Structure, Morphology and Color Tone Properties of the ......[6, 7]. Influence of Al and Si...

Transcript of Structure, Morphology and Color Tone Properties of the ......[6, 7]. Influence of Al and Si...

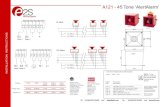

-

*E-mail: [email protected]

Tarequl Islam BHUIYAN

Dept. of Applied Chemistry

Okayama University

3-1-1 Tsushima-naka, Okayama, Japan

Tatsuo FUJII

Dept. of Applied Chemistry

Okayama University

3-1-1 Tsushima-naka, Okayama, Japan

Makoto NAKANISHI

Dept. of Applied Chemistry

Okayama University

3-1-1 Tsushima-naka, Okayama, Japan

Jun TAKADA*

Dept. of Applied Chemistry

Okayama University

3-1-1 Tsushima-naka, Okayama, Japan

Co-precipitation method has been employed to fabricate neodymium substituted

hematite with different compositions from the aqueous solution of their corresponding

metal salts. Thermal analysis and X-ray diffraction studies revealed the coexistence of

Fe2O3 and Nd2O3 phases up to 1050°C and formation of solid solution phase among

them at 1100°C and above temperatures, which was evidenced by shifting of the XRD

peaks. Unit cell parameters and the cell volumes of the samples were found to

increase by adding Nd3+ ions in the reaction process. FESEM studies showed the

suppression of particle growth due to the presence of Nd3+ ions. Spectroscopic

measurement evidenced that neodymium substituted hematite exhibited brighter

yellowish red color tone than that of pure α-Fe2O3.

1. I1. I1. I1. INTRODUCTNTRODUCTNTRODUCTNTRODUCTIONIONIONION

Iron is the fourth most abundant element

(5.1%mass) in the lithosphere. Iron oxides are

widespread in nature and ubiquitous in soils,

rocks and sea floor. The name Hematite

originates from the Greek word for blood, haima.

Hematite called “Bangla” i.e. Bengala in

Japanese, is the well-known compound of iron

This work is subjected to copyright.All rights are reserved by this author/authors.

(Received November 24, 2006)

Structure, Morphology and Color Tone Properties of theNeodymium Substituted Hematite

Memoirs of the Faculty of Engineering, Okayama University, Vol.41, pp.93-98, January, 2007

93

-

oxide. Its chemical composition contains a high

percentage of iron (70%) and it is the primary ore

used to create iron. It is believed that ancient

people grinded the ore into powder, diluted it with

water, animal fat or natural resin, and created a

starchy substance use for paintings. The ancient

Egyptians used Hematite in the creation of their

magical amulets. These precious treasures of

human culture could not have been preserved till

today without the benefit of iron oxide.

The development of the various properties of

hematite has received considerable attention due

to their promising characteristics and wide range

of applications as ceramic pigments [1], sensor for

the detection of dangerous gases [2] and raw

material for the synthesis of magnetic oxide

powders [3]. Due to the variation in crystallinity

[2], particle size [3], shape and extent of

aggregation [4] and cation substitution [5]

hematite exhibits wide range of colors. Cation

substitution has received current interest due to

the fact that the properties of the substituted

hematite change with increasing the substitution

[6, 7]. Influence of Al and Si substitution on the

color tone of hematite [8, 9] already has been

discussed. The effects of cation substitution on

crystal sizes, the magnetic properties and color

tone with the atoms of smaller ionic radii have

already been reported [2]. But the preparation of

lanthanide substituted hematite, especially with

larger ionic radii is scanty. Our previous study

have been described the structural

characterizations of cerium substituted hematite

by sol gel method [10]. Furthermore, the reports

on the preparation of Nd3+ substituted hematite

are not explored so much. Out of the conventional

preparative techniques, co-precipitation has been

identified as one of the promising process for the

preparation of homogeneous and high purity

products. Lanthanide element is being popular as

raw materials for the fabrication of substituted

hematite because of their known low-toxicity [11].

The main advantage of this method is not only to

fabricate low toxic substituted hematite, but also

to control the size and shape of the particles by

controlling over the amount of Nd3+ ion in the

reaction process.

2. E2. E2. E2. EXPERIXPERIXPERIXPERIMENTALMENTALMENTALMENTAL

2.1 Powder Preparation

A series of experiments has been conducted by

maintaining different compositions of Fe:Nd

atomic ratio ranging from 100:0 to 90:10 by

co-precipitation method. FeCl3•6H2O and

NdCl3•6H2O were dissolved in distilled water to

make 0.2 M aqueous solution of the corresponding

metal salts. The solution was stirred magnetically

at room temperature for 3h. Then aqueous NaOH

solution of 0.4 M was prepared and stirred

magnetically under ambient condition. The

mixture of 0.2 M of FeCl3•6H2O and NdCl3•6H2O

solution was slowly added to the 0.4 M NaOH

solution following magnetically stirred until the

pH of the solution lies in the range of 9.30. Dark

brown colored metal hydroxides were formed and

aged under an ambient condition for 12h. Then

the resultant product was filtered and washed by

distilled water until the conductivity of solution

being 0.55 S/cm in order to remove all chlorides

from the product. The wet powder was then dried

at 120°C for 12h in air and then heated at

different temperatures between 300 and 1200°C

for 2h in air.

Tarequl Islam BHUIYAN et al. MEM.FAC.ENG.OKA.UNI. Vol.41

94

-

2.2 Physical measurements

Characterizations procedure has been

performed using Thermogravimetric and

Differential Thermal Analysis (TG-DTA), X-ray

diffractometer (XRD), Field Emission Scanning

Electron Microscopy (FESEM) and

Spectrophotometer Analysis system. TG-DTA

measurements were carried out with a heating

rate of 10 K/min in air comparing with standard

α-Al2O3 by using Rigaku Thermo Plus TG 8120

instrument. Structural characterizations of

samples were performed on RIGAKU RINT 2500

X-ray powder diffractometer using CuK α

radiation (λ = 1.5418 Å). Silicon powder (a =

5.4308 Å) was used as an internal standard and

the diffraction patterns were calibrated with

respect to Si (220) reflection. Hitachi S-4300

FESEM with 15 kV EHT (electrical high tension)

was employed to study SEM measurements. The

wavelength-dependant reflection of a surface

relative to a white standard was measured using

a Spectrophotometer Minolta C-2600D.

3. R3. R3. R3. RESULTS AND DISCUSSIONESULTS AND DISCUSSIONESULTS AND DISCUSSIONESULTS AND DISCUSSION

3.1 Study of Thermal analyses

Fig.1 Thermogravimetric and differential thermal

analysis curves for the sample prepared by

co-precipitation method (Fe:Nd = 90:10 at%).

It was observed by TG-DTA that gel powders

obtained after drying at 95°C displayed a broad

endothermic weight loss centered at 180°C, which

is due to the presence of entrapped water in the

gel powder. Consequently the step wise weight

loss at TG curve from 180°C to 400°C associated

with exothermic peak might be due to the

decomposition of hydroxide to oxide materials

respectively (Fig.1).

3.2 X-ray diffraction studies

Characteristic reflections of the diffraction

patterns of the samples were heat treated up to

1200°C identified to their corresponding phases

as α-Fe2O3 and Nd2O3 (Fig.2). When the samples

Fig.2 XRD pattern of the samples obtained at

Fe:Nd = 95:5 at% at a) 500˚C, b) 600˚C, c)

700˚C, d) 800˚C, e) 900˚C, f) 1000˚C, g) 1100˚C

and h) 1200˚C

were heat-treated between 1100 and 1200°C, the

reflections due to α-Fe2O3 were found to be

slightly shifted towards the lower angles than

that of the pure α-Fe2O3 system (Fig.3). The

shifting of XRD peaks might be due to the

incorporation of larger Nd3+ ion (ionic radius of

Nd3+ = 0.995 Å [12]) into the α-Fe2O3 matrix (ionic

-3.0

-2.5

-2.0

-1.5

-1.0

-0.5

0.0

Weight Change (%)

12001000800600400200

Temperature (°C)

-120

-80

-40

0

Heat Flow (μV)

TG CurveTG CurveTG CurveTG CurveDTA CurveDTA CurveDTA CurveDTA Curve

Intensity (a.u.)

706050403020102θ (deg.) Cu-Kα

� Fe2O3� Nd2O3

�

� �

� �

�

�

�

�

� � � � � � � �

� �

� �

a

b

c

d

e

f

g

h

January 2007 Structure, Morphology and Color Tone Properties of the Neodymium Substituted Hematite

95

-

radius of Fe3+ = 0.49 Å [12]) causing expansion of

the crystal lattice. Calculation of cell volume

(302.80 ± 0.5 Å3) also showed lattice expansion as

compared to that of the pure α-Fe2O3 (301.40 ± 0.2

Å3) suggesting the Nd3+ ion incorporation into the

hematite lattice (Fig.4).

Fig.3 XRD pattern of the samples obtained at

1150°C when Fe:Nd initial compositions were

a) 100:0, b) 95:5 and c) 90:10 at%

Fig.4 Cell volume of the samples obtained at

1150°C at different initial compositions

The XRD patterns of the samples, heat-treated

at 1200°C showed that Nd2O3 still coexisted with

the substituted hematite. This indicates that a

very small amount of Nd3+ ion has been

incorporated into the α-Fe2O3 matrix. The values

of the unit cell parameters for the samples (heat

treated below 1100°C) were very close to that of

the pure α-Fe2O3 (a = 5.032 Å, c = 13.749 Å)

prepared under identical conditions. Unit cell

parameters and the cell volume for the mixed

systems increase with increasing the atomic ratio

of initial Nd3+ ion, suggesting the possibility of

Nd3+ ion incorporation into the hematite.

Fig.5 Crystalline size of the samples obtained at

1150°C at different initial compositions

Crystalline size calculated by Scherrer’s

formula was found on the decrease by increasing

the amount of Nd3+ ion in the reaction process

(Fig.5).

3.3 Morphology of the Particles

The particle size increased with increase in the

heat treatment temperature due to growth of the

particles as expected. But, the suppression of

particle growth was observed by the presence of

Nd3+ ion comparing with that of the pure α-Fe2O3

at the respective temperatures (Fig.6). The

growth of the particles were gradually decreased

with increasing Nd3+ ion in the reaction process

suggesting the possibility of Nd3+ ion

incorporation into the α-Fe2O3 matrix.

Intensity (a.u.)

656463622θ (deg.) Cu-Kα

� α− α− α− α−Fe2O3 � Fe2-xNdxO3

�

�

�

�

aaaa

bbbb

cccc

301.56

302.47

303.23

301.5

302

302.5

303

303.5

0 0.05 0.1

Nd3+ / (Fe

3+ + Nd

3+)

Cell V

olume A

o3

662675

815

650

700

750

800

850

0 0.05 0.1

Nd3+/(Fe

3+ + Nd

3+)

Crystalline Size (A

o)

Tarequl Islam BHUIYAN et al. MEM.FAC.ENG.OKA.UNI. Vol.41

96

-

Fig.6 FESEM images of the samples prepared at

1200°C with various compositions when

Fe:Nd equal to a) 100:0, b) 95:5 and c) 90:10

at%

3.5 Spectrophotometer analyses

Spectroscopic measurement showed that a

brighter yellowish red color than pure hematite

was fabricated by neodymium substitution into

the hematite (Fig.7).

Fig.7 Color tone a* and b* of the samples at the

composition of Fe:Nd equal to a) 100:0 b) 95: 5

and c) 90:10 at% at 1150˚C

In Fig.7, the a* axis stands for red tone, and

the b* axis for yellow. In this case, the particle

sizes and reflective indices of the pigment

produced brighter yellowish-red color tone when

Nd3+ ion added to the hematite in between 1100

and 1200˚C temperatures that is primarily

caused by the various absorption processes.

Samples contained 5 at% Nd3+ ion in initial

solution exhibited wide range of brighter

yellow-reddish pigment. Due to the addition of

more Nd3+ ion into the hematite at 1100°C and

above, particle size decreased and the color tone

turned into dark rapidly. But an interesting

observation is that by comparing with the almost

same particle sizes of pure α-Fe2O3 obtained by

identical condition, it was found that neodymium

substituted hematite by co-precipitation method

exhibited brighter color tone than that of pure

hematite (a* = 6.90 and b*= 2.25).

4444.... C C C CONCLUSIONONCLUSIONONCLUSIONONCLUSION

Hematite substituted with Nd3+ ion (i.e.

Fe2-xNdxO3) was prepared by co-precipitation

5µm

a

5µm

b

5µm

c

3.15, 1.51

9.68, 3.57

7.61, 2.27

1

1.5

2

2.5

3

3.5

4

0 5 10 15

a*

b*

a

b

c

January 2007 Structure, Morphology and Color Tone Properties of the Neodymium Substituted Hematite

97

-

method at 1100°C and above. Several Fe:Nd

atomic ratios were used to study the effect of

substitution on lattice parameters, crystalline

size, morphology and color tone of the Nd3+

substituted hematite. XRD patterns were shifted

towards the lower angle by comparing with

internal silicon standard evidenced the Nd3+ ion

substitution in to the α-Fe2O3. The unit cell

parameters and cell volume of Fe2-xNdxO3 were

found to be expanding also clearly established the

incorporation of larger Nd3+ ion into the α-Fe2O3.

Crystalline size and grain growth of the samples

were found on the decrease by increasing the

amount of Nd3+ ion added to the hematite.

Morphological study of the particles proved the

suppression of particle growth by the presence of

Nd3+ ion. Compared with different compositions

and temperatures, it was found that the

yellowish-red color tone of Fe2-xNdxO3 than that of

pure hematite increased. Fe2-xNdxO3 is suggested

to be formed by solid state reaction between

α-Fe2O3 and Nd2O3 at 1100°C - 1200°C.

Yellowish-red color tone of Fe2-xNdxO3 was also

found brighter than that of sample obtained at

lower temperatures (α-Fe2O3 and Nd2O3) and that

of pure α-Fe2O3 contained almost same particle

size obtained by identical condition.

AAAACKNOWLEDGEMENTCKNOWLEDGEMENTCKNOWLEDGEMENTCKNOWLEDGEMENT

One of the authors (TIB) is thankful to Mr.

Yokoyama and other Lab members for their

constant help in execution of this work.

RRRREFERENCESEFERENCESEFERENCESEFERENCES

[1] D. Hradil, T. Grygar, J. Hradilova, P.

Bezdicka: Appl. Clay Sci., 22222222 (2003), 223.

[2] M. Sorescu, L. Diamandescu, D. T.-Mihaila:

Mater. Lett., 59595959 (2005), 22.

[3] C. Cantalini, M. Pelino: J. Am. Ceram. Soc.,

75757575 (1992), 546.

[4] F. Hund: Angew. Chem.-Int. Edit., 20202020 (1981),

723.

[5] V. Barron and J. Torrent: Clays Clay Miner.,

32323232 (1984), 157.

[6] R.M. Cornel and R. Giovanoli: Clays Clay

Miner., 35353535 (1987), 11.

[7] K. Kandori, Y. Nakamoto, A. Yasukawa and T.

Ishikawa: J. Colloid Interface Sci., 202202202202 (1998),

499.

[8] H. Asaoka, M. Nakanishi, T. Fujii, J. Takada

and Y. Kusano: Mater. Res. Soc. Symp. Proc.,

712712712712 (2002), 435.

[9] H. Asaoka, Y. Kusano, M. Nakanishi, T. Fujii

and J. Takada: J. Jpn. Soc. Powder Powder

Metall., 50505050 (2003), 1062.

[10] N. C. Pramanik, T. I. Bhuiyan, M. Nakanishi,

T. Fujii, J. Takada and S. I. Seok: Mater. Lett.,

59595959 (2005), 3783.

[11] E. Greinacher: Industrial application of rare

earth elements, ed. K. L. Gschneider, Am.

Chem. Soc. (1981), 164.

[12] R. D. Shannon: Handbook of Chemistry and

Physic (74th ed.), CRC Press (1974), 751.

Tarequl Islam BHUIYAN et al. MEM.FAC.ENG.OKA.UNI. Vol.41

98

Index