Research on the Dynamic-Elegance Property of Fabric

Transcript of Research on the Dynamic-Elegance Property of Fabric

,

,,

!"#$%"#&'' !&(&"$$")''

*+!*+ ,+*+ !,**+ ,+*+ !-

*,+'+ +**+!+

Abstract. Fabric deformation performance is an index that characterizes the dynamic performance of

the fabric. However there is no separate study about fabric deformation performance. According to

morphological wave data measured by fabric deformation testing device made by ourselves, we have

determined to cluster analysis fabric deformation performance with the following six indicators, that

is, the wavelength of the first half-wave, amplitude, half-wave area, shape coefficients, amplitude

attenuation coefficient, and the number of half-wave, and also have done comparative analysis of

deformation characteristics of four types of fabric. The results showed that the six indicators can

measure the different kinds of fabric’s deformation characters much better, and showed that the

weight of per square meter of fabrics and bending rigidity have influenced significantly. The research

results have a realistic meaning for fabric processing technology and the rational use.

Introduction

Fabric deformation performance is referred to the characteristics of fabric curved surface

morphological changes when blown by wind or affected by external forces. It’s the indicator of fabric

dynamic performances. Fabrics have different styles of deformation waves. According to the tested

one-way deformation wave data got from the device made by ourselves [1] under the constant

chuck speed and amplitude, we have measured and classified the fabrics with similar waveform with

the clustering analysis [2]. The characteristics of different kinds of deformation waves have been

compared, and the key influencing factors also have been analyzed.

Materials and experimental procedures

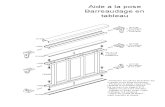

The classification of fabric deformation waves. The chuck

frequency of deformation testing device is 182rpm, the amplitude

is 4.4cm, and the length of samples 31.5in, the width 3.94in. Shot

deformation waveform of samples at the same place, determined

six clustering analysis indexes, classified the fabrics. The

deformation wave morphology is shown in Figure 1.

Since the fabric deformation wave morphology is amplitude

attenuation form[3], by analyzing many relevant indicators[1], we

removed the ones with obvious linear relationship and determined

six indicators for clustering analysis, that is, the wavelength of the

first half-waveλ, amplitude A, half-wave area S(S=Aλ), shape

coefficients Ω(A/λ) , amplitude attenuation coefficient ψ

( λ

Aln4.4ln −

), and the number of half-wave N.

Fig.1 The deformation

wave morphology

Advanced Materials Research Vol. 796 (2013) pp 161-165Online available since 2013/Sep/18 at www.scientific.net© (2013) Trans Tech Publications, Switzerlanddoi:10.4028/www.scientific.net/AMR.796.161

All rights reserved. No part of contents of this paper may be reproduced or transmitted in any form or by any means without the written permission of TTP,www.ttp.net. (ID: 130.15.241.167, Queen's University, Kingston, Canada-17/08/14,19:39:31)

Collect the 32 samples’ waveform data, divide the fabric deformation wave morphologies into four

categories based on the deformation dendrogram [4]2.

Fig.2 Deformation dendrogram ( 37.polyester coating; 44.polyester crepon; 41.tribute silk;

42.wool fabric; 46.polyester velvet; 36.bast fabric; 43.woolen goods; 28.satin brocade;

45.wool valitin; 53.cotton corduroy; 29.bast printed gauze; 23.silk printed gauze; 35.raw silk

hobotai; 22.silk crepe georgette; 12.polyester variegated silk; 52.blue silk hobotai; 24.silk

hobatai; 40.nylon variegatel silk; 30.silk stretch crepe; 34.light silk gauze; 32.silk satin;

33.opal finished georgette crepe; 49.whiht cotton muslin; 33.silk crepe georgette; 26.whihte

polyester silk; 31.silk printed silk; 51.polyester silk; 47.yellow cotton muslin; 21.silk crepe de

chine; 48.white cotton fabric; 25.cotton fabric; 50.rayon lining)

Results and Analysis

Results. The measured deformation representing waveforms of four categories are shown in Figure 3.

(1) (2) (3) (4)

Fig.3 The measured deformation representing waveforms of four categories((1)the first category;

(2)the second category; (3)the third category; (4)the fourth category )

162 Silk, Protective Clothing and Eco-Textiles

Analysis.

The characteristic analysis of deformation waveforms of four categories. From the

deformation wave parameters of four categories, obtain the average parameters of various types of

fabric, as shown in Table 1.

Table 1 The average parameters of four categories

category A λ S N ψ Ω

The first 2.933 20.333 59.644 5 0.011488 0.1459

The second 3.825 19.500 74.588 5 0.006007 0.1972

The third 3.714 25.000 92.857 4 0.004699 0.1497

The fourth 4.200 31.818 133.636 3 0.001278 0.1321

According to the table, draw character maps of four categories, as shown in Figure 4.

Fig.4 The character maps of four categories

It can be seen that the lower the fabric class, the smaller the half-wave area is, the smaller the

energies absorbed by the fabric in the deformation process, and the easier fabric to deform. The

amplitude attenuation coefficient and shape coefficient of the fourth is the least. Therefore, the fourth

is the most difficulty to deform, with dull deformation form, slim wave morphology, and poor sense

of dynamic. Meanwhile the first is the most likely to deform, wave morphology is full, and the sense

of dynamic is strong.

The dimension area of fabric deformation wave

shape. According to the four categories deformation wave

parameters and Table 1, the range of amplitude by

measured various fabrics is 1.10~ 1.73in, the range of

wavelength is 7.48~13.39in, and shape coefficient is from

0.1154 to 0.2222. The fabric shape dimension area is

shown in Figure 5.

It can be seen that for the high-class fabric, the

deformation wave shape dimension is located on the upper

area, and belongs to large-amplitude and long-wavelength

wave, at the same time for low-class fabric, the dimension

on the lower area, and belongs to small-amplitude and

short-wavelength wave.

Fig.5 Waveform shape size region

of fabric

Advanced Materials Research Vol. 796 163

Discussion

The weights and bending stiffnesses of four categories. The averages of weights G(g/m2) and

bending stiffnesses RF(mN﹒cm)of four categories are shown in Table 2.

Table 2 The averages of four categories

G R

The first 27.9 5.5

The second 32.8 17.8

The third 63.4 39.1

The fourth 154.7 118.5

It can be seen that the higher the category of fabric, the larger the weight per square meters, the

larger the bending stiffness.

The weight and half-wave area of four categories. The weight per square meters is an important

influencing factor for deformation wave. The weights per square meters and half-wave areas are

shown in Figure 6.

Fig.6 The scope of fabric weights and half-wave areas

It can be seen that the areas of fabric half-wave are getting larger with the increasing of fabric

weight per square meters.

The effect of fabric weight per square meters on shape coefficients. The relationship between

shape coefficients of deformation wave and fabric weight per square meters is shown in Figure 7.

Fig.7 The area chart of four fabric shape coefficients

164 Silk, Protective Clothing and Eco-Textiles

With the increasing of fabric weight per square meters, the shape coefficients tend to decrease.

And when the former reaches to high level, the latter tends to stable condition. The fabric weights of

per square meters of the third and fourth are the largest, and their shape coefficients are the smallest.

While those of the first and second are higher and more scattering, indicating that the influencing

factors are more complex.

Conclusion

We clustering analyzed 32 kinds of fabrics with six indicators, that is, the wavelength of

half-wave, amplitude, half-wave area, shape coefficients, amplitude attenuation coefficient and the

number of half-wave, and divided them into four categories. Among them, the first ones are thin silk

fabrics belonging to small-amplitude and short-wavelength wave, while the fourth are heavy and

thick fabrics, such as flax, wool and polyester, belonging to large-amplitude and long-wavelength

wave.

With the increasing of the category, the areas of deformation wave half wave are getting larger, and

the amplitude attenuation coefficient, wavelength of half-wave and shape coefficients are getting

small. Among them the average area of half wave of the first is 23.48 in2, which is the least in all

samples, indicating that the energy absorbed by the fabric during deformation is the smallest, so this

category is easy to deform, and the average amplitude attenuation coefficient is 0.011488, which is

the maximum, so the fabrics show the elegant and beautiful morphological changes. The average area

of half wave of the fourth is 52.61in2, which is the largest in all samples, indicating that the energy is

the largest, so this category is hard to deform. The average amplitude attenuation coefficient is

0.001278, which is the minimum, indicating that the energy consumed in the propagation process is

the least and the propagating distance is far. The average shape coefficient is 0.1321, which is the

least in all samples, indicating that the shape is not full and thinner. The second and third are located

in the middle.

The larger the fabric weight of per square meters and bending rigidity are, the higher the category

of fabrics is located. So the fabrics are not easy to perform, and dynamic is also poor.

References

[1] Y.T Zhang. Study on Fabric Possibly Deformation Performance. Scoochow University. 2012.

[2] K.T Fang and E.P Fan .Clustering analysis.Beijing:Geological Publishing House. 1982:

p.23-25.

[3] Y.T Zhang, Y.M Wang and M Yao.Study on Test Methods of Fabric Possibly Deformation

Performance. 8th International Shibori Symposium.2011:p.140.

[4] W.TZhang SPSS11Statistical Analysis Tutorial.Beijing:Hope Electronic Press.2002.

[5] L.H Fan,L.P Shen and Y.F Duan. The relationship between fabric bending properties and

composition parameters.Shanxi Textile.1999(42)2:p.31-33.

Advanced Materials Research Vol. 796 165

Silk, Protective Clothing and Eco-Textiles 10.4028/www.scientific.net/AMR.796 Research on the Dynamic-Elegance Property of Fabric 10.4028/www.scientific.net/AMR.796.161