Offshore July 2013

-

Upload

alexanderchacin8706 -

Category

Documents

-

view

898 -

download

14

Transcript of Offshore July 2013

1

2

3

4

5

6

Manaus

Rosario

Cordoba

Sao Paulo

Curitiba

Porto Alegre

Salvador

Belo Horizonte

Rio de Janeiro

Fortaleza

Recife

Equator

Tropic of Capricorn

Alagoas

Amapá

Amazonas

Bahia

Ceará

Distrito

Federal

Espírito

Santo

Goiás

Mato Grosso

do Sul

Minas Gerais

Mato Grosso

Maranhão

Paraíba

Paraná

Pará

Piauí

Pernambuco

Rio de Janeiro

Rio Grandedo Norte

Rio Grande

do Sul

Rondônia

Roraima

Santa Catarina

São Paulo

SergipeTocantins

FrenchGuiana

Co

lom

bia

Suriname

GuyanaVenezuela

Bolivia

Paraguay

Argentina

Uruguay

Montevideo

Brasilia

Buenos Aires

T

Brazil Offshore Oil & Gas MapBlocks

Blocks

Exploration Licences

Production Licences

Oil

Gas

Oil & Gas

Proposed Pipeline

Capital City

Major Town

Oil

Gas

Terminals

Licence blocks courtesy of the ANP, Brazil - www.anp.gov.br

Fields

Terminals

Pipelines Abbreviations

Cities

ANADARKOBRAZALTA

DEVON ENERGYDONG

GRAN TIERRA ENERGYOGX PETROLEO

PETROBRASPETROGAL

PETROSYNERGYPOTILEO

QUANQUEIROZ

SILVER MARLINSONANGOL STARFISH

STATOILSTRATUS

WASHINGTONVIPETRO

ANADBRAZDEVONDONGGTEOGXPETRAPETROGALPETSYNPOTILEOQUANQUIRSILMARSTARSTATSTRATWASHVIP

DENTAO

GUAIUBA

UBARANA

SALEMABRANC

GUAJA

AGULHA

SIRIARATUM

SERRA

PITIGUARISALINACRIST

GUAMARE

ICAPUI

FAZENDABELEM

POCINHO

MONTEALEGRE

ESTREITO

SERRARIA

CANTODO AMA

PONTA DO MEL

BIQUARA

CIOBA

MACAU

PEDRA SENTADA

ARACARI

BOA VISTA

MORRINHO

REDONDA

NORESTE DOMORRO ROSADO

CHOPIM

FAZENDACANAAN

PAJEU

JANDUI

SABIA

PINTASSILGO

BARRINHALESTE

ACAUA LESTE

BARRINHASUDOESTE

FAZENDACURRAL

RIO MOSSORO

FAZENDAMALAQUIAS

BAIXA DO ALGODAO

RIACHODA FORQUILHA

BOAESPERANCA

ASABRANCA

LESTE DE POCO XAVIER

POCO XAVIER

VARGINHA

LIVRAMENTO CACHOEIRINHA

BAIXA DO JUAZEIRO

PERIQUITO

PARDALLORENA

PERIQUITOUPANEMA

BREJINHO

VARZEA REDONDA

JACANA

TRESMARIAS

ROLINHA

TRINCA-FERRO

ANDORINHA

ALTO DORODRIGUES

PORTOCARAO

ARABAIANA

PESCADA

OESTE DE UBARANA

PORTOCARAO

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA PETRA

UTC

UTC

PETRA

PETROGAL

PETRA

KOCH

KOCH

PETRA

AURIZONIA

PETSYN

PETROGAL

PETRA

PETROGAL

PETRA

PETRA

PARTEX

PARTEX PETRAPETROGAL PETSYN

PARTEXPARTEX

PARTEX

PETRA

PETRA

AURIZONIA

PETRA

PETRAPETRA

PETRA

PETRA

PETRA

PETRA

PETROGAL PETRA PETRASTAR

STAR

STAR

PETRA

PETRA

PETRA

PETRAPETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRAPETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRAPETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRAPETRA

PETRA

PETRA

PETRAPETRA

PETRA

PETRA

PETRAPETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRAPETRA

PETRA

PETRA

PETRA

PETRAPETRA

PETRA

PETRA

BM-POT-11

BM-POT-13

BM-POT-13

BT-POT-4

BT-POT-8

POT-M-853 POT-M-855

BT-POT-10

BT-POT-10

BT-POT-8

POT-T-440

POT-T-488

POT-T-612

POT-T-619

POT-T-656

POT-T-705

POT-T-302

POT-T-352

POT-T-394

POT-T-436

POT-T-478

POT-T-479

POT-T-480

POT-T-513

POT-T-514 POT-T-520

POT-T-521POT-T-528

POT-T-557

POT-T-558

POT-T-559

POT-T-661

POT-T-700

DENTAO

ARABAIANAPESCADA

GUAIUBA

POT-T-609

POT-T-610

POT-T-699

POT-T-743 POT-T-744POT-T-745POT-T-748

POT-T-749

SALEMABRANC

GUAJA

SIRI

UBARANA

SALINA CRIST

SERRA

GUAMARE

FAZ POCINHO

MONTE

ALEGREALTO DO RODR

PAJEU

ACAUA

RIACHO DA FO

SERRARIA

PONTA DO MEL

NO MORRO ROS

CANTO DO AMA

MOSSORO

BT-POT-9

Ceará

Rio Grande do Norte

1

TIGRE

ALAGAMAR

ROBALO

POZ DOVAZA BARRIS

DOURADO

GUARICEMA

CAMORIM

TARTARUGA

ARUARI

ANGELIM

CARMOPOLISSUDOESTE

CASTANHAL

SIRIRIZINHOOESTE

RIACHUELO

AGUILHADA

CIDADEDE ARACUJA

CAIOBA

ILHA PEQUENA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETROGAL

PETROGAL

PETRA

PETRA

SEVERO

UP

PETRA

PETRA

PETRA

PETRA

PETRA

PETRONAS

RAL

PETRA

PETRA

PETRASTAR

ALVOPETRO

PETRA

PETRA

PETRAPETRA

PETRA

PETRA

PETRA

BM-SEAL-4

BM-SEAL-9

GUARICEMA

CAMORIM

SEAL-T-391

SEAL-T-412

SEAL-T-429

SEAL-T-410

TARTARUGA

CARMOPOLIS

SIRIRIZINHO

RIACHUELO

CAMORIMSEAL-T-462

SIRIRIZINHO

SEAL-T-391SEAL-T-391

SEAL-T-410

SEAL-T-390

SEAL-T-390

Sergipe

2

FAZENDAALVORADA

FAZENDABALSAMORIO SUBAUMA

RIO SAUIPE

JURITI

FAZENDAIMBE

BOM LUGAR

ARACAS

LAGOA DO PAULO

FAZENDAONCA

SUSSUARANA

FAZENDASANTO ESTEVAO

BURACICA

JAD

SAOPEDRO

TICO-TICO

FAZENDAPANELAS

CASSARONGONGOAGUA

GRANDE

TAQUIPE

NORTECARUACU

GUANAMBI

MARITACA

CEXIS MAPELE

DOMJOAO

DOM JOAOMAR

ACAJA

LAGOA VERDE

GAMELEIRAPOJUCANORTE

PEDRINHAS

FADENZASORI

RIACHO SAO PEDRO

JACUIPE

RIO JOANESMASSUI

ARATU

NORTEDE IRAI

LAGOA BRANCA

IRAI

MATINHA

ITAPARICA

GTESTAR

ALVORADAALVORADA

GTE ALVORADA

GTE ALVORADA COWAN

IMETAME STAR BRAZ

ALVORADA PETSYN

ALVORADA ALVORADA

IMETAME

GTE

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRAPETRA

PETRA

PETRA

PETRA

PETRA

ALVOPETRO

PETRA

PETRA

EGESA

PETRA

PETRA

PETRA

RONCONCAVO

RONCONCAVO

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

SANTANA

PETRA

PETRA PETRAPETRA

PETRA

PETRA

PETRAPETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRASTAR

PETRA

PETRA

RONCONCAVO

REC-T-129REC-T-130

REC-T-131REC-T-132

REC-T-142 REC-T-144

REC-T-155 REC-T-157 REC-T-158

REC-T-163 REC-T-166REC-T-170

REC-T-182REC-T-183

REC-T-196 REC-T-197

REC-T-211

REC-T-224

REC-T-265

REC-T-181

BALSAMO

REC-T-139

CEXIS

REC-T-250

NORTE

DE IRAI

LAGOA BRANCA

MATINHA

REC-T-265

BT-REC-7

REC-T-195

Bahia

3 CORREGO CEDRO NORTE-SUL

RIO SAO MATEUS OESTE

JACUTINGA

RIO PRETO SUL

CORREGO DAS PEDRAS

INHAMBU

NATIVO OESTE

SAIRA

MOSQUITONORTE

MOSQIUTO

ALBATROZ

FAZENDAQUEIMADAS

CAMPOGRANDE

CORREGODOURADO

BARRA DOIPIRANGA

LAGOABONITA

RIO IBIRIBAS

CORRUIRARIO BARRA SECA

LAGOA SURUACA

CACAO

JACUPEMBA

FAZENDASAO JORGE

CANCA

FAZENDA SAO RAFAEL

FAZENDA SANTA LUZIA

RIO IPIRANGA

CACIMBAS

RIO DOCELAGOA PARDA NORTE

LAGOA PARDA SUL

LAGOA PARDA

BIGUA

SAO MATEUS LESTE

MARIRICU NORTE

VIP VIP

VIP

PETRA

PETRA

PETRA PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRAPETRA

CHEIMPETRA

PETRA

PETRA

PETRA

PETRA PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETROSYNERGY

CENTRAL

PETRAPETRA

ES-T-

391ES-T-

392

ES-T-466

CACAO

ES-M-411

ES-M-436 ES-M-437

BIGUA

INHAMBU

NATIVO

OESTE

ALEGRE

CEDRO

SAO JORLAGOA

SURUAC

BARRA

DO IPI

TABUIAIASAO RAF

RIO

IPIRANGA

LAC PARDA

RIO SAO MATE

ES-T-383

Espírito

Santo

4

PAPA-TERRAMAROMBA

CARATAI

PEREGRINO

POLVO

CARAPICU

PAMPO

LINGUADO TRILHA

ENCHOVA

MARIMBA

CORVINA

CHERNE

CONGRO

CARATINGA

BARARCUDA

MARLIM SUL

MARLIM LESTE

ANEQUIM

GAROUPA NORDESTE

CARAPEBA

VERMELHOALBACORA

ALBACORALESTE

FRADE

RONCADOR

CAXAREU

PIRAMBU

BALEIA AZUL NAUTILUS

JUBARTE

CACHALOTE

CATUA

BICUDO

BONITO

PIRAUNA

ESPADARTE

BIJUPIRA

SALEMA

BAGRE NAMORADO

VOADOR

PARGO

ARGONAUTA

XERELETE

GUARAJUBA

ESPADARTE SUL

PARATI

OSTRA

ABALONE

GUARAJUBA

ARUANA

BALEIABICUDA

BALEIA FRANCA

BALEIA ANA

MOREIA

PETRA

STAT

ANAD

BP

PETRA

ANAD

BP BP

YPF

PETRA

PETRA

PETRA

PETRA

STAT

PETRA

SHELL

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

SHELL

SHELL

PETRA

PETRAPETRA

PETRA

PETRA

PETRA

PETRA

BP

OGX

OGX

STAR OGX

STAT

OGX

OGX

OGX

PETRA

OGX OGX STAR

PETRA

PETRA PETRA PETRA

PETRA

SHELL

PETRA

PETRA

PETRA

PETRA

PETRA

PETRAPETRA

PETRA

CHEVRON

PETRA

SHELL

TOTAL

PETRA PETRA

PETRA

PETRAPETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

SHELL

PETRA

PETRAC-M-530

C-M-101

C-M-61

BMC-31

C-M-202

C-M-471 C-M-473

C-M-403

C-M-401

BM-C-14

BM-C-7

LINGUADO

ESPARDARTE

MARLIM

MARLIM SUL

ALBACORA

LESTE

ALBACORA

PARATI

RONCADOR

CATUA

OSTRA

ABALONE

BM-C-25

C-M-119C-M-120

C-M-145

C-M-146

C-M-333

BADERO

POLVO

C-M-466

C-M-498 C-M-499

C-M-529C-M-535

C-M-539

C-M-560

C-M-591

C-M-592

C-M-593

C-M-620 C-M-621C-M-622

C-M-78

C-M-95 C-M-96 C-M-98

MARIMBA

FRADE

JUBARTE

NAUTILUS

VIOALA

234

ARGONAUTA

Rio deJaneiro

5

TAMBUATA

CARAMBA AZULAO SANTOS GUARANI

ABARE OESTE

GUARABEM-TE-VI

CARIOCA

LULA

LULA ALTO

IRACEMA

IARA

IGUAZU

PARATI

TAMBAU

URUGUA

PIRAPITANGA

JUPITER

MEXILHAO

CARAPIA

S-M-405

S-M-623

BM-S-24BM-S-11

BM-S-11

BM-S-9

BM-S-09

GUARA SUL

BM-S-10

BM-S-8

BM-S-21

TUPI NE

FRANCO

S-M-1127

S-M-226

S-M-239

S-M-268 S-M-270

S-M-314

S-M-322

S-M-324

S-M-415

S-M-619

TAMBUATA

BS-400

PETRA

PETRA

PETRA

PETRA

PETRAPETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

PETRA

OGX

PETRA

OGX OGX

OGX

PETRA

PETRA

PETRA

PETRA

QUEIROZ

QUEIROZ

PETRA PETRA

PETRA

PETRA

PETRA

6

©Copyright Offshore Magazine 2013

2013 Oil and Gas Concession Map

BRAZIL

Map Data Content – provided by Infeld Systems Limited, London©Infeld Systems Limited, All Rights Reserved

www.infield.com

oil | gas | marine | renewables

•Data & Project Database

•Market Forecast Reports

•Online Mapping & GIS

•Business Strategy & Analysis

•M&A & Financial Advisory

Try Infield’s online oil & gas mapping site: www.offshoreenergygateway.com

World Class Project Execution by FloaTEC

www.floatec.com

Early Engineering Requires a Unique Set of Skills, Technology and Experience

ï Solid tools and processes for concept screening, feasibility studies, pre-FEED and FEED execution

ï An unbiased approach to objectively identify the optimum solution that meets your drivers

ï Access to real-time project cost and data to facilitate deepwater portfolio management

ï A proven engineering team with recent, applicable project experience; Big Foot ETLP & Papa Terra P-61 TLWP

��������������������������������� ������������������������������� ��������� ������������������� �������������������������www.oceanworks.com

ENGINEERING YOUR SUBSEA SOLUTIONS

Together we can change the industry— that shapes our world.

Para encontrar produtos

à altura de seus desafos,

visite f-e-t.com

1 Subsea Technologies

2 Drilling Technologies

3 Valve Solutions

4 Surface Production & Process Equipment

5 Well Construction & Completion Tools

6 Flow Equipment & Intervention Products

Soluções Inteligentes.

Produtos Potentes.

1307off_Brazilmap_1 1 6/28/13 3:59 PM

July 2013

Houston London Paris Stavanger Aberdeen Singapore Moscow Baku Perth Rio de Janeiro Lagos Luanda

World Trends and Technology for Offshore Oil and Gas Operations

For continuous news & analysiswww.offshore-mag.com

INSID

E:

Brazil

map a

nd jack

up

drillin

g rig p

oster

Mediterranean update

Drilling rig report

Deepwater intervention

Shipyard capabilities

Brazil/Latin America review

1307off_C1 1 6/28/13 2:01 PM

A quick start guide to MAXIMIZING our interactive features.Welcome to the Digital Edition of

SHARE an article or page via social media.

Click PAGES to view thumbnails of each page and browse

through the entire issue.

Easily browse all BACK ISSUES.

SEARCH for specific articles or content.

View the table of CONTENTS and easily navigate directly to an article.

DOWNLOAD the issue to your desktop.

PRINT any or all pages.SHARE an article via email.

Easily NAVIGATE through the issue.

Click directly on the page to ZOOM in or out. Fit the issue to your screen.

TabTransition_Template.indd 1-2 3/19/13 6:00 PM

A quick start guide to MAXIMIZING our interactive features.Welcome to the Digital Edition of

SHARE an article or page via social media.

Click PAGES to view thumbnails of each page and browse

through the entire issue.

Easily browse all BACK ISSUES.

SEARCH for specific articles or content.

View the table of CONTENTS and easily navigate directly to an article.

DOWNLOAD the issue to your desktop.

PRINT any or all pages.SHARE an article via email.

Easily NAVIGATE through the issue.

Click directly on the page to ZOOM in or out. Fit the issue to your screen.

TabTransition_Template.indd 1-2 3/19/13 6:00 PM

Offshore drilling requires a strategy, especially in

today’s environment where the wrong move can be

more costly than ever. That’s why the first move should

be to look for a company with worldwide

capability and experience. And that’s Transocean.

Transocean has more experience drilling deepwater

and harsh-environment wells than anyone. We also

have the largest and most diverse fleet in the world,

so we can deliver exactly the service our customers

need when and where they need it. And we operate in

every major oil and gas area, so we can save on

mobilization and demobilization costs worldwide.

Put them all together and you can see why

more and more customers have learned that the

right move is frequently the easiest move. That’s

why they call Transocean.

Transocean: We’re never out of our depth.®

www.deepwater.com

1307off_C2 2 6/28/13 2:01 PM

1307off_1 1 6/28/13 2:12 PM

With more than 50 facilities on six continents,

TDW is there from planning to project management

(and every step in between).

1307off_2 2 6/28/13 2:12 PM

North & South America: 918-447-5000

Europe/Africa/Middle East: 32-67-28-36-11

Asia/Pacifc: 65-6364-8520

Offshore Services: 832-448-7200

www.tdwilliamson.com

We are partners.

At TDW, we work with our customers to be operationally

ready for the unexpected. Our emergency pipeline

repair programs combine planning, preparation and

project management with industry-leading products and

services to assist our business partners in preparing

for and responding to pipeline emergencies.

SmartPlug® Tetherless Isolation Technology

® Registered trademark of T.D. Williamson, Inc. in the United States and other countries. ™ Trademark of T.D. Williamson, Inc. in the United States and other counrtries. © Copyright 2013 All right reserved. T.D. Williamson, Inc.

1307off_3 3 6/28/13 2:12 PM

International EditionVolume 73, Number 7

July 2013

C O N T E N T S

Offshore (ISSN 0030-0608) is published 12 times a year, monthly by PennWell, 1421 S. Sheridan Road, Tulsa, OK 74112. Periodicals class postage paid at Tulsa, OK, and additional offices. Copyright 2013 by PennWell. (Registered in U.S. Patent Trademark Office.) All rights reserved. Permission, however, is granted for libraries and others registered with the Copyright Clearance Center, Inc. (CCC), 222 Rosewood Drive, Danvers, MA 01923, Phone (508) 750-8400, Fax (508) 750-4744 to photocopy articles for a base fee of $1 per copy of the article plus 35¢ per page. Payment should be sent directly to the CCC. Requests for bulk orders should be addressed to the Editor. Subscription prices: US $101.00 per year, Canada/Mexico $ 132.00 per year, All other countries $167.00 per year (Airmail delivery: $234.00). Worldwide digital subscriptions: $101 per year. Single copy sales: US $10.00 per issue, Canada/Mexico $12.00 per issue, All other coun-tries $14.00 per issue (Airmail delivery: $22.00. Single copy digital sales: $8 worldwide. Return Undeliverable Canadian Addresses to: P.O. Box 122, Niagara Falls, ON L2E 6S4. Back issues are available upon request. POSTMASTER send form 3579 to Offshore, P.O. Box 3200, Northbrook, IL 60065-3200. To receive this magazine in digital format, go to www.omeda.com/os.

Celebrating Over 50 Years of Trends, Tools, and Technology

LATIN AMERICA REPORT

As exploration heats up, Latin American nations refne offshore regulations ..... 34While Brazil is expected to continue to lead the region’s offshore development, oil and gas exploration is expanding across Latin America. The authors present an overview of the regula-tory environments for the oil and gas industry in selected Latin American nations.

Mexico’s rig renaissance gets under way ................................... 38Mexico is one of the 10 largest oil producers in the world and the third-largest in the Western Hemisphere. While it remains a leader, Mexico faces declining domestic production. Reserve estimates in the country are high, but without increased investment, the country’s huge resources will remain in the ground.

Brazil prepares for the industry’s biggest presalt auction ...................... 42 The record $1.4 billion raised in signing bo-nuses from the Brazil Petroleum Agency’s 11th oil and gas licensing round in May marked a successful conclusion to the frst offshore con-cession issue in Brazil since 2007. However, that fgure is likely to pale against the amounts involved as the world’s biggest oil and gas companies compete for acreage in Brazil’s frst auction of presalt operating licenses scheduled for October.

OFFSHORE

MEDITERRANEAN

Mediterranean Sea plays offer new opportunities ...................... 44In April 2010, the US Geological Survey esti-mated 122 tcf of recoverable natural gas in the eastern-most part of the Mediterranean Sea (the Levant or Levantine basin), more than the world consumes in a year. If this and other esti-mates are correct, these offshore natural gas and oil deposits may play the deus ex machina to the current Greek drama.

RIG REPORT

Deepwater rig feet continues to expand ........................... 50The world’s deepwater drilling rig feet continues to grow in order to meet opera-tors’ increasing demands for rigs capable of drilling wells to deeper depths, operating in ever greater water depths, and having them equipped with the newest technologies and safety features.

Rig construction continues to focus on higher-spec units ............ 52Shipyards that build offshore drilling rigs continue to stay busy with new construction projects. Worldwide, 131 jackups, semisub-mersibles, drillships and tender-assisted units are under construction, and another 81 units are on order at shipyards awaiting construc-tion commencement.

2013 Worldwide MODU construction/new order survey ................................ 54Get the latest detailed and comprehensive list-ing of the worldwide mobile offshore drilling units under construction.

Regional demand spurs steady growth of premium jackup feet ..................... 58In the two years since Offshore’s last premium jackup rig survey, the offshore drilling indus-try has steadily added to its global feet, and all indications point to this trend continuing. However, demand for high-specifcation rigs capable of operating in depths of 350 ft (106 m) or greater and able to drill to depths of at least 25,000 ft (7,600 m) varies substantially by region.

GEOLOGY & GEOPHYSICS

Wide-tow seismic survey sets the pace for frontier exploration ........ 60When it comes to surveying large areas of frontier exploration acreage in limited windows of opportunity, seismic operators are required to think big and move fast. Dolphin Geophysical took this approach to fresh extremes in the Atlantic Ocean offshore South Africa, mobilizing the “world’s largest foating object” on behalf of client Shell.

DRILLING & COMPLETION

Tender-assist semi supports spars, TLPs in wider deepwater regions ...... 64 Singapore-based Energy Drilling has ordered three newbuild tender rigs from COSCO Shipyard in Guangdong, China. Two are barges, while the third – EDrill-3 – will be the frst tender-assist semisubmersible based on GustoMSC’s OCEAN400-TD design. The com-pany aims to be the leading provider of tender drilling solutions.

Research aims to rein in mooring installation costs ............. 66Like all aspects of ultra-deepwater exploration and production, mooring presents extraordi-nary challenges, both to engineers and to the people who hold the purse strings. In many cases, particularly in the Gulf of Mexico, the cost of deploying a mooring system has caught up to or exceeded the price of the equipment that composes the mooring system itself.

ENGINEERING,

CONSTRUCTION,

& INSTALLATION

Offshore oil and gas backlogs easing shipyard overcapacity ............ 68While global shipyard output took a big hit with the recent fnancial crisis, the industry appears to be regaining momentum, largely driven by the oil and gas business. A recent analysis by the Denmark-based shipping as-sociation BIMCO described a “soft landing” for the shipyard industry after a wave of order cancellations, delays, and postponements put the brakes on output.

38

1307off_4 4 6/28/13 2:13 PM

†Mark of M-I L.L.C

www.miswaco.com/rhadiant

Produce ultra-high temperature wells fasterRHADIANT

† ultra-HT non-aqueous drilling fluid system is the industry’s first drilling fluid

proven to deliver stable rheological performance at bottomhole static temperatures (BHST)

greater than 500°F (260°C).

An operator in the Gulf of Thailand’s ‘Ring of Fire’ used the RHADIANT drilling fluid system

to efficiently drill a high-angle well with a BHST of 432°F (222°C) with zero lost circulation.

A total of seven open-hole logging runs were then performed, all with excellent results.

RHADIANTUltra-high temperature

drilling fluid system

1307off_5 5 6/28/13 2:13 PM

6 Offshore July 2013 • www.offshore-mag.com

International EditionVolume 73, Number 7

July 2013

D E P A R T M E N T S

PRODUCTION OPERATIONS

Technology trends seek to reduce the cost of subsea well interventions ............... 70In a large sense, the world’s thirst for abundant supplies of cheap, clean-burning energy continues

to grow. The good news is that despite deepwater complexity, risks and challenges, the value of the

prize exceeds the costs to produce it. The cost of interventions has stimulated considerable innova-

tion on the part of offshore producers and service companies to forestall or eliminate them.

Island Offshore fnding new roles for subsea LWI vessels ....................................... 74Island Offshore management’s decision to commit to light well intervention in subsea wells a

decade ago is proving far-sighted. The company now has three dedicated LWI vessels in full

employment, with more feld operators looking to reap the benefts of maintaining their subsea

wells in good order.

SUBSEA

Fault tolerant, hot swappable subsea control architecture can improve reliability ....... 78Subsea control system architectural concepts can be designed to increase reliability and avail-

ability. Failure of a single subsea electronic module does not have to shut down production nor

does it have to reduce the safety integrity level of the system.

Employing a dynamic approach to fow assurance modeling .................................. 82Computational fuid dynamics can combine with traditional pipeline modeling software to

improve detail and speed of both applications for accurate fow assurance modeling. While

computational powers at present may limit the ability to use CFD across an entire system, this

technology will play an increasingly important role in fow assurance.

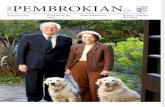

COVER: National and international

oil companies are stepping up their

offshore E&P activities throughout Latin

America, particularly in Brazil, where

Petrobras recently acquired 34 blocks

in the Brazil Petroleum Agency’s 11th oil

and gas licensing round. Even before that

licensing round, Sevan Drilling’s Sevan

Brasil semisubmersible drilling rig (cover)

had received a six-year contract from

Petrobras. But while Brazil is expected

to continue to lead the region’s offshore

development, oil and gas exploration is

expanding across Latin America, with

offshore activities on the rise in Mexico,

Colombia, Peru, Chile, and Argentina.

(Photo courtesy Sevan Drilling ASA)

Online .................................................... 8

Comment ............................................. 10

Data ..................................................... 12

Global E&P .......................................... 14

Offshore Europe .................................. 20

Gulf of Mexico ..................................... 22

Subsea Systems ................................. 24

Vessels, Rigs, & Surface Systems ...... 26

Drilling & Production .......................... 28

Geosciences ........................................ 30

Offshore Automation Solutions .......... 32

Business Briefs ................................... 86

Advertisers’ Index ............................... 91

Beyond the Horizon ............................ 92

1307off_6 6 6/28/13 2:13 PM

Building Partnerships.

Every company is different, every project unique. At Weatherford, we

believe in getting every job right, listening to your concerns, and working

with you to meet your needs and your expectations.

Delivering Results.

We donít succeed until you doóthatís the bedrock principle of our

���������������������������������������� ������������������

our resources are focused on your objectives.

Contact and collaborate with us at

Formation Evaluation | Well Construction | Completions | Production

© 2013 Weatherford. All rights reserved.

1307off_7 7 6/28/13 2:13 PM

PennWell1455 West Loop South, Suite 400, Houston, TX 77027 U.S.A.

Tel: (01) 713 621-9720 • Fax: (01) 713 963-6296

SALES

WORLDWIDE SALES MANAGERHOUSTON AREA SALES

David Davis [email protected] Tel: (713) 963-6206 Shelley Cohen [email protected]

CUSTOM PUBLISHINGRoy Markum [email protected]

Tel: (713) 963-6220

PRODUCTION MANAGERKimberlee Smith [email protected]: (918) 832-9252 • Fax: (918) 831-9415

REPRINT SALESRhonda Brown [email protected]

Tel: (219) 878-6094 • Fax: (219) 561-2023

SUBSCRIBER SERVICE

Contact subscriber service for subscription questions, address changes and back issues

Tel: (847) 559-7501 • Fax: (847) 291-4816

Email: [email protected]

OFFSHORE EVENTSDavid Paganie (Houston) [email protected]

Gail Killough (Houston) [email protected] Niki Vrettos (London) [email protected]

Jenny Phillips (London) [email protected]

CORPORATE HEADQUARTERSPennWell; 1421 S. Sheridan Rd., Tulsa, OK 74112

MemberAll Rights reserved

Offshore ISSN-0030-0608Printed in the U.S.A. GST No. 126813153

CHAIRMAN:Frank T. Lauinger

PRESIDENT/CHIEF EXECUTIVE OFFICER:Robert F. Biolchini

CHIEF FINANCIAL OFFICER:Mark C. Wilmoth

Publications Mail Agreement Number 40052420GST No. 126813153

CONTRIBUTING EDITORS F. Jay Schempf (Houston) Dick Ghiselin (Houston)

Doug Gray (Rio de Janeiro) Nick Terdre (London)

Gurdip Singh (Singapore)

TECHNOLOGY EDITOR,SUBSEA & SEISMIC

Gene [email protected]

EDITOR-EUROPE Jeremy Beckman

ASSISTANT EDITOR Jessica Tippee

SENIORTECHNICAL EDITOR

Russell [email protected]

POSTER EDITORE. Kurt Albaugh, P.E.

PRESENTATION EDITORJosh Troutman

VICE PRESIDENT and GROUP PUBLISHERMark Peters

MANAGING EDITORBruce A. Beaubouef

CHIEF EDITOR/CONFERENCE EDITORIAL DIRECTORDavid Paganie

®

8 Offshore July 2013 • www.offshore-mag.com

Latest newsThe latest news is posted daily for the offshore oil and gas industry covering

technology, companies, personnel moves, and products.

New Videos➤ Shell Olympus

The hull for Shell’s Olympus TLP, centerpiece of the Mars B development in the Gulf of Mexico, was built by Samsung Heavy Industries in South Korea and arrived in Ingleside, Texas in January 2013.

The topsides for the Olympus TLP were installed at the Kiewit Offshore Ser-vices yard in Ingleside. The TLP was scheduled to sail out for the Mars feld in late June 2013.

http://www.offshore-mag.com/topics/video-index

New webcast➤ Deepwater Environments: New Requirements

for Premium Connection TechnologiesAs ultra-deepwater exploration and production activities become a reality,

the bar has been raised for premium connection technologies. When designing deepwater wells, a WCD scenario must be analyzed, using methodologies such as the well containment screening tool. The derived new and more extreme load cases need to be considered for connection design. Turning to risers, today fa-tigue resistance is an absolute must. Find out how Tenaris’ product engineering team is partnering with customers to take on these challenges.

http://www.offshore-mag.com/webcasts/offshore/ 2013/06/deepwater-environments.html

New maps, posters, and surveys • 2013 Worldwide MODU Construction/New Order Survey• 2013 Jackup Drilling Rig Poster• 2013 Brazil Oil and Gas Concession Map • 2013 World Survey of Stimulation Vessels• 2013 Deepwater Solutions and Records for Concept Selection

Download: http://www.offshore-mag.com/maps-posters.html

Browse Offshore magazinePeruse the cover issue and archives back to 1995.

www.offshore-mag.com

Submit an article Offshore magazine accepts editorial contributions. To submit an article, please

review the guidelines posted on our website by following the link below.www.offshore-mag.com/index/about-us/article-submission.html

Available at

Offshore-mag.com

1307off_8 8 6/28/13 2:13 PM

R A I S I N G P E R F O R M A N C E . T O G E T H E R ™

You don’t buy a state-of-the-art rig package every day, so choose one you can rely on daily.

AD00646DRL

If you’re looking for consistent returns in the field, invest in rig equipment that’s made for

the long term. Cameron has built a reputation for reliability, meaning a lower total cost of

ownership. From conceptual design and detailed engineering to our broad range of best-in-class

products, we ensure our total rig package solutions are built for safe, effi cient service throughout

the life of your project. And our unparalleled global aftermarket support is right where you need

us to help keep things running productively 24/7. For more information about Cameron’s lower

total cost of ownership, email us at [email protected].

F L O W E Q U I P M E N T L E A D E R S H I P

CAMERON GIVES A

COMPETITIVE EDGE.

FOR RELIABILITY & EFFICIENCY

1307off_9 9 6/28/13 2:13 PM

+1.713.849.7400

www.wellcontrol.com

COMMITTED TO QUALITY...

DELIVERING VALUE!

� IADC & API Well Control

(Drilling, Workover/Completion,

Coiled Tubing, Snubbing, Wireline)

� GAP Skill Assessment Program

-LEARNING COURSES

INSTRUCTOR - Led COURSES

FOLLOW US ON

TM

� IADC & API Well Control

(Drilling, Workover/Completion,

Coiled Tubing, Snubbing, Wireline)

� IADC Drilling Simulator Workshop

� IADC WellCAP®

Coiled Tubing

� IADC WellCAP®

Snubbing

�� IWCF Well Control

10 Offshore July 2013 • www.offshore-mag.com

To respond to articles in Offshore, or to offer articles for publication,

contact the editor by email ([email protected]).

COMMENT David Paganie • Houston

World’s largest undeveloped discovery for sale

The world’s largest undeveloped discovery, Libra, will be up for bid this October in Brazil’s unprecedented presalt bid round. Aside from the fscal parameters and full-feld appraisal, Brazil’s National Petroleum Agency (ANP) anticipates that the data available from seismic surveys of Libra and analogous discoveries will be suffcient to draw inter-national investors. An independent evaluation by Gaffney, Cline & Associates suggests the feld could hold 4-15 Bbbl of recoverable resources. The best estimate is about 8 Bbbl of oil. Full feld development of the 727-sq km (281-sq mi) area could require at least 10 FPSOs and 200 wells, according to estimates from IHS. The government, however, is moving to a production-sharing framework for the presalt blocks from a concession-based approach that was followed in May’s auction and drew $1.4 billion in signing bonuses. A total of 30 domestic and in-ternational oil and gas companies were awarded 87 onshore and 55 offshore blocks in Brazil’s 11th bid round. Under the new system, the bonus payments and local content requirements will be fxed, and it will be the percentage of proft oil that companies are prepared to sign over to the government that will determine the success of the bids. And the current law requires Petrobras to be the principal operator and 30% minimum stakeholder in the blocks up for auction. Will the increasing regulatory risk, local content require-ments, and government take deter foreign investment in the upcoming lease sale? Will geological data trump fscal terms? A recent industry note by Raymond James calls the Santos basin’s presalt reserves “best in class” among other prominent deepwater areas. That was the conclusion of an economic analysis of the infationary pressures on select deepwater projects in the US Gulf of Mexico, Brazil, and West Africa. These and other pressing issues are explored in our annual Latin America report, beginning on page 34.

The fnal scope of the presalt lease sale is expected to be available to the public this month. For more information, visit www.anp.gov.br.

Rig construction trendsThe global rig construction feet continues to grow as operators seek newer, higher-

spec equipment. According to Offshore’s annual MODU rig construction survey, pro-duced by IHS Petrodata, 131 rigs (37 drillships, 11 semis, 75 jackups, and eight tender-assisted) are under construction and an additional 81 units are on order. Since last year’s survey, 81 rigs have been ordered with the majority being premium jackups rated for 350-ft (107 m) water depth or more. Meanwhile, the older jackups in the global feet are being retired. During the past year, nine jackups left the feet with hulls built between 1975 and 1983. As of June of this year, there are 289 jackups with a year-in-service date of 1983 or earlier. In a special report for Offshore, Cinnamon Odell, IHS Petrodata, discusses these and the other changes in the annual rig construction survey. Odell also reviews the evolution and growth of the deepwater feet, citing trends in the preference of drillships versus semis, deeper water-depth rated rigs, and DP-capable units. The global supply of deepwater rigs has more than doubled during the past 10 years, from 86 in May 2003 to 204 units as of May 2013. Odell’s comprehensive analysis of the global drilling rig feet and accompanying survey begins on page 50.

Libra

1307off_10 10 6/28/13 2:13 PM

6,700

employees

450+ scientific experts

49 manufacturing facilities

12 technology centers

Introducing Nalco Champion, an Ecolab company. Now, the strength and

innovations of Nalco Energy Services, Champion Technologies and CorsiTech

flow together to bring you more service, more technologies and more solutions.

Because together we have more ways to help you produce

the world’s energy. We are taking energy further.

Visit nalcochampion.com to learn more.

Together, we’reTaking Energy FurtherTM

nalcochampion.com

© 2

013

Na

lco

Co

mp

an

y In

c. A

ll righ

ts re

se

rve

d.

1307off_11 11 6/28/13 2:13 PM

Worldwide offshore rig count & utilization rate

June 2011 – May 2013

950

850

750

650

550

450

350

100

90

80

70

60

50

40

No

. o

f ri

gs

Fle

et u

tiliza

tion

rate

%

June 1

1

Sept 11

Dec

11

Marc

h 12

June 1

2

Sept 12

Dec

12

Marc

h13

Contracted fleet utilization Total fleet Contracted Working

Sourc

e: IH

S

Latin America capital expenditures (%) 2008-2017 by country

100

90

80

70

60

50

40

30

20

10

0

Puerto Rico

Falkland Islands

Argentina

Brazil

Uruguay

Peru

Trinidad

Jamaica

Chile

Venezuela

Guyane (French Guiana)

Colombia

Mexcio

2008

Source: Infield Systems Ltd.

2009 2010 2011 2012 2013 2014 2015 2016 2017

US

$m

(%

)

Worldwide day rates

Year/Month Minimum Average Maximum

Drillship

2012 June $50,000 $434,143 $671,000

2012 July $50,000 $438,241 $671,000

2012 Aug $50,000 $442,866 $671,000

2012 Sept $50,000 $429,988 $671,000

2012 Oct $50,000 $429,548 $674,000

2012 Nov $50,000 $429,852 $674,000

2012 Dec $50,000 $441,340 $674,000

2013 Jan $50,000 $434,808 $674,000

2013 Feb $50,000 $449,225 $674,000

2013 Mar $50,000 $444,548 $674,000

2013 Apr $50,000 $451,860 $674,000

2013 May $50,000 $456,792 $674,000

Jackup

2012 June $36,000 $110,715 $368,000

2012 July $30,000 $111,427 $368,000

2012 Aug $40,000 $111,458 $368,000

2012 Sept $40,000 $111,845 $368,000

2012 Oct $30,000 $112,271 $368,000

2012 Nov $30,000 $114,614 $368,000

2012 Dec $30,000 $115,377 $368,000

2013 Jan $30,000 $118,351 $368,000

2013 Feb $30,000 $119,352 $368,000

2013 Mar $30,000 $120,289 $368,000

2013 Apr $30,000 $119,412 $368,000

2013 May $30,000 $121,822 $368,000

Semi

2012 June $125,000 $359,570 $648,000

2012 July $69,825 $354,158 $675,000

2012 Aug $69,825 $360,852 $675,000

2012 Sept $130,000 $358,061 $675,000

2012 Oct $130,000 $358,166 $648,000

2012 Nov $130,000 $363,193 $648,000

2012 Dec $130,000 $364,446 $648,000

2013 Jan $145,000 $363,643 $648,000

2013 Feb $145,000 $361,572 $648,000

2013 Mar $145,000 $363,044 $648,000

2013 Apr $145,000 $372,647 $648,000

2013 May $145,000 $380,095 $648,000

Source: Rigzone.com

G L O B A L D ATA

12 Offshore July 2013 • www.offshore-mag.com

Offshore development in Latin America is expected to remain dominated by Brazil until the end of the decade. Infield Systems expects 86% of the regional offshore capital expenditure to be attributed to Brazil-ian developments between 2013 and 2017. Operator Petrobras is anticipated to account for an 89% share of the market with key projects including the Lula and Franco multi-phase developments. Infield Systems expects the largest proportion of the operator’s capex to be directed toward the subsea market, with pipeline developments also forecast to demand a significant share of the operator’s investment. An additional 10 operators are expected to direct capex offshore Brazil going forward to 2017. Anadarko and OGX-EBX Group are expected to lead investment during the period on fields including Wahoo and the Waimea/Fuji develop-ment for the respective operators. In terms of water depth of developments offshore Latin America, 64% of total capital expenditure is expected to take place

in water depths of 1,500 m (4,921 ft) or greater. Brazil’s presalt prospects are expected to continue to lead the market for deep and ultra-deepwater development.

Elsewhere, capital expenditure is expected to take place across 12 additional countries. Mexico, Venezuela, and Trinidad are forecast to be the largest markets outside of Brazil for offshore develop-ment. The most significant investment is expected on the Ayatsil, Lakach, and Noxal fields offshore Mexico during the period. Offshore Venezuela, capex is likely to be directed toward 13 fields. Offshore Trinidad is also expected to have 13 fields require investment during the period, with key operators anticipated to include BG Group, BHP Billiton, and Centrica.

– Catarina Podevyn, Analyst, Infield Systems Ltd.

1307off_12 12 6/28/13 2:13 PM

© 2

013

Bake

r H

ughe

s In

corp

orat

ed. A

ll Ri

ghts

Res

erve

d. 3

8682

6/2

013

Saying you’re the completions leader is one thing.

Being the completions leader is altogether different.

Learn more at www.bakerhughes.com/thepayzoneleader

Advancing Reservoir Performance

Leaders act

while others

wait and see.Winston Churchill

1307off_13 13 6/28/13 2:13 PM

G L O B A L E & P Jeremy Beckman • London

14 Offshore July 2013 • www.offshore-mag.com

Lekoil has farmed into OPL 310 offshore Nigeria.

Eastern Canada

Husky Energy is pushing ahead with a third satellite extension at the White Rose feld in the Jeanne d’Arc basin, 350 km (217 mi) offshore Newfoundland and Labrador. The company is targeting 20 MMbbl of oil from South White Rose via a subsea tieback to the Sea Rose FPSO. Following regulatory approval, development will now include gas injection for enhanced oil recovery. Technip will install the fowlines, umbilicals, and as-sociated subsea structures with start-up scheduled for 2014. Husky also plans to fle a development application for West White Rose following completion of front-end engi-neering design (FEED).

To the south, EnCana may fnally have brought onstream its Deep Panuke gas feld, 250 km (155 mi) southeast of Halifax, Nova Scotia. SBM provided the mobile offshore production unit following a protracted con-struction delay. The gas will be processed offshore and sent via a subsea pipeline to Goldboro for onward transport through the Maritimes & Northeast Pipeline.

South America

ONGC has won an exploration block off-shore Colombia, assigned under the coun-try’s 2012 bid round. The company has a 100% interest in the Guaoff-2 concession in the Guajira basin.

•••

Peru has launched an international bid round for nine blocks in the Salaverry-Trujil-lo, Lima, Lima-Pisco, Pisco, and Mollendo ba-sins. All are 7 mi (11.2 km) from the coast and away from the protected fshing zone, and cover some of the country’s least explored geological areas. State company Perupetro said there had been enquiries from oil com-panies in North and South America, Russia, South Korea, and the UK; awards should fol-low on Oct. 17. Currently there is production on two Peruvian offshore licenses, operated by Savia Perù and BPZ Energy, respectively.

•••

Brazil’s much anticipated 11th bid round fnally closed. Petrobras, as might be ex-pected, was the biggest winner, paying a total of $454 million for interests in 34 of the 289 blocks on offer. Those with the greatest exploratory potential, the company said, are in the offshore Foz do Amazonas, Espírito Santo, and Barreirinhas basins.

Other big winners included Total, which secured shares in 10 licenses, including fve as operator in the Foz do Amazonas basin. BP picked up stakes in eight deepwater blocks, two as operator, while Statoil operates four of its six new licenses in the Espírito Santo basin, all close to two existing concessions where it is in partnership with Petrobras. Among the successful newcomers is UK in-

dependent Premier Oil, which gained stakes in three blocks off northeast Brazil.

•••

Petrobras has started production from Cidade de Paraty, the second FPSO on the Lula feld in block BM-S-11 in the presalt Santos basin. By the second half of 2014 as gas reinjection systems are commissioned, the facility should be operating at its full ca-pacity, delivering 120,000 b/d of oil and 176 MMcf/d of gas.

Elsewhere in this region, Petrobras has discovered oil with the Entorno de Iara 1 well, drilled 235 km (146 mi) offshore Rio de Janeiro state in 2,266 m (7,434 ft) of water. Wire test samples confrmed 26° API crude from good-quality carbonate reservoirs just below the salt layer at a depth of 5,045 m (16,252 ft). Petrobras plans to follow up with a formation test and another well in the area.

West Africa

Ghana’s government has approved the development plan for the country’s second deepwater production hub. The Tweneboa-Enyenra-Ntomme (TEN) felds are 30 km (18.6 mi) west of the Jubilee feld in the Deepwater Tano contract area, 60 km (37 mi) from the coast. Up to 24 wells will be drilled, connected via subsea facilities to an FPSO moored in 1,500 m (4,921 ft) of water and producing 80,000 b/d of oil at peak. Op-erator Tullow Oil says the partners will use the project to expand Ghana’s fabrication ca-pability. Start-up is scheduled for 2016.

•••

Lekoil has agreed to farm into 17.4% of li-cense OPL 310 offshore Nigeria from Afren. Optimum Petroleum Development operates the license, located in the Upper Cretaceous fairway that runs along the West African Transform Margin. The GSF Transocean Monitor was recently drilling an exploration

well targeting Ogo, a four-way dip-closed structure in Turonian to Albian sandstone reservoirs; a side track was due to follow. Total resources could be over 200 MMboe.

•••

Noble Energy has found oil with a side track of its Carla South I-7 well in block I offshore Equatorial Guinea. According to partner PA Resources, analysis suggests 9-11 m (29-36 ft) of net oil pay in good-quality sandstones.

•••

EurOil has proven more gas and conden-sate with its latest appraisal/development well (IM-5) in the Etinde concession off Cameroon. Production tests from two reser-voir intervals in the Middle and Intra Isongo formations yielded combined fow rates of up to 60 MMcf/d of gas and 7,819 b/d of condensate. EurOil’s parent company Bow-leven now estimates in-place volumes at the IM feld at 155 MMbbl and 1.05 tcf.

•••

Frontier drilling is picking up pace in the southern half of West Africa. The Ocean Rig Olympia recently spudded Diaman No. 1, Ga-bon’s frst presalt deepwater exploration well, for partners Total and Cobalt International Energy. Offshore Namibia, the semisub Trans-ocean Marianas is drilling Murombe-1, HRT’s second exploratory well on license PEL-23 in the deepwater Walvis basin. Wingat-1, the pre-ceding well drilled 15 km (9.3 mi) to the east, recovered samples of light oil and established two different source rocks. Murombe-1 is test-ing two objectives within a turbidite complex.

Mediterranean Sea

Energean Oil & Gas has secured $60 mil-lion in funds for a four-well program offshore Greece, aimed at doubling oil production from the Prinos and South Kavalos areas to 4,000 b/d by year-end. The money will also be used for development of the 32-MMbbl Epsilon

1307off_14 14 6/28/13 2:13 PM

The Worldís Deepest TLP

Big Foot ETLP

ï Leading-Edge ETLP Technology

ï Lighter Design/Payload Flexibility

ï Rigorous Safety Standards

ï Concept Screening to Detailed

Engineering

World Class Project Execution by FloaTEC

www.floatec.com

$%&'$�������������� ���������'�������� �����&&'&����������$���$��&'���''��������������� ���!"����#�#�

FloaTEC, LLC

1307off_15 15 6/28/13 2:13 PM

G L O B A L E & P

structure next year via an unmanned platform connected to the main Prinos production facili-ties.

•••

Offshore Cyprus, the Noble Energy-led block 12 consortium agreed to drill an ap-praisal well on the deepwater Aphrodite gas discovery. Budget for the well, estimated to take four months to complete, is $117 mil-lion, according to partner Delek Drilling.

Additionally, Noble and its partners have confrmed a ffth deepwater gas fnd with re-serves of over 1 tcf in the Israeli Levantine ba-sin. Karish 1 was drilled in 1,740 m (5,700 ft) of water in the Alon C license, 20 mi (32 km) northeast of the Tamar feld, which came on-stream in April. The well encountered 184 ft (56 m) of gas pay in lower Miocene sands.

•••

Two ambitious independents have agreed to farm-in deals offshore Tunisia. EnQuest will take a 70% operating interest in PA Re-sources’ assets, which include the producing Didon oil feld and the planned Zarat feld development. And DNO is set to take from Atlas Petroleum and Eurgas International an 87.5% controlling interest in the shallow water Sfax and Ras El Besh concessions in the Gulf of Gabes. They contain three oil discoveries and 29 prospects with combined prospective resources of up to 700 MMbbl.

Indian Ocean Afren has completed the frst 3D seismic

surveys offshore the Seychelles in areas A and B. These covered a total of 3,375 sq km (1,302 sq mi) on the northern and southern portions of the license, including the Bonit prospect. Evaluation is under way in combi-nation with existing 2D data to assess Ter-tiary, Cretaceous, and Jurassic prospectivity. Offshore Madagascar, Chinese contractor BGP has completed a 2D multi-client survey over the west Morondova region, which will be the focus of an upcoming bid round.

IndiaReliance Industries and partners BP and

NIKO have discovered gas and condensate in the D-55 structure offshore eastern India. The KGD6-MJ1 well was drilled in 1,024 m (3,360 ft) of water, and over 2,000 m (6,562 ft) below producing reservoirs in the D1-D3 gas felds. Analysis suggests the well inter-sected a 155-m (509-ft) gas/condensate col-umn in Mesozoic reservoirs. The partners plan a follow-up appraisal program.

Asia/PacifcRosneft and INPEX will jointly explore

the Magadan-2 and Magadan-3 blocks in the Sea of Okhotsk off northern Russia. Wa-ter depths range from 120-180 m (393-590 ft), with potential recoverable resources of

1307off_16 16 6/28/13 2:13 PM

1307off_17 17 6/28/13 2:13 PM

Australia

Statoil partner

Eucla

Canyon

0 100 km

G L O B A L E & P

1.577 MM metric tons of oil equivalent (1.738 MM tons). The two companies will form a joint venture for the explora-tion program, with INPEX paying Rosneft bonuses for any commercial discoveries.

The 42,780-metric ton (47,157-ton) platform topsides for Exxon Neftegaz’ Arkutun-Dagi feld off Sakhalin Island was due to sail out of DSME’s yard in South Korea. In readiness for the trans-portation, ALE used its Mega Jack sys-tem to jack the topsides in four sets of towers to a height of 24 m (79 ft). The operation was completed in 11 hours and in wind speeds of up to 50 m/s (164 ft/s).

•••

Thang Long Joint Operating Co. (TL-JOC) has started oil production from the Hai Su Trang and Hai Su Den (HST/HSD) felds off southern Vietnam. Both are in 45 m (147 ft) of water in block 15-2/01 in the Cuu Long basin, 75 km (46.6 mi) offshore.

PetroVietnam subsidiary PTSC Mechanical and Construction built the two wellhead platforms; six wells have been drilled, with produc-tion sent by pipeline to the Te Giac Trang FPSO.

•••

Shell has contracted Royal Boskalis Westminster to install a deple-tion compression platform off Palawan Island in the Philippines. The facility will be bridge-linked to the existing gas production platform on the Malampaya feld. Boskalis’ scope extends to seabed prepa-

ration, tow out of the platform to the offshore location, and placement of iron ore gravel ballast on the four platform footings following installation to ensure stability. All work should be completed by late 2014.

Australasia

Statoil has agreed to farm into 30% of four licenses operated by BP offshore South Australia. EPP 37, 38, 39, and 40 cover 24,000 sq km (9,266 sq mi) in the Ceduna sub-basin within the Great Aus-tralian Bight. BP is currently processing a new 12,000-sq km (4,633-sq mi) 3D seismic survey over the license area, and has signed a three-year contract with Diamond Offshore for a new Moss CS60E design harsh environment semi for the drilling program. Hyundai Heavy Industries will build the 10,000-ft (3,048-

m) water depth DP rig at a projected cost of $755 million. It should become available after November 2015.

•••

Total has discovered gas in the Browse basin off northwest Aus-tralia. The Bassett-1 well was drilled in 368 m (1,207 ft) of water in license WA-274P, 475 km (295 mi) northeast of Broome. Logs con-frmed 7.5 m (24.6 ft) of gas pay in Jurassic sandstones on the struc-ture’s western fank. After the well is P&A’d, the partners planned to drill Dufresne-1 in the same license. •

BP’s exploration licenses

offshore South Australia.

1307off_18 18 6/28/13 2:13 PM

9529 shipbuilders have a new nameSTX OSV has changed its name to VARD. Our shipyards will now be known as

Vard Aukra, Vard Brattvaag, Vard Brevik, Vard Langsten, Vard S¯viknes, Vard Braila,Vard Tulcea, Vard Niteroi, Vard Promar and Vard Vung Tau.

Other VARD companies are Vard Design, Vard Electro, Vard Piping, Vard Accommodation, Vard Trading, Vard Engineering, Vard Grenland Industri

and Vard Offshore Brevik.

VARD - built on trust

www.vard.com

ww

w.i

og

m.n

o /

Fo

to:

Sig

ve A

sp

elu

nd

/Tin

ag

en

t.n

o

1307off_19 19 6/28/13 2:13 PM

O F F S H O R E E U R O P E Jeremy Beckman • London

20 Offshore July 2013 • www.offshore-mag.com

Barents Sea dominates latest Norway license round

Statoil’s oil discoveries in the Barents Sea ensured a strong re-sponse to Norway’s frontier 22nd licensing round. The Petroleum and Energy Ministry has issued 20 new licenses in the Barents Sea and four in the Norwegian Sea to a total of 29 companies.

All Statoil’s awards were in the Barents Sea. Its three operated licenses were PL713 in the Bjørnøya basin; PL6158 in the Hoop area, close to an existing license where the company plans to drill two exploration wells in 2014; and PL714, adjacent to the Johan Castberg license, which includes the Skrugard and Havis oilfelds.

New operators in the Barents Sea include Centrica, ConocoPhil-lips, Edison, GDF Suez, RWE Dea and Shell, while Det norske Olje-selskap, Eni, Lundin, Repsol, and Total expanded their interests in the region. Lundin’s award was in the southeast of the sector, which has been opened up following resolution of Norway’s long-running median line demarcation dispute with neighbors Russia. And two of Russia’s leading oil companies, Lukoil and Rosneft, made their debuts as licensees offshore Norway with stakes in Barents Sea blocks.

However, Statoil wants to put on hold an investment decision on the Johan Castberg development, following the government’s planned pe-troleum tax review. The company and partners Eni and Petoro had selected a concept earlier this year for the project, 240 km (149 mi) northwest of Hammerfest in northern Norway. This included build-ing a new oil terminal at Veidnes in Finnmark County. There is uncer-tainty now over whether the construction would qualify for state aid, as was the case with the LNG terminal nearby in Melkoya, which was built to process gas from the offshore Snøhvit felds.

Irish frontier survey under wayIreland’s government has approved the country’s largest regional

offshore seismic survey to date, over the Atlantic Margin off the west coast. The BGP Explorer vessel is performing the 18,000-km (11,184-mi) full-fold 2D program, managed by Eni Ireland in co-operation with the Department of Communications, Energy and Natural Resources. The 145-day campaign is designed to infll data gaps, particularly over the southern Porcupine, Rockall, and Hatton basins, drawing in more bidders for future licensing rounds.

Minister Pat Rabbitte, speaking earlier in a parliamentary debate about a new Joint Committee report on Ireland’s offshore oil and gas exploration, said the country had to deal with realities. The country remains under-explored, he pointed out, with only 156 wells drilled offshore compared with over 1,200 offshore Norway and 4,000 in the UK. Norway is the world’s second largest gas exporter and sev-enth largest oil explorer, while Ireland imports over 95% of its gas and 100% of its oil. And the country has only three felds in produc-tion compared with over 300 in the UK. So more needs to be done, he said, to increase Irish exploration investment and drilling.

However, the report recommends a doubling of Ireland’s existing tax rate on petroleum production, based partly on sustained high oil prices and the impact of advances in technology on exploration success rates worldwide. Neither of these factors gives Ireland a competitive advantage over other areas, Rabbitte said, and without exploratory drilling, the country will have no discoveries. Technol-ogy helps, but only wells produce results, he added.

Statoil contracts purpose-designed jackupsStatoil has commissioned three new “Category J” harsh-environ-

ment jackups for development drilling in the North Sea. Samsung Heavy Industries will build two of the rigs in South Korea, to be operated by KCA Deutag on the Gullfaks and Oseberg Area felds in the Norwegian sector. They will be designed to provide more ef-fcient drilling and completion of subsea wells compared with exist-ing jackups, Statoil says, and to drill wells up to 10,000 m (32,808 ft)

deep. Offshore operations should start in 2016-17.Noble Corp. will manage the drilling contract for the third new

jackup for the heavy oil Mariner feld development in the UK north-ern North Sea. This rig, to be built by Jurong Shipyard in Singapore, will be an enhanced version of Statoil’s Cat J specifcations, devised originally for operations over a very large platform or for subsea drilling in the Norwegian sector. It will be equipped to deploy either a surface or subsea BOP during drilling.

CNR invites views on platform removalCNR International has started the public consultation on its plans

for decommissioning the Murchison platform and pipelines in the UK northern North Sea. The Murchison feld, which also extends into Norwegian waters, is due to cease production early next year. Facilities that may have to be removed include the 24,500-metric ton (27,006-ton) topsides of the platform, installed in 1979 150 km (93 mi) northeast of the Shetland Islands; however, CNR may seek the UK government’s help in applying to leave the steel footings in place on the seafoor because of the structure’s large size, via derogation status under the OSPAR convention.

More positive news concerns Ninian, another elderly platform complex in the UK far north. Here CNR plans to invest $470 mil-lion in life extension measures for the Ninian feld, after success-fully applying for the UK’s Brownfeld Allowance. The government introduced this scheme last year following pressure from numerous operators – it provides tax relief on certain felds already in produc-tion, allowing incremental projects to go forward that might other-wise be uneconomic. CNR plans to drill four new producer wells and four injectors on Ninian, along with various platform/well upgrades. These measures could allow a further 27 MMboe to be produced.

Elsewhere in this sector, Maersk Oil has restarted production through the Gryphon Alpha FPSO, which had to be removed from its offshore location following storm damage in February 2011. Four anchor chains broke, causing the vessel to move off station. The FPSO was transferred to the Damen shipyard in Rotterdam for over-haul/upgrade work on its tanks, process control, power manage-ment, and mooring systems.

In the intervening period, Maersk acquired a 4D seismic survey over the wider Gryphon area, and assumed operatorship from BP of Maclure, one of four felds produced via the foater. Once all the felds are fully operational, combined production should exceed 20,000 boe/d, and Maersk plans a high level of drilling activity over the next few years based on results from the new seismic. Within seven years it aims to double its overall UK production to 80-100,000 boe/d. •

Cat J rig example.

1307off_20 20 6/28/13 2:13 PM

Mokveld Valves BV

PO Box 227�� NL-2800AE Gouda���The Netherlands

T +31 182 59 75 00���� [email protected] ��� www.mokveld.com

�������������������������� �������

���������������������������������

���������������������

������������������������������������������������

������

���"������������

�!��������������������� ���������

�����������������

������������

��������������� ������ �� ��������������������������

���������� ������ �� ������������������������������������

����������� �������������

����������� �������

����������� ������������

�������������

�������

��������� �����������

1307off_21 21 6/28/13 2:13 PM

G U L F O F M E X I C O Bruce Beaubouef • Houston

22 Offshore July 2013 • www.offshore-mag.com

Shell preps Olympus TLP for Mars B installation

The major topsides modules were in-stalled on the Olympus tension leg platform (TLP) as Shell prepared to tow the 120,000-ton structure from Kiewit Offshore Services yard to the deepwater Mars feld.

During a June 5 tour of the TLP – said to be the largest ever deployed in the Gulf of Mexico – Shell offcials said the project will be the frst in the region to employ an ad-ditional foating production system in a pro-ducing deepwater feld.

“This is the frst time in the Gulf of Mex-ico that a company has built another host structure to go in an existing feld,” rather than using subsea tiebacks to expand a feld, said John Hollowell, Shell’s executive vice president for deepwater.

The Olympus platform will be moored in 3,000-ft (914-m) water depths in the Missis-sippi Canyon area, about one mi (1.6 km) from the existing Mars platform, which started production in 1996. The new TLP hosts a 24-slot drilling unit supplied by Na-bors Industries and includes capacity for six subsea wells to gather production from the nearby West Boreas and South Diemos felds. Olympus has a production capacity of about 100,000 boe/d.

Noble Corp.’s Noble Bully I has drilled the top sections of the 24 wells at what Shell has dubbed Mars B, and is on location to drill the satellite wells at West Boreas and South Diemos.

The project is expected to extend the feld life of Mars to at least 2050, Hollowell said. Shell has said the feld could contain recover-able reserves of 1.1 Bboe. Shell operates the feld with 71.5% interest; partner BP holds the remaining 28.5% interest.

When Olympus begins production, likely in the frst half of 2014, the focus of the ex-isting Mars production platform will shift to the feld’s shallower reservoirs and to water injection. Olympus, outftted with 15,000 psi-rated trees furnished by FMC Technologies, will concentrate on high-pressure reservoirs that range in depth from 20,000-22,000 ft.

Shell will install a third platform at its West Delta 143 gathering hub to link production from Mars B with existing pipeline infrastructure.

Heerema’s Balder deepwater construction vessel will be used to install the TLP.

EIA sees greater disruptions in upcoming storm season

The US Energy Information Administra-tion says it expects greater losses in GoM oil and natural gas production from tropical storms this year than was seen in 2012.

As reported by Reuters, the EIA said that in a study, the median loss in Gulf of Mexico crude oil production from tropical storms in 2013 was expected be 19.3 MMbbl, up from 14.3 MMbbl in 2012.

The EIA expects a median loss of 46.4 bcf in natural gas output due to the 13 to 20 named storms forecast by the US National Oceanic and Atmospheric Administration for the six-month 2013 Atlantic hurricane season, which began June 1.

The 19 named storms in the 2012 hurri-cane season accounted for 32.1 bcf in lost natural gas production, the EIA said.

Last year’s season was one of the milder ones to hit US energy production. The total number of named storms was seven above av-erage, but only three tropical storms and two moderate hurricanes came through the Gulf.

The EIA also said the percentage of na-

tional crude oil and natural gas production provided by the US-regulated areas in the northern GoM has shrunk in recent years as onshore production has increased.

In 2012, the Gulf provided 19% of crude oil production, down from 26% in the 2007-2011 period. In 2012, the Gulf accounted for 6% of natural gas output, compared to 26% in 1997, according to the EIA.

The Gulf produces 1.3 MMbbl/d of crude oil, according to the EIA. In 2011, 1.7 tcf/d in natural gas came from the Gulf.

The amount of shut-in production depends on the intensity of a storm and the path it takes across production areas, according to the EIA.

For example, 2012’s Hurricane Sandy, which struck the US East Coast, had no impact on Gulf production. But 2008’s major Hurricane Gustav, which came ashore in Louisiana after passing through the heart of the Gulf’s offshore oil patch, shut 98% of Gulf oil production and 96% of natural gas output.

Exxon awards Julia feld contracts

Exxon Mobil Corp. has awarded feld de-velopment contracts for its Julia feld in the deepwater Gulf of Mexico, with 2H Offshore winning a production riser design contract and Technip winning a deepwater pipelay contract.

The Julia development will be a subsea tieback to a moored semisubmersible in ap-proximately 7,000 ft (2,134 m) of water.

2H Offshore will perform detailed design of two 10-in. production steel catenary risers to use in Phase 1.

Technip will provide project management, engineering, fabrication, installation, and pre-commissioning of more than 48 km (30 mi) of 10.75-in. (27.3-cm) outer diameter insulated fowlines, steel catenary risers, and fowline end terminations.

Technip’s Houston center will provide proj-ect management, with detailed fowline design by Genesis, fowline and riser fabrication in Mobile, Alabama, and installation in 2015 us-ing the Deep Blue pipelay vessel.

Hess taps Wood Group for platform services

Hess Corp. has awarded a fve-year contract to Wood Group PSM (WGPSN) for operations and maintenance services to the Baldpate produc-tion platform in the deepwater Gulf of Mexico.

The company will also provide these servic-es to Hess for the Tubular Bells and Stampede deepwater facilities when they go onstream in the Mississippi Canyon and Green Canyon ar-eas of the GoM.

WGPSN will develop a computerized main-tenance management system to track the main-tenance and repair of rotating equipment and maintenance parts. They will also manage the inventory of engineering parts. •

Shell’s Olympus tension leg platform for the Mars B project will be moored in 3,000-ft (914-m) water

depths in the Mississippi Canyon area, about one mile from the existing Mars platform. (Photo

courtesy Shell)

1307off_22 22 6/28/13 2:13 PM

1307off_23 23 6/28/13 2:13 PM

S U B S E A S Y S T E M S Gene Kliewer • Houston

24 Offshore July 2013 • www.offshore-mag.com

GoM gets rush of subsea equipment orders

Anadarko Petroleum Corp. has ordered subsea hardware for its Heidelberg feld in the Gulf of Mexico from FMC Technologies Inc. FMC will supply fve enhanced hori-zontal subsea trees, tree mounted controls, two manifolds, and other associated tooling and equipment. The Heidelberg feld covers fve Green Canyon blocks in water depths of 5,310 ft (1,618 m). Anadarko also has award-ed Subsea 7 the Heidelberg pipelay contract covering fabrication and installation of ris-ers, pipelines, and fowlines.

Also in the GoM, ExxonMobil has award-ed a $100-million contract to Prysmian Group for the supply and installation of sub-

marine cables in a section of ExxonMobil’s existing offshore operations. Prysmian will replace 50 km (31 mi) of existing submarine power cables with increased capacity 40 kV EPR cables designed for water depths of up to 450 m (1,476 ft). The cables will supply electric power from an existing shore-based generating plant to offshore platforms. The Cable Enterprise vessel will undergo modif-cations in 2014 to become a fully dynamical-ly positioned vessel in order to do the work.

Further south in the Gulf, PEMEX Ex-ploration and Production has signed an $84-million agreement with GE Oil & Gas to supply and install subsea wellheads in deep and ultra-deepwater drilling projects. GE will supply SMS800 and DWHC 700 high-capacity

wellheads; similar GE technology is installed at several other Mexican oil felds, including Perdido, Lakach, and Kunah. Perdido is in water depths of 500 m (1,640 ft) or more. Ku-nah is 125 km (78 mi) northeast of Veracruz in 2,157 m (7,077 ft) water depth. Lakach is in about 988 m (3,241 ft) of water.

Shell has contracted FMC Technologies to supply subsea equipment for the Stones ultra-deepwater project in the Gulf of Mex-ico. The Stones feld is in the Walker Ridge area, about 200 mi (322 km) off the Louisi-ana coast in about 9,600 ft (2,926 m) of water. FMC Technologies’ scope of supply includes eight subsea trees, a subsea manifold, top-side and subsea controls, and associated equipment. Shell plans to develop Stones us-ing an FPSO and subsea infrastructure with eight production wells ultimately tied back to the vessel. Tankers will take the oil to shore and the gas will go via pipeline.

Technip inaugurates subsea Innovation and Technology Center

Technip has inaugurated its Innovation and Technology Center in Rueil-Malmaison, France. The facility opens with more than 50 subsea specialists on staff and is charged to manage Technip’s technology development and to coordinate relevant research and de-velopment centers.

“This new site builds upon our strategic efforts in terms of technology: it is a real showcase of our technological achieve-ments – starting with subsea – targeted at our clients and partners,” said Alain Mar-ion, senior vice president, Innovation and Technology and director of the center. “Its actions will draw on important and regular investments, as well as on Technip’s R&D breakthroughs over the past few years.” •

Deepwater subsea spending to continue growingInfield Systems latest edition of its “Global Perspectives Subsea Market Report To

2017” says high oil prices, technological developments, and declining production in

mature shallow-water basins are driving offshore oil and gas operations into deep

and ultra-deep waters. Operators increasingly target reservoirs over a wider area

than before, using subsea tiebacks to both fixed platforms in shallow waters or to

floating infrastructure in deeper waters.

The report predicts that these operating circumstances will result in capital-intensive

ultra-deepwater developments that will capture 48% of capex and 23% of tree installa-

tions in 2013-2017, in contrast to 37% of capex and 15% of installations in 2008-2012.

Latin America and West Africa account for more than half of the subsea capex ex-

pected between 2013 and 2017. This is driven by large deepwater and ultra-deepwater

discoveries offshore Brazil, particularly in the presalt basins, and offshore Angola

and the Gulf of Guinea.

The US shift from shallow water toward large discoveries further offshore is well

under way. The deepwater Gulf of Mexico is expected to host many new floating

platform developments, combined with the tieback of subsea satellite fields later on

in the forecast period.

Europe remains an area of opportunity, with drilling activity in producing fields and

subsea tiebacks for small, remote reserves.

New large gas discoveries in the last five years in the eastern Mediterranean are

driving subsea investments in the Middle East. Asia, Australasia, and the Middle East

present emerging opportunities for the subsea market. These three regions will to-

gether increase their market share from 8% in 2008-2012 to 15% in the next five years.

The Marine Well Containment Co. (MWCC) now has available a 10k psi capping stack for use in the deepwater U.S. Gulf of Mexico. It joins the 15k psi stack already available. The capping stack stands 25 ft (7.6 m) tall, including the necessary lifting gear, and weighs 50 tons. In support of MWCC, Shell agreed to lead the design and construction efforts for the 10k psi capping stack. With a footprint of 9 ft x 9 ft (2.7 m x 2.7 m), the 10k psi capping stack is easier to maneuver in areas where wellheads and riser systems are closely spaced, such as TLPs, where wells are beneath a floating production facility. The new dual ram capping stack can cap a well in depths up to 10,000 ft.

1307off_24 24 6/28/13 2:13 PM

You are looking at the ësubsea factoryí ñ oil and gas

production facilities located directly on the seabed. Itís

an ingenious response to todayís challenges of declining

reservoir pressures and longer step-outs, and the next

frontier in offshore engineering.

Operating 24/7, itís a factory that runs continually throughout

��������������������������������� �� ��������������

����������������� ��������� �������� �����������������

Welcome to

the factory floor

Subsea production and processing systemsToday only Aker Solutions offers the right subsea

������� ��������������������������� ������������

large-scale project experience required to build, run

����������������������� �������������������

����������������������������� ����������������������� �

www.akersolutions.com/subsea

1307off_25 25 6/28/13 2:13 PM

V E S S E L S , R I G S , & S U R FA C E S Y S T E M S Russell McCulley • Houston

26 Offshore July 2013 • www.offshore-mag.com

Tidewater acquires Troms Offshore

Louisiana-based offshore supply vessel provider Tidewater has entered a $395-mil-lion agreement with HitecVision to acquire Troms Offshore Supply AS.

The purchase of the Norwegian company will add fve large platform supply vessels and an additional PSV under construction at the VARD Aukra yard in Møre og Romsdal, Nor-way, to Tidewater’s feet. Troms Offshore also has an option available to build a seventh vessel.