Supporting Information Growth of 2H Stacked WSe2 …Supporting Information Growth of 2H Stacked WSe2...

Transcript of Supporting Information Growth of 2H Stacked WSe2 …Supporting Information Growth of 2H Stacked WSe2...

Supporting Information

Growth of 2H Stacked WSe2 Bilayers on Sapphire

Ali Han1, Areej Aljarb1, Sheng Liu2, Peng Li1, Chun Ma1, Fei Xue1, Sergei Lopatin3, Chih-Wen

Yang1, Jing-Kai Huang,1,4 Yi Wan1, Xixiang Zhang1, Kuo-Wei Huang1, Qihua Xiong5, Vincent

Tung1,6*, Thomas D. Anthopoulos1*, Lain-Jong Li1,4*

1Physical Sciences and Engineering Division (PSE), King Abdullah University of Science and

Technology, Thuwal 23955-6900, Kingdom of Saudi Arabia

2Division of Physics and Applied Physics, School of Physical and Mathematical Sciences,

Nanyang Technological University, Singapore 637371

3King Abdullah University of Science and Technology (KAUST), Core Labs, Thuwal, 23955-

6900, Kingdom of Saudi Arabia

4School of Materials Science and Engineering, University of New South Wales, Sydney, NSW

2052, Australia.

5Division of Physics and Applied Physics, School of Physical and Mathematical Sciences,

Nanyang Technological University, Singapore 637371. MajuLab, CNRS-UNS-NUS-NTU

International Joint Research Unit, UMI 3654, Singapore 639798. NOVITAS, Nanoelectronics

Center of Excellence, School of Electrical and Electronic Engineering, Nanyang Technological

University, Singapore 639798

6Molecular Foundry Division, Lawrence Berkeley National Lab, Berkeley 94720, USA

* E-mails: [email protected]; [email protected]; [email protected];

Electronic Supplementary Material (ESI) for Nanoscale Horizons.This journal is © The Royal Society of Chemistry 2019

Figure S1. Schematic illustration of the CVD setup and the relative position between WO3, Se and

substrate. The distance between Se powder and WO3 powder is ~25 cm.

Figure S2. Optical images for the WSe2 growth by CVD method. The mass amount of WO3 is

0.3g, while the amount of Se powder is increased. The high-purity of H2/Ar is as the carrier gas

with a fixed flow rate of 5/65 sccm/sccm. The TSe (temperature of Se) is maintained at 250 oC

while TWO3 (the temperature of WO3) is kept at 895 oC. The growth pressure of the furnace is 10

torr for the whole CVD growth. The growth time is 15 mins.

Figure S3. Optical images for the WSe2 growth by CVD method. The mass amount of WO3 is

0.3 g. The high-purity of H2/Ar is as the carrier gas with a fixed flow rate of 5/65 sccm/sccm. a-b,

The amount of Se powder is 5.5 g, TSe = 250 oC and TWO3 = 890 oC; c-d, The amount of Se powder

is 5.0 g, TSe = 260 oC and TWO3 = 895 oC; e-f, The amount of Se powder is 5.5 g, TSe = 250 oC and

TWO3 = 900 oC.

Figure S4. a, Left: optical micrograph of cloud bilayer WSe2 crystal with monolayer WSe2 as

reference; Right: The corresponding SHG mapping intensity obtained by pixel-to-pixel spatial

scanning on the crystals in Fig. S4a; b, The SH signal spectra of different layer number; c, Optical

micrograph of irregular bilayer WSe2 crystal with monolayer WSe2 as reference; d, The

corresponding SHG mapping intensity obtained by pixel-to-pixel spatial scanning on the crystals

in Fig. S4c; e, The SH signal spectra of different layer number.

Figure S5. Low-frequency Raman spectra of bilayer WSe2 crystals for 2H and 3R stacking

configurations with different morphologies.

a b c

Figure S6 a, Low-magnification HAADF-STEM image of top-view bilayer WSe2 sample; b-c, elemental mapping of the region (green frame) in Fig.a.

1.0 nm

-1.0nm

0.4 nm

-0.4 nm

a b

Area 1Bilayer growth

direction

Step direction

Area 1

0.76 nm

Monolayer

Figure S7. a, AFM topographic image of the monolayer WSe2 grain boundary crystal with bilayer

nuclei in the center area; b, The zoom-in AFM topographic image of area 1, indicative of initial

WSe2 bilayer nuclei aligned growth on the atomic steps. Scale bars: a, 2 µm; b, 100 nm.

3.0nm

2 µm 200 nm

2.0nmba

-3.0nm

-2.0nm

Area 1

Area 1

1 2

210.8 nm

0.8 nm

Bilayer growth direction

d

-2.0nm

Area 2

Bilayer growth direction

Step direction

2.0nmc

-2.0nm

Area 2

0.76 nm

2 µm 200 nm

Figure S8. a-b, AFM topographic images of monolayer WSe2 crystal with bilayer nuclei in different areas. The inset height profile is~0.8 nm, indicating a thickness of WSe2 monolayer. The zoom-in AFM image in Fig.R1b shows WSe2 bilayer nuclei initial growth on the atomic steps of sapphire; c-d, AFM topographic images of monolayer WSe2 crystal with bilayer nuclei in different areas. The inset height profile is ~0.76 nm, indicating a thickness of WSe2 monolayer The zoom-in AFM image in Fig. R1d shows WSe2 bilayer nuclei initial growth on the atomic steps of sapphire.

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8-0.4

-0.2

0.0

0.2

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7-0.4

-0.2

0.0

0.2

0.4

Step width65 nm

Hei

ght (

nm)

Distance (m)

Anneal in H2/Ar

0.18 nm

Step height

0.21 nm62 pm

Anneal in air

Hei

ght (

nm)

Distance (m)-0.4 nm

-0.4 nm

0.4 nmc

a

1050 °C in H2/Ar 15 mins

1050 °C in air 60 mins

Step direction

Step direction

0.4 nm b

d

Figure S9. a, AFM topographic image of sapphire surface after high-temperature treatment (1050

°C in H2/Ar for 15 mins); b, the corresponding cross-section height profile of the atomic steps

along the vertical step direction in Fig. S7a; c, AFM topographic image of sapphire surface after

high-temperature treatment (1050 °C in air for 60 mins); d, the corresponding cross-section height

profile of the atomic steps along the vertical step direction in Fig. S7c. Scale bars: a, 100 nm; c,

100 nm.

1.0 nm

-1.0 nm

1.0 nm

-1.0 nm

0.76 nm

Sapphire Sapphire andMonolayer WSe2

a b

Step direction

Area 1

Area 1

1.0 nm

1.0 nm

-1.0 nm

-1.0 nm

Sapphire surface Roughness: 0.115 nm

Monolayer WSe2 surface Roughness: 0.081 nm

dc

Figure S10. a, AFM topographic image of one WSe2 crystal. The inset height profile was ~0.8

nm, indicating a monolayer thickness; b, The zoom-in AFM image in Fig. S8a. And the image

showed irregular atomic steps on bare sapphire surface without any pre-treatment. In contrast, the

apparently periodic atomic steps were shown after covering monolayer WSe2; c, The selected area

for the roughness calculation of bare sapphire surface (300 nm x 300 nm); d, The selected area for

the average roughness calculation of sapphire surface with monolayer WSe2 covering (300 nm x

300 nm). Scale bars: a, 2 µm; b, 200 nm; c, 2 µm; d, 200 nm.

Bilayer

Trilayer

200 250 300 350

B12g

2 LA (M)

Bilayer

Ram

an In

tens

ity (a

.u.)

Raman Shift (cm-1)

Trilayer

E12ga b

Figure S11. a, Optical micrograph of bilayer/trilayer WSe2 crystals as-grown on c-plane sapphire

substrate; b, The Raman spectra measurements for bilayer (red) and trilayer (orange) WSe2

crystals.

-3.0nm

-2.0nm

-3.0nm

-0.5 nm

a

d

c

b

3.0nm

3.0nm

0.5 nm

2.0nm

Area 1

Area 1

1 2

0.8 nm

0.75 nm2

1

Area 2

Bilayer growth

1.55 nm

Area 2

Bilayer

sapphire

2.0 nm

-2.0 nm

1.0 nm

-1.0 nm

e1.56 nm

Area 3

f Area 3

Monolayer

Bilayer growth

Monolayer sapphireStep direction

Step direction

Figure S12. AFM topographic images of three representative bilayer WSe2 crystals as-grown

on sapphire surface. a, The bilayer WSe2 crystal with irregular morphology. The inset height

profiles were both ~0.8 nm, indicating a bilayer thickness in the left part and a monolayer thickness

in the right part of the WSe2 crystal; b, The zoom-in AFM image showed the bilayer WSe2 nuclei

growth orientation following the atomic steps; c, the bilayer WSe2 crystal with truncated triangle

morphology. The inset height profile demonstrated a bilayer thickness of WSe2 crystal; d, The

zoom-in AFM image showed bilayer WSe2 nuclei growth orientation following the atomic steps;

e, The bilayer WSe2 crystal with grain boundary. The inset height profile demonstrated a bilayer

thickness of WSe2; f, The zoom-in AFM image showed bilayer WSe2 nuclei growth orientation

following the atomic steps. Scale bars: a, 2 µm; b, 200 nm; c, 1 µm; d, 200 nm; e, 1 µm; f, 100

nm.

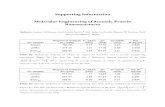

Table S1. Roughness measurements on different surfaces

WSe2 crystals Sapphire Roughness

Monolayer Roughness

Bilayer Roughness

TrilayerRoughness

Sapphire Roughness (1050 ºC)1

Sapphire Roughness (1050 ºC)2

Sapphire (Fig. S7a) - - - - 0.056 nm -

Sapphire (Fig. S7c) - - - - - 0.060 nm

Crystal 1 (Fig. 2b) - 0.070 nm - - - -

Crystal 2 (Fig. 2d) 0.109 nm 0.073 nm 0.068 nm - - -

Crystal 3 (Fig. 3b) 0.129 nm 0.094 nm 0.097 nm 0.076 nm - -

Crystal 4 (Fig. S8b) 0.148 nm 0.056 nm - - - -

Crystal 5 (Fig. S10b) 0.110 nm 0.077 nm 0.082 nm - - -

Crystal 6 (Fig. S10d) 0.125 nm 0.081 nm 0.073 nm - - -

Crystal 7 (Fig. S10f) - 0.075 nm 0.086 nm - - -

1The as-supplied sapphire was annealed in the H2/Ar for 15 mins;2The as-supplied sapphire was annealed in the air for 60 mins.

200 250 300 350 400 600 650 700 750 800 850 900

WSe2 Monolayer

WSe2 Bilayer

WSe2 Monolayer (after device

fabracation)

WSe2 Bilayer (after device

fabracation)

WSe2 Monolayer

WSe2 Bilayer

WSe2 Monolayer

(after device fabracation)

WSe2 Bilayer

(after device fabracation)

Raman Shift (cm-1)

Inte

nsity

(a.u

.)

PL in

tens

ity (a

.u.)

Wavenumber (nm)

a b

Figure S13. a. The Raman spectra measurements for WSe2 monolayer and bilayer crystals before

and after device fabrication on c-plane sapphire substrate; b, The PL spectra measurements for

WSe2 monolayer and bilayer crystals before and after device fabrication on c-plane sapphire

substrate.

-2 -1 0 1 2

-0.8

-0.4

0.0

0.4

0.8

-2 -1 0 1 2

-15

-10

-5

0

5

10

15

I ds (

A)

Vg (V)

Bilayer WSe2

Vg (V)

I ds (n

A)

Monolayer WSe2

a b

-3 -2 -1 0 1 2 31E-6

1E-4

0.01

1

201 mV/dec

Vgs(V)

I ds (

A)

Monolayer WSe2

Bilayer WSe2

229 mV/dec

c

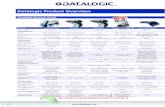

Figure S14. a, Ids as a function of Vg for monolayer device with two terminal. Ids as a function of

Vg for bilayer device with two terminal; b, Ids as a function of Vg for monolayer device. Ids as a

function of Vg for bilayer device. Cg = 5.0 µF/cm2; c, Ids as a function of Vgs for monolayer/bilayer

device. The subthreshold slopes of monolayer and bilayer crystals were measured to be 229 and

201 mV/dec, respectively.