Tom Clancy - Centrul de Comanda - 01. Centrul de Comanda [Ibuc.info]

Nety Comanda

-

Upload

lucian-mihai -

Category

Documents

-

view

48 -

download

7

Transcript of Nety Comanda

eng/OP

2

22

23

24

25

26

27

28

29

21.3 – 21.82

22.1 – 22.2

23.1 – 23.4

24.1 – 24.4

25.1 – 25.2

26.1 – 26.10

27.1 – 27.48

28.1 – 28.4

29.1 – 29.8

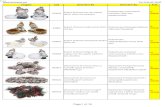

Clamping Tools

• Drill chuck • Tapping chuck/

tapping machines • Taper bore tools• HSK inserts • Tool holder for lathes • Tool pre-setter

• Reduction sleeves• Spindle Sleeves• Ejector Drifts• Adapter sleeves

• Extension pieces • Tap wrench • Tool holder • Holder sets • Arbors • Die stock• Guides for dies

• Lathe centre • Exchangeable

chuck collets • Live lathe centres • Lathe centre attachments

• Face driver • Driving plate • Sleeves

• Turning and lathe chucks • Recessing attachments • Hollow spindle stops • Top jaws • Tenons • Spare jaws

• T-Slot Nuts and Accessories

• Clamp and Accessories • Bench Vice and Jaws • NC compact spanners • Multiple clamping systems

• Permanent-Magnetic Camping Plates

• Round Chucks • Demagnetising tools

• Vertical collet vices• Three-jaw lathe chuck• Dividing Units• Rotary tables• Precision micrometer

tables

21 2

eng/OP

Our suppliers for catalogue-group 2:

0

ß

/

m

$O

l

e

DIACATOR

2

*

Haimer

W

2

;

Mimatic

e

0&

8

d

ä

ß Clamping tools

eng/OP www.hhw.de 21.3

2

Three-Jaw Drill Chucks

8TypeWith gear rim and key, jaws and key hole hardened.

21112Type PrimaTypeIndustrial type with threaded mounting hole.ApplicationFor clockwise operation of manually operatedelectric hand drills and electric impact drills.

Note:21112 107, 21112 109 and 21112 111 for clockwiseand counterclockwise operation (through-hole).

21113Type Prima-MatType Industrial type with Threaded mounting hole and Eccentric clamping force safety device.ApplicationFor electric impact drills with higher impact frequen-cy.

21112 - 21113

Capacity Mounting hole Outside Ø wrench size 21112 … 21113 …mm mm

0,5 - 8,0 3/8 inch x 24 29,5 S 1 1040,8 - 10,0 3/8 inch x 24 34,5 S 2A 1070,8 - 10,0 1/2 inch x 20 34,5 S 2A 1091,5 - 13,0 1/2 inch x 20 42,8 S 2A 1101,5 - 13,0 1/2 inch x 20 42,8 S 2A 1111,5 - 13,0 1/2 inch x 20 42,5 S 2AT 1013,0 - 16,0 5/8 inch x 16 50,0 S 3T 1023,0 - 16,0 M 18 x 2,5 50,0 S 3T 103

21112 - 21113

Three-Jaw Drill Chucks

8TypeType PrimaWith gear rim and key, jaws and key hole hardened.

21110TypeHeavy-duty industry type. With tapered mountinghole in compliance with DIN 238.

ApplicationFor clockwise and counterclockwise operation.For stationary and manual electric hand drills.

21111TypeIndustrial typeApplicationMainly for manually operated drilling machines. For clockwise and counterclockwise operation.

21110 - 21111

Capacity Internal taper Outside Ø wrench size 21110 … 21111 …mm DIN 238 mm

0,5 - 4,0 B 10 24,0 S 1 1010,5 - 6,5 B 12 29,5 S 1 1030,5 - 6,5 B 10 29,5 S 1 1030,5 - 8,0 B 10 29,5 S 1 1040,5 - 8,0 B 12 29,5 S 1 105

0,8 - 10,0 B 12 34,5 S 2A 1061,0 - 10,0 B 16 42,8 S 2A 1091,5 - 13,0 B 12 42,8 S 2A 1071,5 - 13,0 B 16 42,8 S 2A 1111,0 - 16,0 B 18 56,5 S 3 1133,0 - 16,0 B 16 50,0 S 3 1125,0 - 20,0 B 22 65,0 S 4 114

21110 - 21111

Spare Keys21115

ApplicationFor drill chucks with gear rim.

21115 21115 204

Size D L 21115 …mm mm

S 1 4 30 201S 2A 6 41 202S 2AT 6 42 204S 3 8 50 206S 3T 8 51 207S 4 9 75 208

eng/OP

• Drill chuck

www.hhw.de21.4

2

Precision Drill Chucks with Gripping Force Retention

TypeThanks to its special construction suitable forhighest torque values (chucking forces). Strictquality control guarantees a true-running accura-cy of 0,05 mm. Thanks to clamping force amplifica-tion the chucking force is doubled.ApplicationParticularly suitable for machining centres, NC andCNC machines. For clockwise and counterclock-wise operation.

21118

21118

Clamping range Internal taper Outside Ø Torque 21118 …mm DIN 238 mm kp/cm

0 - 13 B 16 51,5 400 101

Quick-Action Three-Jaw Drill Chucks

ßTypeIndustrial type. Self-chucking, keyless. Clampingand unclamping by hand. Only for clockwiseoperation.

21120

21120

Quick-Action Three-Jaw Drill Chucks

8Type SupraTypeSelf-chucking, keyless. For clamping and unclam-ping by hand. Chuck tightens automatically duringdrilling. Only for clockwise operation.

21121TypeHeavy-duty industry type, with tapered mountinghole in compliance with DIN 238.ApplicationFor upright drilling machines.

Note:B18 V shortened by 7 mm.

21122TypeLightweight Industrial type, with tapered mountinghole in compliance with DIN 238.ApplicationMainly for manually operated drilling machines.

Note:B16 V shortened by 2,5 mm.

21123TypeStandard-duty type, with threaded mounting hole.ApplicationFor electric hand drills.

21121

Capacity Internal taper Threaded mounting hole Outside Ø Length 21121 … 21122 … 21123 …mm DIN 238 mm mm

0 - 6,5 B 10 – 32,0 65,6 1020 - 6,5 B 12 – 32,0 65,6 1030 - 8,0 B 12 – 35,8 73,4 104

0 - 10,0 B 12 – 40,2 86,1 1050 - 10,0 B 16 – 40,2 89,1 106

0,5 - 10,0 – 1/2" x 20 35,8 73,7 3060,5 - 10,0 – 3/8" x 24 35,8 73,7 3071,0 - 13,0 – 1/2" x 20 46,0 101,5 3081,0 - 13,0 B 16 – 46,0 101,5 1071,0 - 13,0 B 16 V – 40,2 82,3 1083,0 - 16,0 B 16 V – 46,0 106,0 1093,0 - 16,0 B 18 V – 51,0 106,8 1113,0 - 16,0 – 5/8" x 16 46,0 97,5 313

21121 - 21123

Capacity Internal taper Outside Ø Length 21120 ...mm DIN 238 mm mm

1 - 10 B 12 36,1 76,2 1031 - 16 B 16 50,9 114,4 1051 - 16 B 18 51,0 114,8 107

ß Clamping tools

eng/OP www.hhw.de 21.5

2

Quick-Action Three-Jaw Drill Chucks

8Type Supra STTypeSelf-chucking, keyless. Chuck tightens automaticallyin proportion to cutting force. Gripping force retainseven under heavy-duty conditions. With clampingforce retention.ApplicationFor clockwise and counterclockwise operation.

Note:B16 V shortened by 2,5 mm.

21125

21125

Clamping width Internal taper Threaded mounting hole Outside Ø Length 21125 …mm DIN 238 mm mm

0,5 - 10 B 12 – 40,0 75,7 3010,5 - 10 – 1/2 inch x 20 40,0 73,7 3021,0 - 13 – 1/2 inch x 20 42,8 83,3 3031,0 - 13 B 16 V – 42,8 89,3 304

Keyless Drill Chucks (Plastics)

8TypeForce transmission with fine thread, chuckingsleeve made of plastics, holding fixture made ofsteel, high true-running accuracy. With hexagonalend for mounting onto the spindle.ApplicationFor clockwise and counterclockwise operation.For rechargeable battery drills and electric handdrills.

21127TypeType Extra, through-hole, with holding ring.

21128TypeType Extra RV, with radial locking, through-hole, withholding ring, impact-proof.Chucking capacity 1,5-13 mm jaws with carbidechucking bevel.

21127 - 21128

Clamping width Mounting hole Outside Ø max. machine Power/W 21127 … 21128 …mm mm no. 21127 no. 21128

1,0 - 10 3/8 inch x 24 42,7 450 550 101 1011,0 - 10 1/2 inch x 20 42,7 450 550 102 1021,5 - 13 3/8 inch x 24 42,7 550 1000 103 1031,5 - 13 1/2 inch x 20 42,7 550 1000 104 104

21127 - 21128

Quick-Action Three-Jaw Drill Chucks

8Type SpiroTypePrecision type, self-chucking, keyless. Pointedsleeve shape, high true-running accuracy, hardenedwear parts.ApplicationThanks to automatic re-chucking during drilling,particularly suitable for high rotational speedapplications on electric hand drills, upright drillingmachines and special drilling units.

Note:B18 V shortened by 7 mm.

21126 303-304TypeAdditionally with gripping force retention.ApplicationFor clockwise and counterclockwise operation.

Capacity Internal taper Outside Ø Length 21126 …mm DIN 238 mm mm

0 - 4,0 B 10 28 53,3 1010 - 6,5 B 10 35 68,6 1020 - 6,5 B 12 35 68,6 1030 - 8,0 B 12 38 76,9 104

0 - 10,0 B 12 43 90,1 1050 - 10,0 B 16 43 90,1 1061 - 13,0 B 16 50 102,5 1083 - 16,0 B 16 55 106,8 1093 - 16,0 B 18 V 55 106,8 110

0 - 10 ST B 16 43 88,5 3031 - 13 ST B 16 43 100,3 304

21126 101

21126

eng/OP

• Drill chuck • Fine Drilling Aids • Chuck-Ejector Forks • Chuck Arbors

www.hhw.de21.6

2

Keyless Drill Chucks (Metal)

8TypeType Extra-RV, with radial locking, chuckingsleeve made of Metal, with self-start protection andhexagonal end for mounting and removing from thespindle.ApplicationFor clockwise and counterclockwise operation.For hand drills with rechargeable battery and electricscrewdrivers and hand drills.

21130 101-102TypeThrough-hole.

21130 103TypeThrough-hole. Jaws with carbide chucking bevel.

21130 104TypeNo through-hole.Jaws with carbide chucking bevel.

21130

21130 101

21130 103

Clamping width Mounting hole Outside Ø max. machine power 21130 …mm mm W

1,0 - 10 3/8 inch x 24 42,7 550 1011,0 - 10 1/2 inch x 20 42,7 550 1021,5 - 13 1/2 inch x 20 42,7 1100 1031,5 - 13 1/2 inch x 20 42,7 1100 104

High-Performance Three-Jaw Drill Chucks SBF21151 - 21152

21151

21152

Clamping width Internal taper D L1 L2 21151 … 21152 …mm DIN ISO 239 B mm mm mm

0 - 1,5 B 6 19 35,0 37,5 2010 - 3,0 B 10 24 44,0 47,5 2020 - 5,0 B 10 30 56,0 61,5 2030 - 5,0 B 12 30 56,0 61,5 2040 - 6,5 B 10 34 61,5 68,0 2050 - 6,5 B 12 34 61,5 68,0 2060 - 8,0 B 12 38 69,0 77,5 207

0 - 10,0 B 12 43 80,0 91,0 2080 - 10,0 B 16 43 80,0 91,0 209 1011 - 13,0 B 16 50 90,5 103,0 210 1023 - 16,0 B 16 56 95,5 109,0 2113 - 16,0 B 18 56 95,5 109,0 212 104

/TypeKeyless, clamping and unclamping by hand, chucktightens automatically during drilling. Only forclockwise operation. All wear parts are case-har-dened, ground and replaceable. 100 % concentricitytest with different taper plug-diameters at differentmeasuring heads based on DIN ISO 10888.

21151TypeType SBF Super-drill chuck, Standard version.

Note:B 18 = inside taper shortened by 7 mm.

21151 201TypeWith vernier for presetting.

21152TypeType NCBF Special type, with clamping guard.ApplicationFor quick-braking spindles of NC, CNC machines,etc.

Note:B 18 = inside taper shortened by 7 mm.

ß

eng/OP www.hhw.de 21.7

2

Clamping tools

Fine Drilling Aids

/TypeWith centring pivot B 6 for drill chuck cat.-no. 21151201, fine drilling aid without drill chuck, drilling depth= 20 mm. A spring-loaded system returns the chuckto the starting position.ApplicationFor highly accurate drilling of very small holes byhand, also suited for large machines.

21155 101

Shank Ø D Ø d L1 L2 21155 …mm mm mm mm

13 mm Ø 13 30 66 80 101MT 1 12 30 82 96 102

21155 102

21155

Chuck-Ejector Forks21160

/ApplicationFor easy separation of the chuck from its mount.Prevents damage to spindle or chuck.

for B taper a b c d e 21160 …mm mm mm mm mm

B 6 120 20 7,0 – 8 101B 10, B 12 170 30 11,0 13,0 10 102B 16, B 18 210 40 16,7 18,7 12 103

21160

Chuck Arbors

TypeWith taper in compliance with DIN 238, for mountingof chucks. Hardened and ground. 21170

MT/drill chuck 21170 …Taper1/B 10 2011/B 12 2021/B 16 2032/B 10 2102/B 12 2112/B 16 2122/B 18 213

MT/drill chuck 21170 …Taper3/B 12 2203/B 16 2213/B 18 2223/B 22 2234/B 16 2314/B 18 2325/B 18 242

21170

Chuck Arbors

TypeWith mounting taper in compliance with DIN ISO239 B, with straight shank. Precision guiding with atrue-running accuracy small equal to 2 µm.

21177

Mounting taper Ø x Length 21177 …mm

B 12 10 x 50 101B 16 12 x 60 102B 16 16 x 50 103B 18 16 x 70 104

21177

eng/OP

• Short chucks

www.hhw.de21.8

2

Short Chucks AKL

/Type100 % concentricity tested, based on DIN ISO10888, worm gearing for high chucking forces.Scope of supply:Incl. of wrench with T-handle for high power.ApplicationFor clockwise and counterclockwise operation.

Note:Draw-in bolts see cat.-no. 21733 - 21740. Other balancing grades available on request.Type ULTRA with true-running accuracy less orequal to 0,015 mm available on request.

21185 302

21185

Taper Clamping range A D1 D2 L1 L2 21185 …ST mm mm mm mm mm mm40 0,5 - 10 69 38 45 78 37,5 30240 1,0 - 16 80 50 - 92 - 30350 1,0 - 16 80 50 - 92 - 304

ST d1 G d5 H7 d2 max d3 l1 l2 l3 l4 l5 l6 d6 emm mm mm mm mm mm mm mm mm mm mm mm

30 31,75 M 12 13 45 50,0 47,8 16,4 19,0 15,0 5,5 24 4 2140 44,45 M 16 17 50 63,55 68,4 22,8 25,0 18,5 8,2 32 4 2750 69,85 M 24 25 80 97,5 101,75 35,5 37,7 30,0 11,5 47 6 42

Shanks for machining centres and NC machines. TypeAlloyed case-hardened steel, min. tensile strength 950 N/mm2.Taper angle tolerance more exact than AT3.Case-hardened 60-2 HRC.Working surfaces ground.

DIN 69871 part 1.Shape A: without through-hole,Shape AD: with through-hole for central coolant feed,Shape AD/B: with through-hole for central coolant feed

and 2 boreholes at the flange for lateral coolant feed,Shape B: with 2 boreholes at the flange for lateral coolant feed.

. Tool adapters in compliance with DIN 69871

Precision Short ChucksßTypeShort type, wear parts hardened and ground.Scope of supply: Incl. of wrench with T-handle for high power.ApplicationFor clockwise and counterclockwise operation.

21200

21200

Taper Clamping range L D 21200 ...ST mm mm mm30 1,0 - 13 90 50 20140 1,5 - 16 95 50 20350 1,5 - 16 95 50 205

ß Clamping tools

eng/OP www.hhw.de 21.9

2

Precision Short Chuck 1-16 mm

0Type Short type, wear parts hardened, clamping range 1-16 mm.Scope of supply:Incl. of wrench with T-handle for high power.ApplicationFor clockwise and counterclockwise operation.

Note:Draw-in bolts see cat.-no. 21733 - 21740. 21191

Taper Clamping range A D 21191 ...ST mm mm mm40 1 - 16 80 50 101

21191

Precision Short Chucks

3TypeShort type, wear parts hardened.Scope of supply:Incl. of wrench with T-handle for high power.ApplicationFor clockwise and counterclockwise operation.

Note:Draw-in bolts see cat.-no. 21733 - 21740. 21202

Taper Clamping range A D E 21202 …ST mm mm mm mm40 0,5 - 13 80,0 48,5 29 20140 2,5 - 16 80,0 51,0 29 202

21202

Precision Short Chucks

ÜTypeShort, sturdy, and slim design. High chucking forcesthanks to gear reduction, high precision and true-running accuracy.Scope of supply:Incl. of wrench with T-handle for high power.

ApplicationFor clockwise and counterclockwise operation.

Note:Draw-in bolts see cat.-no. 21733 - 21740.

21206

Taper Clamping range l1 d1 l2 21206 …ST mm mm mm mm40 1,0 - 13 87,5 43 95,5 10140 2,5 - 16 104,5 56 109,5 10250 1,0 - 13 87,5 43 95,5 10350 2,5 - 16 106,5 56 111,5 104

21206

Precision Short Chucks

0TypeShort type, wear parts hardened, high true-running accuracy. Scope of supply:Wrench with T-handle for high power. ApplicationFor clockwise and counterclockwise operation.

Note:Draw-in bolts see cat.-no. 21733 - 21740. Fine balancing up to 35.000 rpm available onrequest.

Taper Clamping range D L L1 max. 21190 …ST mm mm mm mm40 1,0 - 13 50 90 96 10140 2,5 - 16 57 95 101 102

21190

21190

eng/OP

• Short chucks • Tapping Chucks • Collet chucks

www.hhw.de21.10

2

Precision Short Chucks

3TypeExtremely short type, high true-running accuracy.Scope of supply:Incl. of wrench with T-handle for high power.ApplicationFor clockwise and counterclockwise operation.

Note:Draw-in bolts see cat.-no. 21733 - 21740.

21215

21215

Taper Clamping range A D E 21215 …ST mm mm mm mm40 0,5 - 13 80 48,5 29 20140 3,0 - 16 80 51,0 29 20350 1,0 - 13 110 48,5 29 20550 3,0 - 16 110 51,0 29 207

Quick-Change Tapping Chucks

OTypeType WFLC. Precision version with length compen-sation in response to compression and tension.

Note:Quick-change sleeves see cat.-no. 21459 - 21463.Draw-in bolts see cat.-no. 21733 - 21740.

21450

21450

Taper for taps suitable Length compensation L D D2 21450 …ST drill inserts/size compr./tension mm mm mm mm40 M 3 - M 12 1 7,5/7,5 65 39 19 20140 M 6 - M 20 2 10,0/10,0 103 60 31 20250 M 8 - M 20 2 10,0/10,0 88 60 31 20450 M 14 - M 33 3 17,5/17,5 134 86 48 205

Quick-Change Tapping Chucks

ßTypeWith Length compensation in response to compres-sion and tension.

Note:Quick-change sleeves see cat.-no. 21459 - 21463.

Draw-in bolts see cat.-no. 21733 - 21740.21456

Taper for taps suitable Length compensation L D D2 21456 …ST drill inserts/size compr./tension mm mm mm mm40 M 3 - M 12 1 9,0/9,0 60 38 19 10140 M 6 - M 20 2 15,0/15,0 100 55 31 10240 M 14 - M 33 3 24,0/24,0 138 79 48 10350 M 3 - M 12 1 9,0/9,0 62 38 19 10450 M 6 - M 20 2 15,0/15,0 83 55 31 105

21456

High-Performance Precision Short Chuck

3TypeExtremely short type, high true-running accuracy.Scope of supply:Incl. of wrench with T-handle for high power.ApplicationFor clockwise and counterclockwise operation.

Note:Draw-in bolts see cat.-no. 21733 - 21740.

21212

Taper Clamping range A D E 21212 …ST mm mm mm mm40 0,5 - 13 80 48,5 29 10140 3,0 - 16 80 51,0 29 10250 0,5 - 13 110 48,5 29 10350 3,0 - 16 110 51,0 29 104

21212

ß Clamping tools

eng/OP www.hhw.de 21.11

2

ER Collet Chucks slim

ßTypeClamping nut fine balanced for HSC, ER11 through-hole core-drilled, after the hardening, the shank wasturned once more. With Balluf-Chip borehole.ApplicationFor clamping tools with straight shank in collets DIN6499-shape A and B.

Note:Collets sets see cat.-no. 21519, collets see cat.-no.21520 - 21525 and 21534 - 21539. Draw-in bolts see cat.-no. 21733 - 21740.

21500

Taper Size Clamping range Collets A D 21500 ...ST mm Type mm mm40 L ER 11 1 - 7 ER 11/4008 E 100 16 10140 XL ER 11 1 - 7 ER 11/4008 E 160 16 10240 L ER 16 1 - 10 ER 16/426 E 100 22 10340 XL ER 16 1 - 10 ER 16/426 E 160 22 10440 L ER 25 1 - 16 ER 25/430 E 100 35 10540 XL ER 25 1 - 16 ER 25/430 E 160 35 106

21500

0 ßTaper Size Clamping range Collets A D 21512 ... 21512 …ST mm Type mm mm30 ER 32 2 - 20 ER 32/470 E 70 50 20340 ER 16 1 - 10 ER 16/426 E 63 32 304 20440 L ER 16 1 - 10 ER 16/426 E 100 32 305 20540 XL ER 16 1 - 10 ER 16/426 E 160 32 306 20640 ER 25 2 - 16 ER 25/430 E 60 42 307 20740 L ER 25 2 - 16 ER 25/430 E 100 42 315 21540 XL ER 25 2 - 16 ER 25/430 E 160 42 316 21640 ER 32 2 - 20 ER 32/470 E 70 50 308 20840 L ER 32 2 - 20 ER 32/470 E 100 50 317 21740 XL ER 32 2 - 20 ER 32/470 E 160 50 318 21840 ER 40 3 - 26 ER 40/472 E 80 63 309 20940 L ER 40 3 - 26 ER 40/472 E 100 63 319 21940 XL ER 40 3 - 26 ER 40/472 E 160 63 320 22050 ER 16 1 - 10 ER 16/426 E 100 32 21050 L ER 16 1 - 10 ER 16/426 E 160 32 21150 ER 25 2 - 16 ER 25/430 E 60 42 22150 L ER 25 2 - 16 ER 25/430 E 100 42 22250 XL ER 25 2 - 16 ER 25/430 E 160 42 22350 ER 32 2 - 20 ER 32/470 E 70 50 21250 L ER 32 2 - 20 ER 32/470 E 100 50 22450 XL ER 32 2 - 20 ER 32/470 E 160 50 22550 ER 40 3 - 26 ER 40/472 E 80 63 21350 L ER 40 3 - 26 ER 40/472 E 100 63 22650 XL ER 40 3 - 26 ER 40/472 E 160 63 227

ER Collet Chucks21512

TypePrecision version. External and internal taperground, high true-running accuracy.ApplicationFor clamping tools with straight shank in collets DIN6499-shape A and B.

Note:Collets sets see cat.-no. 21519, collets see cat.-no.21520 - 21525 and 21534 - 21539. Draw-in bolts seecat.-no. 21733 - 21740.

21512 304-320

0TypeFine balancing G 2,5 - 25.000 rpm, stainlesscoating. With Balluf-Chip borehole.

21512 203-227ßTypeBalanced G 6,3 - 12.000 rpm.

21512 217

21512 218

ER Collet Chucks Set

ßTypeSet consists of:1 high-performance drilling and milling chuck 3 - 26mm, chucking capacity type ER 40, 1 ea. collet, slit

in two planes, type 472 E, 4 / 5 / 6 / 8 / 10 / 12 / 14 / 16 / 18 / 20 / 22 / 24 / 25 mm Ø, andwrench. in plastic case.

21506 102

Shank 21506 ... 21510 ...

ST 40 - 102- plastic case, empty 107

21506 - 21510

21512 208

HSC

21512 309

eng/OP

• Chuck extensions • Collet chucks

www.hhw.de21.12

2

Collet chuck Centro P

*TypeExternal and internal taper ground. Concentricityand repeatability 0,003 mm (with GER-HP collets).Concentricity and repeatability 0,006 mm (with GERcollets). Clamping nut not included.ApplicationFor high-precision clamping of tools with straightshank, without concentricity and clamping forceloss, up to shank tolerance h10.

21507TypeSlim design.

21507

21507 - 21508

21508

ER Chuck Extensions

TypeCylindrical tool holder with Weldon shank, smallestdimensions.

ApplicationExtension of Weldon mounts and/or collet chucks.

21515

Clamping range Shank Ø d Collets L D 21515 …mm mm Type mm mm1 - 7 16 ER 11/4008 E 162 16 101

1 - 10 20 ER 16/426 E 178 22 1021 - 13 25 ER 20/428 E 190 28 103

21515

Accessories for Collet Chucks Centro P

*Note:Use clamping nuts Centro P (cat.-no. 21509 102-106and 002-006) only in conjunction with roller span-ners (cat.-no. 21509 202-206) and/or roller bearingheads (cat.-no. 21509 302-306).

21509 102-10621509 101

21509

Standard clamping nuts for sealing discsSize for Ø D 21509 … 21509 ...

collets mmHPC 11 M ER 11/4008 E 16 101HPC 16 ER 16/426 E 30 102HPC 25 ER 25/430 E 40 104HPC 32 ER 32/470 E 50 106HPC 16-DI ER 16/426 E 30 002HPC 25-DI ER 25/430 E 40 004HPC 32-DI ER 32/470 E 50 006

21509 101Miniature clamping nut

21509 102-106Standard clamping nut

21509 002-006Clamping nuts for sealing discs

21509 202-206Roller spanner

21509 302-306Torque roller bearing heads

Note:Collets with square drive are not suitable for taps.Clamping nuts and wrench see cat.-no. 21509. GER-HP collets see cat.-no. 21546 - 21551. GER collets see cat.-no. 21534 - 21539. Draw-inbolts see cat.-no. 21733 - 21740.

21508TypeMely slim design.

Taper Size Clamping range Collets Dimension D Dimension A Insertion depth E 21508 ...ST mm Type mm mm mm40 CP 11 M 1 - 7 ER 11/4008 E 16 100 68 10140 CP 11 M 1 - 7 ER 11/4008 E 16 160 68 102

Taper Size Clamping range Collets Dimension D Dimension A Insertion depth Insertion depth 21507 …ST mm Type mm mm E* mm F** mm40 CP 16 1 - 10 ER 16/426 E 30 70110 – 10340 L CP 16 1 - 10 ER 16/426 E 30 100 140 – 10440 XL CP 16 1 - 10 ER 16/426 E 30 160 200 – 10540 CP 25 2 - 16 ER 25/430 E 40 70 110 – 10840 L CP 25 2 - 16 ER 25/430 E 40 100 113 – 10940 XL CP 25 2 - 16 ER 25/430 E 40 160 118 – 11040 CP 32 2 - 20 ER 32/470 E 50 70 111 55 11340 L CP 32 2 - 20 ER 32/470 E 50 100 114 55 11440 XL CP 32 2 - 20 ER 32/470 E 50 160 119 55 11550 CP 32 2 - 20 ER 32/470 E 50 70 120 62 11650 L CP 32 2 - 20 ER 32/470 E 50 100 150 58 11750 XL CP 32 2 - 20 ER 32/470 E 50 160 200 58 118* Dimension E for tool shanks less than 16 mm ** Dimension F for tool shanks bigger than 16 mm

ß Clamping tools

eng/OP www.hhw.de 21.13

2

for HPC 16-Di for HPC 25-Di for HPC 32-DiSize = clamping Ø 21513 ... 21513 ... 21513 ...

mm1 1012 102 202 3023 103 203 3034 104 204 3045 105 205 3056 106 206 3067 107 207 3078 108 208 3089 109 209 309

10 110 210 310

for HPC 16-Di for HPC 25-Di for HPC 32-DiSize = clamping Ø 21513 ... 21513 ... 21513 ...

mm11 211 31112 212 31213 213 31314 214 31415 215 31516 216 31617 31718 31819 31920 320

OZ Collet Chuck Set

ßTypeSet consists of:1 drilling and milling collet chuck 2 - 25 mm clampingrange, 1 ea. collet type 462 E 4 / 6 / 8 / 10 / 12 / 14 /16 / 18 / 20 / 22 / 24 and 25 mm Ø and hook wrench. In plastic case.

21544 102

Shank 21544 ... 21540 ...

ST 40 – 102- plastic case, empty 205

21540 - 21544

21509 202-206

21509 302-306

Roller clampSize For 21509 ...

Clamping nutRO 30 HPC 16 202RO 40 HPC 25 204RO 50 HPC 32 206

Roller bearing headsSize For Insert mounts 21509 ...

Clamping nut mmDRO 30 HPC 16 9 x 12 302DRO 40 HPC 25 14 x 18 304DRO 50 HPC 32 14 x 18 306

Sealing Discs for ER Clamping Nuts Centro P

*TypeVulcanised sealing discs up to 80 bar. 0,5 mmclamping Ø extension (+0,4/-0,1).

Note:Not suitable for other sealing disc systems! Sealingdiscs with 0,5 mm increments available on request.

21513 101-110For type HPC 16-DID x L 12,6 x 2 mm

21513 202-216For type HPC 25-DID x L 20,2 x 2 mm

21513 302-320For type HPC 32-DID x L 26,2 x 2 mm

21513

21513

OZ Collet Chucks

ßTypeExternal and internal taper ground, ball-bearingmounted union nut.Scope of supply:Incl. of clamping nut.ApplicationFor the clamping of tools with straight shank incollets DIN 6388.

Note:ST 30 is delivered in the AD version. Collets seecat.-no. 21522 - 21524. Draw-in bolts see cat.-no. 21733 - 21740.

21543

Taper Clamping range For collets A D 21543 …ST mm Type mm mm30 2 - 16 415 E 60 43 10140 2 - 25 462 E 70 60 10340 3 - 32 467 E 90 72 10450 2 - 25 462 E 70 60 10550 3 - 32 467 E 80 72 106

21543

eng/OP

• Power chucks • Hydro expansion chucks • Reduction sleeves • Shrinking chucks

www.hhw.de

Taper d1 d2 d3 l1 l2 l3 l4 g 21580 …ST mm mm mm mm mm mm mm40 6 26 49,5 80,5 37 10 29,5 M 5 30140 8 28 49,5 80,5 37 10 30,0 M 6 30240 10 30 49,5 80,5 41 10 35,0 M 8 x 1 30340 12 32 49,5 80,5 46 10 40,0 M 10 x 1 30440 14 34 49,5 80,5 46 10 40,0 M 10 x 1 30540 16 38 49,5 80,5 49 10 45,0 M 12 x 1 30640 18 40 49,5 80,5 49 10 46,0 M 12 x 1 30740 20 42 49,5 80,5 51 10 47,0 M 16 x 1 30850 6 26 49,5 80,5 37 10 29,5 M 5 31050 8 28 49,5 80,5 37 10 30,0 M 6 31150 10 30 49,5 80,5 41 10 35,0 M 8 x 1 31250 12 32 49,5 80,5 46 10 40,0 M 10 x 1 31350 14 34 49,5 80,5 46 10 40,0 M 10 x 1 31450 16 38 49,5 80,5 49 10 45,0 M 12 x 1 31550 18 40 49,5 80,5 49 10 46,0 M 12 x 1 31650 20 42 49,5 80,5 51 10 42,0 M 16 x 1 317

Hydro expansion Chucks

0TypeHigh true-running accuracy and torque transmissi-on. Low maintenance thanks to enclosed clampingsystem. Material 1600-1800 N/mm2 tensile strength,hardened (52+2 HRC). Max. coolant pressure 80bar, axial length adjustment 10 mm. Advantages:anti-vibration clamping, increase of tool life,reduction of micro breaks of the tool cutting edge,easy handling, high positioning and repetitionaccuracy, flexible thanks to the usage of reductionsleeves.

Scope of supply:Incl. of hexagon T-handle wrench.ApplicationFor drilling, reaming, and milling.

Note:Also suitable for clamping of Weldon and Whistle-Notch shanks.Reduction sleeves see cat.-no. 21581. Cylinder cleaner see cat.-no. 22956. Draw-in bolts see cat.-no. 21733 - 21740.

21580 101-102TypeShort, heavy.

21580 301-317TypeShort, slim.

21580

Taper d1 d2 l1 l2 l3 g Weight 21580 ...ST mm mm mm mm mm kg40 20 49,5 64,5 51 10 M 16 x 1 1,3 10150 32 72,0 81,0 61 10 M 16 x 1 3,9 102

21580 101-102

21580 301-317

Power Chucks

0TypeClamping nut with needle roller cage, robustdesign, simple in presetting and application. Hightrue-running accuracy, torque transmission andstability. Thanks to reductions, usable from 3-32mm.Scope of supply: incl. of clamping nut.

ApplicationFor clamping tools with straight shank. Also suitablefor clamping Weldon shanks. Particularly suited forroughing.

Note:Reduction sleeves see cat.-no. 21582. Wrench see cat.-no. 50650. Draw-in bolts see cat.-no. 21733 - 21740.

21577

Taper d D A L 21577 …ST mm mm mm mm40 20 48 60 41 10140 32 66 95 82 102

Taper d D A L 21577 …ST mm mm mm mm50 20 48 80 61 10350 32 66 75 56 104

21577

Reduction sleeves

021581TypeWith sealing ring for hydro expansion chucks.

21582TypeWithout sealing ring for power chucks.

21581-21582

Suitable Reduc. 21581 … 21582 ...for D1 mm for D2 mm

20 3 098 09820 4 099 09920 5 100 10020 6 101 10120 8 102 10220 10 103 10320 12 104 104

Suitable Reduc. 21581 … 21582 ...for D1 mm for D2 mm

20 14 105 10520 16 106 10632 3 11032 4 11132 5 11232 6 113 11332 8 114 114

Suitable Reduc. 21581 … 21582 ...for D1 mm for D2 mm

32 10 115 11532 12 116 11632 14 117 11732 16 118 11832 18 119 11932 20 120 12032 25 121 121

2158221581

21.14

2

ß Clamping tools

eng/OP www.hhw.de 21.15

Shrinking Chucks

2TypeHighest true-running accuracy and taper toleran-ce. Manufactured in climatised environment. Advantages: high chucking forces and long servicelife thanks to the usage of high-quality hot wor-king steel and special heat treatment. Coated forstainlessness. Patented nominal-size increaseallows for an automatic shrinking and facilitatedhandling.ApplicationSuitable for clamping carbide, HSS, and steelshanks with a tolerance of h6.

Note:Extension pieces see cat.-no. 21598. Draw-in bolts see cat.-no. 21733 - 21740.Shrinking machines see cat.-no. 21584 - 21595.

21596 701-722TypeSlim.

21596 498-608

Taper d1 d2 d3 l1 l2 A V g 21596 …ST mm mm mm mm mm mm mm40 3 15 20 20 32 80 5 M 6 49840 4 15 20 20 32 80 5 M 6 49940 5 15 20 25 32 80 5 M 6 50040 6 20 27 36 45 80 10 M 5 50140 8 20 27 36 45 80 10 M 6 50240 10 24 32 42 50 80 10 M 8 x 1 50340 12 24 32 47 50 80 10 M 8 x 1 50440 14 27 34 47 50 80 10 M 10 x 1 50540 16 27 34 50 50 80 10 M 12 x 1 50640 18 33 42 50 57 80 10 M 12 x 1 50740 20 33 42 52 57 80 10 M 16 x 1 50840 25 44 50 58 60 100 10 M 16 x 1 50940 32 44 50 62 38 100 10 M 16 x 1 51040 L 6 21 27 36 45 120 10 M 5 55040 L 8 21 27 36 45 120 10 M 6 55140 L 10 24 32 42 50 120 10 M 8 55240 L 12 24 32 47 50 120 10 M 8 55340 L 14 27 34 47 50 120 10 M 8 55440 L 16 27 34 50 50 120 10 M 12 55540 L 18 33 42 50 57 120 10 M 12 55640 L 20 33 42 52 57 120 10 M 16 55740 XL 6 20 27 36 45 160 10 M 5 60140 XL 8 20 27 36 45 160 10 M 6 60240 XL 10 24 32 42 50 160 10 M 8 x 1 60340 XL 12 24 32 47 50 160 10 M 8 x 1 60440 XL 14 27 34 47 50 160 10 M 8 x 1 60540 XL 16 27 34 50 50 160 10 M 12 x 1 60640 XL 18 33 42 50 57 160 10 M 12 x 1 60740 XL 20 33 42 52 57 160 10 M 16 x 1 608

21596

21596 701-722

slimTaper d1 d2 d3 l1 NL A V g 21596 ...ST mm mm mm mm mm mm mm40 3 9 13 20 60 83 5 M 6 70140 4 10 14 20 60 83 5 M 6 70240 6 12 18 36 60 83 5 M 5 70340 8 14 20 36 60 83 5 M 6 70440 10 16 22 42 60 83 5 M 8 x 1 70540 12 18 24 47 60 83 5 M 10 x 1 70640 16 22 28 50 60 83 5 M 12 x 1 70740 20 27 33 52 60 83 5 M 16 x 1 70840 L 3 9 16 20 100 123 5 M 6 70940 L 4 10 17 20 100 123 5 M 6 71040 L 6 12 22 36 100 123 5 M 5 71140 L 8 14 24 36 100 123 5 M 6 71240 L 10 16 26 42 100 123 5 M 8 x 1 71340 L 12 18 28 47 100 123 5 M 10 x 1 71440 L 16 22 32 50 100 123 5 M 12 x 1 71540 L 20 27 37 52 100 123 5 M 16 x 1 71640 XL 6 12 26 36 140 163 5 M 5 71740 XL 8 14 28 36 140 163 5 M 6 71840 XL 10 16 30 42 140 163 5 M 8 x 1 71940 XL 12 18 32 47 140 163 5 M 10 x 1 72040 XL 16 22 36 50 140 163 5 M 12 x 1 72140 XL 20 27 41 52 140 163 5 M 16 x 1 722

2patentednominal-size

eng/OP

• Toolholders • Taper sleeves • Milling sleeves

www.hhw.de21.16

2

Tool holder for Screw-in Milling Cutters17676

d3 ST d1 d2 D L A 17676 …mm mm mm mm mm mmM 6 40 6,5 10 13 25 44 101M 6 40 6,5 10 20 50 69 102M 6 40 6,5 10 23 75 94 103M 8 40 8,5 13 15 25 44 104M 8 40 8,5 13 23 50 69 105M 8 40 8,5 13 23 75 94 106M 8 40 8,5 13 25 100 119 107

M 10 40 10,5 18 20 25 44 108M 10 40 10,5 18 23 50 69 109M 10 40 10,5 18 28 75 94 110M 10 40 10,5 18 32 100 119 111M 12 40 12,5 21 24 25 44 112M 12 40 12,5 21 31 75 94 113M 12 40 12,5 21 36 125 144 114M 16 40 17,0 29 29 25 44 115M 16 40 17,0 29 34 75 94 116M 16 40 17,0 29 40 125 144 117

17676TypePrecision version. External taper and fit ground.ApplicationFor mounting screw-in milling cutters with thread.

Note:Draw-in bolts see cat.-no. 21733 - 21740.

Performance requires quality.

www.atorn.com

Solid carbide milling cutters by ATORN:

ATORN‘s high-quality milling tools.

ß Clamping tools

eng/OP www.hhw.de 21.17

2

Taper Sleeves

TypePrecision version.ApplicationFor mounting tools with MT shank and drive tang.

Note:Draw-in bolts see cat.-no. 21733 - 21740.

21609 204-210

0TypeFine balancing G 2,5 - 25.000 rpm, stainlesscoating. With Balluf-Chip borehole.

21609 301-319ßTypeBalanced G 6,3 - 12.000 rpm.

21609 306

0 ßExternal taper Internal taper l2 l1 d1 21609 … 21609 ...

ST MT mm mm mm30 1 50 97,8 25 30130 2 65 112,8 32 30230 3 80 127,8 40 30340 1 50 118,4 25 204 30440 2 50 118,4 32 205 30540 2L 117 184,5 32 206 30640 3 70 138,4 40 207 30740 3L 133 201,4 40 208 30840 4 95 163,4 48 209 30940 4L 156 224,4 48 210 310

0 ßExternal taper Internal taper l2 l1 d1 21609 … 21609 ...

ST MT mm mm mm50 1 45 146,75 25 31150 2 60 161,75 32 31250 2L 117 218,75 32 31350 3 65 116,75 40 31450 3L 137 238,75 40 31550 4 95 196,75 48 31650 4L 167 268,75 48 31750 5 105 206,75 63 31850 5L 197 298,75 63 319

21609 305

21609

Milling Sleeves

ßTypePrecision version with built-in draw-in screw.ApplicationFor mounting tools with MT shank and draw-inthread.

Note:Draw-in bolts see cat.-no. 21733 - 21740.

21613

External taper Internal taper Draw-in thread A D 21613 …ST MT internal mm mm40 1 M 6 50 25 10140 2 M 10 50 32 10240 3 M 12 70 40 10340 4 M 16 95 48 10450 2 M 10 60 32 10650 3 M 12 65 40 10750 4 M 16 70 48 108

21613

Tool Adapters for Drill Chucks

ßTypePrecision version.ApplicationFor mounting drill chucks in milling machines.

Note:Draw-in bolts see cat.-no. 21733 - 21740.

21601

Taper Mount d1 l2 l1 21601 …ST DIN 238 mm mm40 B 16 25 93,4 30150 B 16 25 126,75 303

21601

21609 207

eng/OP

• Adapter sleeves • Collet chucks • Collets • Milling cutter mounts

www.hhw.de21.18

2

HG Collet Chucks

HaimerTypeHigh-precision chuck, reliable clamping, high true-running accuracy.Scope of supply:With clamping screw and extraction hook.ApplicationVery suitable for high-speed machining. Forclamping tools with straight shank.

Note:HG collets see cat.-no. 21627. Draw-in bolts see cat.-no. 21733 - 21740.

21625 107

Taper Size A Ø D for HG collet Ø 21625 …ST mm mm cat.-no. 2162740 1 65 30 3 / 4 / 5 / 6 / 8 10140 L 1 100 30 3 / 4 / 5 / 6 / 8 10250 1 65 30 3 / 4 / 5 / 6 / 8 10450 L 1 100 30 3 / 4 / 5 / 6 / 8 10540 2 70 35 10 / 12 / 14 10740 L 2 100 35 10 / 12 / 14 108

Taper Size A Ø D for HG collet Ø 21625 …ST mm mm cat.-no. 2162750 2 70 35 10 / 12 / 14 11050 L 2 100 35 10 / 12 / 14 11140 3 75 48 16 / 18 / 20 11340 L 3 100 48 16 / 18 / 20 11450 3 75 48 16 / 18 / 20 11650 L 3 100 48 16 / 18 / 20 117

21625

HG Collets

HaimerTypeSpring steel hardened, ground, and coated.ApplicationFor HG chucks and shank tolerances h6.

21627

clamping Ø for 21627 …mm size

3 1 1014 1 1025 1 1036 1 1048 1 105

10 2 106

clamping Ø for 21627 …mm size

12 2 10714 2 10816 3 10918 3 11020 3 111

21627

Adapter Sleeves

ßTypePrecision version with built-in draw-in screw.ApplicationFor mounting and extending ST shanks.

Note:Draw-in bolts see cat.-no. 21733 - 21740.

21618

External taper Internal taper Draw-in Thread Draw-in Thread l2 l1 d1 21618 …ST ST external internal mm mm mm40 40 M 16 M 16 100 168,40 63 20250 40 M 24 M 16 70 171,75 70 20350 50 M 24 M 24 120 221,75 97 204

21618

21625 108

HSC

ß Clamping tools

eng/OP www.hhw.de 21.19

2

Milling Cutter Mounts

TypePrecision version, borehole tolerance < 0,004 mm.ApplicationFor clamping tools with lateral driving face incompliance with DIN 1835 B and DIN 6535 HB

Note:Draw-in bolts see cat.-no. 21733 - 21740.Spare screw see cat.-no. 21635.

21631

0TypeFine balancing G 2,5 - 25.000 rpm, stainlesscoating. With Balluf-Chip borehole.

21632ßTypeBalanced G 6,3 - 12.000 rpm.

21631 - 21632

21631 109

21632 125

21632 126

21632 127

0 ßTaper for milling cutter A D 21631 … 21632 ...ST shank Ø d mm mm mm30 6 50 25 10130 8 50 28 10230 10 50 35 10330 12 50 42 10430 16 63 48 10630 20 70 52 10840 6 50 25 209 10940 L 6 100 25 210 11040 XL 6 160 25 211 11140 8 50 28 212 11240 L 8 100 28 213 11340 XL 8 160 28 219 11440 10 50 35 220 11540 L 10 100 35 221 11640 XL 10 160 35 222 11740 12 50 42 223 11840 L 12 100 42 224 11940 XL 12 160 42 225 12040 14 50 44 226 12140 L 14 100 44 227 12240 XL 14 160 44 228 12340 K 16 35 45 20540 16 63 48 229 12540 L 16 100 48 230 12640 XL 16 160 48 231 12740 18 63 50 232 12940 L 18 100 50 233 13040 XL 18 160 50 234 13140 K 20 35 45 20640 20 63 52 235 13340 L 20 100 52 236 13440 XL 20 160 52 237 13540 K 25 35 50 20740 25 100 63 241 137

0 ßTaper for milling cutter A D 21631 … 21632 ...ST shank Ø d mm mm mm40 L 25 160 63 242 13840 K 32 65 50 20840 32 100 72 243 14040 L 32 160 72 24440 40 120 80 245 14150 6 63 25 14550 L 6 100 25 14650 XL 6 160 25 14750 8 63 28 14850 L 8 100 28 14950 XL 8 160 28 15050 10 63 35 15150 L 10 100 35 15250 XL 10 160 35 15350 12 63 42 15450 L 12 100 42 15550 XL 12 160 42 15650 14 63 44 15750 L 14 100 44 15850 XL 14 160 44 15950 16 63 48 16050 L 16 100 48 16150 XL 16 160 48 16250 18 63 50 16350 L 18 100 50 16450 XL 18 160 50 16550 20 63 52 16650 L 20 100 52 16750 XL 20 160 52 16850 25 80 65 16950 L 25 160 65 17050 32 100 72 17150 L 32 160 72 17250 40 100 80 173

eng/OP

• Milling cutter mounts • Toolholders • Combination milling cutter arbors

www.hhw.de21.20

2

Milling Cutter Mounts slim

ßTypeExtended, slim version. Borehole tolerance <0,004 mm, after the hardening, the shank wasturned once more for smoother operation. With balljoint clamping screw for Weldon and Whistle-Notch. By default with Balluf-Chip borehole.

Scope of supply:Through-hole stop screw.ApplicationFor clamping tools with lateral Driving face incompliance with DIN 1835 B and DIN 6535 HB.

Note:Draw-in bolts see cat.-no. 21733 - 21740.Spare screw see cat.-no. 21635.

Taper for milling cutter A D2 D3 D4 21620 ...ST shank Ø D1 mm mm mm mm mm40 L 6 100 13 18 29 10140 XL 6 160 13 18 34 10240 L 8 100 15 20 31 10340 XL 8 160 15 20 37 10440 L 10 100 16 21 33 10540 XL 10 160 16 21 40 10640 L 12 100 17 22 35 10740 XL 12 160 17 22 43 10840 L 14 100 19 24 37 10940 XL 14 160 19 24 45 11040 L 16 100 21 26 39 11140 XL 16 160 21 26 47 11240 L 18 100 23 28 41 11340 XL 18 160 23 28 49 11440 L 20 100 25 30 43 11540 XL 20 160 25 30 50 116

21620

21620 103

21620 104

Milling Cutter Mounts with Coolant Bore

ßTypePrecision version, borehole tolerance < 0,004 mm, with coolant bore. Advantage: the chips are removed better thanks tothe coolant pressure.ApplicationFor clamping tools with lateral Driving face incompliance with DIN 1835 B and DIN 6535 HB.

Note:Draw-in bolts see cat.-no. 21733 - 21740.Spare screw see cat.-no. 21635.

21637

Taper for milling cutter A D 21637 …ST shank Ø d mm mm mm40 6 50 25 20140 L 6 100 25 20240 8 50 28 20440 L 8 100 28 20540 10 50 35 20740 L 10 100 35 20840 12 50 42 21040 L 12 100 42 21140 14 50 44 21340 L 14 100 44 21440 16 63 48 21640 L 16 100 48 21740 18 63 50 21940 L 18 100 50 22040 20 63 52 222

Taper for milling cutter A D 21637 …ST shank Ø d mm mm mm40 L 20 100 52 22340 25 100 63 22540 32 100 72 22740 40 120 80 22950 6 63 25 30150 8 63 28 30250 10 63 35 30350 12 63 42 30450 14 63 44 30550 16 63 48 30650 18 63 50 30750 20 63 52 30850 25 80 63 30950 32 100 72 31050 40 100 80 311

21637

Toolholder for reversible Cutting Insert solid drilling tool21639

21639

ßTypePrecision version, high true-running accuracy thanksto surface ground contact surface (accuracy < 0,003 mm). Advantages: Thanks to the offset threaded pin, thecontact surface of the drill is drawn towards theenlarged diameter. This provides for an improvedsupport of the tool and therefore for higher feedrates.

ApplicationFor all solid drilling tools with straight shankDIN 6595 part 1.

Note:Draw-in bolts see cat.-no. 21733 - 21740.Spare screw see cat.-no. 21635.

Taper d A D 21639 …ST mm mm mm40 20 65 40 10140 25 70 45 10240 32 75 52 103

Taper d A D 21639 …ST mm mm mm50 20 70 40 10450 25 70 45 10550 32 70 52 106

ß Clamping tools

eng/OP www.hhw.de 21.21

2

Combination Milling Cutter Arbors

TypePrecision version, surface ground contact surface(accuracy < 0,003 mm).Scope of supply:Incl. of feather key, driving ring and draw-in screw.ApplicationWith feather key for milling cutters with longitudinalkeyway e.g. DIN 841 and driving ring for millingcutters with transverse slot DIN 1880 and millingheads DIN 1830.

Note:Draw-in bolts see cat.-no. 21733 - 21740. Driving rings see cat.-no. 21655. Draw-in screws see cat.-no. 21656 u. 21659. Draw-in screw wrenches see cat.-no. 21657.

21650 601-614

0TypeFine balancing 2,5 - 25.000 rpm, stainlesscoating. With Balluf-Chip borehole.

21650 102-520ßTypeBalanced 6,3 - 12.000 rpm

0 ßTaper d A D l 21650 ... 21650 …ST mm mm mm mm30 16 50 32 17 10230 22 50 40 19 10330 27 55 48 21 10440 16 55 32 17 601 20240 L 16 100 32 17 602 20340 XL 16 160 32 17 603 21340 22 55 40 19 604 20440 L 22 100 40 19 605 20540 XL 22 160 40 19 606 21540 27 55 48 21 607 20640 L 27 100 48 21 608 20740 XL 27 160 48 21 609 21740 32 60 58 24 610 20840 L 32 100 58 24 611 20940 XL 32 160 58 24 612 21940 40 60 70 27 613 21040 L 40 100 70 27 614 21140 XL 40 160 70 27 22150 16 55 32 17 50150 L 16 100 32 17 50250 XL 16 160 32 17 51250 22 55 40 19 50350 L 22 100 40 19 50450 XL 22 160 40 19 51450 27 55 48 21 50550 L 27 100 48 21 50650 XL 27 160 48 21 51650 32 55 58 24 50750 L 32 100 58 24 51850 40 55 70 27 50950 L 40 100 70 27 51050 XL 40 160 70 27 520

21650

21650 215

21650 205

21650 204

21650 604

eng/OP

• Milling head mounts • Basic mount • Boring bar blanks • Short chucks

www.hhw.de21.22

2

Milling Head Mounts

TypePrecision version with enlarged and surface groundcontact surface. Short overhang for increasedstability.ApplicationFor Shell End Milling Cutters and Milling Cutterswith Transverse Keyway.

Note:d = 40 and 60 mm additionally with 4 threaded holesfor direct mounting. Draw-in bolts see cat.-no. 21733 - 21740. Draw-in screws see cat.-no. 21656 u. 21659. Draw-in screw wrenches see cat.-no.. 21657.

21671 101-114

0TypeFine balancing G 2,5 - 25.000 rpm, stainlesscoating. With Balluf-Chip borehole.

21671 304-410ßTypeBalanced G 6,3 - 12.000 rpm.

0 ßTaper d A D l 21671 ... 21671 …ST mm mm mm mm40 16 35 38 17 101 30440 L 16 100 38 17 102 30540 22 35 48 19 104 30540 L 22 100 48 19 105 30940 27 40 58 21 107 30640 L 27 100 58 21 108 31040 32 50 78 24 110 30740 L 32 100 78 24 111 31140 40 50 88 27 113 30840 L 40 100 88 27 114 31250 22 35 48 19 40250 L 22 100 48 19 40750 27 40 58 21 40350 L 27 100 58 21 40850 32 50 78 24 40450 L 32 100 78 24 40950 40 50 88 27 40550 L 40 100 88 27 41050 60 70 128 40 406

21671

21671 310

21671 306

ABS®-Basic Mount

;TypeShape B, with sealing disc and modification set forshape AD.ApplicationFor Komet reversible cutting insert solid drillingtools.

21692

Taper ABS d L L1 Weight 21692 ...ST mm mm mm approx. kg40 40 50 19 1,07 10140 50 50 30 1,10 10240 63 90 70 2,05 10350 40 60 20 3,30 10650 50 60 22 3,30 10750 63 60 29 3,37 108

21692

Boring Bar Blanks

TypeST and shoulder hardened and ground, material 16MnCr5.ApplicationFor manufacturing special tools.

21683

Taper Boring bar Ø d1 l2 21683 …ST mm mm40 63,0 250 10250 97,0 315 201

21683

21671 104

ß Clamping tools

eng/OP www.hhw.de 21.23

2

. Tool holders in compliance with JIS B 6339 (MAS-BT)

JIS B 6339(Japan, former standard > MAS-BT).TypeTaper angle tolerance more exact than AT3.Case-hardened 60-2 HRC.Working surfaces ground.

MAS-BT d1 G d5 H7 d2 a l1 l2 l3 l5 l6mm mm mm mm mm mm mm mm mm

30 31,75 M 12 12,5 46 2 48,4 22 16,3 7,0 2440 44,45 M 16 17,0 63 2 65,4 27 22,6 8,2 3250 69,85 M 24 25,0 100 3 101,8 38 35,3 11,0 47

Short Chucks21189

ßTypeShort type, wear parts hardened and ground.Scope of supply:Incl. of wrench with T-handle for high power.ApplicationFor clockwise and counterclockwise operation.

Note:Draw-in bolts see cat.-no. 21737 - 21739.

Taper Clamping range L D 21189 ...MAS-BT mm mm mm

40 1,5 - 16 103 50 10350 1,5 - 16 114 50 105

21189

CNC Short Chucks 1-16 mm

0TypeShort type, wear parts hardened and ground,clamping range 1-16 mm.Scope of supply:Incl. of wrench with T-handle for high power.ApplicationFor clockwise and counterclockwise operation.

Note:Draw-in bolts see cat.-no. 21737 - 21739. 21192

Taper Clamping range A D 21192 ...MAS-BT mm mm mm

40 1 - 16 88 50 101

21192

eng/OP

• Short chucks • Tapping Chucks • Collet chucks • Power chucks • Taper sleeves

www.hhw.de21.24

2

Precision Short Chucks

ÜTypeShort, sturdy, and slim design, for clockwise andcounterclockwise operation. High chucking forcesthanks to gear reduction, high precision and true-run-ning accuracy.Scope of supply:Incl. of wrench with T-handle for high power.

Note:Draw-in bolts see cat.-no. 21737 - 21739.

Taper with drill chuck l1 d1 l2 21207 …MAS-BT mm mm mm mm

40 1,0 - 13 95,5 43 103,5 10140 2,5 - 16 114,5 56 119,5 10250 1,0 - 13 106,5 43 114,5 10350 2,5 - 16 125,5 56 130,5 104

21207

21207

Quick-Change Tapping Chucks

ßTypeWith Length compensation in response to compres-sion and tension.

Note:Quick-change sleeves see cat.-no. 21459 - 21463. Draw-in bolts see cat.-no. 21737 - 21739.

21458

Taper for Taps suitable Length compensation L D D2 21458 …MAS-BT inserts/size compr./tension mm mm mm mm

40 M 3 - M 12 1 9,0/9,0 68 38 19 10140 M 6 - M 20 2 15,0/15,0 93 55 31 10240 M 14 - M 33 3 24,0/24,0 138 79 48 10350 M 6 - M 20 2 15,0/15,0 102 55 31 105

21458

ER Collet Chucks

ßTypeST 40 = shape AD/BST 50 = shape ADPrecision version. Hohe Rundlaufgenauigkeit.ApplicationFor clamping tools with straight shank in collets DIN6499-shape A and B.

Note:Collet sets see cat.-no. 21519. Collets see cat.-no. 21520 - 21525 and 21534 -21539. Draw-in bolts see cat.-no. 21737 - 21739.

21514

Taper Size Clamping range Collets l2 l1 d1 21514 …MAS-BT mm Type mm mm mm

40 ER 25 1 - 16 ER 25/430 E 60 125,4 42 10140 ER 32 2 - 20 ER 32/470 E 70 135,4 50 10240 ER 40 3 - 26 ER 40/472 E 80 145,4 63 10340 ER 32 2 - 20 ER 32/470 E 70 171,8 50 10440 ER 40 3 - 26 ER 40/472 E 80 181,8 63 105

21514

OZ Collet Chucks

ßTypePrecision version. Ball-bearing mounted union nut.Scope of supply: Incl. of clamping nut.ApplicationFor the clamping of tools with straight shank incollets DIN 6388.Note:

Collets see cat.-no. 21522 - 21524. Draw-in boltssee cat.-no. 21737 - 21739.

21545

Taper Clamping range for collets A D 21545 …MAS-BT mm Type mm mm

40 2 - 25 462 E 70 60 10140 4 - 32 467 E 90 72 102

21545

Performance requires quality.www.atorn.com

Digital slide callipers by ATORN:

ATORN‘s high-quality measuring tools.

ß Clamping tools

eng/OP www.hhw.de 21.25

2

Toolholder for Drill Chuck

ßTypePrecision version.ApplicationFor mounting drill chucks in milling machines.

Note:Draw-in bolts see cat.-no. 21737 - 21739. 21602

Taper Mount d1 l2 l1 21602 …MAS-BT DIN 238 mm mm

40 B 16 32 97,4 401

21602

Taper Sleeves

ßTypeBT 40 = shape AD/BBT 50 = shape ADPrecision version.ApplicationFor mounting tools with MT shank and drive tang.

Note:Draw-in bolts see cat.-no. 21737 - 21739. 21611

External taper Internal taper A l1 D 21611 …MAS-BT MT mm mm mm

40 1 50 115,4 25 10140 2 50 115,4 32 10240 3 70 135,4 40 10340 4 95 160,4 48 10450 2 60 161,8 32 10650 3 65 166,8 40 10750 4 95 196,8 48 108

21611

Power chucks

0TypeClamping nut with needle roller cage, robustdesign, simple in presetting and application. Hightrue-running accuracy, torque transmission andstability. Thanks to reductions, usable from 3-32mm.Scope of supply:Incl. of clamping nut.ApplicationFor clamping tools with straight shank. Also suitablefor clamping Weldon shanks. Particularly suited forroughing.

Note:Reduction sleeves see cat.-no. 21582. Wrench see cat.-no. 50650. Draw-in bolts see cat.-no. 21737 - 21739.

21578

Taper d D A L 21578 …MAS-BT mm mm mm mm

40 20 48 63 36 10140 32 66 90 53 10250 20 48 85 47 10350 32 66 95 57 104

21578

eng/OP

• Milling cutter mounts • Combination milling cutter arbors • Basic mount • Short chucks • Tapping Chucks

www.hhw.de21.26

2

Combination Milling Cutter Arbors21651

ßTypePrecision version, surface ground contact surface(accuracy < 0,003 mm).Scope of supply:Incl. of feather key, driving ring and draw-in screw.ApplicationWith feather key for milling cutters with longitudinalkeyway e.g. DIN 841 and driving ring for millingcutters with transverse slot DIN 1880 and millingheads DIN 1830.

Note:Draw-in bolts see cat.-no. 21737 - 21739. Driving rings see cat.-no. 21655. Draw-in screws see cat.-no. 21656 u. 21659. Draw-in screw wrenches see cat.-no. 21657.

Taper d2 l4 l3 d1 I5 I2 21651 …MAS-BT mm mm mm mm mm mm

40 16 55 45 32 17 27 30240 22 55 43 40 19 31 30340 27 55 43 48 21 33 30440 32 60 46 58 24 38 30540 40 60 46 70 27 41 30650 22 70 58 40 19 31 40350 27 70 58 48 21 33 40450 32 70 56 58 24 38 40550 40 70 56 70 27 41 406

21651

Milling Cutter Mounts

ßTypePrecision version, borehole tolerance < 0,004 mm.ApplicationFor clamping tools with lateral Driving face incompliance with DIN 1835 B and DIN 6535 HB.

Note:Draw-in bolts see cat.-no. 21737 - 21739.

21633

21633

Taper for milling cutter shank Ø d A D 21633 …MAS-BT mm mm mm

40 6 50 25 11140 8 50 28 11240 10 63 35 11340 12 63 42 11440 14 63 44 11540 16 63 48 11640 18 63 50 11740 20 63 52 11840 25 90 63 12040 32 100 72 121

Taper for milling cutter shank Ø d A D 21633 …MAS-BT mm mm mm

50 6 63 25 21150 8 63 28 21250 10 63 35 21350 12 80 42 21450 14 80 44 21550 16 80 48 21650 18 80 50 21750 20 80 52 21850 25 100 63 22050 32 105 72 22150 40 110 80 222

ABS®-Basic Mount

;TypeShape B, with sealing disc and modification set forshape AD.ApplicationFor Komet reversible cutting insert solid drillingtools.

Note:Draw-in bolts see cat.-no. 21737 - 21739.

21694

Taper ABS d L L1 Weight 21694 ...MAS-BT mm mm mm approx. kg

40 40 60 33 1,21 10140 50 60 33 1,29 10240 63 70 43 1,68 10350 40 70 24 3,86 10550 50 70 24 4,07 10650 63 80 37 4,33 107

21694

ß Clamping tools

eng/OP www.hhw.de 21.27

2

Short Chucks AKL 1-16 mm21184

Taper Clamping range A D1 L1 21184 …ST mm mm mm mm40 1 - 16 73 50 85 301

/Type100 % concentricity tested, based on DIN ISO10888, worm gearing for high chucking forces.Scope of supply:Incl. of wrench with T-handle for high power.ApplicationFor clockwise and counterclockwise operationand quick-breaking spindles.

Note:Other balancing grades available on request.

21184

. Tool Adapters in Compliance with DIN 2080

ST shank ST 30 - ST 50 with internal draw-in thread, manual clamping and lock ring for automatic clamping DIN 2080.TypeAlloyed case-hardened steel, min. tensile strength 950 N/mm2.Taper angle tolerance more exact than AT3.Case-hardened 60-2 HRC.Working surfaces ground.

SK d1 a b k G d2 d3 d4 l1 l2 l3 l4 l5mm mm mm mm mm mm mm mm mm mm mm mm

30 31,75 1,6 16,1 8 M 12 50,0 - 17,1 68,4 16,2 - - 2440 44,45 1,6 16,1 10 M 16 63,0 21,1 25,0 93,4 22,5 7 82 3250 69,85 3,2 25,7 12 M 24 97,5 32,0 39,3 126,8 35,3 13 115 47

Short Chucks21205

ÜTypeShort, sturdy, and slim design. High chucking forcesthanks to gear reduction, high precision and true-run-ning accuracy.Scope of supply:Incl. of wrench with T-handle for high power.

ApplicationFor clockwise and counterclockwise operation.

21205

Taper Clamping range l1 d1 l2 21205 …ST mm mm mm mm40 1,0 - 13 80,0 43 88,0 10140 2,5 - 16 97,0 56 102,0 102

Quick-Change Tapping Chucks21455

ßTypewith Length compensation in response to compres-sion and tension.

Note:Quick-change sleeves see cat.-no. 21459 - 21463. Draw-in bolts see cat.-no. 21733 - 21740.

21455

Taper for Thread suitable Length compensation L D D2 21455 …ST drill inserts/size compr./tension mm mm mm mm40 M 3 - M 12 1 9,0/9,0 53 38 19 20140 M 6 - M 20 2 15,0/15,0 77 55 31 20240 M 14 - M 33 3 24,0/24,0 118 79 48 20350 M 6 - M 20 2 15,0/15,0 79 55 31 205

eng/OP

• Collet chucks • Taper sleeves • Milling sleeves • Adapter sleeve

www.hhw.de21.28

2

ER Collet Chucks Set

ßTypeSet consists of:1 high-performance drilling and milling chuck 3 - 26mm, chucking capacity type ER 40, 1 ea. collet, slitin two planes, type 472 E, 4 / 5 / 6 / 8 / 10 / 12 / 14 /16 / 18 / 20 / 22 / 24 / 25 mm Ø, and wrench. inplastic case.

21510 101

Shank 21510 …

ST 40 – 101plastic case, empty 107

21510

ER Collet Chucks

ßTypePrecision version. Hohe Rundlaufgenauigkeit.ApplicationFor clamping tools with straight shank in collets DIN6499-shape A and B.

Note:Collet sets see cat.-no. 21519. Collets see cat.-no. 21520 - 21525 and 21534 -21539.

Taper Size Clamping range Collets l2 l1 d1 21511 …ST mm Type mm mm mm30 ER 32 2 - 20 ER 32/470 E 50 118,4 50 10240 ER 32 2 - 20 ER 32/470 E 50 143,4 50 10740 ER 40 4 - 26 ER 40/472 E 80 173,4 63 108

21511 107-108

21511

OZ Collet Chuck Set21540

ßTypeSet consists of:1 drilling and milling collet chuck 2 - 25 mm clam-ping range, 1 ea. collet type 462 E 4 / 6 / 8 / 10 / 12/ 14 / 16 / 18 /20 / 22 / 24 and 25 mm Ø and hookwrench. In plastic case.

Shank 21540 …

ST 40 – 201plastic case, empty 205

21540 201

OZ Collet Chucks

ßTypeWith ball-bearing mounted union nut.Scope of supply:Incl. of clamping nut.ApplicationFor the clamping of tools with straight shank incollets DIN 6388.

Note:Collets see cat.-no. 21522 - 21524.

21542

Taper Clamping range for collets l2 d1 21542 …ST mm Type mm mm30 2 - 16 415 E 50 43 10140 2 - 25 462 E 66 60 10340 4 - 32 467 E 95 72 10450 2 - 25 462 E 71 60 10550 4 - 32 467 E 73 72 106

21542

ß Clamping tools

eng/OP www.hhw.de 21.29

2

Taper Sleeves

ßTypePrecision version.ApplicationFor mounting tools with MT shank and drive tang.

21606 102

External taper Internal taper l2 l1 d1 21606 …ST MT mm mm mm30 2 50 118,4 32 10140 1 50 143,4 25 10240 2 50 143,4 32 10340 3 65 158,4 40 10540 4 95 188,4 48 107

External taper Internal taper l2 l1 d1 21606 …ST MT mm mm mm50 1 45 171,8 25 10950 2 60 186,8 32 11050 3 65 191,8 40 11250 4 70 196,8 48 11450 5 105 231,8 63 116

21606

Tool Adapters for Drill Chucks

ßTypePrecision version.ApplicationFor mounting drill chucks in milling machines.

21600

Taper Mount d1 l2 l1 21600 …ST DIN 238 mm mm40 B 16 17 110,4 10150 B 16 20 146,8 103

21600

Milling Sleeves

ßTypePrecision version with built-in draw-in screw.ApplicationFor mounting tools with MT shank and draw-inthread.

21612

External taper Internal taper Draw-in thread A D 21612 …ST MT Internal mm mm40 2 M 10 50 32 10240 3 M 12 65 40 10340 4 M 16 95 48 104

21612

Adapter Sleeve

ßTypePrecision version with built-in draw-in screw.ApplicationFor mounting and extending ST shanks.

21617

External taper Internal taper Draw-in thread Draw-in thread l2 l1 d1 21617 …ST ST external internal mm mm mm50 40 M 24 M 16 50 176,8 70 203

21617

eng/OP

• Milling cutter mounts • Arbors • Milling head mounts • Basic mount

www.hhw.de21.30

2

Combination Milling Cutter Arbors21649

ßTypePrecision version, surface ground contact surface(accuracy < 0,003 mm).Scope of supply:Incl. of feather key, driving ring and draw-in screw.ApplicationWith feather key for milling cutters with longitudinalkeyway e.g. DIN 841 and driving ring for millingcutters with transverse slot DIN 1880 and millingheads DIN 1830.

Note:Driving rings see cat.-no. 21655. Draw-in screws see cat.-no. 21656 and 21659.Draw-in screw wrenches see cat.-no. 21657.

21649

Taper d A D l 21649 …ST mm mm mm mm30 16 34,6 32 17 30230 22 34,6 40 19 30330 27 34,6 48 21 30440 16 51,6 32 17 30740 22 51,6 40 19 30840 27 51,6 48 21 30940 32 51,6 58 24 310

Taper d A D l 21649 …ST mm mm mm mm40 40 51,6 70 27 31150 16 55,2 32 17 40250 22 55,2 40 19 40350 27 55,2 48 21 40450 32 55,2 58 24 40550 40 55,2 70 27 406

Milling Cutter Mounts

ßTypePrecision version, borehole tolerance < 0,004 mm.ApplicationFor clamping tools with lateral Driving face incompliance with DIN 1835 B and DIN 6535 HB.

21630

Taper for milling cutter shank Ø d A D 21630 …ST mm mm mm40 6 50 25 20140 8 50 28 20240 10 50 35 20340 12 50 42 20440 14 50 44 20540 16 63 48 20640 18 63 50 20740 20 63 52 20840 25 80 63 21040 32 80 72 211

Taper for milling cutter shank Ø d A D 21630 …ST mm mm mm50 6 63 25 40150 8 63 28 40250 10 63 35 40350 12 63 42 40450 14 63 44 40550 16 63 48 40650 18 63 50 40750 20 63 52 40850 25 80 63 41050 32 80 72 41150 40 90 80 412

21630

Arbors for Shell end Milling Cutters

TypePrecision version, surface ground contact surface(accuracy < 0,003 mm).Scope of supply:Incl. of feather key and draw-in screws.ApplicationWith feather key for milling cutter with longitudinal

keyway e.g. DIN 841.

Note:Draw-in screws see cat.-no. 21656 and 21659.Draw-in screw wrenches see cat.-no. 21657. Millingcutter arbor collars see cat.-no. 21665 - 21667.

21653 305

Taper d2 l3 d1 l2 l5 21653 …ST mm mm mm mm mm40 22 36,6 36 25 40 30640 27 36,6 43 25 60 30740 32 36,6 48 25 60 30850 22 40,2 36 25 40 40350 27 40,2 43 25 60 40450 32 40,2 48 25 60 40550 40 40,2 56 25 60 406

21653

ß Clamping tools

eng/OP www.hhw.de 21.31

2

Milling Head Mounts

ßTypePrecision version with enlarged and surface groundcontact surface. Short overhang for increasedstability.Scope of supply:Incl. of draw-in screws.ApplicationFor Shell End Milling Cutters and Milling Cutterswith Transverse Keyway.

Note:d = 40 mm additionally with 4 threaded holes for direct mounting. Draw-in screws see cat.-no. 21656 and 21659.Draw-in screw wrenches see cat.-no. 21657.

21670

Taper d A D l 21670 …ST mm mm mm mm40 22 30 48 19 30540 27 30 58 21 30640 32 30 78 24 30740 40 30 88 27 30850 27 35 58 21 40350 32 40 78 24 40450 40 33 88 27 405

21670

Taper ABS d L L1 Weight 21690 …ST mm mm mm approx. kg40 40 50 38 1,04 10140 50 50 38 1,15 10240 63 70 58 1,81 103

ABS®-Basic Mount21690

;TypeShape B, with sealing disc and modification set forshape AD.ApplicationFor Komet reversible cutting insert solid drillingtools.

21690

www.atorn.com

Performance requires quality.

Adjustable wrenches by ATORN:

ATORN‘s high-quality hand tools.

eng/OP

• Drill chuck • Quick-Change Chucks • Chuck Collets • Tapping Chucks • Tapping Attachments

www.hhw.de21.32

2

Quick-Change Chucks

*TypePrecise quick-change mount.ApplicationFor boring mills and drills.

Note:Quick-change sleeves see cat.-no. 21323 and21325.

21321

Size Shank for boreholes L1 L2 D for chuck collet Ø 21321 …MT in steel Ø mm mm mm mm mm

2 3 32 176 82 61 34 1043 4 50 222 104 86 46 1054 5 60 282 133 107 60 106

21321

Morse Taper Chuck Collets

*ApplicationFor quick-change mounts cat.-no. 21321. Formounting tools with morse taper shank and drivetang in compliance with DIN 228 B and adaptersleeves in compliance with DIN 6329 cat.-no. 22711(for tools with straight shank).

21323

for chuck for tools D2 sleeve Ø L1 L2 D1 21323 …size with MT mm mm mm mm

2 1 34 65 22 46 1052 2 34 65 26 46 1062 3 34 65 43 46 1073 1 46 82 23 58 1083 2 46 82 23 58 1093 3 46 82 27 58 110

for chuck for tools D2 sleeve Ø L1 L2 D1 21323 …size with MT mm mm mm mm

3 4 46 82 53 58 1114 2 60 105 26 74 1124 3 60 105 26 74 1134 4 60 105 29 74 1144 5 60 105 68 74 115

21323

High-Performance Three-Jaw Drill Chucks SBF-plus

/TypeDrill chuck with integrated MT shank. Keylessclamping, automatic tightening, high true-runningaccuracy. Optimal stability thanks to a compactdesign.

ApplicationOnly for clockwise operation.

21180

21180

Clamping width Clamping shank D L1 21180 …mm mm mm

1 - 13 MT 2 50 85,0 1011 - 13 MT 3 50 85,0 1021 - 13 MT 4 50 86,5 1031 - 13 Ø 16 50 79,0 1043 - 16 MT 3 56 89,0 1053 - 16 MT 4 56 90,0 106

. Tool Adapters in Compliance with DIN 228

Morse taper shank MT 3 - MT 5 DIN 228 parts 1 shape A with drive tang DIN 2207.

MK l1 d1 G a d2 d3 l2 l3 l4 l5 SW Amm mm mm mm mm mm mm mm mm degrees/minutes/seconds

3 86 23,825 M 12 5,0 19,0 36 5,5 24 12 18 24 1/26/164 109 31,267 M 16 6,5 25,0 43 8,2 32 15 23 32 1/29/155 136 44,399 M 20 6,5 35,7 60 10,0 40 18 28 45 1/30/26

ß Clamping tools

eng/OP www.hhw.de 21.33

2

Tapping Attachments

*TypeWith infinitely adjustable clamping jaws. Built-inretraction 2:1. Adjustable safety friction clutch toprevent tool breakage. Rotation change immediatelyafter an exchange of feed direction.

ApplicationFor cutting internal threads with right-turning tableand column drilling machines.

21408

21408

Shank Cutting range Clamping range Rotational speed D L 21408 …MT shank mm max. rpm mm mm

2 M 3 - M 10 2,5 - 10,0 600 69 158 1023 M 6 - M 16 4,5 - 12,5 400 82 183 1043 M 14 - M 27 11,0 - 22,4 250 105 244 105

Tapping Attachments21410

OTypeWith morse taper shank in compliance with DIN 228B with length compensation in response to tension. ApplicationFor thread cutting with hand drills and manual feedand without spindle reservation. Maintenance-freeand for right- and left-hand threads.

Note:Quick-change sleeves see cat.-no. 21459 - 21460. Tapping heads with further shanks available onrequest.1) Self feed2) Torque support

Size Type for n max. B L L1 D D1 D2 21410 …taps rpm mm mm mm mm mm mm

1 TA 12/MT 2 M 3 - M 12 1200 6 140 60 80 32 19 1021 TA 12/MT 3 M 3 - M 12 1200 6 140 60 80 32 19 1032 TA 20/MT 3 M 8 - M 20 500 8 170 86 100 50 31 104

21410

Tapping Chucks

OTypeDouble chuck, clamps shank and square-end.Adjustable safety friction clutch to prevent toolbreakage. Pendulum action to compensate formisalignments between machine and tool. Elasticlength compensation in response to compressionand tension.Scope of supply:Incl. of wrench.

ApplicationFor cutting internal threads with reversible drills,lathes, and milling machines. Can be mountedhorizontally or vertically.

21406

21406

Shank Ø d □ K Metric Whitworth Whitworth Pendulum Length compensation d1 d2 l l1 21406 …MT mm mm thread thread pipe thread action mm compr./tension mm mm mm mm mm

2 2,5 - 10 0,0 - 8 M 3 - 12 1/8 - 1/2 inch G 1/8 inch 1,0 10/20 53 58 135 18 - 20 1013 2,5 - 10 0,0 - 8 M 3 - 12 1/8 - 1/2 inch G 1/8 inch 1,0 10/20 53 58 135 18 - 20 1023 6,0 - 16 4,7 - 12 M 8 - 20 1/4 - 13/16 inch G 1/8 - 1/2 inch 1,5 10/20 76 83 170 23 - 28 1034 6,0 - 16 4,7 - 12 M 8 - 20 1/4 - 13/16 inch G 1/8 - 1/2 inch 1,5 10/20 76 83 171 23 - 28 1044 11,0 - 23 0,0 - 18 M 14 - 30 9/16 - 1.1/8 inch G 1/4 - 7/8 inch 2,0 10/30 100 106 230 25 - 34 105

Tap Collets21325

21325

for chuck Cutting range D/Z L1 L2 D1 D2 Inserts 21325 …size mm mm mm mm mm size

2 M 3 - M 12 7,5 65 45 36 34 1 1012 M 6 - M 20 12,5 65 69 53 34 2 1023 M 3 - M 12 7,5 82 45 36 46 1 1033 M 6 - M 20 12,5 82 69 53 46 2 1044 M 6 - M 20 12,5 105 69 53 60 2 1064 M 14 - M 33 20,0 105 102 78 60 3 107

*TypeFor mounting quick-change sleeves without frictionclutch (cat.-no. 21459) or with adjustable safetyfriction clutch (cat.-no. 21460). With Length compen-sation in response to compression and tension (D/Z).

ApplicationFor quick-change mounts cat.-no. 21321. For clampingtaps with square drive.

eng/OP

• Collet chucks • Combination milling cutter arbors • Shrinking chucks

www.hhw.de21.34

2

Combination Milling Cutter Arbors21648

TypeMorse taper shank with internal draw-in thread.

ApplicationWith feather key for milling cutters with longitudinalkeyway e.g. DIN 841 and driving ring for millingcutters with transverse slot DIN 1880 and millingheads DIN 1830.

21648

Taper d A l 21648 …MT mm mm mm

3 16 48 17 1013 22 48 19 1023 27 48 21 1034 22 55 19 1064 27 55 21 107

. Toolholders in Compliance with DIN 69893

The different shapes of the hollow shaft taper DIN 69893:

Hollow shaft taper HSK for automatice tool exchange with gripper groove.

Hollow shaft taper HSK for manual tool changing without gripper groove.

Shape A

• For machining centres with automatic tool changing.• Central coolant supply through coolant tube.

Shape B

• For machining centres and turning machines with automatic toolchanging.

• Enlarged contact.• Coolant through flange or central with coolant tube.

Shape C

• Preferred type in transfer lines and special machines with manualtool exchange.

• Central coolant supply.

Shape D

• For applications requiring good support through face rest .• Manual tool exchange.• Enlarged contact.• Coolant through flange or central with coolant tube.

Hollow shaft taper HSK for high rotational speed applications during high speed machining (HSC) with gripper groove.Shape E

• Prefered for high-speed machining.• Symmetric without driver slots.• Central coolant supply possible through coolant tube.

Shape F

• Enlarged contact.• Central coolant supply possible

through coolant tube.

OZ Collet Chucks

TypeMorse taper shank with internal draw-in thread. Withclamping nut.

Note:Collets see cat.-no. 21552 - 21554.

21541

Taper MT / Clamping range for collets l2 d1 21541 …draw-in thread mm Type mm mm

2 / M 10 2 - 16 415 E 62 43 1003 / M 12 2 - 25 462 E 70 60 1014 / M 16 2 - 25 462 E 70 60 1025 / M 20 2 - 25 462 E 65 60 104

21541

TypeAlloyed case-hardened steel, min. tensile strength 950 N/mm2. Taper tolerance less than AT3 in compliance with DIN 7187and DIN 2080. Hardness and depth match the respective mount. In order to avoid breakage or cracks, the thin-walled HSKchucks are not full-hardened.

ß Clamping tools

eng/OP www.hhw.de 21.35

2

Shrinking Chucks

2TypeHighest true-running accuracy and taper toleran-ce. Special heat treatment. Coated for stainlessness. Patented nominal-size

increase allows for an automatic shrinking andfacilitated handling.ApplicationSuitable for clamping carbide, HSS, and steelshanks with a tolerance of h6.

21597 501-532TypeSlim.

21597 101-310

21597 501-532

HSK d1 d2 d3 l1 l2 A V g 21597 …mm mm mm mm mm mm mm

63 3 15 20 20 30 90 5 M 6 10163 4 15 20 20 30 90 5 M 6 10263 5 15 20 25 30 90 5 M 6 10363 6 21 27 36 45 80 10 M 5 10463 8 21 27 36 45 80 10 M 6 10563 10 24 32 42 50 85 10 M 8 x 1 10663 12 24 32 47 50 90 10 M 10 x 1 10763 14 27 34 47 50 90 10 M 10 x 1 10863 16 27 34 50 50 95 10 M 12 x 1 10963 18 33 42 50 57 95 10 M 12 x 1 11063 20 33 42 52 57 100 10 M 16 x 1 11163 25 44 53 58 57 115 10 M 16 x 1 11263 32 44 53 62 57 120 10 M 16 x 1 11363 L 6 21 27 36 45 120 10 M 5 20163 L 8 21 27 36 45 120 10 M 6 20263 L 10 24 32 42 50 120 10 M 8 x 1 20363 L 12 24 32 47 50 120 10 M 10 x 1 20463 L 14 27 34 47 50 120 10 M 10 x 1 20563 L 16 27 34 50 50 120 10 M 12 x 1 20663 L 18 33 42 50 57 120 10 M 12 x 1 20763 L 20 33 42 52 57 120 10 M 16 x 1 20863 XL 6 21 32 36 45 160 10 M 5 30163 XL 8 21 32 36 45 160 10 M 6 30263 XL 10 24 34 42 50 160 10 M 8 x 1 30363 XL 12 24 34 47 50 160 10 M 10 x 1 30463 XL 14 27 42 47 50 160 10 M 10 x 1 30563 XL 16 27 42 50 50 160 10 M 12 x 1 30663 XL 18 33 51 50 57 160 10 M 12 x 1 30763 XL 20 33 51 52 57 160 10 M 16 x 1 30863 XL 25 44 53 58 57 160 10 M 16 x 1 30963 XL 32 44 53 62 57 160 10 M 16 x 1 310

21597

slimHSK d1 d2 d3 l1 NL A V g 21597 ...

mm mm mm mm mm mm mm63 3 9 13 20 40 70 5 M 6 50163 4 10 14 20 40 70 5 M 6 50263 6 12 18 36 60 90 5 M 5 50363 8 14 20 36 60 90 5 M 6 50463 10 16 22 42 60 90 5 M 8 x 1 50563 12 18 24 47 60 90 5 M 10 x 1 50663 16 22 28 50 60 90 5 M 12 x 1 50763 20 27 34 52 70 100 5 M 12 x 1 50863 25 34 41,5 58 75 105 5 M 16 x 1 50963 L 3 9 16 20 70 100 5 M 6 51063 L 4 10 17 20 70 100 5 M 6 51163 L 6 12 21 36 90 120 5 M 5 51263 L 8 14 23 36 90 120 5 M 6 51363 L 10 16 25 42 90 120 5 M 8 x 1 51463 L 12 18 27 47 90 120 5 M 10 x 1 51563 L 16 22 31 50 90 120 5 M 12 x 1 51663 L 20 27 37 52 100 130 5 M 16 x 1 51763 L 25 34 44 58 100 130 5 M 16 x 1 51863 XL 3 9 19 20 100 130 5 M 6 51963 XL 4 10 20 20 100 130 5 M 6 52063 XL 6 12 24 36 120 150 5 M 5 52163 XL 8 14 26 36 120 150 5 M 6 52263 XL 10 16 28 42 120 150 5 M 8 x 1 52363 XL 12 18 30 47 120 150 5 M 10 x 1 52463 XL 16 22 34 50 120 150 5 M 12 x 1 52563 XXL 6 12 27 36 150 180 5 M 5 52663 XXL 8 14 29 36 150 180 5 M 6 52763 XXL 10 16 31 42 150 180 5 M 8 x 1 52863 XXL 12 18 33 47 150 180 5 M 10 x 1 52963 XXL 16 22 37 50 150 180 5 M 12 x 1 53063 XXL 20 27 42 52 150 180 5 M 16 x 1 53163 XXL 25 34 47 58 150 180 5 M 16 x 1 532

HSC HPC

Note:Coolant tube see cat.-no. 21864. Wrench for coolant tube see cat.-no. 21865. Shrinking machines see cat.-no. 21584 - 21595.

patentednominal-size

eng/OP

• Shrinking chucks • Short chucks • Quick-change tapping chucks

www.hhw.de21.36

2

Shrinking Chucks

2TypeHighest true-running accuracy and taper tolerance,manufactured in climatised environment. Advantages: high chucking forces and long servicelife thanks to the usage of high-quality hot workingsteel and special heat treatment. Coated forstainlessness. Patented nominal-size increaseallows for an automatic shrinking and facilitatedhandling.

ApplicationSuitable for clamping carbide, HSS, and steelshanks with a tolerance of h6.

Note:Shrinking machines see cat.-no. 21584 - 21595.

21599 201-223TypeSlim.

21599 101-128

21599 201-223

HSK d1 d2 d3 l1 A V g 21599 ...mm mm mm mm mm mm

40 3 15 20 20 60 5 M 6 10140 4 15 20 20 60 5 M 6 10240 5 15 20 25 60 5 M 6 10340 6 21 27 36 65 – – 10440 8 21 27 36 65 – – 10540 10 24 30 42 65 – – 10640 12 24 30 47 65 – – 10740 14 27 34 47 65 – – 10840 16 27 34 50 65 – – 10940 L 3 15 20 20 80 5 M 6 11040 L 4 15 20 20 80 5 M 6 11140 L 5 15 20 25 80 5 M 6 11240 L 6 21 27 36 80 10 M 5 11340 L 8 21 27 36 80 10 M 6 11440 L 10 24 32 42 80 10 M 8 x 1 11540 L 12 24 32 47 90 10 M 10 x 1 11640 L 14 27 34 47 90 10 M 10 x 1 11840 L 16 27 34 50 90 10 M 12 x 1 11940 XL 3 15 20 20 120 5 M 6 12040 XL 4 15 20 20 120 5 M 6 12140 XL 5 15 20 25 120 5 M 6 12240 XL 6 21 27 36 120 10 M 5 12340 XL 8 21 27 36 120 10 M 6 12440 XL 10 24 32 42 120 10 M 8 x 1 12540 XL 12 24 32 47 120 10 M 10 x 1 12640 XL 14 27 34 47 120 10 M 10 x 1 12740 XL 16 27 34 44 120 10 M 12 x 1 128

slimHSK d1 d2 d3 l1 NL A V g 21599 ...

mm mm mm mm mm mm mm40 3 9 12 20 24 50 5 M 6 20140 4 10 13 20 24 50 5 M 6 20240 6 12 15 34 24 50 – – 20340 6 12 16 36 38 60 – – 20440 8 14 18 36 38 60 – – 20540 10 16 20 42 38 60 – – 20640 12 18 22 42 38 60 – – 20740 L 3 9 13 20 40 64 5 M 6 20840 L 4 10 14 20 40 64 5 M 6 20940 L 6 12 18 36 60 84 5 M 5 21040 L 8 14 20 36 60 84 5 M 6 21140 L 10 16 22 42 60 84 5 M 8 x 1 21240 L 12 18 24 47 60 84 5 M 10 x 1 21340 XL 3 9 16 20 70 94 5 M 6 21440 XL 4 10 17 20 70 94 5 M 6 21540 XL 6 12 21 36 90 114 5 M 5 21640 XL 8 14 23 36 90 114 5 M 6 21740 XL 10 16 25 42 90 114 5 M 8 x 1 21840 XL 12 18 27 47 90 114 5 M 10 x 1 21940 XXL 6 12 24 36 120 144 5 M 5 22040 XXL 8 14 26 36 120 144 5 M 6 22140 XXL 10 16 28 42 120 144 5 M 8 x 1 22240 XXL 12 18 30 47 120 144 5 M 10 x 1 223

21599 HSC HPC

patentednominal-size

ß Clamping tools

eng/OP www.hhw.de 21.37

2

Short Chucks21825

ßTypeVery high precision, working surfaces hardened andground.Scope of supply:Incl. of wrench with T-handle for high power.ApplicationFor clockwise and counterclockwise operation.

HSK Clamping range L D 21825 ...mm mm mm

63 1,5 - 16 110 50 103

21825

Short Chucks 1-16 mm21829

0TypeShort type, wear parts hardened and ground,clamping range 1-16 mm.Scope of supply:Incl. of wrench with T-handle for high power.ApplicationFor clockwise and counterclockwise operation.

Note:Coolant tube see cat.-no. 21864. Wrench for coolant tube see cat.-no. 21865.

HSK Clamping range A D 21829 ...mm mm mm

63 1 - 16 100 50 201

21829

Short Chucks

0TypeShort type, wear parts hardened and ground, hightrue-running accuracy.Scope of supply:Incl. of wrench with T-handle for high power.ApplicationFor clockwise and counterclockwise operation.

Note:Coolant tube see cat.-no. 21864. Wrench for coolant tube see cat.-no. 21865.

21835

HSK Clamping range D L L1 max. weight 21835 ...mm mm mm mm kg

63 0,5 - 13 50 104 110 1,7 10163 2,5 - 16 57 109 115 1,9 102

21835

Quick-change Tapping Chucks

ßTypeType WFLC. Precision version with length compen-sation in response to compression and tension.

Note:Quick-change sleeves see cat.-no. 21459 - 21463. Coolant tube see cat.-no. 21864. Wrench for coolant tube see cat.-no. 21865.

21838

HSK for taps Suitable Length compensation L D Ø D2 Ø 21838 …drill inserts/size compr./tension mm mm mm mm

63 M 3 - M 12 1 7,5/7,5 72 41 19 10163 M 6 - M 20 2 10/10 110 60 31 102

21838

Performance requires quality.www.atorn.com

ATORN‘s taps:

ATORN‘s high-quality drilling tools.

eng/OP

• Expansion chucks • Arbors • Collet chucks

www.hhw.de21.38

2

Hydro expansion Chucks short, slim

0TypeHigh true-running accuracy and torque transmissi-on. Low maintenance thanks to enclosed clampingsystem. Material 1600 - 1800 N/mm2 tensilestrength, hardened (52+2 HRC). Max. coolantpressure 80 bar, axial length adjustment 10 mm.Advantages: anti-vibration clamping, increase oftool life, reduction of micro breaks of the tool cuttingedge, easy handling, high positioning and repetitionaccuracy, flexible thanks to the usage of reductionsleeves.

Scope of supply:Incl. of hexagon T-handle wrench.ApplicationFor drilling, reaming, and milling.

Note:Also suitable for clamping of Weldon and Whistle-Notch shanks.Reduction sleeves see cat.-no. 21581. Cylinder cleaner see cat.-no. 22956. Coolant tube see cat.-no. 21864. Wrench for coolant tube see cat.-no. 21865.

21840

HSK d1 d2 d3 l1 l2 l3 l4 g 21840 …mm mm mm mm mm mm mm

63 6 26 50 70 37 10 24 M 5 09463 8 28 50 70 37 10 24 M 6 09563 10 30 50 80 41 10 32 M 8 x 1 09663 12 32 50 85 46 10 40 M 10 x 1 09763 14 34 50 85 46 10 40 M 10 x 1 09863 16 38 50 90 49 10 46 M 12 x 1 09963 18 40 50 90 49 10 46 M 12 x 1 10063 20 42 50 90 51 10 48 M 16 x 1 10163 25 57 53 120 57 10 63 M 16 x 1 10263 32 63 53 125 61 10 61 M 16 x 1 103

21840 HSC

Arbors for Milling Cutters with Draw-in thread

ßTypePrecision version. External taper and fit ground.ApplicationFor mounting screw-in milling cutters with thread.

Note:Coolant tube see cat.-no. 21864. Wrench for coolant tube see cat.-no. 21865.

21841 110

21841 111

21841 113

HSK d1 d2 D A L M 21841 ...mm mm mm mm mm

63 6,5 10 13 51 25 6 10163 8,5 13 15 51 25 8 10263 L 8,5 13 23 76 50 8 10363 XL 8,5 13 23 101 75 8 10463 10,5 18 20 51 25 10 10563 L 10,5 18 23 76 50 10 10663 XL 10,5 18 32 126 100 10 10763 XXL 10,5 18 36,5 176 150 10 10863 12,5 21 24 51 25 12 10963 L 12,5 21 24 76 50 12 11063 XL 12,5 21 31 101 75 12 11163 XXL 12,5 21 33 126 100 12 11263 XXXL 12,5 21 40 176 150 12 11363 17 29 29 51 25 16 11463 L 17 29 34 76 50 16 11563 XL 17 29 34 101 75 16 11663 XXL 17 29 36 126 100 16 11763 XXXL 17 29 42,5 176 150 16 118

21841 HSC

Performance requires quality.www.atorn.com

Roughing end milling cutter by ATORN:

ATORN‘s high-quality milling tools.

ß Clamping tools

eng/OP www.hhw.de 21.39

2

ER Collet Chucks

0TypePrecision version. High true-running accuracy.ApplicationFor clamping tools with straight shank in collets DIN 6499-shape A and B.

Note:Collet sets see cat.-no. 21519. Collets see cat.-no. 21520 - 21525 and 21534 -21539. Coolant tube see cat.-no. 21864. Wrench for coolant tube see cat.-no. 21865.

21843 301

21843

HSK - ER Clamping range A D Ø 21843 …mm mm mm

63 - 16 1 - 10 100 32 30163 L - 16 1 - 10 160 32 302

63 - 25 2 - 16 100 42 30363 L - 25 2 - 16 160 42 304

63 - 32 2 - 20 100 50 30563 L - 32 2 - 20 160 50 306

63 - 40 3 - 26 120 63 30763 L - 40 3 - 26 160 63 308

ER Collet Chucks slim

ßTypeClamping nut fine balanced for HSC, ER11 through-hole core-drilled, after the hardening, the shank wasturned once more. With Balluf-Chip borehole.ApplicationFor clamping tools with straight shank in collets DIN6499-shape A and B.

Note:Collet sets see cat.-no. 21519. Collets see cat.-no. 21520 - 21525 and 21534 -21539. Coolant tube see cat.-no. 21864. Wrench forcoolant tube see cat.-no. 21865.

21845

HSK - ER Clamping range A D Ø 21845 ...mm mm mm

63 L - 11 1 - 7 100 16 10163 XL - 11 1 - 7 160 16 102

63 L - 16 1 - 10 100 22 10363 XL - 16 1 - 10 160 22 104

63 L - 25 1 - 16 100 35 10563 XL - 25 1 - 16 160 35 106

21845 HSC

Collet Chucks Centro P Mini

*TypeExtremely slim design, external and internal taperground. Concentricity and repeatability 0,003 mm(with GER-HP collets). Concentricity and repeatabili-ty 0,006 mm (with GER collets). Clamping nut notincluded.ApplicationFor high-precision clamping of tools with straightshank, without concentricity and clamping forceloss, up to shank tolerance h10.

Note:Collets with square drive are not suitable for taps.Clamping nuts and wrench see cat.-no. 21509.GER-HP collets see cat.-no. 21546. GER collets seecat.-no. 21534. Coolant tube see cat.-no. 21864.Wrench for coolant tube see cat.-no. 21865.

21844

HSK Size Clamping range Collets Dimension D Dimension A Insertion depth E 21844 ...mm Type mm mm mm

63 CP 11 M 1 - 7 ER 11/4008 E 16 100 68 10163 CP 11 M 1 - 7 ER 11/4008 E 16 160 68 102

21844 HSC HPC

Performance requires quality.www.atorn.com

Burrs by ATORN:

ATORN‘s high-quality grinding and cutting tools.

eng/OP

• Collet chucks • Taper sleeves • Milling cutter mounts

www.hhw.de21.40

2

Collet Chucks Centro P