Research Article Cartesian Mesh Linearized Euler Equations...

Transcript of Research Article Cartesian Mesh Linearized Euler Equations...

Research ArticleCartesian Mesh Linearized Euler Equations Solver forAeroacoustic Problems around Full Aircraft

Yuma Fukushima1 Daisuke Sasaki2 and Kazuhiro Nakahashi3

1 Institute of Fluid Science Tohoku University Sendai 980-8577 Japan2Department of Aeronautics Kanazawa Institute of Technology Nonoichi 921-8501 Japan3Japan Aerospace Exploration Agency Chofu 182-8522 Japan

Correspondence should be addressed to Yuma Fukushima fukushimaedgeifstohokuacjp

Received 30 January 2015 Accepted 26 March 2015

Academic Editor Mohamed Gad-el-Hak

Copyright copy 2015 Yuma Fukushima et al This is an open access article distributed under the Creative Commons AttributionLicense which permits unrestricted use distribution and reproduction in any medium provided the original work is properlycited

The linearized Euler equations (LEEs) solver for aeroacoustic problems has been developed on block-structured Cartesian meshto address complex geometry Taking advantage of the benefits of Cartesian mesh we employ high-order schemes for spatialderivatives and for time integration On the other hand the difficulty of accommodating curved wall boundaries is addressedby the immersed boundary method The resulting LEEs solver is robust to complex geometry and numerically efficient in aparallel environmentThe accuracy and effectiveness of the present solver are validated by one-dimensional and three-dimensionaltest cases Acoustic scattering around a sphere and noise propagation from the JT15D nacelle are computed The results showgood agreement with analytical computational and experimental results Finally noise propagation around fuselage-wing-nacelleconfigurations is computed as a practical example The results show that the sound pressure level below the over-the-wing nacelle(OWN) configuration is much lower than that of the conventional DLR-F6 aircraft configuration due to the shielding effect of theOWN configuration

1 Introduction

To satisfy the severe requirements of environmentally fri-endly aircraft the applications of significant technologicaladvances to conventional aircraft are needed Presentlysome of the most urgent targets are noise emission andfuel consumption Green aviation which seeks to meet thedemands of the noise regulations of the next generationhas been proposed and intensively studied worldwide [1ndash9]The continual reduction of noise has been steadily advancedfor about 40 years mainly due to improvements in engineperformance [4] Examples of these advances are an increaseof the bypass ratio the use of geared fan machinery andthe improvement of liners and vanes However airport noiseregulations are becoming increasingly stringent Aircraftof the next generation must meet these regulations withsufficient margin for future tougher limits

The noise generated from aircraft is classified into twomain groups airframenoise and engine noise Airframenoiseis mainly turbulent noise generated from high-lift devices

and landing gears Engine noise is the sum of fan andjet noises During takeoff fan and jet noises are dominantbecause the engine is at full throttle On the other handthe airframe and fan noises are dominant during landingUnder both conditions fan noise is one of the dominantfactors of community noise generated fromaircraft To realizea dramatic reduction of engine noise shielding the fannoise from the engine nacelle by the fuselage or wings isone of the reasonable approaches that have been applied[10ndash12] Various unique aircrafts have been proposed andevaluated from this point of view using computational andexperimental approaches To design such unconventionalaircraft it is imperative that noise propagation be reliablyanalyzed to estimate the shielding effect accurately

A common computational approach used to analyzenoise propagation is based on the linearized Euler equations(LEEs) which is one of the accurate methods available forcapturing the propagation of sound [13] LEEs can addressnoise propagation from known noncompact sound sourcesin a nonuniform mean flow field The method can also

Hindawi Publishing CorporationInternational Journal of Aerospace EngineeringVolume 2015 Article ID 706915 18 pageshttpdxdoiorg1011552015706915

2 International Journal of Aerospace Engineering

address scattering diffraction and reflection by objects LEEsare often solved on body-fitted structured and unstruc-tured meshes [14ndash17] From a practical point of view thesemeshes have some drawbacks in the computation of realisticcomplex geometries Body-fitted structured mesh is fit tothe object and is able to adapt to detailed componentsprecisely however the computational cost of mesh gener-ation around an entire aircraft or more complex geometryis quite high Unstructured mesh is applicable to complexgeometry however it generally achieves low-order accuracyin space In addition high-order unstructuredmethods incurconsiderable computational cost Due to these reasons asimple Cartesian mesh is the focus of the present researchGeneration of Cartesian mesh is based on the simple divisionof the computational domain and thus it can easily accom-modate complex geometries Furthermore a high-orderscheme is easily employed by the extension of stencils Rapidcomputation is achieved owing to the simple computationalstructure of the Cartesian mesh However the main problemassociated with Cartesian mesh is numerical error causedby the staircase wall boundary In this research a block-structured Cartesian mesh method denoted as the building-cube method (BCM) [18ndash22] and the immersed boundarymethod (IBM) are applied to solve the abovementionedproblemUsing the BCM an appropriatemesh resolution canbe locally assigned over the entire computational domainIBM helps to maintain a practical minimum mesh size andto achieve highly accurate wall boundary conditions

The purpose of this research is to develop the LEEs solverto compute noise propagation around complex geometryeasily and robustly To achieve this purpose the BCM isemployed in conjunction with IBM First a one-dimensionalwave propagation problem is evaluated Second acousticscattering around a sphere is computed Third noise prop-agation from the JT15D nacelle is computed and comparedwith results obtained from other sources At last noisepropagation around fuselage-wing-nacelle configurations iscomputed and the noise shielding effect of the over-the-wing nacelle (OWN) configuration is estimated as a realisticcomputation around complex geometry

2 Computational Method

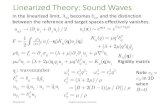

21 Linearized Euler Equations In the Euler equations thephysical quantities 119876 are divided into a mean flow fieldvector 119876

0and fluctuation vector 119876

1015840 By linearization of theEuler equations around 119876

0= 119876 minus 119876

1015840 the time evolutionequations of 119876

1015840 are obtained in (1) These are the LEEs Inthe LEEs the sound source term 119878 is added to incorporatea realistic sound source For computation of the LEEs Sand the mean flow field vector 119876

0are introduced The time

evolution of 1198761015840 is then computed The governing equations

are nondimensionalized by the mean flow density 1205880 speed

of sound c and reference length D

1205971198761015840

120597119905+ 11986010

1205971198761015840

120597119909+ 11986020

1205971198761015840

120597119910+ 11986030

1205971198761015840

120597119911+ 1198601015840

1

1205971198760

120597119909

+ 1198601015840

2

1205971198760

120597119910+ 1198601015840

3

1205971198760

120597119911= 119878

1198761015840

=

[[[[[[[[[

[

1205881015840

1199061015840

1

1199061015840

2

1199061015840

3

1199011015840

]]]]]]]]]

]

1198760

=

[[[[[[[[

[

1205880

11990610

11990620

11990630

1199010

]]]]]]]]

]

1198601198950

=

[[[[[[[[[[[[[[

[

1199061198950

1205751119895

1205880

1205752119895

1205880

1205753119895

1205880

0

0 1199061198950

0 01205751119895

1205880

0 0 1199061198950

01205752119895

1205880

0 0 0 1199061198950

1205753119895

1205880

0 1205741205751119895

1199010

1205741205752119895

1199010

1205741205753119895

1199010

1199061198950

]]]]]]]]]]]]]]

]

1198601015840

119895=

[[[[[[[[[[[[[[[

[

1199061015840

1198951205751119895

1205881015840

1205752119895

1205881015840

1205753119895

1205881015840

0

0 1199061015840

1198950 0 minus120575

1119895

1205881015840

12058820

0 0 1199061015840

1198950 minus120575

2119895

1205881015840

12058820

0 0 0 1199061015840

119895minus1205753119895

1205881015840

12058820

0 1205741205751119895

1199011015840

1205741205752119895

1199011015840

1205741205753119895

1199011015840

1199061015840

119895

]]]]]]]]]]]]]]]

]

(1)

Here 120574 = 14 is the specific heat ratio 120575119894119895is the Kronecker

delta In the computations with mean flow field 1205971198760120597119909

1205971198760120597119910 and 120597119876

0120597119911 are neglected to avoid the instability

waves caused by the shear mean flow field The effect ofneglecting the terms about the gradient of themean flow fieldis discussed in [23]

22 Computational Mesh of the BCM The computationalmesh of BCM is generated by the following procedures intwo dimensions [24] The computational domain is dividedinto an aggregation of square areas (cubic areas in threedimensions) where each area is denoted as a ldquocuberdquo as shownin Figure 1(a) Each cube is then divided by an equispacedCartesianmesh as shown in Figure 1(b) Cells located outsidethe wall boundary are defined as fluid cells On the otherhand cells located inside the wall boundary are defined aswall cells In this method all cubes have the same number ofcells so that the computational effort required for all cubes isessentially equivalent in parallel computation and excellentparallel efficiency is achieved Each cube has three overlapcells as shown by the hatched cells in Figure 1(b) for data

International Journal of Aerospace Engineering 3

Cube

(a) Computational domain and cube boundary (b) Computational cells in a cube (15 times 15 cells 3 overlap cells)

Figure 1 Computational mesh of the building-cube method (BCM) in two dimensions

exchange When a cube is locally refined the cube selectedfor refinement is divided into four cubes (eight cubes in threedimensions) and each cube is subdivided by prescribed cellsAfter the refinement the size of the cube is smoothed so thatthe sizes of adjacent cubes are restricted to the same doubleor half that size The sizes of adjacent cubes are checked forall cubes If the size of an adjacent cube is larger than doublethe size of a focusing cube the adjacent cube is divided intofour cubes (eight cubes in three dimensions) and each cubeis subdivided by prescribed cells

23 Computational Algorithm of the LEEs Solver Figure 2shows the computational algorithm of the LEEs solverAt the beginning mesh information object shape initialconditions and the mean flow field are given The meanflow field is computed by the compressible Euler solver inthis research The details of the compressible Euler solverare provided in [25] The computational scheme of inviscidflux is changed from that of the reference to the simple low-dissipative advection upstream splitting (SLAU) [26] scheme

The spatial derivative of the LEEs solver is computedby the dispersion relation preserving (DRP) scheme [27]Through the use of the overlap cells a fourth-order DRPscheme using seven-point stencils can be implemented overthe entire area of the computational domain Time integra-tion is computed by a six-stage fourth-order Runge-Kuttascheme [28] In the time integral six subiterations constituteone time step In addition artificial selective damping [27] ofthe seven-point stencils is applied at each iteration to elim-inate the nonphysical oscillation The above computationsincluding boundary treatments are parallelized for all cubesusing Open Multi-Processing (OpenMP)

24 Wall Boundary For computation by Cartesian mesh itis important to apply mesh to wall boundaries realistically

because real surfaces have curvature Therefore variousIBMs have been proposed for diverse implementations Inthe present solver an IBM that employs a ghost cell (GC)approach using an image point (IP) [29] is applied Wallcells adjacent to fluid cells are defined as GCs The IP isdefined from the GC in the direction normal to the closestwall boundary as shown in Figure 3(a) In this processsurface stereo lithography (STL) data is used to determinethe intersection point of the normal vector with the wallboundary The physical quantities of the IP are interpolatedby the inverse distance weighting method of (2) using 3 times 3 times

3 = 27 stencils as illustrated in Figure 3(b)

119876IP =

27

sum

119894=1

119908 (119894) times 119876119904

(119894) times mask (119894)

119908 (119894) =ℎ (119894)minus2

sum27

119895=1ℎ (119895)minus2

(2)

Here 119876IP is the physical quantities of the IP 119876119904isthe physical

quantities of stencils 119908 is the weight function based on thedistance ℎ between the IP and stencils and mask is a valuethat reflects whether the stencil is a fluid cell or wall cell Fluidcells have mask = 1 and wall cells have mask = 0

The physical quantities of a GC are computed by thefollowing equations so that the slip condition is satisfied usingthe physical quantities of the IP

VGC = VIP minus (1 + (119889IP119889GC

)) times (VIP sdot n)n

119901GC = 119901IP

120588GC = 120588IP

(3)

Here 119889IP is the distance from the IP to the wall surface 119889GCis the distance from the GC to the wall surface n is the unit

4 International Journal of Aerospace Engineering

Input mesh initial condition and mean flow field

Data exchange at cube boundary

Compute spatial derivative and input

Damping in buffer zone

Output data

Para

llel f

or cu

bes

Subi

tera

tion

Upd

ate t

ime s

tep

Update of Q998400sub(n)

Q998400sub(n)

Fluctuation vector Q998400(n+1)

Fluctuation vector Q998400(n)

120655Q998400120655x 120655Q

998400120655y 120655Q

998400120655z 120655Q0120655x 120655Q0120655y 120655Q0120655z S

Figure 2 Computational algorithm of the linearized Euler equations (LEEs) solver

Fluid cell

Ghost cell

Wall cell

Wall boundary

Image point

(a) Definition of GC and IP

Fluid cell

Ghost cell

Qs(1)

Qs(2)

Qs(3)

Qs(4)

Qs(5)

Qs(6)

Qs(7)

Qs(8)

Qs(9)

QIP

mask(1) = 1

mask(6) = 0

h(1)

(b) Interpolation to IP

Figure 3 The immersed boundary method (IBM) using an image point (IP) based on a ghost cell (GC)

normal vector of the wall surface and VIP 119901IP and 120588IP arethe velocity vector pressure and density at the IP and VGC119901GC and 120588GC are those at the GC respectively In this study119889GC + 119889IP = 175Δ119909 to avoid the instability caused by thewall boundary condition The spatial derivative at the fluidcell adjacent to the GC is conducted using the second-ordercentral difference based on the physical quantities of the GC

25 Cube Boundary At the boundaries between cubes withdifferent sizes the three overlap cells are hanging nodesTherefore data exchange with interpolation is needed In

the solver Lagrange interpolation [30] is employed for dataexchange at the boundary as given by

119876119900

(119909119900 119910119900 119911119900)

= sum

119895119896119897

119876119904

(119909119895 119910119896 119911119897) times 119908119895

(119909119900) times 119908119896

(119910119900) times 119908119897(119911119900)

119908119895

(119909119900) = prod

119894 =119895

(119909119900

minus 119909119894)

(119909119895

minus 119909119894)

International Journal of Aerospace Engineering 5

119908119896

(119910119900) = prod

119894 =119896

(119910119900

minus 119910119894)

(119910119896

minus 119910119894)

119908119897(119911119900) = prod

119894 =119897

(119911119900

minus 119911119894)

(119911119897

minus 119911119894)

(4)

Here 119876119900represents the physical quantities of an overlap

cell 119876119904represents the physical quantities of stencils 119908

119895 119908119896

and 119908119897are computed weight functions based on the distance

between an overlap cell and stencils and 119909119900 119910119900 and 119911

119900are the

coordinates of an overlap cellFigure 4(a) illustrates the stencils used for data exchange

from smaller to larger cubes in two dimensions In this figureblack points are the fluid cells of a larger cube The shadedfluid cells of the larger cube are the overlap cells The whitecircles are stencils of the smaller cube and are used for theinterpolation Interpolation to three overlap cells per one rowis needed The stencils of the overlap cell that is closest to theboundary are 2 times 2 times 2 = 8 points and those of the other twocells are 4 times 4 times 4 = 64 points so that the location of stencils issymmetrical For interpolation from larger to smaller cubesas shown in Figure 4(b) stencils of 3 times 3 times 3 = 27 points areused for four rows in three dimensions which achieves third-order accuracy

26 Outer Boundary In LEEs computation outgoing wavesshould be damped so that the inner sound field is notdisturbed by reflected waves To this end the buffer zoneboundary condition [31] is implemented in the presentsolver To damp the outgoing waves gradually the magnitudeof the damping coefficients varies as a quadratic functionof the coordinates toward the outer boundary Equations(5) provide the damping equation in the buffer zone Thefluctuation vector is damped in each direction individually

1198761015840(119899)119909

= (1 minus 120590 (119909)) times 1198761015840(119899)

1198761015840(119899)119910

= (1 minus 120590 (119910)) times 1198761015840(119899)

1198761015840(119899)119911

= (1 minus 120590 (119911)) times 1198761015840(119899)

120590 (119909) =2

Δ119909

1003816100381610038161003816100381610038161003816100381610038161 minus

119909119887

minus 119871119887119909

119871119887119909

100381610038161003816100381610038161003816100381610038161003816

2

120590 (119910) =2

Δ119910

1003816100381610038161003816100381610038161003816100381610038161003816

1 minus119910119887

minus 119871119887119910

119871119887119910

1003816100381610038161003816100381610038161003816100381610038161003816

2

120590 (119911) =2

Δ119911

1003816100381610038161003816100381610038161003816100381610038161 minus

119911119887

minus 119871119887119911

119871119887119911

100381610038161003816100381610038161003816100381610038161003816

2

(5)

Here 1198761015840(119899) is the fluctuation vector at each iteration and

with respect to each direction 1198761015840(119899)119909 1198761015840(119899)

119910 and 1198761015840(119899)

119911are

the damped fluctuation vectors 120590(119909) 120590(119910) and 120590(119911) are thedamping coefficients in the buffer zone Δ119909 Δ119910 and Δz arethe mesh spaces 119871

119887119909 119871119887119910 and 119871

119887119911are the widths of the

buffer zone and119909119887 119910119887 and 119911

119887are the distances from the inner

end of buffer zone Figure 5 shows the buffer zone (illustratedas the hatched area) and an expanded view of the bottom leftcorner in a two-dimensional case

3 Evaluation of the Order of Accuracy

The order of accuracy of the present computational methodis evaluated by the one-dimensional wave propagation prob-lem The IBM and Lagrange interpolation are employed intheir three-dimensional forms Equations (6) are the one-dimensional wave equationsThe initial pressure distributionis given by

1205971199011015840

120597119905+

1205971199061015840

1

120597119909= 0

1205971199061015840

1

120597119905+

1205971199011015840

120597119909= 0

(6)

1199011015840

(initial) = 05 times exp [minus(ln 2)

2(1199092

+ 1199102

+ 1199112)] (7)

The root mean square error (RMSE) between the analyticalsolution and the computed solution is computed by

RMSE = radic1

119873

119873

sum

119894=1

1003816100381610038161003816100381610038161199011015840(computed) minus 1199011015840

(analytical)100381610038161003816100381610038161003816

2

(8)

The RMSE is computed for two meshes Figure 6 illustratesthe computational cubes with and without cube refinementThe size of the computational domain is 16119863 times 4119863 times 4119863The periodic boundary condition is set at the end of the 119909-directional boundaries The RMSE is also computed in thecase where a wall boundary exists When the wall boundaryexists the wave reflects at the end of the 119909-directionalboundaries

The RMSE and the order of accuracy are listed in Table 1The order of accuracy of each mesh is computed using theRMSEof onemesh and that of a coarsermesh Case 1 employsno wall boundary and is conducted without cube refinementTherefore the prescribed order of accuracy is as shown InCase 2 the order of accuracy is slightly reduced becausethe spatial derivative at the fluid cell adjacent to the GCis conducted using the second-order central difference Theorder of accuracy of Case 3 is approximately two becausethe accuracy of the cube boundary is dominated by theinterpolation from a larger to smaller cube Case 4 providesa slightly smaller order of accuracy than that of Case 3because of the existence of the wall boundary These resultsindicate that the general order of accuracy of the presentcomputational method is approximately two

4 Acoustic Scattering around a Sphere

Acoustic scattering around a sphere [32] is computed undervarious mesh conditions in this section The magnitude oferror relative to an analytical solution and the computational

6 International Journal of Aerospace Engineering

Cube boundary

Fluid cellOverlap cellStencil

Stencils (4 times 4)

Stencils (2 times 2)

(a) From a smaller to larger cube

Cube boundary

Fluid cellOverlap cellStencil

Stencils (3 times 3)

(b) From a larger to smaller cube

Figure 4 Stencils used for Lagrange interpolation in two dimensions

Buffer zone

(a) Buffer zone in the computational domain

Lbx

xb

yb

Lby

Buffer zone

(b) Expanded view of the bottom left corner of (a)

Figure 5 Buffer zone boundary condition

time are compared A sphere is located at the origin of a three-dimensional domain The reference length 119863 is the diameterof the sphere A monopole Gaussian sound source 119878 is givenby the following equation as a function of time t

119878 = exp[minus (ln 2) ((119909 minus 4119863)

2+ 1199102

+ 1199112

(02119863)2

)] sin (6120587) 119905 (9)

The influence of three important parameters on the erroris investigated the minimum cell size around the spherepoints per wavelength (PPW) in the computational domainand the size of the buffer zoneTheminimum cell size aroundthe sphere has an effect on the error generated from the wall

boundary A small cell size not only suppresses the errorbut also restricts the time step size and results in greatercomputational time The PPW is an important factor foracoustic simulations because insufficient PPW introducesdissipation and dispersion errors in wave propagation Thesize of the buffer domain is important for setting the outerboundary condition If the width of the buffer zone is shortthe reflected wave is generated at the outer boundary and thereflected wave disturbs the inner sound field

Figure 7 shows computational domains of the CoarseBCM Middle2 and BCM Fine3meshes listed in Table 2Thegray lines indicate the cube boundaries Table 2 summarizesthe mesh information of all the cases used for the parametric

International Journal of Aerospace Engineering 7

y x

z

(a) Cubes without cube refinement

y x

z

(b) Cubes with cube refinement

Figure 6 Computational cubes for the one-dimensional wave propagation problem

8D

16D

8D

8D

y

x

y

z

(a) Coarse

16D

32D

16D

16D

y

x

y

z

(b) BCM Middle2

16D

32D

16D

16D

y

x

y

z

(c) BCM Fine3

Figure 7 Computational domains and cube boundaries for acoustic scattering around a sphere of diameter D

8 International Journal of Aerospace Engineering

Table 1 Root mean square error and the order of accuracy

Wall Cube refinement Number of cells in one cube Root mean square error Order of accuracy

Case 1 Without Without36 times 36 times 36 1063 times 10minus5 mdash48 times 48 times 48 3422 times 10minus6 394172 times 72 times 72 6887 times 10minus7 3954

Case 2 With Without36 times 36 times 36 1269 times 10minus5 mdash48 times 48 times 48 4145 times 10minus6 389072 times 72 times 72 8326 times 10minus7 3959

Case 3 Without With36 times 36 times 36 1200 times 10minus4 mdash48 times 48 times 48 6574 times 10minus5 209372 times 72 times 72 2890 times 10minus5 2027

Case 4 With With36 times 36 times 36 1258 times 10minus4 mdash48 times 48 times 48 7086 times 10minus5 199572 times 72 times 72 3156 times 10minus5 1995

Table 2 Mesh information for acoustic scattering around a sphere of diameter 119863

Minimum cellsize

Number ofcubes Number of cells in one cube PPW Width of buffer zone

[119909 119910 119911]Coarse 00415D 128 48 times 48 times 48 8 1D 1D 1DUniform Middle 00277D 128 72 times 72 times 72 12 1D 1D 1DBCM Middle1 00208D 184 48 times 48 times 48 8 16 1D 1D 1DBCM Middle2 00208D 296 48 times 48 times 48 4 8 16 9D 5D 5DBCM Middle3 00208D 408 48 times 48 times 48 4 8 16 9D 5D 5DUniform Fine 00208D 128 96 times 96 times 96 16 1D 1D 1DBCM Fine1 00104D 240 48 times 48 times 48 8 16 32 1D 1D 1DBCM Fine2 00104D 352 48 times 48 times 48 4 8 16 32 9D 5D 5DBCM Fine3 00104D 464 48 times 48 times 48 4 8 16 32 9D 5D 5D

study Coarse mesh forms the base mesh of the other meshesemployedThe size of the computational domain is 16119863times8119863times

8119863 referring to [33] where 128 cubes of a size 1119863 times 1119863 times 1119863

constitute the domain as shown in Figure 7(a) The numberof cells in one cube is 48 times 48 times 48 and the PPW is eight Inthe Uniform Middle and Uniform Fine meshes the domainsize and the number of cubes are the same as those of theCoarse mesh The number of cells in one cube is 72 times 72times 72 in the Uniform Middle mesh and 96 times 96 times 96 in theUniform Fine mesh thus the PPW is 12 and 16 respectivelyIn the BCM Middle1 mesh the eight cubes in the Coarsemesh surrounding the sphere are subdivided into half sizecubes Similarly the eight cubes surrounding the sphere aresubdivided from the BCM Middle1 mesh in the BCM Fine1mesh The number of cubes is 184 in the BCM Middle1mesh and 240 in the BCM Fine1 mesh and the maximumPPW is 16 and 32 respectively In the BCM Middle2 meshshown in Figure 7(b) and BCM Fine2 meshes the bufferzone is expanded to add 112 cubes to the BCM Middle1 andBCM Fine1 meshes In the BCM Middle3 and BCM Fine3(shown in Figure 7(c)) meshes eight cubes located at 2 le xle 6 minus2 le y le 2 and minus2 le z le 2 and eight cubes located at minus6le x le minus2 minus2 le y le 2 and minus2 le z le 2 are subdivided from theBCM Middle2 and BCM Fine2 meshes to increase the PPWof the computational domain The inner end of the buffer

zone is set at x = [minus7D 7D] y = [minus3D 3D] and z = [minus3D3D] in all meshes to compare the sizes of the buffer zones

Figure 8 shows the instantaneous pressure distributionaround the sphere computed using the Coarse mesh In thisfigure the buffer zone is not drawn Waves generated fromthe sound source are scattered by the sphere and interferencefringes appear The computation is executed in nondimen-sional time 119879 = 15 and a periodic steady state is observedafter119879 = 11 Figure 9 shows the pressure distributionnear theinner end of the buffer zone and the time history of the pres-sure near the sphere for all meshes The pressure distributionis sampled at minus6119863 le 119909 le minus4119863 on the 119909-axisThe time historyof the pressure is sampled at (minus2D 0 0) and 14 le 119879 le 15

In Figures 9(a) and 9(b) the uniform meshes arecompared The pressure distributions do not follow thedecreasing trend of the analytical solution in Figure 9(a)Reflection occurs at the outer boundary because of theinsufficient width of the buffer zone Additionally theUniform Middle and Uniform Fine meshes show a higherpressure amplitude compared with the pressure distributionof the Coarse mesh It is assumed that the sound wave isdamped at the Coarse mesh because of the insufficient PPWThe time histories of the uniform meshes provide loweramplitudes than the analytical solution

International Journal of Aerospace Engineering 9

Table 3 Comparison of errors relative to an analytical solution and respective computational times for the meshes listed in Table 2

Total number ofcells

Normalized root meansquare error []

Normalizedmaximum error []

Computational time[120583sectimestepcell]

Real time [sec](128 CPUs)

Coarse 14155776 1197 2382 008454 302Uniform Middle 47775744 502 1131 008631 1388BCM Middle1 20348928 362 1486 010891 1088BCM Middle2 32735232 307 714 011027 1710BCM Middle3 45121536 289 734 009665 2172Uniform Fine 113246208 357 1093 007329 4240BCM Fine1 26542080 614 2224 008851 2654BCM Fine2 38928384 304 700 008777 3358BCM Fine3 51314688 162 500 009019 4794

Non

dim

ensio

nal p

ress

ure

000E + 000

minus500E minus 005

500E minus 005

minus100E minus 004

100E minus 004

Figure 8 Instantaneous pressure distribution (Coarse mesh) around a sphere of diameter D

In Figures 9(c) and 9(d) the BCM Middle meshes arecompared The BCM Middle2 and BCM Middle3 meshesfollow the analytical solution in Figure 9(c) These mesheshave a buffer zone of width 9D in the 119909 direction andoutgoing waves are damped appropriately However theBCM Middle2 mesh provides a lower amplitude This isowing to the insufficient PPW at the sampling points On theother hand phase error is not observed in the BCM Middle2mesh In Figure 9(d) the amplitude of the pressure convergesto the analytical solution for the BCM Middle2 mesh Onlythe BCM Middle1 mesh provides a lower amplitude Thisamplitude is the same as that of the uniform meshes There-fore it is confirmed that the amplitude of the inner soundfieldis diminished when using a buffer zone of short width

In Figures 9(e) and 9(f) the BCM Fine meshes arecompared The pressure distributions and the time historiesof the BCM Fine meshes exhibit similar tendencies as thoseof the BCM Middle meshes

To compare the magnitude of errors more quantitativelythe root mean square pressure 119875rms of the scattered soundis computed and the normalized RMSE (NRMSE) and thenormalized maximum error (MME) between the analytical

solution and the solutions of each mesh are compared asgiven by

NRMSE = radic1

119873

119873

sum

119894=1

1003816100381610038161003816100381610038161003816100381610038161003816

119875rms(computed) minus 119875rms(analytical)

119875rms(analytical)

1003816100381610038161003816100381610038161003816100381610038161003816

2

NME = max1003816100381610038161003816100381610038161003816100381610038161003816

119875rms(computed) minus 119875rms(analytical)

119875rms(analytical)

1003816100381610038161003816100381610038161003816100381610038161003816

(10)

The number of sampling points 119873 are set clockwise ata radius 119903 = 2D from the origin The points (minus2D 00) and (2D 0 0) correspond to 0 deg and 180 deg Theerrors are summarized in Table 3 As shown in the table therefined meshes provide lower errors than the coarser meshand the meshes that utilize a large buffer zone also providelower errors The minimum cell size around the sphere alsoaffects the errors The smallest errors are provided by theBCM Fine3 mesh A comparison of the uniform and BCMmeshes indicates that the BCM Middle3 and BCM Fine3meshes which use cubes of different sizes at the appropriatelocations provide lower errors than Uniform Middle meshes

10 International Journal of Aerospace Engineering

Non

dim

ensio

nal p

ress

ure

AnalyticalCoarse

minus150E minus 04

minus100E minus 04

minus500E minus 05

000E + 00

500E minus 05

100E minus 04

150E minus 04

Uniform_MiddleUniform_Fine

minus6 minus55 minus5 minus45 minus4

x coordinate

(a) Pressure distributions of uniform meshes

Non

dim

ensio

nal p

ress

ure

minus150E minus 04

minus100E minus 04

minus500E minus 05

000E + 00

100E minus 04

150E minus 04

AnalyticalCoarse

Uniform_MiddleUniform_Fine

500E minus 05

14 142 144 146 148 15Nondimensional time

(b) Time histories of uniform meshes

Non

dim

ensio

nal p

ress

ure

minus150E minus 04

minus100E minus 04

minus500E minus 05

000E + 00

500E minus 05

100E minus 04

150E minus 04

AnalyticalBCM_Middle1

BCM_Middle2BCM_Middle3

minus6 minus55 minus5 minus45 minus4

x coordinate

(c) Pressure distributions of BCM Middle meshes

Non

dim

ensio

nal p

ress

ure

minus150E minus 04

minus100E minus 04

minus500E minus 05

000E + 00

500E minus 05

100E minus 04

150E minus 04

AnalyticalBCM_Middle1

BCM_Middle2BCM_Middle3

14 142 144 146 148 15Nondimensional time

(d) Time histories of BCM Middle meshes

Non

dim

ensio

nal p

ress

ure

minus150E minus 04

minus100E minus 04

minus500E minus 05

000E + 00

500E minus 05

100E minus 04

150E minus 04

minus6 minus55 minus5 minus45 minus4

x coordinate

AnalyticalBCM_Fine1

BCM_ Fine2BCM_ Fine3

(e) Pressure distributions of BCM Fine meshes

Non

dim

ensio

nal p

ress

ure

minus150E minus 04

minus100E minus 04

minus500E minus 05

000E + 00

500E minus 05

100E minus 04

150E minus 04

14 142 144 146 148 15Nondimensional time

AnalyticalBCM_Fine1

BCM_ Fine2BCM_ Fine3

(f) Time histories of BCM Fine meshes

Figure 9 Pressure distributions (minus6119863 le 119909 le minus4119863) and time histories at (minus2D 0 0) and (14 le 119879 le 15) around a sphere of diameter 119863 forthe meshes listed in Table 2

International Journal of Aerospace Engineering 11

that utilize a similar number of mesh points Moreover theerrors of the BCM Fine3 mesh are about one-half the errorsof the Uniform Fine mesh which has twice the number ofmesh points as the BCM Fine3 mesh These results indicatethe effectiveness of the BCM arrangement

The computational wall-clock times for a single timestep per cell and the total wall-clock time required toreach a nondimensional time 119879 = 15 are also listed inTable 3 All meshes were computed using 128CPUs of anSGI AltixUV1000 computer Regarding the wall-clock timeper one time step per cell the computational times of theuniformandBCMmeshes are comparableHowever the totalwall-clock times of the BCM meshes are slightly longer thanthose of the uniform meshes The BCM meshes employ alarger number of cubes than the number of CPUs used in theevaluationThemismatch between the numbers of cubes andCPUs can degrade the load balance Computations using anequivalent number of CPUs and cubes are more effective forBCMmeshes

5 Noise Propagation from the JT15D Nacelle

Noise propagation from the JT15D [34] nacelle is computedand the far-field sound pressure level (SPL) is compared withdata derived from experiment and the computational resultsof others The JT15D is a small Pratt and Whitney turbofanenginewith a bellmouth inletThe sound source is introducedvia a discrete frequency spinning mode The spinning modeinput [35] is a typical sound source generated by the fan orrotor-stator intersections in the engine The sound source ofa single spinning mode (119898 119899) is defined by

119878 = [119869119898

(119896119903119903) + 1198881119884119898

(119896119903119903)] cos (119896119905 minus 119896

119886119909 minus 119898120579) (11)

Here 119869119898and119884119898are themth order Bessel functions of the first

and second kind respectively 119896 is the angular frequency 119896119886

is the axial wavenumber 119896119903is the radial wavenumber and 120579

is the phase The 119899th solution 119896119903of the following equation is

determined by the hard-wall boundary condition of the duct

119889 [119869119898

(119903outer119896119903)]

119889119903

119889 [119884119898

(119903inner119896119903)]

119889119903

minus119889 [119869119898

(119903inner119896119903)]

119889119903

119889 [119884119898

(119903outer119896119903)]

119889119903= 0

(12)

Here 119903outer and 119903inner are the bypass duct inner wall radius andthe inner hub radius respectively The axial wave number 119896

119886

is computed from

119896119886

=119896

1 minus 1198722119895

(minus119872119895

plusmnradic

1 minus1198962

119903(1 minus 119872

2

119895)

1198962) (13)

where 119872119895is the Mach number at the fan face The selection

of plus or minus signs in the parentheses is determined bythe propagation direction of the sound wave where plus(+) represents the positive propagation direction along the

axial coordinate and vice versa The constant 1198881satisfies the

following relation

1198881

= minus(119889119889119903) [119869

119898(119903outer119896119903)]

(119889119889119903) [119884119898

(119903outer119896119903)]

= minus(119889119889119903) [119869

119898(119903inner119896119903)]

(119889119889119903) [119884119898

(119903inner119896119903)]

(14)

Parameters are set from experimental data (119898 119899) =

(minus13 0) 119903outer = 02667m and 119903inner = 00998m Thereference length D = 06223mis the length from the fanface to the leading edge of the nacelle The blade passingfrequency (BPF) is set to 3150Hz which is derived fromthe fan rotating speed of 6750 rpm The experiments wereconducted in the static condition and the fan face axial Machnumber is 0175 The present computation is also conductedin the static condition In the present computation the axialflow velocity of the ghost cell at the fan face boundary isdirectly modified to this Mach number The pressure andthe density are the same values as those of the adjacent fluidcells The SPL is measured at a radius of 49D The integrationmethod of Ffowcs-Williams and Hawkings (FW-H) [36] isemployed to estimate the far-field pressure from thenear-fieldpressure

Figure 10 shows the computational domain and Table 4lists the mesh information The computations of the com-pressible Euler solver and the LEEs solver are conductedusing the samemeshThePPW inTable 4 is the PPWreducedby the Doppler effect of the fan face axial Mach number Thecomputational domain is set at minus1119863 le 119909 le 7119863 minus8119863 le 119910 le

8119863 and minus8119863 le 119911 le 8119863The fan face is at 119909 = 05119863The innerend of the buffer zone is set at 119909 = [0 4119863] 119910 = [minus4119863 4119863]and 119911 = [minus4119863 4119863] The FW-H surfaces are located at thecube boundaries between the smallest size cubes and thelarger size cubes

Figure 11 shows theMachnumber distribution around theJT15D nacelle In Figure 11 the acceleration region near theinternal wall of the nacelle lip and the stagnation at the spikeare shown Because the experiments and computations wereconducted under the static condition the mean flow fieldexists only near the nacelle

Figure 12 shows the instantaneous pressure distributionsat the planes defined at 119911 = 0 and 119909 = 17119863 In the figure onlythe distributions of the smallest sized cubes are drawn Thefan noise is diffracted at the inlet of the nacelle and propagatesalong the radial direction The 13 peaks and valleys of theswirling fan noise at the 119909 = 17119863 plane are clearly capturedwhich is equivalent to the number of spinning modes Thetime history of the pressure is sampled at the establishedpoints on the FW-H surface and the periodic steady state isobserved after 119879 = 8

Figure 13 shows a comparison of the predicted SPL withthe experimental results conducted by Heidmann et al [37]and the computational results computed by Lan et al [34]The horizontal axis in the figure is the angle from the +119909-axialdirection In the figure the predicted SPL using the presentsolver shows good agreement with the computational resultof Lan et al (within 1 dB) Compared with the experimental

12 International Journal of Aerospace Engineering

Table 4 Mesh information for the JT15D nacelle

JT15D Minimum cell size Number of cubes Number of cells in one cube Total number of cells PPWCase 1 00166D 1544 30 times 30 times 30 41688000 87Case 2 00125D 1544 40 times 40 times 40 98816000 116

16D

8D

16D

16D

y

x

yzy

x z

Figure 10 Computational domain for the JT15D nacelle

Mac

h nu

mbe

r

02000100

0000

Figure 11 Mach number distribution around the JT15D nacelle

data a difference of about 3 dB is found at 60 deg Howeverthis discrepancy is also shown between the experimental dataand the result of Lan et al The SPL peak obtained near55 deg is equivalent to that obtained by Lan et al and thatobtained experimentally

6 Noise Propagation arounda Fuselage-Wing-Nacelle Configuration

The noise propagation around a fuselage-wing-nacelle con-figuration is computed as a realistic exampleThe focus of theexample was that of the OWN configuration [38] where theengine nacelle is mounted over the main wing which servesas one of the configurations designed to achieve substantialairport noise reduction The main feature of this configu-ration is that the main wing serves as a shield between the

ground and the noise generated by the engine To investigatethe effect of the OWN configuration the propagation of fannoise of both the conventional DLR-F6 aircraft configuration[39] and the OWN configuration is computed and the SPLbelow the aircraft for both configurations is comparedTheseconfigurations have complex geometry with large curvaturesnear the wing-body and the nacelle-pylon junctions In theOWN configuration the nacelle is moved 11D in the +119909

direction and 06D in the +y direction relative to its locationin the DLR-F6 configuration Here the reference length 119863 =

49m is the longitudinal length of the nacelle The cross-sectional geometry of the pylon is used without any changesand has a sweepback angle of 40 deg A mean flow fieldof Mach number 03 with zero angle of attack is computedusing the compressible Euler solver The sound source isintroduced via a discrete frequency spinning mode As anexample of a modern turbofan engine the CFM56-7B engineis considered The bypass ratio is 55 the fan diameter is154m the number of blades is 24 the maximum rotationalrate is 5382 rpm and the fundamental BPF is 21528HzTheBPF is used as the input frequency of the spinning modeThespinning mode (119898 119899) is set to (minus24 0) The SPL is measuredat a radius of 10D using the FW-H method

Figure 14 shows the computational domain of each con-figuration The black dot shows the origin of coordinatesystem The computations of the compressible Euler andLEEs solvers are conducted using an equivalent mesh Thesize of the computational domains is 4119863 times 2119863 times 2119863 Thesymmetric boundary condition is set at the minusz boundaryThe computational domains are set to ensure that sufficientcomputational domains surround the nacelle It is assumedthat the geometry out of the computational domain has littleinfluence on the noise directivity below the aircraft The

International Journal of Aerospace Engineering 13

Pressure

5000E minus 003

0000E + 000

minus5000E minus 003

(a) 119911 = 0 plane

Pressure

5000E minus 003

0000E + 000

minus5000E minus 003

(b) 119909 = 17119863 plane

Figure 12 Instantaneous pressure distributions of two cross-sectional surfaces

0deg

90deg

45deg

y

x70

75

80

85

90

95

0 10 20 30 40 50 60 70 80 90 100

SPL

(dB)

Angle (deg)

Heidmann et al (1979)Lan et al (2004)

Case 1Case 2

Figure 13 The sound pressure level (SPL) distributions at a radius of 119903 = 49D

minimum size cubes are located within the domain whereinthe reflection and diffraction by the aircraftmust be resolvedThe inner end of the buffer zone is set at 119909 = [minus075119863 175119863]119910 = [minus05119863 05119863] and 119911 = 175119863 in the DLR-F6 calculationand at 119909 = [0119863 275119863] 119910 = [minus025119863 075119863] and 119911 = 175119863

in the OWN calculation FW-H surfaces are located at theinner end of the buffer zone and the symmetrical plane Thesize of the buffer zones of the DLR-F6 calculation is 075D inthe minus119909 and +119909 directions 05D in the minusy and +y directionsand 025D in the +z direction The size of the buffer zonesof the OWN calculation is 05D in the minusx direction 075Din the +x direction 025D in the minusy direction 075D in +ydirection and 025D in the+z direction Table 5 lists themeshinformation of the computations The PPW in Table 5 is thePPW reduced by the Doppler effect of the mean flow fieldMach number

Figure 15 shows the Mach number distributions at thenacelle center for the two configurations In Figure 15 the

acceleration region over the wing and the stagnation at theinlet of the nacelle are shown A Mach number greater than03 is shown in the acceleration region Figure 16 showsthe SPL distributions on the aircraft surface for the twoconfigurations Noise from the nacelle propagates in theradial direction and the noise is shielded by the main wingin the OWN configuration On the other hand noise fromthe inlet reaches the fuselage and generates a high SPL in theOWN configuration compared to the DLR-F6 configuration

To check the propriety of the computations the SPLdistribution computed for the OWN configuration on thesuction side of themain wing is compared with data capturedduring flight and the computations of others [40] The flightdata of a twin-engine business jet aircraft was acquired ata flight Mach number of 03 at an altitude of 1500m Thisaircraft has the aft fuselage nacelle configuration that the inletof the engine nacelle is located over themain wingThereforequalitative comparisons can be conducted The SPL on thesuction side of the main wing was measured using Kulite

14 International Journal of Aerospace Engineering

2D

2D

2D

4D

y

z

x

z

(a) DLR-F6 configuration

2D

2D

2D

4D

y

z

x

z

(b) OWN configuration

Figure 14 Computational domains for the fuselage-wing-nacelle configurations (black dot origin of coordinate system)

Mac

h nu

mbe

r

0100

0300

0000

0200

0400

(a) DLR-F6 configurationM

ach

num

ber

0100

0300

0000

0200

0400

(b) OWN configuration

Figure 15 Mach number distributions at the nacelle center

minus27500

minus2500

minus40000

minus15000

10000

SPL

(a) DLR-F6 configuration

minus27500

minus2500

minus40000

minus15000

10000

SPL

(b) OWN configuration

Figure 16 The sound pressure level (SPL) distributions on the aircraft surfaces

International Journal of Aerospace Engineering 15

Table 5 Mesh information for calculations of noise propagation around the fuselage-wing-nacelle configurations

Minimum cell size Number of cubes Number of cells in one cube Total number of cells PPWDLR-F6 00025D 3474 50 times 50 times 50 434250000 90OWN 00025D 3425 50 times 50 times 50 428125000 90

120579n

0

10

20

30

40 45 50 55 60 65 70SP

L (d

B)Angle from inlet axis (deg)

Flight dataXu et al (2003)

OWN configuration

minus30

minus20

minus10

Figure 17 Sound pressure level (SPL) distributions on the main wing surface

microphones The computation of Xu et al was conductedusing the discrete frequency spinning mode (20 0) without amean flow field The computed SPL is normalized so that thepeak SPL is equal to that of the flight data Figure 17 showsthe SPL versus the angle from the inlet axis The computedSPL agrees with the flight data from 50 to 70 deg within 3 dBThe peak SPL is at 63 deg This is similar to the peak given bythe flight data which has a peak at 60 deg The discrepancyat an angle of 40 deg is caused by the different clearancesbetween the engine and the main wing where the clearanceof the aircraft employed in the experiment is smaller than thatof the present computation

Figure 18 shows the estimated SPL distribution at a radiusof 10D based on the center of the front face of nacelle Basedon International Civil Aviation Organization rules aircraftnoise is determined by the noise levels at the side and thebottom locations relative to the fuselage Therefore the SPLdistribution below the aircraft is estimated From Figure 18the SPL of the OWN configuration is lower than that ofthe DLR-F6 configuration by about 10 dB over the range of40 deg to 70 deg This represents significant noise reductionrelative to conventional aircraft design Using the proposedmethod it would be possible to optimize the position of thenacelle to obtain maximum noise shielding performance

7 Conclusion

The linearized Euler equationssolver on block-structuredCartesianmesh of the building-cubemethod (BCM) coupledwith the immersed boundary method (IBM) has been devel-oped to compute noise propagation around complex geome-try The accuracy and effectiveness of the solver for practical

problems were validated by application to one-dimensionaland three-dimensional noise propagation problems and theapplication of fan noise propagation around fuselage-wing-nacelle configurations

For the one-dimensional noise propagation problem theIBM slightly decreased the order of accuracy of the systembecause the second-order central difference is employed atfluid cells adjacent to ghost cells However a fourth orderof accuracy is nearly retained even when employing theIBM Interpolation between cubes of different sizes causesdegradation to a second order of accuracy

For the problem of acoustic scattering around a spherethe error was suppressed by mesh refinement near the sphereand by expansion of the buffer zone The results computedon the BCM meshes provided quantitative agreement withthe analytical solution A normalized root mean square errorof 162 and a normalized maximum error of 5 for theresults computed by the BCM Fine3 mesh were about one-half of the errors computed by theUniform Finemesh whichhas twice as many mesh points as the BCM Fine3 mesh Thecomputational time required for the BCM mesh was slightlylonger than that required for the uniformmesh because of themismatch between the number of CPUs and cubes

The estimated sound pressure level (SPL) from the JT15Dnacelle provided good agreement with experimental dataand with other computational results The present solverdemonstrated accurate computations for a curved object likean axisymmetric nacelle

Noise propagation around two fuselage-wing-nacelleconfigurations was computed as a realistic example to verifythe capability of the present solver and to estimate thenoise shielding effect of the OWN configurationThe aircraftconfiguration has complicated geometries especially near the

16 International Journal of Aerospace Engineering

3540455055606570758085

40 50 60 70 80 90 100 110 120 130 140

SPL

(dB)

Angle (deg)

DLR-F6OWN configuration

0deg 180deg

90deg

y

x

Figure 18 The sound pressure level (SPL) distributions at a radius of 119903 = 10D based on the center of front face of nacelle

wing-body and the nacelle-pylon junctions and the presentsolver demonstrated a robust treatment of these geometriesFor the OWN configuration the noise from the nacelle inletwas shielded effectively by the main wing because the noisediffracted strongly in the radial directionThe computed SPLat the suction side of themain wing agrees with data obtainedduring flightThe SPL distribution of theOWNconfigurationbelow the aircraft was lower by about 10 dB than that of theconventional DLR-F6 configuration

Through application to simple test cases and realisticcases the effectiveness of the solver was confirmed Usingthe present solver noise propagation around next-generationunconventional aircraft can be estimated and the method isexpected to contribute to the future of aircraft design

Nomenclature

119894 119895 119896 119897 Cell index coordinates119909 119910 119911 Coordinates in the computational domainΔ119909 Δ119910 Δ119911 Mesh spacing119876 Physical quantities vector1198761015840 Fluctuation vector

1199061 1199062 1199063 Velocity fluctuation of 119909 119910 and 119911

direction1198760 Mean flow field vector

11990610

11990620

11990630 Mean velocity of 119909 119910 and 119911 direction

119878 Sound source vector120574 Specific heat ratio120575 Kronecker deltan Unit normal vectorVIP Velocity vector at the image pointVGC Velocity vector at the ghost cell119889IP Distance from the image point to the wall

surface119889GC Distance from the ghost cell to the wall

surface119876119900 Physical quantities at an overlap cell

119876119904 Physical quantities at a surrounding cell

119909119900 119910119900 119911119900 119909 119910 119911 coordinates of an overlap cell

120590 Damping coefficient in the buffer zone119909119887 119910119887 119911119887 Distance from the inner end of the buffer

zone119871119887119909

119871119887119910

119871119887119911 Width of the buffer zone

119863 Reference length1199011015840

(initial) Initial pressure1199011015840

(computed) Computed pressure1199011015840

(analytical) Analytical solution of the pressure119879 Nondimensional time119875rms Root mean square pressure119888 Speed of sound(119898 119899) Input spinning mode119869119898

119884119898 119898th order Bessel functions of the first and

second kind

Conflict of Interests

The authors declare that there is no conflict of interestsregarding the publication of this paper

Acknowledgments

This work was supported by JSPS KAKENHI Grant nos21226018 and 25sdot9225 The computation in this research wasconducted using an SGI AltixUV1000 of the Institute ofFluid Science Tohoku University The Ffowcs-Williams andHawkings code used in this research was provided by theAviation Program Group of Japan Aerospace ExplorationAgency (JAXA)

References

[1] D-Y Kwak T Hirotani M Noguchi and T Ito ldquoExperimen-tal research for aerodynamic interference by upper mountedengine exhaust jet on sst configurationsrdquo in Proceedings of the27th Congress of the International Council of the AeronauticalSciences 2010 (ICAS rsquo10) pp 1211ndash1219 Nice France September2010

International Journal of Aerospace Engineering 17

[2] H Ishikawa K Tanaka Y Makino and K YamamotoldquoSonic-boom prediction using euler CFD codes with struc-turedunstrucutured overset methodrdquo in Proceedings of the 27thCongress of the International Council of the Aeronautical Sciences(ICAS rsquo10) pp 744ndash751 September 2010

[3] A Murakami ldquoSilent supersonic technology demonstrationprogramrdquo in Proceedings of the 25th Congress of InternationalCouncil of the Aeronautical Sciences Hamburg GermanySeptember 2006

[4] E Envia ldquoEmerging community noise reduction approachesrdquoin Proceedings of the 3rd AIAA Atmospheric Space EnvironmentsConference AIAA Paper 2011-3532 June 2011

[5] T Russell B Casey and O Erik ldquoHybrid wing body aircraftsystem noise assessment with propulsion airframe aeroacousticexperimentsrdquo in Proceedings of the 16th AIAACEAS Aeroacous-tic Conference AIAAPaper 2010-3913 Stockholm Sweden June2010

[6] J L Felder H D Kim and G V Brown ldquoTurboelectric dis-tributed propulsion engine cycle analysis for hybrid-wing-bodyaircraftrdquo in Proceedings of the 47th AIAA Aerospace SciencesMeeting including the New Horizons Forum and AerospaceExposition January 2009 AIAA paper 2009-1132

[7] S Redonnet G Desquesnes E Manoha and C ParzanildquoNumerical study of acoustic installation effects with a compu-tational aeroacoustics methodrdquoAIAA Journal vol 48 no 5 pp929ndash937 2010

[8] M Hepperle ldquoEnvironmental friendly transport aircraftrdquo inNewResults in Numerical and Experimental FluidMechanics IVvol 87 of Notes on Numerical Fluid Mechanics and Multidisci-plinary Design Springer 2004

[9] A B Nagy ldquoAeroacoustics research in Europe the CEAS-ASCreport on 2010 highlightsrdquo Journal of Sound and Vibration vol330 no 21 pp 4955ndash4980 2011

[10] S Powell A Sobester and P Joseph ldquoPerformance and noisetrade-offs on a civil airliner with over-the-wing enginesrdquo inProceedings of the 49th AIAA Aerospace Sciences Meeting AIAApaper 2011-0266 Orlando Fla USA 2011

[11] S Fukata K Hayama G Sylvand S Alestra and T AxumaldquoStudy of jet noise source modeling and shielding effect forfuture aircraftrdquo Inter-Noise 2011 2011

[12] M Czech R Thomas and R Elkoby ldquoPropulsion airframeaeroacoustic integration effects for a hybrid wing body aircraftconfiguraionrdquo inProceedings of the 16thAIAACEASAeroacous-tics Conference AIAA Paper 2010-3912 Stockholm SwedenJune 2010

[13] X Huang X Chen Z Ma and X Zhang ldquoEfficient compu-tation of spinning modal radiation through an engine bypassductrdquo AIAA Journal vol 46 no 6 pp 1413ndash1423 2008

[14] K Chiba T Imamura K Amemiya and K Yamamoto ldquoDesignoptimization of shielding effect for aircraft engine noiserdquoJournal of Environment and Engineering vol 2 no 3 pp 567ndash577 2007

[15] T Kamatsuchi ldquoComputational aeroacoustic analysis aroundan airfoil using linearized Euler equationsrdquo Journal of JapanSociety of Fluid Mechanics vol 23 pp 285ndash294 2004

[16] X Chen X Huang and X Zhang ldquoSound radiation from abypass duct with bifurcationsrdquo AIAA Journal vol 47 no 2 pp429ndash436 2009

[17] M Bauer J Dierke and R Ewert ldquoApplication of a discon-tinuous Galerkin method to discretize acoustic perturbationequationsrdquo AIAA Journal vol 49 no 5 pp 898ndash908 2011

[18] H Onda R Sakai D Sasaki and K Nakahashi ldquoUnsteadyflow and aerodynamic noise analysis around JAXA landing gearmodel by building-cube methodrdquo in Proceedings of the 49thAIAA Aerospace Sciences Meeting AIAA Paper 2011-1081 2011

[19] D Sasaki H Onda A Deguchi R Sakai and K NakahashildquoLanding gear aerodynamic noise prediction using building-cube methodrdquo in Proceedings of the 29th AIAA Applied Aero-dynamics Conference June 2011 AIAA Paper 2011-3366

[20] A Deguchi D Sasaki K Nakahashi M Murayama KYamamoto and Y Yokokawa ldquoAeroacoustic simulation ofJAXA landing gear by building-cube method and non-compactCurlersquos equationrdquo in Proceedings of the 50th AIAA AerospaceSciences Meeting AIAA Paper 2012-0388 2012

[21] K Nakahashi and L-S Kim ldquoHigh-density mesh flow com-putations by building-cube methodrdquo in Computational FluidDynamics 2004 C Groth and D W Zinggm Eds pp 121ndash126Springer Berlin Germany 2006

[22] K Nakahashi ldquoBuilding-cube method for flow problemswith broadband characteristic lengthrdquo in Computational FluidDynamics 2002 S Armfield R Morgan and K Srinivas Edspp 77ndash81 Springer 2003

[23] C Bogey C Bailly and D Juve ldquoComputation of flow noiseusing source terms in linearized Eulerrsquos equationsrdquo AIAAJournal vol 40 no 2 pp 235ndash243 2002

[24] T Ishida S Takahashi and K Nakahashi ldquoEfficient and robustCartesian mesh generation for building-cube methodrdquo Journalof Computational Science and Technology vol 2 pp 33ndash45 2011

[25] K Nakahashi ldquoImmersed boundary method for compressibleEuler equations in the building-cube methodrdquo in Proceedingsof the 20th AIAA Computational Fluid Dynamics ConferenceAIAA Paper 2011-3386 2011

[26] E Shima and K Kitamura ldquoOn new simple low-dissipationscheme of AUSM-family for all speedsrdquo in Proceedings of the47th AIAA Aerospace Sciences Meeting AIAA Paper 2009-136January 2009

[27] C K W Tam ldquoRecent advances in computational aeroacous-ticsrdquo Fluid Dynamics Research vol 38 pp 591ndash615 2006

[28] V Allampalli R HixonM Nallasamy and S D Sawyer ldquoHigh-accuracy large-step explicit Runge-Kutta (HALE-RK) schemesfor computational aeroacousticsrdquo Journal of ComputationalPhysics vol 228 no 10 pp 3837ndash3850 2009

[29] R Mittal H Dong M Bozkurttas F M Najjar A Vargasand A von Loebbecke ldquoA versatile sharp interface immersedboundary method for incompressible flows with complexboundariesrdquo Journal of Computational Physics vol 227 no 10pp 4825ndash4852 2008

[30] T Ishida S Kawai and K Nakahashi ldquoA high-resolutionmethod for flow simulations on block-structured Cartesianmeshesrdquo in Proceedings of the 6th International Conference onComputational Fluid Dynamics (ICCFD6 rsquo10) Saint PetersburgRussia July 2010

[31] B Wasistho B J Geurts and J G M Kuerten ldquoSimulationtechniques for spatially evolving instabilities in compressibleflow over a flat platerdquo Computers and Fluids vol 26 no 7 pp713ndash739 1997

[32] C K W Tam and J C Hardin Second Computational Aeroa-coustics (CAA) Workshop on Benchmark Problems NASA Con-ference Publication 3352 1997

[33] J H Seo and R Mittal ldquoA high-order immersed boundarymethod for acoustic wave scattering and low-Mach numberflow-induced sound in complex geometriesrdquo Journal of Com-putational Physics vol 230 no 4 pp 1000ndash1019 2011

18 International Journal of Aerospace Engineering

[34] J H Lan Y Guo and C Breard ldquoValidation of acousticpropagation code with JT15D static and flight test datardquo inProceedings of the 10th AIAACEAS Aeroacoustic ConferenceAIAA paper 2004-2986 May 2004

[35] J M Tyler and T G Sofrin ldquoAxial flow compressor noisestudiesrdquo SAE Transactions vol 70 pp 309ndash332 1962

[36] A S Lyrintzis ldquoSurface integral methods in computationalaeroacousticsmdashfrom the (CFD) near-field to the (Acoustic) far-fieldrdquo International Journal of Aeroacoustics vol 2 no 2 pp 95ndash128 2003

[37] M F Heidmann A V Saule and J G McArdle ldquoAnalysis ofradiation patterns of interaction tones generated by inlet rods inthe JT15D enginerdquo in Proceedings of the 5th AIAA AeroacousticsConference AIAA paper 79-0581 1979

[38] D Sasaki and K Nakahashi ldquoAerodynamic optimization ofan over-the-wing-nacelle-mount configurationrdquoModelling andSimulation in Engineering vol 2011 Article ID 293078 13 pages2011

[39] K R Laflin SM Klausmeyer T Zickuhr et al ldquoData summaryfrom second AIAA computational fluid dynamics drag predic-tion workshoprdquo Journal of Aircraft vol 42 no 5 pp 1165ndash11782005

[40] J XuD StanescuMYHussaini and F Farassat ldquoComputationof engine noise propagation and scattering off an aircraftrdquo inProceedings of the 41th AIAA Aerospace Sciences Meeting AIAAPaper 2003-0542 Reno Nev USA January 2003

International Journal of

AerospaceEngineeringHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

RoboticsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Active and Passive Electronic Components

Control Scienceand Engineering

Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

International Journal of

RotatingMachinery

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporation httpwwwhindawicom

Journal ofEngineeringVolume 2014

Submit your manuscripts athttpwwwhindawicom

VLSI Design

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Shock and Vibration

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Civil EngineeringAdvances in

Acoustics and VibrationAdvances in

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Electrical and Computer Engineering

Journal of

Advances inOptoElectronics

Hindawi Publishing Corporation httpwwwhindawicom

Volume 2014

The Scientific World JournalHindawi Publishing Corporation httpwwwhindawicom Volume 2014

SensorsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Modelling amp Simulation in EngineeringHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Chemical EngineeringInternational Journal of Antennas and

Propagation

International Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Navigation and Observation

International Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

DistributedSensor Networks

International Journal of

2 International Journal of Aerospace Engineering

address scattering diffraction and reflection by objects LEEsare often solved on body-fitted structured and unstruc-tured meshes [14ndash17] From a practical point of view thesemeshes have some drawbacks in the computation of realisticcomplex geometries Body-fitted structured mesh is fit tothe object and is able to adapt to detailed componentsprecisely however the computational cost of mesh gener-ation around an entire aircraft or more complex geometryis quite high Unstructured mesh is applicable to complexgeometry however it generally achieves low-order accuracyin space In addition high-order unstructuredmethods incurconsiderable computational cost Due to these reasons asimple Cartesian mesh is the focus of the present researchGeneration of Cartesian mesh is based on the simple divisionof the computational domain and thus it can easily accom-modate complex geometries Furthermore a high-orderscheme is easily employed by the extension of stencils Rapidcomputation is achieved owing to the simple computationalstructure of the Cartesian mesh However the main problemassociated with Cartesian mesh is numerical error causedby the staircase wall boundary In this research a block-structured Cartesian mesh method denoted as the building-cube method (BCM) [18ndash22] and the immersed boundarymethod (IBM) are applied to solve the abovementionedproblemUsing the BCM an appropriatemesh resolution canbe locally assigned over the entire computational domainIBM helps to maintain a practical minimum mesh size andto achieve highly accurate wall boundary conditions

The purpose of this research is to develop the LEEs solverto compute noise propagation around complex geometryeasily and robustly To achieve this purpose the BCM isemployed in conjunction with IBM First a one-dimensionalwave propagation problem is evaluated Second acousticscattering around a sphere is computed Third noise prop-agation from the JT15D nacelle is computed and comparedwith results obtained from other sources At last noisepropagation around fuselage-wing-nacelle configurations iscomputed and the noise shielding effect of the over-the-wing nacelle (OWN) configuration is estimated as a realisticcomputation around complex geometry

2 Computational Method

21 Linearized Euler Equations In the Euler equations thephysical quantities 119876 are divided into a mean flow fieldvector 119876

0and fluctuation vector 119876

1015840 By linearization of theEuler equations around 119876

0= 119876 minus 119876

1015840 the time evolutionequations of 119876

1015840 are obtained in (1) These are the LEEs Inthe LEEs the sound source term 119878 is added to incorporatea realistic sound source For computation of the LEEs Sand the mean flow field vector 119876

0are introduced The time

evolution of 1198761015840 is then computed The governing equations

are nondimensionalized by the mean flow density 1205880 speed

of sound c and reference length D

1205971198761015840

120597119905+ 11986010

1205971198761015840

120597119909+ 11986020

1205971198761015840

120597119910+ 11986030

1205971198761015840

120597119911+ 1198601015840

1

1205971198760

120597119909

+ 1198601015840

2

1205971198760

120597119910+ 1198601015840

3

1205971198760

120597119911= 119878

1198761015840

=

[[[[[[[[[

[

1205881015840

1199061015840

1

1199061015840

2

1199061015840

3

1199011015840

]]]]]]]]]

]

1198760

=

[[[[[[[[

[

1205880

11990610

11990620

11990630

1199010

]]]]]]]]

]

1198601198950

=

[[[[[[[[[[[[[[

[

1199061198950

1205751119895

1205880

1205752119895

1205880

1205753119895

1205880

0

0 1199061198950

0 01205751119895

1205880

0 0 1199061198950

01205752119895

1205880

0 0 0 1199061198950

1205753119895

1205880

0 1205741205751119895

1199010

1205741205752119895

1199010

1205741205753119895

1199010

1199061198950

]]]]]]]]]]]]]]

]

1198601015840

119895=

[[[[[[[[[[[[[[[

[

1199061015840

1198951205751119895

1205881015840

1205752119895

1205881015840

1205753119895

1205881015840

0

0 1199061015840

1198950 0 minus120575

1119895

1205881015840

12058820

0 0 1199061015840

1198950 minus120575

2119895

1205881015840

12058820

0 0 0 1199061015840

119895minus1205753119895

1205881015840

12058820

0 1205741205751119895

1199011015840

1205741205752119895

1199011015840

1205741205753119895

1199011015840

1199061015840

119895

]]]]]]]]]]]]]]]

]

(1)

Here 120574 = 14 is the specific heat ratio 120575119894119895is the Kronecker

delta In the computations with mean flow field 1205971198760120597119909

1205971198760120597119910 and 120597119876

0120597119911 are neglected to avoid the instability

waves caused by the shear mean flow field The effect ofneglecting the terms about the gradient of themean flow fieldis discussed in [23]

22 Computational Mesh of the BCM The computationalmesh of BCM is generated by the following procedures intwo dimensions [24] The computational domain is dividedinto an aggregation of square areas (cubic areas in threedimensions) where each area is denoted as a ldquocuberdquo as shownin Figure 1(a) Each cube is then divided by an equispacedCartesianmesh as shown in Figure 1(b) Cells located outsidethe wall boundary are defined as fluid cells On the otherhand cells located inside the wall boundary are defined aswall cells In this method all cubes have the same number ofcells so that the computational effort required for all cubes isessentially equivalent in parallel computation and excellentparallel efficiency is achieved Each cube has three overlapcells as shown by the hatched cells in Figure 1(b) for data

International Journal of Aerospace Engineering 3

Cube

(a) Computational domain and cube boundary (b) Computational cells in a cube (15 times 15 cells 3 overlap cells)

Figure 1 Computational mesh of the building-cube method (BCM) in two dimensions

exchange When a cube is locally refined the cube selectedfor refinement is divided into four cubes (eight cubes in threedimensions) and each cube is subdivided by prescribed cellsAfter the refinement the size of the cube is smoothed so thatthe sizes of adjacent cubes are restricted to the same doubleor half that size The sizes of adjacent cubes are checked forall cubes If the size of an adjacent cube is larger than doublethe size of a focusing cube the adjacent cube is divided intofour cubes (eight cubes in three dimensions) and each cubeis subdivided by prescribed cells

23 Computational Algorithm of the LEEs Solver Figure 2shows the computational algorithm of the LEEs solverAt the beginning mesh information object shape initialconditions and the mean flow field are given The meanflow field is computed by the compressible Euler solver inthis research The details of the compressible Euler solverare provided in [25] The computational scheme of inviscidflux is changed from that of the reference to the simple low-dissipative advection upstream splitting (SLAU) [26] scheme

The spatial derivative of the LEEs solver is computedby the dispersion relation preserving (DRP) scheme [27]Through the use of the overlap cells a fourth-order DRPscheme using seven-point stencils can be implemented overthe entire area of the computational domain Time integra-tion is computed by a six-stage fourth-order Runge-Kuttascheme [28] In the time integral six subiterations constituteone time step In addition artificial selective damping [27] ofthe seven-point stencils is applied at each iteration to elim-inate the nonphysical oscillation The above computationsincluding boundary treatments are parallelized for all cubesusing Open Multi-Processing (OpenMP)

24 Wall Boundary For computation by Cartesian mesh itis important to apply mesh to wall boundaries realistically

because real surfaces have curvature Therefore variousIBMs have been proposed for diverse implementations Inthe present solver an IBM that employs a ghost cell (GC)approach using an image point (IP) [29] is applied Wallcells adjacent to fluid cells are defined as GCs The IP isdefined from the GC in the direction normal to the closestwall boundary as shown in Figure 3(a) In this processsurface stereo lithography (STL) data is used to determinethe intersection point of the normal vector with the wallboundary The physical quantities of the IP are interpolatedby the inverse distance weighting method of (2) using 3 times 3 times

3 = 27 stencils as illustrated in Figure 3(b)

119876IP =

27

sum

119894=1

119908 (119894) times 119876119904

(119894) times mask (119894)

119908 (119894) =ℎ (119894)minus2

sum27

119895=1ℎ (119895)minus2

(2)

Here 119876IP is the physical quantities of the IP 119876119904isthe physical

quantities of stencils 119908 is the weight function based on thedistance ℎ between the IP and stencils and mask is a valuethat reflects whether the stencil is a fluid cell or wall cell Fluidcells have mask = 1 and wall cells have mask = 0

The physical quantities of a GC are computed by thefollowing equations so that the slip condition is satisfied usingthe physical quantities of the IP

VGC = VIP minus (1 + (119889IP119889GC

)) times (VIP sdot n)n

119901GC = 119901IP

120588GC = 120588IP

(3)

Here 119889IP is the distance from the IP to the wall surface 119889GCis the distance from the GC to the wall surface n is the unit

4 International Journal of Aerospace Engineering

Input mesh initial condition and mean flow field

Data exchange at cube boundary

Compute spatial derivative and input

Damping in buffer zone

Output data

Para

llel f

or cu

bes

Subi

tera

tion

Upd

ate t

ime s

tep

Update of Q998400sub(n)

Q998400sub(n)

Fluctuation vector Q998400(n+1)

Fluctuation vector Q998400(n)

120655Q998400120655x 120655Q

998400120655y 120655Q

998400120655z 120655Q0120655x 120655Q0120655y 120655Q0120655z S

Figure 2 Computational algorithm of the linearized Euler equations (LEEs) solver

Fluid cell

Ghost cell

Wall cell

Wall boundary

Image point

(a) Definition of GC and IP

Fluid cell

Ghost cell

Qs(1)

Qs(2)

Qs(3)

Qs(4)

Qs(5)

Qs(6)

Qs(7)

Qs(8)

Qs(9)

QIP

mask(1) = 1

mask(6) = 0

h(1)

(b) Interpolation to IP

Figure 3 The immersed boundary method (IBM) using an image point (IP) based on a ghost cell (GC)