Revista E&P - Agosto 2011

Transcript of Revista E&P - Agosto 2011

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 1/92

E P M A G . C O

NOCs changethe game

A U G U S T 2 0 1 1

ROV/AUV

Rock Physics

Cost and Risk Management

DownholeSystems and

Solutions

Drilling and

CompletionFluids

BIGGERPLAYGROUND

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 2/92

GE

Gil

&

Gas

Dri l l ing

& Production

Extreme

Conditions.

Expert

Navigation

Required.

More

options

and lower risks with GE s MWD and

LWD

Systems.

When

you run GE'

s MWD/LWD

Systems

,

your company not only bids

on

more

profitable

jobs

but

also

minimizes operational

risks.

GE'

s

MWD

and LWD Systems are designed to withstand

extreme

environments

while

providing accurate

,

reliable

measurements.

They also

feature multiple

options

to address a

wide

variety

of

drilling conditions.

Add

our

purchase business

model and

GE's commitment

to

R&D ,and your profit picture

gets even

brighter.

To

find

out how GE Oil &

Gas

can help

you

offer innovative oilfield services

today, please

visit

our

website

at

www.ge-energy.com/oi l f ield.

Innovation

N

ow: You

and

GE'

s

Drilling

&

Production.

imagination at work

?

.

.. .

?

?

•

r.?

?„ .

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 3/92

COST AND RISK MANAGEMENT

Understanding shale fractures leads to betterproduction, lower cost

Real-time whirl detector improves RSS reliability,drilling efficiency

New approach takes health, safety interventionto a new level offshore

Enterprise risk management evolves to take onglobal business

ROCK PHYSICS

From seismic data to prospect identificationand drilling models

Digital rock physics provides new insight intoshale reservoir quality

DRILLING AND COMPLETIONS FLUIDS

Chrome-free WBM a viable option forultra-HP/HT applications

Unconventional resources benefit from custom

chemical regimes

DOWNHOLE SYSTEMS AND SOLUTIONS

Pump up the volume

ROV/AUV

Investment resurgence buoys ROV market

AUVs take on pipeline inspection

IndustryPULSE:The business case for a newleadership paradigm

Industry executives must lead the push to regain thepublic’s trust.

EXPLORATION & PRODUCTIONW O R L D W I D E C O V E R A G E

AUGUST 2011VOLUME 84 ISSUE 8

A HART ENERGY PUBLICATION www.EPmag.com

COVER STORY

30

Friends or Foes?The changing role of NOCs meansIOCs must leverage their expertiseto access new reserves.

6

WorldVIEW: Unconventionalenergy matters

Informed by more than 40 years in theenergy industry, investment banker Thomas A. Petrielooks forward to what the future holds for the oil andgas industry.

10

Unconventional: Granite Wash

Midcontinent’s Granite Washhas true grit

A revival in the Anadarko basin has awakened a

geologically challenging, liquids-prolific tight sandsresource play.

38

41

44

46

48

52

54

57

62

66

82 REGIONAL REPORT:

SOUTH EAST ASIA

72

74

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 4/92

AS I SEE IT

Safety takes a step forward 5

MANAGEMENT REPORT

Maximize business efficiency through

all-encompassing processes 14

DIGITAL OIL FIELD

G&G software accelerates user productivity 16

SAP application executes more data loads in less time 21

EXPLORATION TECHNOLOGY

RTM aids in earthquake study 25

WELL CONSTRUCTION

Is the ‘old school’ still the only school? 27

PRODUCTION OPTIMIZATION

Technology tidies up EOR’s act 29

TECH WATCH

New production profile predictor methoddetermines well performance 76

TECH TRENDS 80

INTERNATIONAL HIGHLIGHTS 86

ON THE MOVE/INDEX TO ADVERTISERS 91

LAST WORD

Getting to ‘yes’ on shale gas 92

E&P (ISSN 1527-4063) (PM40036185) is published monthly by Hart Energy Publishing, LP, 1616 S. Voss Road, Suite 1000, Houston, Texas 77057.Periodicals postage paid at Houston, TX, and additional mailing offices. Subscription rates: 1 year (12 issues), US $149; 2 years (24 issues), US $279. Singlecopies are US $18 (prepayment required). Advertising rates furnished upon request. POSTMASTER: Send address changes to E&P, 1616 S Voss Road, Suite 1000,Houston, Texas 77057. Address all non-subscriber correspondence to E&P, 1616 S. Voss Road, Suite 1000, Houston, Texas 77057; Telephone:713-260-6442. All subscriber inquiries should be addressed to E&P, 1616 S Voss Road, Suite 1000, Houston, TX 77057; Telephone: 713-260-6442 Fax: 713-

840-1449; [email protected]. Copyright © Hart Energy Publishing, LP, 2011. Hart Energy Publishing, LP reserves all rights to editorial matter in this maga-zine. No article may be reproduced or transmitted in whole or in parts by any means without written permission of the publisher, excepting that permission tophotocopy is granted to users registered with Copyright Clearance Center/0164-8322/91 $3/$2. Indexed by Applied Science, Technology Index and Engineering IndexInc. Federal copyright law prohibits unauthorized reproduction by any means and imposes fines of up to $25,000 for violations.

DEPARTMENTS AND COMMENTARY

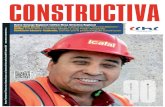

ABOUT THE COVER The main photo illustrates the global dynamic

between NOC/IOC relationships, a strategy that has created major link-ups in the

form of strategic partnerships, alliances, and areas of mutual cooperation down

all avenues of the energy pipeline. On the left is an Epidote Amphibolite metamor-

phic rock core sample (colorized for our cover) imaged at 100 x magnification.

(Image courtesy of PetroArc International; cover design by Laura J. Williams)

COMING NEXT MONTH Read the September issue of E&P to find out what’s new in the geo-

physical market and to get an update on activity in the North Sea. Additional features in the issue take

a look at advances in multilaterals and extended reach drilling, stimulation technology, and ways to

improve production rate and quality. The Marcellus shale, one of the most active unconventional plays

in North America, is the shale focus for the month.

As always, while you’re waiting for the next copy of E&P , remember to visit www.epmag.com for news,

industry updates, and unique industry analysis.

The Low PRESSURE A U T O C H O K E

CONSOLE* (LPAC*) unit g

ives

precise bottomhole pressure

control during

MPD and

UBD

drilling o p era t i o n s

- keeping

y ou

in the pressure stability window.

Di

g

ital touch

screen interfaces

located

in the

driller

s

cabin

and

rig floor

offer

greater coordination

during

pressure-critical operations.

With simultaneous high-resolution

monitoring and direct

pressure

control

of

our unique A U T O C H O K E

unit

,you gain greater

operat ional

performance and efficiency.

During

the

underbalanced

drilling

of

a

series

of

laterals

, the system

doubled overall ROP from 15 to

30 f

/hr and held the required

surface

pressure of

350

psi

during

connections. As

a

result

,

the

operator

cut drilling time by

10 days

,

saving Sim.

MiSWACO

A Sch lumberger

Company

www.miswaco.s lh.com/LPAC

kv

FM

_

I

P.

`

o

f

r

0

ij i1

?:

y _

.

c?

c?,

V?i

l1 ?R :

t

A,

1 .

I

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 5/92

ONLINE CONTENT AUGUST 2011

Gullfaks sidetrack hits 170-m

gas, condensate zoneStatoil has reported pay in its Opal

exploration well in the Norwegian

North Sea.

PREMIUM CONTENT Subscribe @ EPmag.com/explorationhighlights

Hydrocarbon shows in Green Point shale in NewfoundlandAccording to Shoal Point Energy, a petrophysical analysis from the

#3K-39 well in Newfoundland’s Green Point shale play has confirmed

a thick section of producible unconventional light oil.

AVAILABLE ONLY ONLINE

Arctic, Deepwater Drilling To

Drive Global Rig DemandBy Larry Prado, Activity Editor

Harsh environments – Arctic and deepwater –

will fuel growth in rig demand through 2015.

Management approach addressesasset lifecycle

By Judy Murray, Editor

Total cost of ownership considers the

value of an asset from installation to

decommissioning.

Coast Guard reinforcessupervision of foreignoffshore drilling unitsBy Elizabeth Johnston, Editorial Intern

New policy focuses on risk-based

targeting of foreign-flagged vessels

in US waters.

R E AD T H E L AT E S T E P m a g .c o m

I N D U S T R Y N E W S

Tullow taps oil in Ugandaexploration areaLondon-based Tullow Oil Ltd. reportedthat the #1-Jobi-East and #3-Mpyo wells

in Uganda’s onshore Exploration Area 1

(EA1) have encountered oil accumulations.

WEBINARS

Cyber Security

Best Practicesand Lessonsfor EnterprisesUnderPersistentThreat

Argentina’sNeuquénBasin:A World

Hotspot ForUnconventionalResources

UDerFI

oge

System

Our

suite

of field-proven liner hanger

syste

is

fully integrated within Schlumberger

completion technologies

,

allowing you to

comp

lete your wells using one trusted sou

Complete your wells with confidenc

www

.slb.com/hangers

Schiumberge

:

II V I I I l m ik

.

I I I

I

P

Scblumberger

-

noon-

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 6/92

Want to bring geology back into

geop

hysical interpretation?

All

Abo

ard

Landmark

s new DecisionSpace

° Desktop software

accelerates

seismic interpretation with geomodel-enabled

workflows.

The

geophysics and

geology

modules

in

Landmark s

new

unified Decis ionSpace

Desktop

software share the same

topo logy

engine. This gives geophysic is ts easy access

to

f ramework construct ion tools that

combine

well p icks

and horizons

to

produce a

high

resolut ion

,

accurate geomodel .

The

geomodel uses conformance

technology to

produce

wel l -based sur faces at the same

resolut ion

as seismic data, enabl i ng a model that t ruly represents your reservoir.

Get better

answers faster.

Visit halliburton.com/decisionspacedesktop.

High Science

Simplif ied

HALLIBURTON

Landmark Sof tware

Serv ices

ml

K jl

2011 Hallibu

ri

on . All rights reserved ?7 •

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 7/92

Safety has long been a priority for the global oil and gas industry, but it moved

onto center stage nationally in the US following the Macondo incident in the

Gulf of Mexico. The Bureau of Ocean Energy Management, Regulation and

Enforcement (BOEMRE) was formed from the Minerals Management Service fol-

lowing the event and took on the responsibility of overseeing the safe and environ-mentally responsible development of energy and mineral resources on the US

Outer Continental Shelf.

The BOEMRE has led some of the most aggressive and comprehensive reforms

to offshore oil and gas regulation and oversight in US history. These reforms,

which strengthen requirements from well design and workplace safety to corporate

accountability, are being pursued with the goal of ensuring the US can safely and

responsibly develop its energy resources.

In working toward this goal, BOEMRE recently announced that it would employ

multidisciplinary teams instead of individual inspectors to carry out inspections on

offshore oil and gas facilities. While this approach will be more thorough, it presents

a challenge because it requires additional human resources from an industry in

which human resources are extremely limited.Fortunately, there may well be a host of qualified understudies waiting in the

wings.

As the Space Shuttle program winds down at NASA, there are thousands of techni-

cians, engineers, and scientists who will be laid off. According to Emil Peña, execu-

tive director of the National Corrosion Center at Rice University, this is a skilled

workforce that could – with some training – step into the roles that need to be filled

by the BOEMRE.

The goal of transferring technology in the form of human capital was the impetus

behind the formation over the last two months of the Energy Safety Institute (ESI).

Peña, who was instrumental in the creation of ESI under the umbrella of the

Greater Houston Partnership, said preserving human resources is one of the key

objectives of the institute. “One of ESI’s primary goals is to facilitate technology transfer by moving people from their roles in SRQA (safety, reliability, quality assur-

ance) at the Johnson Space Center (JSC) into new roles with the BOEMRE.”

ESI is basically about technology, Peña said. “You can transfer some of this tech-

nology, and there also is the opportunity of utilizing some of the assets that are avail-

able at JSC, such as labs, buildings, test facilities, and other resources.”

Peña believes using JSC to transfer knowledge

from the space program to energy, whether it is

ocean or land, is a win-win situation because it

allows SRQA programs developed for the space

program to be refocused on an industry that is

comparably challenging in terms of safety.

As ISEE IT

EPmag.com | August 2011

1616 S. VOSS ROAD, STE 1000HOUSTON, TEXAS 77057

TEL: +1 713.260.6400FAX: +1 713.840.0923

www.EPmag.com

Safety takes a step forward

5

Read more commentary at

EPmag.com

JUDY MURRAY

Editor

Editor JUDY [email protected]

Senior Editor RHONDA [email protected]

Senior Editor TAYVIS [email protected]

International Editor MARK THOMAS

Associate Editor NANCY [email protected]

Corporate

Art Director ALEXA [email protected]

Senior GraphicDesigner LAURA J. WILLIAMS

Production Director& Reprint Sales JO LYNNE POOL

Senior Editor/ManagerSpecial Projects JO ANN DAVY

Executive EditorOnline RICHARD MASON

Online Editor REBECCA [email protected]

Director ofBusiness Development ERIC ROTH

Group Publisher RUSSELL [email protected]

Vice President, Digital Media

RONS DIXON

Senior Vice President, Consulting Group

E. KRISTINE KLAVERS

Executive Vice President and CFO

KEVIN F. HIGGINS

Executive Vice President

FREDERICK L. POTTER

President and Chief Executive Officer

RICHARD A. EICHLER

O

o

H A R T

E N E R G Y

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 8/92 Aug ust 201 1 | EPm ag.com 6

industryPULSE

The business case for anew leadership paradigmIndustry executives must lead the push to regain the public’s trust.

Ahuman resources executive at a Fortune 500 natural

gas company, acclaimed for world-class environmen-

tal and sustainable energy solutions, recently bemoaned

his firm’s inability to interest talented students in employ-

ment opportunities with his firm – even during the softest recruiting year in memory. His explanation: students

believe the oil and gas industry is broken.

And no wonder.

Words and actions of opinion leaders in media, gov-

ernment, academia, and even business make it appear

that the industry is focused solely on money and profits

for shareholders without regard for the environment or

the communities in which it does business. For example,

accounts of the 2010 Macondo oil spill in well-read busi-

ness publications indicted the entire offshore drilling

industry along with BP’s approach to managing safety

and risk.Similarly, journalists and politicians publicly

question the effects of transforming

densely settled urban and suburban areas

into “heavy industrial sites” to

produce natural gas, saying

that contamination and

pollution result in unac-

ceptable health risks

that demand restric-

tion through taxa-

tion and regulation.

To counter theseperceptions, indus-

try spokespeople

point out that tech-

nology has enabled the energy industry to meet the ris-

ing worldwide demand for fuel, power generation, and

petrochemical feedstock with expanded supplies; more

efficient extraction, production, and distribution meth-

ods; and lower emissions. They speak about research

results that show that offshore industry professionals

have extremely high job satisfaction scores. These rebut-

tals have not been effective in stemming the tide of neg-

ative perceptions about the industry, however.The truth? It is a mixed bag. There are many strong,

effective, and ethical leaders in the oil and gas industry

who are highly motivated to bring discipline and purpose

to the forefront in both practice and perception. How-

ever, there are other companies that are just coming

around to this viewpoint, and yet others that are lagging.

The entire industry needs to more swiftly develop new

paradigm leaders or risk that the laggards’ actions will

continue to serve as a drag on the industry’s reputation.

A new leadership paradigm

So what does the industry need to do tochange the perception that it is broken,

establish trust with customers, and attract

a new generation of employees? A very

good start would be to embrace

a new type of leadership that

rewrites the broken

script that has left

certain companies

unable to adapt to

the leadership

demands of the

21st century.This new leader-

ship model provides

a different frame-

work for the industry

to address its challenges,

one founded on the pillars

of purpose, ethics, and value for

multiple stakeholders.

The new paradigm demands an

expanded set of leadership capabilities

at all levels in oil and gas firms.

W. Bruce Bullock and Frank R. Lloyd,

SMU Cox School of Business

New paradigm oil and gas

leaders must be multidimensional

and embody the industry’s commitments,

externally and internally, including those

that express larger purpose, social legitimacy,

and ethical responsibility. (Image courtesy of

SMU Cox School of Business)

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 9/92

I have

someone

retiring after 33

years

on the job.

I

have someone

taking

33

years

of

experience

with him.

And now

someone

with just

3

years

has to do

that

job.

4P

EMERSON.

Process

Managemen

E M E R S O N

.

C O N S I D E R I T S O L V E D .

11

/

PO

SS

IB

With new Human Centered Design technologies

from Emerson

,

it s

like the

experience

never

left.Using our deep insig hts into

how your peop

le perform their roles and tasks

,

Emerson

is

designing all of

our

new products based on

the

science of

Human

Centered Design.

This

lets us

embed

the same experience and understanding that

'

s

walking

through

your

plant into our control

and

monitoring

technologies - making them the easiest and most intuitive to

use.

Tasks are

accomp

lished in fewer steps

,

and with

greater confidence ,

even when

rel

ying

on

less expertise

and specialization.

It'

s the

certainty

that jobs are done right

,

no matter who

'

s doing

them. Find

the

experience you

'

ve been

missing at

EmersonProcess.com/

Experience

LE

P

G RY

MATUSEK

A a

483,

JEFF

Lo1B?

98

1652

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 10/92 Aug ust 201 1 | EPm ag.com 8

• Purpose. New paradigm leaders articulate the organi-

zation’s larger purpose and focus on organizational

rather than individual success;

•Ethics. New paradigm leaders communicate truthfully and with transparency, maintain relationships based

on reliability and reciprocity – in a word, trust – andstand up for their beliefs while providing channels for

others to constructively address conflicts betweenstated and enacted values in the organization; and

• Multiple stakeholders. New paradigm leaders strive to

align the organization’s multiple stakeholders’ interests

and get them moving in the same direction.

This new thinking is already under way. Rex Tillerson,ExxonMobil’s chairman and CEO, articulates key ele-

ments of the new paradigm in ExxonMobil’s 2010 Outlook

for Energy . “Demand for energy is tied to the human desirefor a better life,” Tillerson writes. “By enabling people to

become more productive – and expanding their opportu-

nities – access to reliable, affordable energy can transformpeople’s lives and the communities in

which they live. Energy also plays a key role in advancing social progress.

“Expanding access to modern energy

will be essential to meeting global targetsfor reducing poverty and hunger and

improving health and education.”

It is this kind of purpose put into

motion that must guide actions and yield results. Purpose serves as a motiva-tor for employees and a compass for the

long-term direction of the company.

Of necessity, energy firms have long been among themost engaged within communities and the political enti-

ties with whom they operate. As the complex globalindustry matured in the 1960s beyond the founding gen-

erations of explorers, successive industry challenges made

it difficult to embrace leadership behaviors beyond thosefocused on production, efficiency, and profits.

New paradigm leadership is a way to regain behaviors

needed to gain trust and respect from a wide range of stakeholders: communities; customers; prospective

employees; and opinion leaders in politics, education,and journalism.

Big payoffThe payoff for the energy industry to develop new para-

digm leaders is potentially huge. New paradigm leader-ship can attract the best investors. A 2007 University of

Pennsylvania Wharton School of Business study found that

30 companies that managed to optimize stakeholder valuerather than shareholder value outperformed the S&P 500

at three-, five-, and 10-year intervals up to 700%. In Built to

Last , Jim Collins and Jerry Porras show that organizations

driven by purpose outperformed the general market 15:1

and outperformed comparison companies 6:1.New paradigm leadership also can attract the best cus-

tomers. The Edelman Trust Barometer shows customerstake positive action based on their trust in a company,

including 84% recommending it to friends and colleaguesand 77% paying more for its products and services.

Research also shows trust and leadership integrity are

key factors that move employees to higher engagement,bringing about greater customer loyalty, employee reten-

tion, productivity, quality, and safety. 2010 data from the

Ethics Resource Center show that employees respond toan ethical culture with improved loyalty and willingness

to go the extra mile. Organizations with strong ethical values experience less misconduct, more frequent report-

ing of misbehavior, and less retaliation on the job.

The biggest payoff for a new leadership paradigm inthe energy industry could be its effect on

new talent. Meeting the global demand forreliable and affordable sources of energy

produced responsibly requires new tech-

nologies and enormous investments. As aresult, the industry’s workforce will become

increasingly skilled and sophisticated. At

the same time, the industry faces an exodus

of experienced employees as the baby boom generation retires. Attracting andretaining new skilled talent therefore is

mission-critical.

If the industry were better known for its new paradigm– its larger purposes, its ability to align the interests of

multiple stakeholders, and its ethical climate – it would

do better in attracting and retaining talented young peo-ple, especially those of the millennial generation who

wish to do well by doing good.

Talent pool

Based on the behavior of students at the Cox Schoolattending undergraduate, graduate, and executive devel-

opment programs, energy holds a lot of appeal as anindustry because of its potential purpose. Student interest

in these programs is growing, and the school is adding

programs to meet the demand. However, many energy

companies have a way to go in terms of moving from an

interesting opportunity to a preferred employer or even an

esteemed employer, such as a Southwest Airlines, Apple

Computer, or GE. An energy industry guided by new para-

digm leadership can attract the best talent, best customers,

and best investors and thus face a bright future.

industryPULSE

The new paradigm

demands

an expanded set

of leadership

capabilities at

all levels in oiland gas firms.

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 11/92

L E A D E R S H I P

-1

r

n

rn

n

n n

A

K

/

Upstream to Downstream ,

Onshore to Offshore. We

re There.

Across continents, across environments,

Cameron

is everywhere you need

us.

We

re there

at

more than 300

locations covering virtually

all of the world's

oil and

gas operating basins.

And

we

'll

be

there

for

you

at

Offshore

Europe.

Meet

us there

to

discover

solutions

that

bring

together

comprehensive

systems

and

services that address

your

challenges.

On land

or

at

sea.

See how our aftermarket network

is always there

24/7/365

to respond to your

needs.

An d

experience how field-proven products and practical know-how combine to

deliver the advantages

yo u

ve

been looking for.

Discover Cameron

at

Offshore Europe.

www.c-a-m.com

R A I S I N G

P E R F O R M A N C E

.

TOGETHER`

D I S C O V E R

C A M E R O N

AT

O F F S H O R E E U R O P E 2011

B O O T H S 5D70

&

5D80

0

C

AM

ERON

S

w

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 12/92

Unconventional energy matters

Informed by more than 40 years in the energy industry, investment banker Thomas A. Petrielooks forward to what the future holds for the oil and gas industry.

This summer, Thomas A. Petrie celebrates 40 years inthe oil and gas industry, first as an oil securities ana-

lyst and subsequently as an M&A advisor and investment banker. He has been vice chairman of Bank of America

Merrill Lynch since Petrie Parkman & Co., the Denver-

and Houston-based energy investment banking firm that he co-founded, merged with Merrill Lynch in December

2006. Formerly he was managing director and senior oil

analyst with First Boston Corp.Petrie was a keynote speaker at the Hart Energy Devel-

oping Unconventional Oil (DUO) Conference in Den- ver in late May, after which he spoke one-on-one with a

Hart Energy editor.

You have said that the development of unconventional oil in

the US has come at an especially fortuitous time, given geopo-

litical events and your belief in peak oil.

Yes. I see development of unconventional oil in theBakken shale and the Three Forks formation in NorthDakota and Montana as a world-class, 21st-century

opportunity. It’s a function of people-driven innovationand significant technological advances.

The timing of these unconventional opportunities and

a host of others that are candidates to become sources of new liquids in the US couldn’t be more propitious. When

you look at what’s going on geopolitically, with unrest

ranging up to civil war throughout the Middle East andNorth Africa and the post-Macondo implications for off-

shore drilling and US supply, to have such a new set of opportunities unfold at this time is remarkable.

The North American upstream oil and liquids sector is

morphing into a new era and a new ballgame. Further,the opportunities to develop associated midstream infra-

structure to fully exploit these resources are enormous.

What are current macro supply-and-demand fundamentals?

In terms of demand, some one-half trillion bbl of oilhave been consumed since 1945. The peak oil argument

would say there’s another 1.2 trillion or so remaining; amore optimistic viewpoint would add about 30% to 50%

to that figure.Regardless, prodigious consumption is the order of

the day. It’s important to keep that in mind despite

crosscurrents of political unrest and concerns about a

slowdown in US and worldwide energy demand fromthe weak economy.

Another big driver in the supply-demand picture isthat since 1970, miles driven in the US have declined.

But population growth worldwide continues. In 1950,

there were 2.5 billion people on the planet. Today, thereare just under 7 billion, and through 2030, it’s expected

we’ll add another 1 billion; from 2030 to 2050, another

1.5 billion.So, from now until 2050, we’ll add as many new peo-

ple to the planet as were present in 1950. And much of that population growth is occurring in emerging mar-

kets where per-capita consumption rates are rising quite

rapidly. The developed world is expected to stay fairly

Thomas A. Petrie, vice chairman, Bank of America Merrill Lynch,

recently spoke at the Hart Energy DUO Conference in Denver in

late May. The development of unconventional oil, he noted, is a

function of people-driven innovation and significant technologi-

cal advances.

Susan Klann, Contributing Editor

Aug ust 201 1 | EPm ag.com 10

worldVIEW

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 13/92

ri

BAKER

HUGHES

Dr. Satya Gupta , Sr. Research Director

Not every choice is an

either

...

or.

Some would have

you

bel ieve

that

choosing

environmentally

preferred

frac chemistry

means sacrif ic ing performance.

We beg

to

differ.

At

Baker

Hughes

,

we

'

ve developed

a r igorous

process for benchmarking

both environmental

compat ibi l i ty and

overall

performance.

The resulting

BJ Services SmartCare

''

products and

systems

are

qualified to

ensure

that

you meet critical production and

HSE

goals-while

still providing unmatched t ransparency for your

investors

,

neighbors, and regulators. That

'

s

because

every component of your customized SmartCare solution-from sur factants

and

bacter ia-control agents

to

the

slickwater system-has alread

y

been screened by

an

independent third party,

employ ing

rigorous environmental protocols.

The

bottom

line?

Maximum performance.

Minimum

impact .

Find out how Satya and others

on

our

pressure pumping team

designed a thorough

process

for ensuring

superior well

stimulation

treatments with

negligible environmental

impact

.

Get

the

full story at

www.bakerhug hes.com/satya

www.bakerhughes.com

Q

201

1 Bak pr H: gees m:mp

araied.

All Rights Reserved . 32700

56

fu

PK

a

nip

9

a

re the peop

le

of

Baker

Hughes

,f

impact

PPP_

and

our

perform a

nceour

frac

not on our

environment

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 14/92

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 15/92EPmag.com | August 2011

There’s also a confrontation/power struggle develop-

ing between Saudi Arabia and Iran, and I think what

happened was a warning shot across the bow to let Iranknow that the Saudis are looking to take definitive action.

There’s only so much the Saudis can do to increase out-put over the course of the year, however, until more refin-

ery capacity opens up that can handle their oil. At the

end of this year, new capacity will come on in Port Arthur(Texas), and in the near term, about 1 MMbbl/d will

come on elsewhere in the world to allow them to pushcrude to India, China, and other parts of Asia.

OPEC’s president has signaled there may be an emer-

gency meeting before the fall meeting. The situation willturn on what happens to oil prices if the Saudis make

good on their threat to push more oil to market.

What about the stability of Saudi Arabia? Saudi Arabia is the linchpin for security of supply out of the Persian Gulf. During my recent trip there, I was struck

by how much King Abdullah is on top of the situation. It

isn’t a totally clear case that Saudi Arabia remains stable,but the issue is at least largely deferred because of some

very proactive actions he has taken and because of thegood will he enjoys thanks to his anti-corruption pro-

grams of the past decade.

I think the issue is succession. Now may be the time forSaudi Arabia to break out of the rough resemblance it has

had to China in the 1970s and Russia in the 1980s, when

octogenarians ruled. It’s time for leadership to pass to at least the next generation, and maybe ultimately two.

The concept that a monarch in the Middle East is anabsolute power – nothing could be further from the

truth. Effectively it is a consensus-building position,

more so than our own US presidential role is, at least incurrent times.

In the region as a whole, this is just the beginning of the first chapter of change in the Middle East. It will

take decades to work out.

What’s your view on the recent decision to release oil from the

Strategic Petroleum Reserve? This was a coordinated effort with 27 other nations, with

the US supplying half of the 60 MMbbl/d total over the

30 days, at 30 MMbbl or 1 MMbbl/d. It gets criticized by some as price management, but really it is supply man-

agement, given the loss of Libyan oil, which is tough on

Europe. Putting oil on the market helps to loosen upthe ability of the world supply system to adjust, with

some supply from Nigeria and Algeria that would have

gone to the US being redirected to Europe.

It also applies some pressure to prices, which theSaudis are probably willing to accept. It contributes to

pressure on Iran, which wants to maintain levels of out-put and keep prices higher. The bottom line is we were

flirting with significant demand destruction at oil prices

above $100/bbl.

If you had the Obama administration’s ear, what would you

recommend?

We need to figure out how to accelerate the use of more

natural gas to substitute for oil imports and how to con- vert optimal development of unconventional oil into the

system. These two actions would create jobs and

enhance energy security.

If we can intelligently use more gas to displace coalin power generation and in more portions of our trans-portation network – a variation on T. Boone Pickens’

plan involving 18-wheelers – we can, on the margin,

make a difference, with lower emissions, cleaner air, andreduced import dependence. This is alongside the bene-

fits from 1.2 MMbbl/d coming out of the Bakken in thenext decade, 800,000 bbl from the Eagle Ford in the

same time frame, and something additional from the

Niobrara and Monterey shales.That’s what’s so wonderful about the petroleum sector –

the ability of producers to adapt down the food chain, fig-

uring out how to capture exposure and move it on to thenext party that can prosecute it. The development of the

unconventionals is bottoms-up and technology-driven, with astute people figuring out what to do next.

“I refer to it as the looming reality of practical peak oil. We’re

there.” – Thomas A. Petrie

worldVIEW

1

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 16/92

For many oilfield services companies, global market

opportunities mean international assignments are

becoming the rule rather than the exception. People

and equipment work with projects that demand signifi-

cant attention to such things as logistics, local legislativerequirements, payroll, and local content requirements.

At the same time, customers of oilfield services compa-

nies are concerned with the continuing rise in operating

costs and demand that goods and services are provided

ever more cost-effectively – exerting pressure on margins

and profitability.

Traditional generic management systems already strug-

gle to deal effectively with the complexities of the oil and

gas business. When components of the business in differ-

ent locations use different systems, it can be a struggle to

bring together the vital information necessary to support

successful international project assignments.Failure to manage this information results in higher

costs, lower productivity, and greater potential for human

error. A disjointed approach to managing people, suppli-

ers, equipment, and billing puts operations and busi-

nesses at risk.

Integration is the key A single integrated system is the key to having the right

people, with the right equipment, in the right part of

the world with the right certifications at the right time –

at a profit.

Integrated software packages such as SAP allow compa-nies from medium-sized enterprise to major oilfield serv-

ice and drilling companies to increase efficiency across

the board. The resultant improvements in information

distribution and reporting support management deci-

sion-making and aid delivery of more effective services.

The Advantage Oil & Gas for Oilfield Services System,

which is based on SAP best practice, was developed by

Absoft in response to requests from the industry for a

solution capable of aligning human resources planning;

equipment order and delivery; certification; payroll;

billing streams; and more.

Advantage provides a complete picture of these opera-

tions and facilitates complex planning, taking intoaccount very specific issues related to people, supply

chain, and equipment handling.

For example, the system is able to communicate any

effects that a delay to a trained staff member or certificated

piece of equipment coming on site could have on the next

phase of a project. As well as tracking people, Advantage is

able to track materials and equipment from the vendor to

the yard and onward to projects, improving asset utiliza-

tion and management of third-party equipment.

The system maximizes the use of both human resources

and equipment while reducing the cost of management

and boosting revenue by capturing all billable work. It enables companies to establish and maintain a standard-

ized process across their worldwide operations, which is

crucial to the global oil and gas marketplace.

Programmed with local standards for more than 45

countries worldwide, Advantage ensures legal compliance

and reporting requirements are met in the UK and else-

where. It simplifies and unifies the onerous tasks of sched-

uling and tracking workforce movements and handling

industry-specific workforce events such as the registration

and maintenance of regular and irregular shift patterns

and mass crew rotation changes.

Maximize business efficiencythrough all-encompassing processesTraditional management systems struggle to deal effectively with the complexities of global

oil and gas operations. A new approach gives companies an edge.

Don Valentine, Absoft Ltd.

Aug ust 201 1 | EPm ag.com 14

managementREPORT

A single integrated system is the key to allowing companies

to increase efficiency across the board. (Image courtesy of

Absoft Ltd.)

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 17/92EPmag.com | August 2011 1

managementREPORT

Routine daily tasks such as completion of timesheets

and work progress logs also are integrated into the system

to ensure accurate billing. Accessing Advantage at the

worksite allows urgent updates to be carried out on thestatus of a piece of work if an issue arises, which in turn

allows appropriate action to be planned and executed to

keep work on schedule. The integrated system provides a

clear and unified overview of operations and allows main-

tained profitability. Detailed cost planning, tracking, and

reporting procedures mean service companies can prove

competence during both tender and work phases.

The system at work Absoft recently implemented the SAP HR solution using

the Advantage implementation methodology and tools

for a major international oil and gas company, migratingall of its data from a legacy system to SAP in harmony with

the company’s other global business units.

The data transfer included sensitive personnel informa-

tion for more than 500 employees across the UK, includ-

ing principal bases in Aberdeen and

London, making complete and secure

transfer crucial to the implementation.

Moving all of the employee data to

the SAP system allows for the future

implementation of the Advantage sys-

tem’s wider human capital manage-

ment elements, including personnelcost planning, appraisal tracking, and

competency mapping.

Centralizing data from disparate sys-

tems into SAP is fundamental to the

system, as this allows its components

to be used globally, handling regional

variations such as currency or legisla-

tive requirements in a single package.

Because the data are held in SAP, the

client is able to add further modules

with the knowledge that all of the data

required are available within the systemin use when new processes like person-

nel cost planning are being enabled.

The client’s main goal was to bring

its UK system in line with its global

implementation of SAP across its busi-

ness operations, a goal that has been

completed successfully.

Central to the implementation was

knowledge transfer. Absoft’s team

trained the client’s IT management

group and the business to ensure on-

going administration could be taken forward on site.

Absoft provides additional support when required.

Developing the solutionThe ability to share the necessary knowledge and training

on the ongoing development of the system, which helped

the company clinch the deal at competitive tender, was a

key aspect of Absoft’s service.

The company’s oil and gas team continues to engage

with the sector to investigate solutions to challenges

faced in day-to-day operations. These include quarterly

forums specifically aimed at oil sector employees work-

ing in supply chain, operations, and maintenance.

SAP is used by a significant number of energy compa-

nies. Providing an arena where participants can discuss

good practice and topical issues is already helping busi-nesses to make the most of their investment in the system.

The sessions also have allowed Absoft to continue to

develop additional capabilities within the software that

reflect the industry’s needs.

Borehole

Data

Management Solutions

Collected over a

long

period of time and at

si

gnificant cost,

borehole data is essential to effectivel y

maximize

existing

reservoirs

,exp

lore for

additional energy sources

and

drive

growth

for

your

company.

--

I

W .

1

,

1

=1 ,l?

1?

l x

'11 a

L I K I

www.Petris.com

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 18/92 Aug ust 201 1 | EPm ag.com 16

Oil and gas operators often deal with large regional

projects, sometimes involving more than 200,000

wells, which can result in a tidal wave of data coming from

a number of different users and various disciplines. Thechallenge for many operators is to improve decision-mak-

ing by using data that are relevant, qualified, and sani-

tized. With rapidly expanding functionality, it is becoming

increasingly important for geology and geophysics (G&G)

software users to quickly find the specific data workflows

they need to use on a day-to-day basis. For this reason, the

latest release of Petrel includes improvements that focus

on the behavior and needs of the human users – the most

critical element of success with G&G projects.

A new way of working

The Studio E&P knowledge environment has beencreated to streamline everyday tasks through workflow

improvements and is scalable from the individual to the

largest enterprise. Studio functionality enables organiza-

tions to scale to the enterprise level while also allowing

multi-user collaboration without the burden on perform-

ance issues. Users can use data within an earth-model

context while interpretation team knowledge is also cap-

tured and stored so that it is carried forward and embel-

lished rather than recreated. Through the live knowledge

environment, data are kept fresh. This allows the users of

that data to make decisions based on the most up-to-date

information available as opposed to the “stale” data that often plague many G&G projects.

Despite using advanced science and technology, G&G

interpretation and modeling has always required an ele-

ment of art where the geologists and geophysicists become

the artists. As a studio provides a space for artists to profi-

ciently execute their craft, the Studio environment focuses

on ease of use and intuitive design to empower the G&G

professional.

Finding relevant dataE&P companies have access to massive volumes of private,

commercial, and public data from a diverse range of loca-

tions. The search capability of Studio, Studio Find, can

provide an index to this distributed database and enable

users to look within the context of their specific projects

to reduce or eliminate irrelevant information. This

focused process of information retrieval has been widely

documented in academic research about “dimensions of

relevance,” where relevance can refer to what is valid, reli-

able, and current. The new environment enables a variety

of searches in addition to geographical area such as proj-

G&G software acceleratesuser productivityA new knowledge environment focuses on the human interface to improve user efficiency

and advance corporate knowledge capture.

Floyd Broussard, Patrick Dineen and Keith Tushingham,

Schlumberger Ltd.

The Studio Find allows users to see all data available in the main

Petrel 2-D or 3-D window. (Images courtesy of Schlumberger Ltd.)

Users can access, transfer, publish, and store information to

enhance the company knowledge base with Studio Knowledge.

digitalOIL FIELD

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 19/92

mKc i

McJunkin

Red Man

Corporation

m

B

C

I

MIDFIELD

mic

Trans

m

ar

kq

°

p

7

i

qffimmmmmmmmw?

1921 2011

r

i

?Jq

Global

Supplier

of Choioe

®

oStrength

oLongevity oDependability

Proud of

Our Past .

Prepared

for Our Future .

a

......................................................................................... www.mrcpvf .com

?`

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 20/92 Aug ust 201 1 | EPm ag.com 18

ect type (e.g. exploration, development) and the role of

the person searching to aid in the fast access of data and

information significant to their needs.

Map services A growing volume of information is available in the form

of visual maps – some public (e.g. Google Earth), some

commercial, and some proprietary to E&P organizations.

This information, which is typically updated frequently,

has historically been uploaded at the start of a project,

where it can soon become out-of-date. Studio Find pro-

vides immediate access to live ArcGIS data via web map

and ArcGIS services in current 2-D and 3-D windows. It

automatically handles multiple coordinate reference sys-

tems, which can be a major issue in exploration projects

that cover large areas.The map data are available as a series of layers and can

be filtered using smart search capabilities such as particu-

lar keywords, data types, projects, users (originators), or

well depths. Users can zoom in to reveal increased detail

of information. This zooming often involves further filter-

ing to focus the search and bring the data volume to a

manageable level and maximum relevance. For example,

users can select wells penetrating a particular depth,

drilled by a particular operator, and/or completed with

specific technologies.

Data annotationThe data and map-based information discovery capabili-

ties of the Studio environment are key elements to its

focus on collaboration and knowledge capture. Another

component is the ability to tag content, therefore helping

to qualify the information, provide context and insight

into previous ideas, and enrich the combined thought

processes. This basic functionality is common in PC appli-

cations such as Adobe Acrobat, where text editors can

leave sticky notes or links to comments. Petrel users

might insert geo-referenced comments such as “This

was a quick interpretation done in a rush to meet a tight

deadline,” or “The interpretation of these West Africanturbidites is based on an analog from deepwater Brazil.”

In addition to simple text comments, Studio Annotate

allows links to related documents that give users a more

complete understanding of their peers’ contribution to

projects. These could include details of well completions

such as the additives and proppants used. Annotation also

can contain diagrams and photographs, like those of sur-

face equipment installed downhole. Easy access to this

type of information should enable a more comprehensive

analysis of offset wells to optimize the design of new

drilling and completions programs.

Session sharingThe old adage “a picture is worth a thousand words” is

certainly the case with G&G modeling. Appropriate visu-alization makes it possible for people with diverse expert-

ise to absorb large amounts of information quickly. These

people often are in different locations, so multinational

oil and gas companies use web-based systems for remote

collaborative meetings. A long-standing problem even for

high-performance applications is that many commercial

global collaboration tools cannot handle data volumes

fast enough. The new Studio Share software module

has been specifically tailored for the 3-D visualization

tools of Petrel, presenting a high-performance system

in which sessions can be shared on multiple screens

around the globe.

Capturing knowledgeNew collaboration tools and integrated multidisciplinary

workflows permit multiple members of an asset team

to build models and develop plans together. Team mem-

bers often change, and details can be quickly forgotten as

people move between projects. Studio Annotate provides

context through quality tagging attributes, indications as

to who contributed to certain parts of the G&G processes,

and notes on different decisions.

A structured “Publish” model enables shared access to

content “blessed” by an expert individual or team whilemaintaining privacy of the “sandbox,” where individuals

can test their ideas. The result is a higher quality corpo-

rate data repository, with intermediate and trial datasets

and models remaining on individual users’ computers for

personal use. Real-time alerts are sent to relevant users

when new qualified information is published, notifying

them of updates and synchronizing versions among the

multidisciplinary team. Team members can be notified as

soon as information changes or when a new surface has

been created or updated. Users can then view and load it

immediately, so interpretation is always up to date.

digitalOIL FIELD

The Studio Annotate feature allows users to enrich projects with

knowledge in context.

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 21/92

FluidControl noun 1.

experts

2. technology and

service

driven company focused

on

minimizing

fluid creation

,

r e d u c i n g

disposal costs and im pr ov ing

over l l

drilling and

production

per fo rmance 3

.

delivering environmentally sound

solutions that emphasize wel lbore integrity

?

I

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 22/92

Sha

le

Solutions

Cudd Energy

Services

(CES)

has

the

experience

and reputation for providing

integrated services in today s

oil

and

gas shale p

lays. Our

experienced

eng ineers

and

staff

will

develop

a plan

,

design the solution and

mobilize

the

resources to

help you

release the full potential of your

oil

and gas wells

.

To

learn

more

call

your

local

CES representat ive

today

at +1

.

83 2

.

295

.

5555

.

Proven

Experience

.TrustedResults

www.cudd.com

1 1

I?

Aa?

1

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 23/92EPmag.com | August 2011 2

Global companies need reliable enterprise solutions

to manage their assets. While enterprise resource

planning tools such as SAP help to streamline these

processes, their sheer size can sometimes compromise

the flexibility required to nimbly manage a worldwide

portfolio.Rowan Companies Inc. has a fleet of 22 high-spec off-

shore jackup rigs and 32 deep-well land drilling rigs, and

it also owns and operates a manufacturing division that

produces equipment for the drilling, mining, and tim-

ber industries. The company’s specialty is delivering

innovative drilling products and systems for hard-to-drill

deep gas wells.

Rowan’s operations – from company headquarters in

Houston to offshore drilling locations in the Gulf of Mex-

ico, the Middle East, the North Sea, Mexico, Egypt, and

Trinidad – require robust information technology such as

SAP’s enterprise applications, specifically SAP ECC 6.0.Because the company uses hundreds of SAP financial

documents and thousands of line items on a regular

basis, maintaining accurate records and keeping data up

to date for planning, billing, and accounting purposes is

a major challenge. SAP’s reliability, breadth, and depth

make it a critical investment for Rowan companies. How-

ever, the breadth and depth that make the system so

valuable frequently result in new levels of complexity

and inflexibility, making it difficult for nontechnical

users to fully leverage the power of SAP.

ChallengesRowan tasked its SAP project team with improving the

efficiency of monthly billing cycles as well as simplifying

the process for entering new financial data into the sys-

tem. The team quickly encountered several challenges.

Integrating master data from multiple legacy systems

into SAP was creating faulty data and causing frequent

errors. While assessing the monthly billing process, the

SAP project team discovered that every company bill

required significant manual input. For example, numer-

ous line items for operating hours, catering, mainte-

nance, etc., had to be input manually from forms into

SAP. Finally, the Rowan team found that the billing and

journal-entry process consisted of painstaking copying

and pasting, as much as 13 lines at a time from Excel

spreadsheets. This combination of erroneous data and

tedious manual entry caused delays in month-end clos-

ing as well as a lot of frustration.

Solution

Initially, the SAP project team and IT support staff usedSAP’s Legacy System Migration Workbench (LSMW),

a tool that supports the one-time or periodic transfer of

data from a variety of sources without programming to

upload journal entries. However, the LSMW data-migra-

tion fixes were inflexible and, due to the constantly

changing requirements either internal or mandated by

governing organizations, time-consuming to update.

Then Capgemini, a provider of consulting, technol-

ogy, and outsourcing services, introduced Rowan to Win-

shuttle’s Transaction tool at a technology conference.

The Transaction tool records the steps that a user takes

to complete any SAP transaction and maps the relevant

SAP fields to an Excel spreadsheet, creating a file tem-

plate that can be run to “shuttle” data between Excel

and SAP.

Rowan Assistant Controller Andy Hart immediately

recognized the value of Transaction. With Winshuttle

Transaction, Hart and his team members discovered

digitalOIL FIELD

SAP application executesmore data loads in less timeNew user-friendly tool eases data transfer.

Ray Vincenzo, Contributing Editor

The Transaction tool sped up Rowan’s master data cleanup proj-

ect. (Image courtesy of Winshuttle)

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 24/92

Change

Your

P

e

rformance

9

1

1

0

700

,000

600

000

500

,

000

400

,000

300

,000

200

,000

100

,

000

-100

,000

-200,000

-300,000

Weatherford

introduces the TruForm

r°

expandable

liner hanger system.

.

,,,w,

-A(=

-2000

0

2000

4000

d0011

EkODW

eo o on

2W

Am

V Y

-14

,

000 -

12000

-

10000

Above

pressu re

When high-pressure annular seal integrity is

critical

,there is nothing like

the Tru orm system

.

VO

qualified*

at

12

000psi (82.7 MPa ), this one-of-

a-kind

technology

performs like no

other.

Dr i ling

, e, a a t L n

Well

construct ion

Cementing products

Cement ing services

Drilling fluids

Drilling tools

Inflatable packers

Lner systems

Expandable

iner

hangers

Liner

accessories

Liner cementing

systems

Liner

hangers

Liner packers

Liner

tie-back

equipment

Running

tools & accessories

Surface equipment

Mechanized rig

systems

Solid

expandable

systems

Swellable products

Tubular running services

The

Tru orm hanger features a one-piece,

thick-wall

expandable

body

that

provides maximum seal integrity while recessed tungsten carbide inserts

enable higher hanging capacity for a longer life than rubber elements.

We call it Tactical Technology

'

.

Yo u

ll call

it

true performance.

Visit

weatherford.com/TruForm

,

or contact

a Weatherford representative

for the true story.

The ch nge will do you

good

1W

Weatherford

weatherford.com

7.000- x

9.625-in.,

47.0-

to

53.5-

lb

hanger

,

tested to ISO

14310

(API

11D1)

standards

V

: r i t

0 2m t

w o

rm

&dord

ntmaaonal Ld WI

ng

nt$

rme\0C Irco2.

I : i

I

Pr)iuction

40

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 25/92

they could better focus their efforts on specific pieces of data cleanup. “We

had one large LSMW that was built to edit all of the fields in a Vendor Mas-

ter Record,” Hart said. “However, it was the Vendor Tax ID numbers withinthese records that specifically needed to be cleaned up.” Once the team

gathered the Tax ID numbers, they could easily create a Winshuttle tem-plate on the fly to update the Tax ID number field without having to worry

about an Excel spreadsheet that contained all of the Vendor fields.“Projected to take six months, the master data clean-up project was

completed in just four, leaving time for additional end-user training and

post-production support,” Hart said. Winshuttle Transaction also allows the Rowan SAP project team to address

error elimination when uploading data from legacy system. Because Transac-tion tracks all of the data it “shuttles” into SAP, the software provides auto-

mated error alerts to the Rowan team, making it easy and efficient to retrace

the data migration steps in Winshuttle and address specific causes of faulty data.

Results

Winshuttle enables Rowan to greatly accelerate SAP data transfer, complet-

ing thousands of journal entries in a fraction of the time required with man-ual data entry. “What were once dreaded and laborious journal entries are

now user-friendly and easy to organize,” Hart said. “We have saved so much

time that we consider Winshuttle worth the cost just for the journal entry input.”

Not only do the books now close on time, they are completed a weekearly. In addition, Transaction reduces the time associated with reporting

and reconciliation. Hart said he generated 1,274 cost center reports in 13minutes.

Transaction also helps increase productivity within the billing department.

Employees used to spend many unnecessary hours copying nine lines at atime from the customer contract into Excel, updating the billable hours for

each line, and then pasting them into the billing screen in SAP. Now all of

Rowan’s contract billings are created with a Winshuttle template. The billingagent puts in all the header type information (customer, contract number,

date, etc.) and then runs a script to read the contract lines out to the tem-plate. The agent fills in the time to bill for each type of service, marking the

unused lines for deletion, and runs a second script to create the sales order.

“It probably wouldn’t be too bold to say that Winshuttle saved us from an

entire process redesign of billing,” said Rick Sonora, billing manager at Rowan.

Future plans

Since Winshuttle makes it possible for Rowan to execute more accurate data

loads in less time, Hart’s team has more resources available to think strategi-cally about SAP deployment.

“Winshuttle improves our productivity as a team and as an organization,so we’re better able to step back and take a broad look at the overall effi-

ciency of our financial implementation,” Hart said. “The more we do that,

the more opportunities we see for Winshuttle to help us perform data con- versions in far less time.”

EPmag.com | August 2011

digitalOIL FIELD

1W

Weatherford'

TacticalTechnology

TM

in action:

TruForm

expandable

liner hanger system:

Forming

a

true seal

L

mvts

?I I

??

I

lit,

The TruForm hanger uses the

industry '

s

only low-pressure ,

self-

adjusting expansion system that truly

forms the

hanger

body to the

parent

casing geometry.

To learn more about how the TruForm

system can perform

for you

,

visit

weatherford.com/TruForm.

The

change

will

do

you good

-

weatherford.com

t

2C.'

lePrtaafortl

MenwrFn?l

Ltd Al r jms resenNd

Ircntp.;rataspropmtary

nd pstcntcddk,,I

L,

ad tor agy.

I I I

' '

F

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 26/92

E P and

FOR

Related Services

c

L

L

Dril l ing and

Comp

le t ion

W ell Intervention Services

Dri l l ing F lu id Services

\Vire l ine

Logg ing and

Perforatio n Services

M u d

Logg

ing and Auxiliary

Services

Well T e s t i ng and Produc

t i o n

Services

c

t

E P

Program

Research

and

Desi

gn

Heavy

Oil Reservo ir Development

Directional Dri l l i n g

Cement ing

C

o r i n g .

For iua t ion

and Rc ., e r \o i l E v a l u a t i o n

Provid ing Integrated

Solutions from Geolog ical Research

,

Development Progra m and Well

Desi

gn to Well Comp

letion.

tl E m a i l : n n a r k e t i n g (u c n l c . c n ; m a r k e t i n g l . g w d c (a e i i p c . c o i n . c n ? www.cn lc .cn ?i T e l : 8 6 - 1 0 - 5 9 2 8 5 6 9

ma

CNL C

1 11 II? ra ja

1

?

P

AID

?

?

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 27/92

When Repsol-YPF launched its Kaleidoscope project

four years ago, its purpose was to study new hard- ware alternatives to realize the promise of reverse time

migration (RTM) for oil and gas exploration.

What the company perhaps didn’t envision was theother potential uses of the computer. Repsol is now

partnering with the US government to develop a betterunderstanding of how earthquakes occur. The project,

being conducted offshore Costa Rica, is intended to

help scientists visualize and monitor the folds in the tec-tonic plates in the region.

“We’re really trying to understand zones around the

world that produce large earthquakes,” said Nathan L.Bangs, senior research scientist, Institute for Geophysics

at the University of Texas-Austin. “This is a scientific pur-suit to understand the process of subduction zones,

which are the settings that produce large earthquakes.”

In addition to the University of Texas, the Universityof California-Santa Cruz and the Spanish Institution

for Research are also involved in the project.

Costa Rica is a natural choice for the study. Bangs said

the area regularly produces fairly large earthquakes inthe range of 6.5 to 7.2 magnitude on the Richter scale.

Already it has been the subject of much study.

“There have also been some 2-D profiles,” he said.

But we really need 3-D seismic to look at some of thestructural details and to map out the plate interface zone

that slips during the earthquake.”Because of the nature of the area,

it is possible for the team to

study the subduction zone at relatively shallow

depths. Bangs said

the Cocos plate, anoceanic crust, is

subductingand

extending beneath

the Caribbean plate. A large 3-D survey

was collected earlier

this year, and Repsolis processing that

data, first in a con-

ventional time domain and then in depth. The depthimaging will be conducted using the RTM algorithm

Repsol developed for the Kaleidoscope project.

“Usually people think that RTM is only good for sub-salt,” said Francisco Ortigosa, geophysics director for

Repsol-YPF. “In other areas of the world where we

explore, we’ve found that RTM is very suitable for thiskind of environment where you have thrusting over

thrusting and complex structures.“We think we have technology that is very suitable for

this environment.”

Time processing should be complete by November,

with a final depth migration ready in May 2012. “It’sgoing to be a challenging project, but we are pretty sure

we can get a very high-fidelity image of the subsurface in

this part of the world,” Ortigosa said.

For Bangs and his colleagues, this will be a tremen-dous help. “These are very complicated structural set-

tings,” he said. “This is a subduction zone that has a

collision between two plates, and the collision processproduces a tremendous amount of deformation of the

overlying plates.”He added that the goals are to see the plate interface

more clearly and also to study the effect of the tectonic

movement on fluids. Fluids are squeezed out of therocks, and the pressures they produce are important for

controlling the strength of the fault zone, he said.

For Ortigosa, the partnership is a good example of cooperation between industry and academia. “We are

concentrated on our business, of course,” he said. “But it’s a nice opportunity to collaborate with academia in a

mutually beneficial project for

both parties. It’s part of Rep-sol’s commitment to be socially

responsible.”

RTM aids in earthquake studyRepsol’s Kaleidoscope project is being tapped to increase understandingof tectonic movement.

Read more commentary at

EPmag.com

RHONDA DUEYSenior Editor

2

explorationTECHNOLOGY

EPmag.com | August 2011

We thinkwe have

technologythat is very

suitable for thisenvironment.

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 28/92

FRACTURI

"Introducing a

quick

,

more efficient

completion

process

that

will neve

r

ove

rstay its

welcome

Now

, you can

improve f ractur ing efficiency while saving

time

and

money

with BioVert ' NWB diverter from Halliburton. Using BioVert

NWB

diverter

can reduce

the

number or even eliminate

the

need for frac plugs and

drillout

,

resulting

in

improved completion efficiency and increased reservoir

contact. Then

it degrades

completely, eliminating the cost

,

t ime and effort

of removal.

And

with

Halliburton '

s

FracTrac

racture

mapping

service ,

yo u

can instantly validate

you

r diversion e ffectiveness.

BioVert NWB diverter

and FracTrac service-two more ways Halliburton gives you even

better

multi-stage completion results.

What

'

s your

fracturing

challenge?

For

solutions go to halliburton.com/fracturing.

Solving

challenges

:

HALLIBURTON

l

4ft

'7

r

tq

s

6

8/10/2019 Revista E&P - Agosto 2011

http://slidepdf.com/reader/full/revista-ep-agosto-2011 29/92

wellCONSTRUCTION

More and more, engineers are developing new

ways to improve on the old way of doing things.

As Hart Energy ramps up for its DUG Eagle Ford

Conference to be held in San Antonio, Texas, Oct.

10-12, the question of how technology impacts uncon-

ventional resource development has become a major

focus for the E&P editors.

Newer tools, such as rotary steerable systems and

real-time acquisition devices designed specifically forhorizontal applications (i.e. an average shale well),

make headlines on a regular basis. Rig design, namely

in the areas of automation, pad drilling, and smaller

footprints, are a major focus for many operators and

the companies that supply these rigs to market.

The debate looms large over whether or not

the burgeoning unconventional resource sector

requires an unconventional approach to rig design.

This debate is compounded by the generation gap

among all fields within the industry. As older, more

experienced crews become exposed to newer, more

advanced systems, there often is resistance to adopt-ing these tools or even admitting that they some-

times work. The “old school” is often the only

school when discussing the best methods to drill

a well.

The expression “Nintendo generation” is

sometimes used to refer to the newest genera-

tion of oil and gas workers. These engineers

are characterized by a high level of computer

literacy, a keen disposition to plug-and-play

technology, and a tendency to lose interest

in careers that do not consistently introduce more

advanced technology at a rapid pace. The “new

school,” as it seems, will require different approaches

to drilling technology, which is often set on doing

things the old way.

The difficult decision is for drilling contractors and

their customers to determine exactly what tools and

equipment are obsolete, which ones will be

standard in the future, and what

other technologies can have major

benefits if adopted for the oil and gas

industry.In an effort to define some of these