TruBend_10-14

Transcript of TruBend_10-14

-

7/24/2019 TruBend_10-14

1/24

Machine Tools / Power ToolsLaser Technology / Electronics

TruBend:

More bendingfreedom.

-

7/24/2019 TruBend_10-14

2/24

2

The best

bending

solutions.

Contents

The best bending solutions. 2

Why TruBend is better. 4

TruBend Series 3000 6

TruBend Series 5000 10

TruBend Series 7000 14

TruBend Cell 18

ToolShuttle 19

Bending tools. 20

Press force calculator. 21

Software:

Programmed for success. 22

TruServices:

Service like no other. 23

TruBend machines incorporate a wealth of experience in press

brake technology coupled with pioneering innovations. They

enable you to fabricate parts in any format, from the simplest

to the most complex, precisely and cost-effectively.

TRUMPF has been designing and manufacturing press brakes

since 1989. Among the most important developments are the

ACB angle measuring system, patented 4-cylinder drive technology,

machine control unit and operator ergonomics with innovative

details. TRUMPF leads the field in programming convenience

and ease of operation. TruBend machines are renowned above

all for their flexibility, finished part quality, and high cost-benefit

ratio. Moreover, TRUMPF can meet all of your additional

requirements for tools, automation and software from a

single source. Designed for years of continuous operation at

full capacity, TRUMPF press brakes are favored by industrial

customers the world over.

1 The right machine for every part geometry.

2 Cost-effective bending due to high productivity.

3 Parts of the highest quality.

4 Single source for all requirements, includingtop-quality tools.

5 Ease of operation and ergonomic design.

TruBend:Benefits at a glance.

-

7/24/2019 TruBend_10-14

3/24

TruBend Series 7000

Ergonomic high-speed machine.

Incorporating innovative features for high-speed bending of small

and larger parts under optimized working conditions.

TruBend Series 5000

Productive jack of all trades.

High productivity throughout, from programming and tool setup

to the bending process. The TruBend Series 5000 is capable of

performing bending work on a wide range of parts, always with

the greatest precision.

TruBend Series 3000

Economical standard machine.

The right choice for manufacturers who value TRUMPF quality,

simple operating procedures, and a favorable cost-performance

ratio.

-

7/24/2019 TruBend_10-14

4/24

4

Why TruBend

is better.

Precise results regardless of format.

CNC sheet followers make large bending

parts easy to handle.

4-cylinder hydraulic technology allows

for faster, cooler operation.

The OCB accelerates angle

measurement.

The right machine for every part geometry.

TruBend bending machines enable you to process parts of

any geometry economically and with high-quality results.

The advantages for your business include:

Wide choice of machine configurations.

Numerous press forces and working lengths.

Choice of air bending, bottom bending,

and precision-angle bending.

Exact positioning with 2-, 3-, 4-, 5- or 6-axis

backgauge systems.

Cost-effective bending due to high productivity.

TruBend machines enable you to minimize your cost per part.

Several factors contribute to this cost-saving effect:

High axis and working speeds.

Minimum tool setup time.

Automatic tool clamping systems.

Energy-efficient drives.

BendGuard: Maximum speed and optimum safety.

TruBend back gauges are designed for

long-term durability and precision.

-

7/24/2019 TruBend_10-14

5/24

Top-quality parts.

With TruBend machines, you achieve precise results every time.

The stable machine frame guarantees precision.

Precise angles every time with integrated CNC crowning.

Precise results through ingenious angle measuring

systems.

Single source for all requirements.

TRUMPF does not only develop and produce press brakes.

We also provide:

TRUMPF LASERdur quality tools.

Highly advanced machine controls.

Customized automation solutions.

TRUMPF software and services.

Ease of operation and ergonomic design.

The interaction between operator and machine is a decisive

factor in bending. That is why TruBend machines are designed

with the operator in mind, to lighten the workload:

Individually selectable control settings.

User-friendly man-machine interface.

Ergonomic bending supports and consoles.

Less walking due to the MobileControl.

Simple, vertical tool loading.

The footrest increases operator

ergonomics.

2D code scanner facilitates program

selection.

LED lighting ensures optimal visibility.

Efficient consultation through

teleservices.

-

7/24/2019 TruBend_10-14

6/24

6

TruBend

Series 3000

1 Cost-efficiency, even when operated at low capacity.

2 High part accuracy.

3 High productivity.

4 Simple operation, well thought-through control.

5 Access to complete TRUMPF expertise.

TruBend Series 3000:Benefits at a glance.

Economical standard machine.

The TruBend Series 3000 combines outstanding TRUMPF quality

with user-friendly operation in a superb value-for-money package,

enabling cost-efficient production even for small batches. You

can be confident of getting high precision results and enjoying

maximum safety standards at an affordable price.

Designed to impress.

The compact architecture and integrated hydraulic drive are

designed to deliver symmetrical force distribution. With the

closed machine enclosure design you can safely work with the

entire bending length. And automatic CNC crowning guarantees

a precise and identical angle whatever the length of the bend.

Simple to operate, robust and reliable, the TruBend Series 3000

offers the perfect combination of components to make it the

fastest machine in its class.

Clearly structured and self-explanatory multi-touch control system.

-

7/24/2019 TruBend_10-14

7/24

Use all available tools.

Manually with an Allen key, manually with QuickClamp or

automatically with hydraulics, the TruBend Series 3000 allows

you to choose from a range of different tool clamping systems.

Each tool is automatically centered and quickly secured in place

by the Safety Click locking mechanism. Third-party tools can

also be used without requiring an adapter, so you can continue

to use your existing stock of tools even after making the switch

to TRUMPF press brakes.

Easy loading of tools from below with Safety Click.

Multi-touch control,

teleservice via Internet

2-, 4- or 5-axis

backgauge

Complete controlof the full bending

length

Automatic

crowning facility

QuickClamp

and hydraulic tool

clamping system

LED front/rear area lighting

BendGuard

Support

bracket

-

7/24/2019 TruBend_10-14

8/24

8

-

7/24/2019 TruBend_10-14

9/24

Technical data

TruBend 3066 TruBend 3100

Press force 72 tons 110 tons

Bending length 80 in. 120 in.

Width between columns 93 in. 133 in.

Maximum table / beam distance 18.5 in. 18.5 / 24.5[1]in.

Usable open height withmanual and hydraulic tool clamping

14 in. 14 / 20[1]in.

Usable open height with TRUMPF QuickClamp 17 in. 17 / 23[1]in.

Operating height[2] 41 42 in. 41 42 in.

Inclination of beam 0.12 in. 0.25 in.

Speeds[3]

Y rapid 472 in / min 472 in / min.

Y working max. 35 in /min. max. 35 in / min.

Y return traverse speed 472 in / min. 472 in / min.

X axis 1181 in / min. 1181 in / min.

R axis 472 in / min. 472 in / min.

Z axis 2362 in / min. 2362 in / min.

Precision

Y axis position accuracy 0.0004 in. 0.0004 in.

X axis position accuracy 0.002 in. 0.002 in.

R axis position accuracy 0.004 in. 0.004 in.

Working range

Y axis stroke 8 in. 8 / 14[1]in.

Travel path X axis 24 in. 24 in.

Max. gauge area in X 34 in. 34 in.

Travel path R axis 6 in. 6 in.

Control T3500T T3500T

Connection values

Connected load 15 kVA 20 kVA

Oil capacity (approx.) 32 gal. 32 / 44[1]gal.

Dimensions and weight

Length x Width 102 x 65 in. 142 x 65 in.

Height 93 in. 93 / 101[1] in.

Weight 12,456 lbs. 16,975 / 17,637[1]in.

[1]With enlarged open height.

[2]With lower tool height 4 inches. Working height varies with the height of the installation material.

[3]Speeds freely programmable.

Subject to alteration. Only specifications in our offer and orde r confirmation are binding.

-

7/24/2019 TruBend_10-14

10/24

10

TruBend

Series 5000

1 Handles the widest range of parts in its class.

2 Maximum precision.

3 Dynamic axis positioning.

4 ACB: precise angles from the very first part.

5 Intuitive programming and machine controls.

TruBend Series 5000:Benefits at a glance.

Productive jack of all trades.

The TruBend Series 5000 is TRUMPFs best-selling press brake.

It features outstanding productivity at every stage of the process,

from programming and tool setup to the actual bending operation.

Built for maximum precision.

The high precision achieved when parts are produced on a

TruBend Series 5000 machine is attributable to its heat-treated

machine frame, industry-proven 4-cylinder drive system, and

CNC crowning.

Optical tool setup and positioning aid.

A line of red LEDs indicates the position at which the bending

tool needs to be installed with millimeter-scale precision.

The optical positioning aid indicates the station where the

next bending operation is required.

Mobile Control enables the operator to control machine functions remotely, without

having to move from place to place.

Optical tool setup and positioning aid.

-

7/24/2019 TruBend_10-14

11/24

Guaranteed precision with ACB.

Dynamic back gauges.

User-friendly TASC 6000 control unit.

ACB precise angles from the very first part.

The user-friendly, patented ACB (Automatically Controlled Bending) angle measuring

system guarantees bending-angle precision:

n Equipped with up to 8 angle sensors.

n Ability to process short leg lengths.

n 3-point angle feedback control for long parts.

Dynamic positioning with multi-axis back gauges.

A variety of back gauge systems are available to suit different part geometries

and levels of complexity. In the standard version, TruBend Series 5000 machines are

equipped with a 2-axis back gauge. This can be upgraded to 4 or 5 axes as an

option. There is even a 6-axis version, in which each back gauge finger can be set

independently. This makes the 6-axis back gauge the ultimate choice for flexible

manufacturing.

Intuitive programming and machine controls.

TRUMPFs Advanced Specialized Control, or TASC 6000, enables you to operate the

machine using a mouse, keyboard or touch screen, as desired. Representing the latest

generation in control systems, the interactive user interface simplifies programming

and guides the operator throughout the process with intuitive, safe instructions. It

only takes a few steps to input the numerical or CAD data for the part and generate

the corresponding program. A 3D animated display allows the bending process to

be monitored in-line.

-

7/24/2019 TruBend_10-14

12/24

12

-

7/24/2019 TruBend_10-14

13/24

Et, suscil irit,

vent lobore.

Lesenim quam:

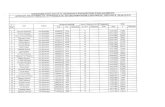

Technical data

TruBend 5050 TruBend 5085 TruBend 5130 TruBend 5170 TruBend 5230 TruBend 5320

Press force 55 tons 94 tons 141 tons 187 tons 253 tons 353 tons

Bending length 50 in. 87 / 107[1]in. 127 in. 127 / 167[1]in. 127 / 167[1]in. 174 in.

Width betweencolumns

41 in. 69 / 89[1]in. 106 in. 106 / 145[1]in. 106 / 145[1]in. 145 in.

Maximum

table / beam distance20 in. 20 / 29 [1] in. 20 / 29 [1] in. 29 in. 29 in. 29 in.

Usable installationheight

15 in. 15 / 24[1]in. 15 / 24[1]in. 24 in. 24 in. 24 in.

Throat 16.5 in. 16.5 in. 16.5 in. 16.5 in. 16.5 in. 16.5 n.

Operating height[2] 42.7 43.5 in. 43.1 43.8 in. 43.1 43.8 in. 43.1 43.8 in. 43.1 43.8 in. 43.7 44.5 in.

Inclinationof beam

0.39 in. 0.39 in. 0.39 in. 0.39 in. 0.39 in. 0.39 in.

Speeds[3]

Y rapid 520 in / min. 520 in / min. 520 in / min. 520 in / min. 520 in / min. 520 in / min.

Y working 24 to 48 [4]in / min. 24 to 48[4]in / min. 24 to 48[4]in / min. 24 to 36[4]in / min. 24 to 36[4]in / min. 24 to 36[4]in / min.

Y return traverse speed 520 in / min. 520 in / min. 520 in / min. 520 in / min. 520 in / min. 520 in / min.

X axis 2362 in / min. 2362 in / min. 2362 in / min. 2362 in/ min. 2362 in / min. 2362 in / min.

R axis 780 in / min. 780 in / min. 780 in / min. 780 in / min. 780 in / min. 780 in / min.

Z axis 2362 in / min. 2362 in / min. 2362 in / min. 2362 in / min. 2362 in / min. 2362 in / min.

Precision

Y axis position accuracy 0.0002 in. 0.0002 in. 0.0002 in. 0.0002 in. 0.0002 in. 0.0002 in.

X axis position accuracy 0.002 in. 0.002 in. 0.002 in. 0.002 in. 0.002 in. 0.002 in.

R axis position accuracy 0.003 in. 0.003 in. 0.003 in. 0.003 in. 0.003 in. 0.003 in.

Working range

Y axis stroke 8.5 in. 8.5 / 17.5[1]in. 8.5 / 17.5[1]in. 17.5 in. 17.5 in. 17.5 in.

Travel pathX axis

24 in. 24 in. 24 in. 24 in. 24 in. 24 in.

Max. gauge areain X

34 in. 34 in. 34 in. 34 in. 34 in. 34 in.

Travel path R axis 10 in. 10 in. 10 in. 10 in. 10 in. 10 in.

Control TASC 6000 TASC 6000 TASC 6000 TASC 6000 TASC 6000 TASC 6000

Connection values

Connectedload

10 kVA 17 kVA 24 kVA 28 kVA 42 kVA 42 kVA

Oil capacity (approx.) 24 gal. 32 gal. 58 gal, 58 gal. 87 gal, 111 gal.

Dimensions and weight

Length x Width 86 x 66 in.122 x 69 in.

143 x 69 in.[1]160 x 69 in.

167 x 73 in. 206 x 73 in.[1]

168 x 77 in. 207 x 77 in.[1]

209 x 77 in.

Height 94 in. 94 / 112[1]in. 94 / 112[1]in. 118 in. 126 in. 126 in.

Weight 10,803 lbs.16,094 / 17,195[1]lbs.

18,0781]/18,960[1]lbs.22,487/24,030[1]lbs. 26,456 / 35,274[1]lbs. 35,274 / 42,990[1]lbs. 49,384 lbs.

[1]Second figure relates to extended ver sion (optional).

[2]For tools with an effec tive height of 4 inches. May vary according to the size of the tool suppo rt.

[3]Speeds freely programmable.

[4]Depending on selected lower tool opening and application. May var y in accordance with local regulations.

Subject to alteration. Only specifications in our offer and order confirmation are binding.

-

7/24/2019 TruBend_10-14

14/24

14

TruBend

Series 7000

1 Outstanding productivity.

2 Maximized, multi-axis dynamics.

3 Engineered for maximum comfort.

4 Low energy consumption.

5 Reduced footprint.

TruBend Series 7000:Benefits at a glance.

Better quality assurance.

An integrated bending line laser projects a line of light onto the

surface of the sheet metal, indicating precisely where it will be

bent and enabling the operator to verify that the workpiece is in

the correct position.

Ergonomic high-speed machine.

The TruBend Series 7000 is a perfect example of the coordinated

interaction between operator and machine. You can be sure of

achieving outstanding productivity at every stage of the process

due to its high speed and acceleration, and the optimized

working environment provided by its ergonomic features. It is

a particularly cost-effective solution for bending small- and

medium-sized parts.

Certified ergonomic quality.

Human factor engineering played a significant role in the conceptual

design of the TruBend Series 7000. As a result, the machines are

a pleasure to use, operators can work quickly and efficiently, and

part quality is consistently high. It is the first press brake to be

awarded a quality certificate specifically for its ergonomic design.

Working without fatigue at the TruBend Series 7000.

The integrated bending line laser ensures spot-on positioning.

-

7/24/2019 TruBend_10-14

15/24

The user-friendly touch screen with intuitive menus

can be tilted to avoid reflections.

Outstanding productivity.

The gearless, direct-drive motor delivers high torque even when rotating at low

speed the optimum requirements for achieving a high press force coupled with a

high throughput rate. This extremely energy-efficient electric motor helps you to

reduce energy costs.

Maximized, multi-axis dynamics.

The time required to bend small parts depends only partly on the operating speed of the

ram. An even more important factor is the acceleration of the backgauges. To enable

them to be positioned more rapidly, they are built to a special design using a lightweight,

stable carbon-fiber material. The machine can operate much faster because the mass it

has to move is significantly lower. The system is available with either 3 or 6 axes.

Cool LED lighting Electric torque motor

Bending line laser

Automated tool clamp

Tiltable TASC 6000

touch-control

3-, 6-axis backgauge

Adjustable armrest

Adjustable footrest

-

7/24/2019 TruBend_10-14

16/24

16

-

7/24/2019 TruBend_10-14

17/24

Technical data

TruBend 7018 TruBend 7036

Press force 20 tons 40 tons

Bending length 20 in. 40 in.

Width between columns 17 in. 37 in.

Maximumtable / beam distance

16.5 in. 16.5 in.

Usable installation height 12 in. 12 in.

Throat 6 in. 6 in.

Operating height[1] 45 in. 45 in.

Speeds[2]

Y rapid 520 in / min. 520 in / min.

Y working max. 59 in / min. max. 59 in / min.

Y return traverse speed 520 in / min. 520 in / min.

X axis 2362 in / min. 2362 in / min.

R axis 780 in / min. 780 in / min.

Z axis 2362 in / min. 2362 in / min.

Precision

Y axis position accuracy 0.00008 in. 0.00008 in.

X axis position accuracy 0.0008 in. 0.0008 in.

R axis position accuracy 0.0008 in. 0.0008 in.

Working range

Y axis stroke 5 in. 5 in.

Travel path X axis 9 in. 9 in.

Max. gauge areain X

20 in. 20 in.

Travel path R axis 3 in. 3 in.

Control TASC 6000 TASC 6000

Connection values

Connected load 5 kVA 6 kVA

Dimensions and weight

Length x Width 51 x 52 in. 71 x 52 in.

Height 94 in. 94 in.

Weight 3968 lbs. 5732 lbs.

[1]For dies with a height of 4 inches.

[2]Speeds freely programmable.

Subject to alteration. Only specifications in our offer and orde r confirmation are binding.

-

7/24/2019 TruBend_10-14

18/24

18

TruBend Cell

Productive all-purpose bending cell.

TruBend Cell 5000 enables you to process parts cost-efficiently

and achieve high productivity. The BendMaster relieves the operator

of many onerous tasks, especially when processing large and

heavy workpieces weighing up to 220 lbs. The bulk of the work

is handled by the machine working around the clock, seven days

a week, if necessary. You can always rely on our automated

bending solutions to produce parts of consistently high quality.

Innovative high-speed bending cell.

Ideally suited for the automatic bending of small parts, the

TruBend Cell 7000 is the compact solution for fabricators looking

to increase their productivity. The innovative bending units are

a unique feature of the machine, with their lightweight backgauges

and modern drive concept. All in all, the TruBend Cell 7000

is the fastest bending cell in its class.

-

7/24/2019 TruBend_10-14

19/24

ToolShuttle

The right tool always at hand.

The ToolShuttle quickly and ergonomically sets up your tools and accommodates 525 linear feet of bending tools. The compact tool

storage can directly supply up to two bending machines, with the transfer carriage transporting the tools to the machines.

The tools are stored in drawers and automatically delivered. In the process the tools are delivered in setup position and at the right

height, so the operator is ideally assisted. No time is lost looking for and transporting tools, minimizing set up time. With the ToolShuttle

every tool setup operation is reduced by 60%.

-

7/24/2019 TruBend_10-14

20/24

20

Bending

tools.

Tailored to your requirements.

Bending tools from TRUMPF enable you to meet any

challenge, however complex it may be. They are backed

by the extensive experience of our experts, who are

always there to help you:

Customized advice and tailored design

solutions.

Development and testing of application

specific systems.

Fast availability.

High precision and a long service life.

A single source for machines and tools.

The LASERdur process used to harden

the tools.

Everything you need from a single

source.

Bending tools from TRUMPF live longer.

Precision and quality are the characteristics that count when

manufacturing bending tools. Our unique LASERdur technique

results in extremely hard-wearing tools. We use a laser hardening

process to selectively strengthen tools in those areas that are most

subject to wear.

Flexible standard tools.

We offer a range of over 150 punches and dies from which to

choose those best suited to your application. And, you are free

to decide whether you wish to order a complete set or compile

your own personal selection.

Custom-designed tools.

If your requirements are out of the ordinary, TRUMPF will develop

a customized tool solution, just for you. To ensure that it meets

the quality requirements for your parts, we will test the tools

using the materials you specify and produce prototype parts for

you to evaluate.

Measuring tools.

We can provide automeasuring tools based on our proven ACB

system for almost every standard tool in our portfolio. Sensor

disks incorporated in the forming tool send back measurement

data directly from the operating zone. With ACB, you can

reproduce angles of the highest accuracy.

-

7/24/2019 TruBend_10-14

21/24

s

6 8 10 12 16 20 24 30 40 50 60 70 80 90 100 120 w

4,5 6 7,5 9 12 15 18 22,5 30 37,5 45 52,5 60 67,5 75 90 b

1 1,3 1,6 1,9 2,6 3,2 3,8 4,8 6,4 8 9,6 11 13 14 16 19 Ri

0,75 87 65 52 44

1 155 116 93 78 58

1,25 242 182 145 121 91 731,5 349 262 209 175 131 105

1,75 356 285 238 178 143 119

2 372 310 233 186 155

2,5 485 364 291 242 194

3 524 419 349 279 209

3,5 570 475 380 285 228

4 621 497 372 298 248

4,5 628 471 377 314 269

5 582 466 388 333 291

6 838 670 559 479 419

7 912 760 652 570 507

8 1192 993 851 745 662 596

10 1330 1164 1034 931 776

12 1675 1490 1340 1118

Fin kNs, w, b, Riin mm

= optimum die opening

Press force required for 90 air bend

Mild steel

400 N / mm2

Stainless steel

700 N / mm2

F / m

s

6 8 10 12 16 20 24 30 40 50 60 70 80 90 100 120 w

4,5 6 7,5 9 12 15 18 22,5 30 37,5 45 52,5 60 67,5 75 90 b

1 1,3 1,6 1,9 2,6 3,2 3,8 4,8 6,4 8 9,6 11 13 14 16 19 Ri

0,75 52 39 31 26

1 93 70 56 47 35

1,25 145 109 87 73 55 44

1,5 209 157 126 105 79 63

1,75 214 171 143 107 86 71

2 223 186 140 112 93

2,5 291 218 175 145 1163 314 251 209 168 126

3,5 428 342 285 228 171 137

4 447 372 298 223 179 149

4,5 566 471 377 283 226 189 162

5 466 349 279 233 200 175

6 670 503 402 335 287 251 223

7 684 547 456 391 342 304 274

8 715 596 511 447 397 358 298

10 798 698 621 559 466

12 1005 894 804 670

s

b

w

F

F / m

Press force

calculator.

The charts allow you to easily read the required bending force (F) for a part measuring 1 m

(39 in.) in length. The necessary force varies as a function of the sheet thickness (s, vertical

scale) and the selected width of the die opening (w, horizontal scale). The tables also show

the minimum leg length (b) and the inside radius (Ri) associated with the selected die size

(w, width of die opening).

TRUMPF calculation table.

Calculation table

also available as app.

-

7/24/2019 TruBend_10-14

22/24

22

Programmed

for success.

Software:

TruTops Bend:Offline programming during machine operation.

TruTops Bend improves the productivity of your manufacturing

operations by allowing you to create programs while your press

brake is in use. The database includes shortening factors and

algorithms for tool selection and the calculation of complete

bending sequences. This allows you to benefit from TRUMPFs

bending expertise and ensures that you will obtain best-quality

results right from the very first part.

A detailed setup plan tells you which tools need to be installed,

what parts will be produced, and how they will be stacked on

pallets. Simulation functions guarantee high process reliability and

help to avoid tooling conflicts. Naturally, you can also use TruTops

Bend to program a TruBend Cell in the same programming

environment.

The Autorun function automatically compiles your bending

programs, for instance overnight, taking care to limit the number

of tool changes to a minimum. This reduces setup time and

saves costs.

TruTops Bend:The benefits it offers.

n High productivity through offline programming

during operation.

n Integrated knowledge leading to excellent

bending results.

n Autorun to save programming time.

n A single program for press brake and

bending cell.

n BendCalculation to simplify the calculation

of offers.

-

7/24/2019 TruBend_10-14

23/24

Service like

no other.

TruServices:

Regardless of the TRUMPF technology you use, you will always

get the best service. With our award-winning spare parts

logistics, we guarantee the highest availability of spare parts

and provide you with the products you need in the shortest time.

TRUMPF offers individual financing solutions quickly and without

a lot of paperwork. Our service technicians are highly trained

and always available when you need them.

A Service Agreement is the ideal way of ensuring the highest

availability of your machine. Should your requirements change,

we have flexible upgrade options and technical innovations that

will make your machine even better. Our broad range of training

courses with experienced trainers and hands-on practice will give

you a head start in understanding and operating your machine.

The TRUMPF Group ranks among the worlds leading manufacturers of production technology and industrial lasers. Technical and

efficient solutions for our customers have been our focus since 1923. As a leading technology supplier, TRUMPF is a one-stop shop

for all of your technology needs: machines, automation, storage technology and services.

Throughout the lifecycle of your machine.

Financing

Bending Tools

Punching Tools

Software

Spare Parts

Pre-owned Machines

Consulting

Customer Training

Product Enhancements

Service Agreements

Technical Service

-

7/24/2019 TruBend_10-14

24/24

TRUMPF is cert ified according to ISO 9001:2008