Raw Mix Preparation

Transcript of Raw Mix Preparation

Raw Mix PreparationIndustrialIT Solutions for the Cement Industry

��

OptimizeIT Raw Mix Preparation

OptimizeIT Raw

Mix Preparation

is ABB’s answer to

feed quality pro-

blems. Our whole

experience and

know-in the field

of cement produc-

tion and advanced

process control

has been merged

to create real solu-

tions for our cus-

tomers.

•Increased profits (5%–10%)•Increased production (3%–10%)•Energy savings (3%–7%)•More stable product quality (10%–20%)

BEnEfITS

OPTIMIZED PROCESSOPTIMIZED PROCESS

Application Support

Training

Product Support

OptimizeIT

Raw MixPreparation

Pre-blending Optimization

Knowledge Based Solutions Technology

ApplicationCommissioning

ConfiguredStrategyPackage

Raw MixPreparation

Raw Mix Optimization

Raw Mill Optimization

What is OptimizeIT Raw Mix Preparation?Theconsequencesofpoorlypreparedrawmeal

arewellknown.Highlimecausesmealtobe

burnedharderandrefractorylifedrops.High

alkalinesmaycausecycloneblockageandrestrict

theuseofthecementproduced.Moisturecontent

risesandsodoesenergyconsumption.Andof

course,oversizemealbringslowreactivityand

burnability.

Asleadersinkilncontrolandoptimizationusing

OptimizeITExpertOptimizer,ABBunderstands

thewoesofill-preparedrawmealenteringthe

kiln–andthejoysofwell-preparedmeal.Fluctu-

ationsinthechemicalcompositionofexcavated

rawmaterialsareunavoidableatthestartofthe

manufacturingprocess.However,ifundetected

orleftuncorrected,stablekilnoperationbecomes

difficult.

ThatiswhyABBhasdevelopedOptimizeIT Raw

Mix Preparation (RMP):toofferrawmixquality

assurancetotheleadersofthecementindustry.

OptimizeITRawMixPreparation(RMP)depictsa

comprehensivesetofsoftwaresolutionsthatcover

allstagesoftherawmixblending,fromthequar-

rytoitsgrinding,makingsurethatyourquality

targetsarereachedatthelowestpossiblecost.

RMPisafullyintegratedsolutioninABB’sCPM

cementportfolio,consistingofKnowledge

ManagementSystems,LaboratoryInformation

ManagementSystems,AutoLabandofcourseour

solutionsforkilnandmilloptimization.ThusRMP

iscreatingthebasisforthemodulargrowthand

developmentofyoursystem,adaptedtoyour

plant’sneeds.

��

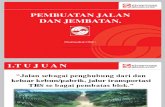

Three optimizati-

on modules work

in concert to help

the cement plants

to achieve their

desired quality,

cost and safety

targets.

OnlineMeasurement

Composition Control

Limestone/Clay

Composition Control

OnlineMeasurement

RawMill

HomogenizingSilo

Kiln FeedPre-blending

Optimization ModuleRaw Mix

Optimization ModuleRaw Mill

Optimization Module

Sampler

OfflineXRF

How does OptimizeIT Raw Mix Preparation work?RMPachievesthegoalofminimizationoffeed

chemistryfluctuationsatthelowestpossiblecost

byconcatenatingthreestrongfunctionalmodules.

Thesemodulesproducevaluetoourcustomers

asstandalonesolutions,butthemaximumbene-

fitsandsynergiesarereachedwhendeployed

together.Theyconformauniquesolutioninits

strength,performanceandcompleteness.

Pre-blending OptimizationThequarryfluctuationsaresmoothedearlyin

therawmealpreparationprocess,namelyatthe

pre-blendingbeds.Optimumproportioningof

thedifferentrawmaterialsonthecombinedpre-

blendingbedisachievedwiththeABBPre-blen-

dingOptimizationModule.ModelBasedControl

technologyisusedtoitsfullstrengthinorderto

copewiththechallengesposedbythematerial

propertiesvariabilityandthetimedelaysinherent

tothesystem.

Raw Mix OptimizationTheRawMixOptimizationModulereduces

andcontrolsshort-termfluctuationstothetarget

valuesbyoptimizingandcontrollingtherawmeal

materialproportionsintherawmillfeed.Asin

theformermodule,ModelBasedControltechno-

logyplayshereacrucialroletoattainthedesired

qualitytargets.Withthehelpofmathematical

modelsthismoduleisabletoforeseecomingqua-

litydeviationsinthemillorsilos,orforinstance

findremedytofeedersmalfunctions.Thispermits

implementationofpredictiveactionsratherthan

reactiveones.

Raw Mill OptimizationTheRawMillOptimizationModuleachievesstable

milloperationatthemaximumeconomicproduc-

tionrateforthefineness,moisture,andchemical

compositionrequired.Short-termfluctuationsare

dampened.Theoptimizationthereforesupports

boththeoperatorsandthoseresponsiblefor

qualityalike..

• Tirelessly supervises desired process parameters

• Unchallenged reaction speed• Consistently takes the best decision• Executes many small changes as

opposed to few large changes• Immediately recognizes

abnormal conditions and acts accordingly

BEnEfITS

��

Pre-blending Optimization Module

ThePre-blendingProportioningModulebalan-

cestheanalysisvalueswiththecorresponding

quantityvaluesofthecombinedpre-blending

bed.TargetvaluesareusuallyCaOand/orAI2O3.

Thecrushedmaterialsareanalyzedusinganon-

lineanalyzer,oralternatively,samplesregularly

taken,automaticallyprocessedandanalyzed.In

automaticmodethefeedersreceivecalculatedset-

pointsvalues.

ThePre-blendingModellingModuletracksthe

rawmaterialflow.Amathematicalmodelisbuilt

usingthechemicalcompositionandthelocation

oftherawmaterialinthepre-homogenization

bed.Duringthereclaimingprocess,themodule

deliversthechemicalcompositionofthereclai-

medrawmaterialtorefinetheperformanceofthe

RawMealProportioningModule.

Thecontrolalgorithmsaredesignedtodealwith

longtermdisturbancesmakingsurethatmostof

theproblemscanbecorrectedattheirorigin.On

theotherhand,thesolutionissuchthatamaxi-

mumofrobustnessandreliabilityisguaranteed

atalltimes.

Thismoduleisthefirststeptowardshomogeniza-

tionofthematerialchemistry.Itsaimistoreduce

mediumtermfluctuationsofthematerialproper-

tiesandtopreparethegroundforfurtherimpro-

vementsusingthesubsequentmodulesavailable

inthesystem.

• Early smoothing of long- and medium-term compositions

• Mathematical modelling of pre-blended structures

• Correlation with modelling when reclaiming

BEnEfITS

The Pre-blending

Optimization

Module tackles

quality problems

very early at the

root cause by hel-

ping to achieve

the best possible

bed of raw mate-

rials.

��

TheRawMixOptimizationModuleaimsforthe

lowestpossibledeviationsfromthequalitytargets

attheconveyorbelts,themillandhomogenizati-

onsilos.Thisisachievedviaonlinecontrolofthe

weighfeederratesactiveattheplant.

Theoptimizationisadaptedtoproducestable

rawmealcharacteristicsenteringthekiln,using

regularlytakensamplesfromlaboratoryoronline

analysers,feedingadigitalcontrolalgorithm.

Therawmixchemicalcompositioncorresponds

tothequalityrequirementsexpressedeitherby

thespecificlimestandard(LS),silicamodule(SM)

andaluminamodule(AM),orbythepotential

clinkerphasesC2S,C3S,C4AF,C3A.Bothgroups

ofmagnitudescanbederivedfromthemainraw

mixoxidesCaO,SiO2,AI2O3andFe2O3.

Raw Mix Optimization Module

Thecontrolalgorithmisbasedonthelatest

controltechnologieslikeModelPredictiveControl

(MPC)usingMixedLogicalDynamic(MLD)

processingandgraphicalmodelbuilding.This

allowsexplicitconsiderationoftimedelays,

actuatordynamics,planttopology,etc.Theresult

isthebesteversolutioninthemarketplace.

Theoptimizationallowstheprioritizationand

tuningofdifferentgoalslikerawmaterialcost

optimizationandachievementofdesiredquality

targets.Italsoallowsyoutoreducethesensitivity

tomeasurementnoise,specifyfeedervariability,etc.

• Optimization of raw mix chemical compositions

• Minimize raw material costs• Reduce manufacturing costs

downstream • Internationally recognized quality

standards

BEnEfITS

The Raw Mix

Optimization

Module executes

online control of

the weigh feeders

in order to gua-

rantee the optimal

trade-off between

deviations from

quality targets and

material costs.

Based on state-

of-the-art control

technology, it

offers optimal

results and high-

est robustness.

��

Raw Mill Optimization Module

TheRawMillOptimizationoptioncontrolsboth

thetemperature,thefeedratetothemillandthe

separatorspeedinordertoachievetherequired

throughputforkiln.Wherestartingthemill

requiresdamperstobemoved,tochangegas

flowpaths,themodulewillalsorespondtothese

effectstokeepthesystemstable.

TheRawMillOptimizationModulestabilizesmill

operationandthencontinuouslyoptimizesits

mainprocessvariablesofthroughput,particle

sizeandenergyconsumed–relievingoperators

oftediouscorrectiveactions.Stabilitycontroluses

afeedcontrolstrategytoobtainastablegrinding

process.Freshfeedoptimizationdeterminesthe

millpowerconsumptionsetpointthatgivesthe

highestfreshfeedrate.Finenessandmoisture

controlareincluded.

Theprinciplebywhichthismoduleprovides

benefitsisasfollows.First,stabilizationofthe

keyprocessparametersisachieved.Notethat

themoduleimplementssmallactionsfrequently,as

opposedtotheinfrequentlargeactionstypicalof

humanoperator,theresultisamoresmoothope-

ration,largerproductivity,lesswearandtear,etc.

Inasecondstep,theMillOptimizationModule

movestheprocesstowardsitsconstraints,seeking

optimalsetpointsintheeconomicsensewhilestill

meetingalltheconstraintsoftheprocess.

Processsafetyissuesaretakenintoaccountauto-

maticallymakingsurethattheplanttechnicaland

humanassetsarenotjeopardizedatanypointin

time.

• Stable operation of raw mills• Maximum economic production rates• fine tuning of particle size and mois-

ture content • Operator Support and Training

BEnEfITS

Rely on the Raw

Mill Optimization

Module in order

to obtain maxi-

mum operational

stability, highest

throughput and

safety.

��

RMP Control Technology

Pre-blendingbed

Feeders Raw mill Homogenizationsilo

Quarry

Long termfluctuations

Kiln

Quality

Middle termfluctuations

Short termfluctuations

«Zero»Short termfluctuations

Pre-blendingOptimization

Module

Raw MixOptimization

Module

Raw MillOptimization

Module

RMPisbasedonthemostmoderncontroltechno-

logiesavailable.Thesystem

• Usesamathematicalmodelsoffeeders,con-

veyorbelts,mills,andsilos,etctopredictinto

thefuturetheeffectofdifferentcontrolmoves

• pickstheoptimalonesforapplicationinthe

plant.

Forcreationofthemathematicalmodelalibrary

ofcomponents(feeders,conveyorbelts,silos,

mills)isavailabletoconfigurethecustomerappli-

cation.Thisisdoneusinghighlyefficientgraphi-

caltoolsthatviadraganddropoperationscreate

theoverallplantlayout.Generationoftheoverall

processmodel,optimizationproblemsolvingand

simulationofresultsistakenoverbythesoftware!

RMP software key factsRMPisbasedonthemostmodernsoftware

technologiesavailable:webservers,thinclients,

graphicalmodelbuilding,OPC,latestWindows

version,etc.Thisensuresmaximumperformance

andlowestpossibleownershipcosts.

• DataacquisitionandStorage

• Standardinterafacestoprocessandonline

analyzers

• IndustryspecificOracledatabasestructure

• Databackupandrestorefunctions

• Control

• Rawmillcontrol

• Closedloopcontroloffeedersetpoints

• Costminimization

• Constraintsatisfaction

• HumanMachineInterface

• Latestwebtechnology:server-thinclient

architecture

• Basicsetofstandardreports,processdis-

plays,trendsandmenus

OptimizeIT is

an outstanding

robust solution for

quality issues at the

cement plant. It puts

the most modern

software and control

technology at the

service of our

customers.

• Enhanced process stability• Better response to disturbances• Compensation for delays in

conveyor belts• Handling of delays in sampling,

X-Ray analysis, etc.• Recognition and correction of weigh

feeder errors• Prediction of moduli values in the

mill and the silos

fEaTURES

3BH

S 2

11 5

45 Z

AB

E01

/Rev

A (0

7.06

500

Pom

cany

’s)

• stablecoatinginthekilnwithstablerawmealfedtothekiln

• formationoffavourableclinkerphasesgrownfromraw

mealwithconsistentproperties

• kilnoptimizationhasfewerfluctuationstocopewith

• cementisgroundtohighqualityfromconsistentclinker

qualitywithwell-balancedphases

• ABBassuresqualitywithacomprehensivesetofsolutions

fortheautomationandoptimizationofrawmealpreparation.

OptimizeIT Raw Mix PreparationRawmixpreparationisthequalitykeycontrolparameter

upstreamforstable,continuousmanufactureofhighqua-

lityclinkerandcement.Downstreamqualityandupto5%

productionincreasesorsavingsoriginatefromABB’squa-

lityassurancesystemOptimizeITRawMixPreparation.The

reasonsareclear:

ConsultABBonhowtooptimizeyourupstreamoperations.

aBB Switzerland LtdCH-��0� Baden � DättwilSwitzerlandPhone: +�1 (0)�8 �8� 8� �� Fax: +�1 (0)�8 �8� �� ��[email protected]/cement