应大于 1:10。

Install the lubricating oil station near the lubrication points. The piping system should be

equipped according to the actual situation of the site and oil stations to ensure smooth oil

return and the inclination of return pipe should be greater than 1:10.

u 按用户外购的其有关技术文件及图纸资料进行。

Carry on according to the relevant technical documents and drawings purchased by the user.

5.8 磨机传动装置的主电动机、主减速机、辅助传动和电器控制设备的安装分别按用户外

购的其有关技术文件及图纸资料进行。

Installation of main motor, main reducer, auxiliary transmission and electrical control

equipment for mill driving device shall follow the relevant technical documents and

drawings purchased by the user.

5.9 对筒体衬板及滑履轴承内的刮油刷等均有方向性的零件,安装时要特别注意与磨机回

转方向的关系。

To parts of the barrel liner and the oil scraping brush inside the sliding shoe bearing which

have the direction requirement, special attention should be paid to the mill rotation direction

during installation.

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 28 of 48

5.10螺栓、螺母安装要求及紧固力矩见附录 B。

Check Appendix B for installation requirements of bolts and nuts and tightening torques.

6 试运转 Commissioning

磨机安装完毕并检查合格或大修后,都要进行试运转,试运转按下述步骤进行。

Test run should be carried out after the qualified inspection of the mill installation or

overhaul. Test run should be carried out according to the following steps.

6.1 试运转前的准备工作 Preparation before test run

1) 检查所有润滑油路是否已安装好。

Check whether all the lubrication pipelines are assembled.

2) 按图纸要求,向两个滑履轴承、主电动机轴承和减速器内注入适量正确牌号的润滑

油。润滑油牌号按附录 C。

Fill proper amount of lubricating oil with correct trademark in two sliding shoe bearings,

main motor bearings and reducer according to the drawing requirements. Check Appendix

C for lubricating oil trademark.

3) 按油站技术文件要求,向各润滑油站油箱内注入适量正确牌号润滑油。润滑油牌号

按附录 C。

Fill proper amount lubricating oil with correct trademark in each oil tank of oil station

according to technical documentation requirements. Check Appendix C for lubricating oil

trademark.

4) 润滑油的正确选择是保证磨机正常运转并提高其使用寿命的重要保证,故在加入润

滑油之前,应检查润滑油合格证上的牌号、标准号及粘度值等技术指标是否符合附

录 C的要求。

The right choice of lubricating oil is an important guarantee to ensure the normal

operation of the mill as well as improvement of operation life. Therefore, technical

guideline such as trademark on the lubricating oil certification, standard number and

viscosity value should be checked before fill in the lubricating oil to see whether they are

complying with the requirements of Appendix C.

5) 磨机启动前,先试开启各润滑系统和高压启动装置,检查其是否有异常振动、漏油

现象,油量是否符合要求,洒油是否正常;磨机主体是否能够浮升,回油情况是否

良好;各个机构运转是否正常。

Before the mill starts, try to open the lubrication system and high pressure starting device

first to check whether there is abnormal vibration or oil leakage; whether oil quantity

meets the requirements and the oil besprinkle is normal; whether mill body can float up

and oil return is good; whether each machine can operate properly.

6) 冬季试运转时,试运转前应将各个部分润滑油加热,以免油凝而影响设备正常运转。

If the test run happens in winter, heat up the lubricating oil in advance in order to avoid the

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 29 of 48

oil solidification affecting the normal running of equipments.

7) 对冷却水系统进行检查,通水是否畅通,管路有无漏水、渗水现象。对于滑履轴承

的冷却水管道,在装配后应进行 0.5MPa的水压试验,时间为 10分钟,不得有渗漏

现象,尤其处于轴承内部的接头必须严密可靠。

Check the cooling water system to see whether water runs smoothly, pipelines are without

leakage or water penetration. For cooling water pipelines of sliding shoe bearing, take

0.5MPa hydraulic test after assembly for 10 minutes. No leakage is allowed. Especially

joints inside the bearing must be sealed and reliable.

8) 所有润滑系统管道安装完毕后,应进行油循环和油压试验,试验压力为工作压力的

1.25倍,时间为 15分钟,不得有渗漏现象发生。

After all the lubrication piping system has been installed, oil circulation and oil pressure

test should be performed with the test pressure of 1.25 times working pressure for 15

minutes without the leakage.

9) 检查所有具有方向性的零件是否符合安装要求。

Check whether the directional parts meet the installation requirements.

10) 检查所连接螺栓及地脚螺栓是否均已拧紧。

Check whether all the connecting bolts and anchor bolts are tightened.

11) 各密封部位要密封良好,不准出现金属间的摩擦。

All the sealing parts must be sealed well without friction between metals.

12) 电动机及控制系统、仪表、照明、信号装置应完整良好。

Motor and control system, instruments, lighting, signal device should be complete well.

13) 所有附属设备应运转正常。

All the auxiliary equipments should run normally.

14) 料仓内物料要有足够的储备量。

Material warehouse should have enough material reserves.

15) 在试运转前,作好以下测量记录:沉降观测点标高、磨机中心线的位置及减速机底

板的高度。

Before commissioning, record the following measurements: elevation of settlement

observation point, the position of mill center line and height of reducer base plate.

16) 试运转时,操作人员均应在安全地区;设备内部不应有遗留杂物;设备周围无妨碍

运转的物件。

During the commissioning, the operators shall stay in the safety area. No sundries

should be left over inside the equipment. Any workpiece disturbed the operation of

equipment is not allowed to be placed around it.

6.2 空负荷试运转 Empty load test run

凡是新安装完毕并检查合格的磨机,都应进行空负荷试运转。

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 30 of 48

Empty load test run should be carried out after the qualified inspection of the mill.

1) 在空负荷试运转之前,先开动润滑系统(包括主电动机及减速系统装置的润滑)及

高压启动系统,使筒体浮升并有润滑油进入磨擦副。

Start the lubrication system (including the lubrication of main motor and reducer system

devices) and high pressure starting system before the empty load test, making the barrel

float and the lubricating oil enter into the friction pair.

2) 开动慢速驱动装置,慢转筒体 1~2转,要求无碰撞及妨碍正常运转之处,然后停

磨,将慢速驱动离合器脱开到位,最后开动主电动机。

Start the slow driving device. Slowly rotates the barrel for one to two turns without

collision and distribution of normal operation according to the requirements. Stop

grinding and disconnect slow driving clutch. Finally start the main motor.

3) 开动主电动机后进行空负荷运转(不装研磨体,不喂入物料),保证筒体正确的旋

转方向,严禁反转。空负荷转动 1小时,在此期间应进行检查并符合下述要求:

Operate the empty load running after start the main motor (without the grinding body or

feeding material) to ensure the correct rotation direction of the barrel. No reverse is

allowed. Rotate with empty load for an hour. Give inspection during this period and

meet the following requirements:

a. 电动机电控系统启动、运行和各部位联锁装置的工作正常;

The startup, operation and interlocking devices of each part in the motor electric control

system are working normally;

b. 各部位的润滑装置及冷却系统的工作正常,各个监视检测仪表反应正常;

Lubricating devices of each part and cooling system are working normally. Each

monitoring testing instrument reacts normally;

c. 各润滑点的温度正常;

Temperature of each lubricating point is normal;

d. 磨机运转应平稳,减速器、电机不应有不正常的振动和噪音;

The mill rotation should be stable. Reducer and motor are without abnormal vibration

and noise;

e. 衬板以及各转动零件无松动;

Liners and rotating parts are without loosening;

f. 所有润滑系统,水冷却系统均不应有漏油、渗油现象和漏水、渗水现象。

All lubrication system and water cooling system should not have oil leakage or oil

seepage, water leakage or water seepage.

一旦发现上述各项有问题时,应立即停车检查、调整,处理。

Once the above issues are found, stop the mill at once for inspection, adjustment and

treatment.

4) 在空负荷试运转期间,高压润滑系统不准停止运行。

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 31 of 48

During the empty load test run, the high pressure lubricating system is not allowed to

stop running.

6.3 负荷试运转 Load test run

在空负荷试运转确认无问题后,方可进行负荷试运转。

After the empty load test run is confirmed to be out of question, the load test run can be

performed.

1) 负荷试运转前,先开动粉磨系统的其它附属设备。

Before the load test run, start other auxiliary equipment of powder grinding system first.

2) 负荷试运转应按逐步加载程序进行,并在加载的同时喂入相应量的物料。

Load test run should be performed gradually according to the loading program, and feed

the material of relative amount at the same time.

a. 装入研磨体额定负荷量的 30%,运转 24小时;

Put in 30% rated load of the grinding media. Run for 24 hours.

b. 装入研磨体额定负荷量的 50%,运转 72小时;

Put in 50% rated load of the grinding media. Run for 72 hours.

c. 装入研磨体额定负荷量的 75%,运转 120小时;

Put in 75% rated load of the grinding media. Run for 120 hours.

d. 按 100%额定负荷量装入研磨体,连续运转 96小时。

Put in 100% rated load of the grinding media. Run for 96 hours continuously.

3) 负荷试运转期间,除按空负荷试运转规定的有关内容检查外,还应检查电动机的电

流波动是否正常;电动机电流不得超过额定值,否则应适当减少装载量;各处螺栓

有无松动;检查进料及出料装置是否有漏料、漏灰现象;检查各处密封情况是否良

好,轴承温度不应超过设定值。

During the load test run, in addition to the relevant inspection according to the empty

load test run, the inspection of whether the motor current fluctuation is normal should

also be taken. The motor current shall not exceed the rated value; otherwise the loading

capacity should be reduced appropriately. Check whether bolts here and there are

loosening or not. Check whether feeding device and discharge device have material

leakage or ash leakage problem. Check whether airproof condition is good or not. The

bearing temperature should not exceed the set value.

4) 在各负荷试运转期间,一旦发现不正常情况时,应立即停止运转,并进行处理。

During the load test run, the running must be stopped immediately once the abnormal

condition occurs and treatment should be taken.

6.4 对传动部分、滑履轴承润滑装置以及电控部分等配套件,请按其各自的技术文件进行。

Conduct according to the respective technical documents to match parts such as the

transmission parts, sliding shoe bearing lubrication device and electric control parts.

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 32 of 48

7 操作、维护及检修 Operation, Maintenance and Repair

7.1 操作 Operation

磨机经试运转并鉴定合格后,才能正式投入生产。生产中磨机应有专人操作,操

作人员应熟悉掌握磨机的主要结构、设备性能及操作要点。

The mill can be put into use after the test run and qualified inspection. The mill should

be operated by special person. The operators should be familiar with the main structure of

the mill, equipment performance and operation points.

7.2 磨机的启动 Mill starting

磨机及其附属设备的启动顺序如下:

The starting order of the mill and its auxiliary equipment is as follows:

a. 滑履轴承的高低压润滑装置及传动装置的润滑系统,冷却系统;

Lubrication system of high and low pressure lubrication devices and driving devices of

sliding shoe bearings and cooling system;

b. 收尘器、选粉机及其出料输送设备;

Dust collector, powder separator and its discharge conveyer equipment;

c. 磨机出料输送设备;

Mill discharge conveyer equipment;

d. 磨机主电动机(筒体旋转);

Mill main motor (barrel rotation);

e. 喂料系统。

Feeding system;

f. 磨机正常运转后,可停止滑履轴承的高压润滑装置。

After the mill runs normally, high pressure lubrication system of the sliding shoe bearings

can be stopped.

7.3 磨机的运转 Mill operation

磨机运转时应注意以下事项:

Attention should be paid to the following during mill operation period:

a. 没有喂料时,磨机不能长时间运转(一般不超过 15分钟),以免损伤衬板和消耗钢

球;

Mill can not run for a long period of time (usually not more than 15 minutes) without

feeding material so as not to damage the liners and consume steel balls;

b. 均匀喂料是磨机获得稳定高产的重要条件之一,磨机操作人员应根据工况精心调整

喂料量;

Feeding material evenly is one of the important conditions for the mill to obtain stable

production. The mill operator should adjust material feeding quantity according to

conditions carefully;

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 33 of 48

c. 应根据物料的水份及时调整入磨的风量和风温;

Adjust air flow and blast temperature according to the moisture of the material in a

timely manner;

d. 严格控制入磨物料的粒度与水份,粒度和水份不能超出设计要求;

Strictly control particle size and moisture of the material getting into the mill. The

particle size and moisture can not exceed the design requirements;

e. 根据工况要求调整研磨体级配,及时向筒体内补充研磨体,使研磨体的装载量和级

配始终保持在最佳状态

Adjust grinding body gradation according to working conditions, supply the grinding

body into the barrel in a timely manner and keep the loading capacity and gradation of

grinding body always in the best condition;

7.4 紧急停磨 Emergency mill stop

当磨机在运转中发生下列异常情况时,应与有关岗位联系,按规定顺序停磨,检

查原因,排除故障:

When following unusual circumstances occur during the mill operation, contact the

relative post, stop the mill in a specified order, and check the reason and get rid of the

trouble:

a. 滑履轴承润滑或冷却系统发生故障,轴瓦温度超过设定值(60℃)并继续上升时;

When sliding shoe bearing lubrication or cooling system fails, and the bearing

temperature exceeds the set value (60 ° C) and continue to rise;

b. 联接螺栓发生松动、折断或脱落时;

When connecting bolts become loosen, broken or dropped off;

c. 磨机内机件脱落时;

When the parts inside the mill drop off;

d. 隔仓板或出料篦板孔堵塞而影响生产时(即停止喂料系统,再视情况而定);

When the diaphragm plates and discharge grate plates affect production because of

clogging in holes (stop feeding system immediately and decide according to the

condition);

e. 减速器及其润滑系统的异常情况出现时(详见减速机及其润滑系统有关文件);

When the reducer and its lubrication system have abnormal situation (check relative

documents of reducer and its lubrication system for detail);

f. 电动机及其润滑系统的异常情况出现时(详见电动机及其润滑系统有关技术文件);

When the motor and its lubrication system have abnormal situation (check relative

documents of the motor and its lubrication system for detail);

g. 如果磨机在运转中突然停电时,应立即将磨机及其附属设备的电动机电源切断,以

免来电时发生意外事故。

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 34 of 48

If the power off occur during the mill operation, switch off the power of mill and its

auxiliary equipment in case of the accident happens when the power is back.

7.5 停磨顺序 Mill stop sequence

a. 喂料系统;

Feeding system

b. 主电动机;

Main motor

c. 磨机出料输送系统;

Mill discharge conveyer system

d. 收尘系统、选粉机;

Dust collection system, powder separator

e. 收尘系统的出料输送设备;

Discharge conveyer equipment of dust collection system

f. 在磨机主体和滑履轴承、减速机及电动机降至常温后,停润滑及冷却系统。

After the mill, sliding shoe bearing, reducer and motor cools down to the room

temperature, stop the lubrication and cooling system.

7.6 在停磨前和停磨后的注意事项:

Items to be notice before and after mill stop

a. 磨机停止运转前 10分钟,应启动运行滑履轴承高压装置,以防止磨机冷却收缩时

损伤轴承合金,直至磨体完全冷却到常温(环境温度)为止;

Ten minutes before the mill stops operation, the sliding shoe bearing high pressure

device should be started to prevent bearing alloy from damage when the cooling of mill

cause contraction until the mill is completely cooled to room temperature (ambient

temperature);

b. 在磨机主体和滑履轴承温度尚未降至常温之前,不准停止润滑和水冷却系统;

Lubrication and water cooling system are not allowed to stop before the mill and sliding

shoe bearing cools down to the room temperature.

c. 为防止磨机筒体变形,停磨后应开启慢驱动装置按图四的时间间隔转动磨机,每次

转动磨体 180°,直到磨机温度降至环境温度为止。用户也可根据具体情况确定转

磨的时间间隔。

To avoid the deformation of mill barrel, start slow driving device to rotate mill

according to the time interval of Chart 4 after stop mill. Rotate mill to 180°each time

until the mill temperature cools down to the room temperature. The customer can

confirm the time interval of rotating mill according to real condition.

d. 当停机时间较长时,应将筒体内研磨体卸出,以免筒体变形;

When the mill stops for a long period of time, disassemble the grinding body inside the

φ3.8x13m水泥磨φ3.8x13mCement mill K4536.00SM page 35 of 48

barrel to avoid deformation of barrel.

e. 另外,当在冬季较长时间停机,各处冷却水要放净(托瓦水道中的冷却水,最好能

用压缩空气吹净),以免冻裂设备。

When the mill stops for a long period of time, drain off the cooling water everywhere

(cooling water in pillow water pipe, best use compressed air to blow off) to avoid

equipment cracking from freezing.

图四 Chart 4

7.7 维护与检修 Maintenance and Repair

7.7.1 磨机的日常维护和定期检查是保证设备性能良好、长期安全运转的重要措施,因此,

日常应有专职人员轮班检查维护,具体方案由设备使用单位自行制订。另外,设备

在运转过程中,必然会产生磨损,当磨损达到一定程度时,就不能保证安全、正常

运转,为保持良好的设备性能,对磨损的零部件必须及时修复或更换。具体检修计

划可根据有关技术文件要求自行制订。

The routine maintenance periodic inspections of mill are the important measures to

ensure the well performance of the equipment and long-term safe operation. Therefore,

specially assigned person should give inspection and maintenance by shifts day-to-day.

The specific schedule can be made according to the user party. In addition, the device will

inevitably cause some wear and tear during operation. When the wears reach certain

degree, safe and normal operation can not be guaranteed. In order to maintain the good

performance of the device, the worn parts must be timely repair or replaced. The specific

maintenance plan can be made according to the relevant technical document

requirements.

7.7.2 维护与检修方面的一些主要注意事项

Pay attention to the main items regarding maintenance and repair

a. 要密切注意滑履轴承托瓦温度的变化;

Pay close attention to pillow temperature changes of sliding shoe bearing;

b. 要经常检查滑履轴承、减速机和电动机的润滑系统运行情况,并要及时处理,保证

设备在正常工况下运行。

Check the sliding shoe bearing, reducer and lubrication system operation condition of