JOINT JST-NSF WORKSHOP ON SUSTAINABILITY FOR … · joint jst-nsf workshop on sustainability for...

Transcript of JOINT JST-NSF WORKSHOP ON SUSTAINABILITY FOR … · joint jst-nsf workshop on sustainability for...

JOINT JS

T-NSF WORKSHOP ON SUSTAINABILITY

FOR SYNTHESIS

(持続可能社会を目指す素材生産の革新)

平成18年3月

JST/CRDS

CRDS-FY2005-WR-13

JOINT JST-NSF WORKSHOP ON SUSTAINABILITY FOR SYNTHESIS

JST-NSFジョイントワークショップ持続可能社会を目指す素材生産の革新

Center for Research and Development Strategy Japan Science and Technology Agency

独立行政法人科学技術振興機構 研究開発戦略センター

2005年12月13日、14日 開催

-i-

Executive Summary 物質生産のあらゆる製造プロセスを環境低負荷型にする努力が行われており、これをグ

リーン化と表現する。できあがった製造法はグリーンプロセスであり、化学技術がその主

柱である場合を、グリーンケミストリーと呼ぶ。本ワークショップはこの課題についての

日米共同作業であり、日本のJST(科学技術振興機構)米国のNSF(全米科学財団)と

の共同主催で、2005年12月13日から14日まで、米国ハワイ州ホノルル市で行われた。

講演と討論を繰り返す形式で行われた。日本側の主張の特色は、既に従来からプロセス

のグリーン化の努力がなされており、特に1970年代の「公害」問題を生かした技術が多

く今日も生きているというものであった。米国の主張の特色は、ある物質を製造するとき

に現行法を改良するのではなく、根本的に新しい別ルートで生産する道を探ろうというも

のであった。これらの中で、反応装置、反応系、分離法はまだまだ未踏技術が多く、多く

の研究者の幅広い努力が必要な分野であることがわかった。

以下に、本ワークショップから得られた今後推進すべきテーマを例示する。

①触媒化学とプロセス化学の融合

②反応媒体の統一的検討

③安全プロセスの開拓

④バイオマス

-ii-

目 次[1]開催概要 ···················································································································· 1

1.1 開催主旨 ················································································································ 1

1.2 概要 ······················································································································· 1

1.3 参加者 ··················································································································· 2

1.4 プログラム ············································································································ 4

[2]討議の内容 ················································································································· 6

2.1 ワークショップの構成 ·································································································6

2.2 討論内容 ························································································································6

2.3 21世紀におけるGSC(グリーン&サステイナビリティー・ケミストリー) ·······7

(1)多元的化学研究推進とインタラクション ································································7

(2)社会との協調 ··············································································································7

[3]ワークショップの総括と提案 ···················································································· 9

3.1 プレゼンテーションのまとめ ······················································································9

3.2 ワークショップの総括 ·································································································9

3.3 ワークショップからの研究課題提案 ·······································································10

①触媒化学とプロセス化学の融合 ··················································································10

②反応媒体の統一的検討 ·································································································10

③安全プロセスの開拓 ·····································································································10

④バイオマス ·····················································································································10

[4]各講演の要旨 (参加者の詳細は「1.3参加者」に記述) ······································· 12

4.1 Kenneth M. Doxsee (U. of Oregon) ························································ 12

4.2 Yasuhiro Uozumi (魚住泰広・分子研) ························································ 16

4.3 Robin Rogers (U. of Alabama) ································································· 20

4.4 Edward Grabowski (Merck) ······································································· 24

4.5 Isaburo Fukawa (府川伊三郎・旭化成) ······················································· 27

4.6 Naoto Chatani (茶谷直人・阪大工) ···························································· 31

4.7 Tomislav Rovis (Colorado State U.) ······················································· 36

4.8 Kazuaki Ishihara (石原一彰・名大工) ························································· 41

4.9 Yoshiro Furukawa (古川喜朗・ダイソー) ··················································· 43

4.10 Ingrid Meier (Air Products & Chemicals) ············································ 46

4.11 Eric Beckman (U. of Pittsburgh) ·························································· 50

4.12 Jun-ichi Yoshida (吉田潤一・京大工) ····················································· 55

-iii-

4.13 Laura Babcock (Nature Works, LLC) ··················································· 58

4.14 Yoshihiko Yasohara (八十原良彦・カネカ) ············································ 63

4.15 Dawn Brooks (Eli Lilly) ············································································ 67

4.16 Shin Tatematsu (立松伸・旭硝子) ·························································· 70

4.17 Marvin Yu (Fluorous Technologies) ····················································· 73

4.18 Toshio Hayashi (林利生・日本触媒) ························································ 77

4.19 Marie Kraff t (Florida State U.) ······························································· 79

4.20 Takashi Tatsumi (辰巳敬・東工大資源研) ·············································· 84

4.21 Terrence Collins (Carnegie Mellon U.) ················································ 89

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-1-

[1]開催概要

1.1 開催主旨

研究開発センターでは、研究開発戦略を立案のための効果的な活動として、適切なテー

マを設定し学会等の活動と連携した戦略ワークショップの開催を行い、最新の研究開発の

動向を調査している。この一環として、JSTと米国NSFとの共催でグリーンケミストリー

についてのワークショップを実施した。日米の最新の研究開発の動向を把握し、今後の研

究開発戦略の立案に役立てることを目的とする。

化学および化学産業が未来世代のために良好な地球環境を確保しつつ、現在世代の持続

的発展に貢献するためには、「環境にやさしい化学合成」「あぶない物質をださない化学合

成」の確立は不可欠である。本ワークショップにおいて、日米両国の第一線研究者、とく

にこれらの課題に主導的役割を担う合成化学・プロセス化学の専門家、及び日米双方の

ファンディング担当者が一堂に会して議論することは極めて有意義であり、問題点の究明

と今後の指針について討議を行い、今後の研究開発戦略に資することを目指す。

1.2 概要

1)コーディネータ

大寺純蔵、 (Prof. Junzo Otera)

岡山理科大学 応用化学科 教授

Prof. Dennis P. Curran,

University of Pittsburgh

2)開催日

2005年 12月13日~14日

3)開催場所

Sheraton Waikiki Hotel (Honolulu Room)

4)参加者

25名 (JSTから2名、NSFから1名を含む)

5)開催方式

クローズド・ディスカッション方式

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-2-

1.3 参加者

Japan US

Junzo Otera (大寺純蔵)Okayama University of Science, Department of Applied Chemistry1-1 Ridai-cho, Okayama 700-0005, [email protected]

Dennis P. Curran, University of Pittsburgh,Faculty of Arts and SciencePittsburgh, Pennsylvania 15260, [email protected]

Naoto Chatani (茶谷直人)Osaka UniversityDepartment of Applied ChemistryFaculty of EngineeringSuita, Osaka 565-0871, [email protected]

Laura BabcockNatureWorks, LLCMinnetonka, MN [email protected]

Isaburo Fukawa (府川伊三郎)Asahi Kasei Chemicals1-2 Yuraku-cho 1-chomeChiyoda-kuTokyo, [email protected]

Eric BeckmanUniversity of Pittsburgh1140 Benedum Engineering HallPittsburgh, PA [email protected]

Yoshiro Furukawa (古川喜朗)Daiso Co., Ltd.Research Laboratories9 Otakasu-cho, AmagasakiHyogo 660-0842, [email protected]

Dawn BrooksEli Lilly Co.Indianapolis, IN 46285BrooksšDawnš[email protected]

Toshio Hayashi (林 利生)Nippon Shokubai Co., Ltd.5-8 Nishi Otabi-cho, SuitaOsaka 564-8512, [email protected]

Terrence CollinsCarnegie Mellon UniversityDept. of Chemistry, Pittsburgh, [email protected]

Kazuaki Ishihara (石原一彰)Nagoya UniversityDept. of BiotechnologyGrad. Sch. of EngineeringNagoya 464-8603 [email protected]

Edward GrabowskiMerck & Co., Inc. (Retired)[email protected]

Takashi Tatsumi (辰巳 敬)Tokyo Inst. of Technology2-12-1 Ookayama, Meguro-kuTokyo 152-8550 [email protected]

Marie Kraff tFlorida State UniversityDept. of ChemistryTallahassee, FL [email protected]

-3-

Yasuhiro Uozumi (魚住泰広)Institute for Molecular ScienceHigashiyama 5-1, Okazaki 444-8787 [email protected]

Ingrid MeierAir Products & Chemicals, Inc.Allentown, PA [email protected]

Shin Tatematsu (立松 伸)Asahi Glass Co., Ltd1-12-1, Yurakucho, Chiyoda-kuTokyo 100-8405, [email protected]

Robin RogersUniversity of AlabamaDepartment of ChemistryTuscaloosa, AL [email protected]

Yoshihiko Yasohara (八十原良彦)Kaneka Corp.Fine Chemical Res. Lab.1-8 Miyamae-machi, Takasago-choTakasago 676-8688, [email protected]

Tomislav RovisColorado State UniversityDept. of ChemistryFort Collins, CO [email protected]

Jun-ichi Yoshida (吉田潤一)Kyoto UniversityDept. of Synthetic Chem. & Biological Chem.Graduate School of EngineeringNishikyo-ku, Kyoto 615-8510, [email protected]

Marvin YuFluorous Technologies, Inc.970 Wm Pitt WayPittsburgh, PA 15128m.yu@fl uorous.com

Shinji Murai (村井眞二)Japan Science and Technology AgencyKojimachi Square Bldg.3, Nibanncho Chiyoda-kuTokyo 102-0084, [email protected]

Kenneth M. DoxseeProgram Offi cer, Organic and Macromolecular Chemistry ProgramNational Science FoundationUniversity of Oregon, Dept. of ChemistryEugene, Oregon [email protected]; [email protected]

Tomohiro Nakayama (中山智弘)Japan Science and Technology AgencyKojimachi Square Bldg.3, Nibanncho Chiyoda-kuTokyo 102-0084, [email protected]

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-4-

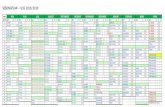

1.4 プログラム

Tuesday, December 13, 20058:10 - 8:50 AM Kenneth M. Doxsee

“Identifying Achievable Research Objectives in Green Chemistry”(グリーンケミストリーにおける達成すべき研究課題の見極め)

8:50 - 9:30 AM Yasuhiro Uozumi“Aquacatalysis with Polymeric Palladium Complexes toward Ideal Organic Synthesis”(理想的有機合成のための水中での高分子パラジウム触媒)

10:00 - 10:40 AM Robin Rogers“Green (or Not) Ionic Liquids to Access Biorenewable Polymer Materials”(生物的に再生可能な高分子を得るためのグリーンなイオン性液体)

10:40 - 11:20 AM Edward Grabowski“Process Research & Green Chemistry: A Natural Partnership”(プロセス研究とグリーンケミストリー:当然のパートナー)

11:20 - 11:50 AM Isaburo Fukawa“Development of Sustainable Technology in Asahi-Kasei”(旭化成におけるサステイナビリティーテクノロジーの開発)

1:00 - 1:40 PM Naoto Chatani“Skeletal Reorganization of Enynes”(エンイン化合物の骨核変換反応)

1:40 - 2:20 PM Tomislav Rovis“Reversing Aldehyde Reactivity in Asymmetric Catalysis using Chiral Nucleophilic Carbenes”(不斉求核的カルベンを用いる不斉触媒におけるアルデヒドの反応性の逆転)

2:20 - 3:00 PM Kazuaki Ishihara“Design of Dehydrative Ester Condensation Catalysts”(エステルの脱水縮合触媒の設計)

3:30 - 4:10 PM Yoshiro Furukawa“Practical Synthesis of Fine Chemicals Using Catalysts and Enzymes”(触媒と酵素を用いるファインケミカルズの実際的合成法)

4:10 - 4:50 PM Ingrid Meier“Sustainable Chemical Synthesis Within the US Specialty Chemicals Industry”(米国のスペシャリティー化学品業界における持続可能性を目指す化学合成)

4:50 - 5:30 PM Eric Beckman“Green Chemical Product Design: The Need For Collaboration Between Chemistry and Engineering”(化学製品をグリーンにデザインする:化学と工学との共同作業の必要性)

-5-

Wednesday, December 14, 20058:10 - 8:50 AM Jun-ichi Yoshida

“Sustainable Chemical Synthesis through Microreactors”(マイクロ反応装置を用いるサステイナビリティ化学合成)

8:50 - 9:30 AM Laura Babcock“Polylactic Acid - The Challenges of Developing Functional, Sustainable Materials”(ポリ酪酸持続可能な機能性物質開発への挑戦)

10:00 - 10:40 AM Yoshihiko Yasohara“Biocatalytic Reduction System for the Production of Chiral Compounds”(不斉化合物製造のための生化学的触媒系)

10:40 - 11:20 AM Dawn Brooks“Evolution Toward Simplicity: Green Chemistry in the Process Development of a Selective PPAR-Agonist”(単純化のための革新:選択的PPAR-アゴニスト生成プロセスでのグリーンケミストリー)

11:20 - 12:00 AM Shin Tatematsu“Greener Process and Products Developed by Asahi Glass”(旭硝子㈱におけるグリーンプロセスと製品開発)

1:00 - 1:40 PM Marvin Yu“Solvent Tuning for Fluorous Biphasic Reactions”(フローラスな2層反応系における溶膜の選択)

1:40 - 2:20 PM Toshio Hayashi“Selective Oxidation Over Supported Nano Gold Catalyst”(担持ナノ金触媒での選択的酸化)

2:20 - 3:00 PM Marie Kraff t“New Life for the Morita-Baylis-Hillman Reaction”(モリタ-ベイリス-ヒルマン反応の新展開)

3:30 - 4:10 PM Takashi Tatsumi“Novel Large Space Zeolite Catalysts Extremely Active in the Oxidation with H2O2 as a Green Oxidant”(グリーンな酸化剤の過酸化水素による酸化における高活性新しい大空間ゼオライト触媒)

4:10 - 4:50 PM Terrence Collins“Designing Green Catalytic Oxidation Processes”(グリーンな触媒的酸化プロセスの設計)

4:50 - 5:20 PM Conclusions and Closing Remarks(終りに)

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-6-

[2]討議の内容

開催主旨にて既述のように、人類文化の持続的発展への鍵は「原理的にゴミを産出しな

い技術」であり、必然的に物質変換(加工・成形・組み立てではなく)を司る化学変換プ

ロセスの刷新に焦点をあてることとした。すなわちグリーン&サステイナビリティー・ケ

ミストリー(GSC)領域を核とした議論が展開された。

2.1 ワークショップの構成

日本からはGSC文部科学大臣賞受賞者2名、環境ナノ触媒CREST代表者2名、NEDO

マイクロリアクター研究代表者1名に加え、産業界からも実績と力量を兼ね備えた企業研

究者5名の研究報告と将来展望、およびGSCへの取り組み姿勢が示され、極めて高レベ

ルの話題提供と議論がなされた。米国からはGSCを志向する大学研究者4名(ゴードン

カンファレンス・グリーンケミストリー幹事を含む)に加え大手企業2名、ベンチャー企

業4名の参加を得ることができ、各々話題提供と活発な討論が行われた。

2.2 討論内容

日米双方の大学の研究者から、GSCを目指した新方法論の開発に関する最新動向につ

いての紹介があった。それらを概観すると以下の3点に集約される。

①GSC触媒反応開発(リサイクル、無害、原子効率)

②新反応メディア(省資源、無害)

③装置・システム(省エネルギー、安全)

日米双方の一線級研究者が一致してこれら3点を挙げるということは、これらに関する

新方法論を提案することに関する重要性の認識は、正しいものと考えられる。

一方産業界からは、GSCプロセスの実践例を主とする講演と、GSCプロセスを標榜す

る各社のコンセプトや、取り組みの方向性及び将来展望が示された。またベンチャー企業

からは、GSCプロセスに貢献する独自のノウハウや手法が紹介された。日本の全ての企

業からの講演、ならびに米国メルク社による最新実践例の紹介に見られたように、現在な

されているGSCに関する概念の提唱よりも早い段階から効率と採算性を極限まで追究し、

その過程で必然的に高度な環境調和性(Chemical Greenness)を達成した成功例が数

多くあった。基礎化学・化学技術のイノベーションが、環境調和性および企業採算性と矛

盾なく本質的に合致することが強く示唆されたと考える。

日本の企業研究の息の長さと、プロセスの独自性ならびに完成度の高さに驚きと称賛の

意見も多く寄せられた。一方、幾つかの米国企業の研究では、研究開発の期間が比較的短

いため、新手法開発よりも既存の方法論の中から最適のものを選ぶ傾向が強いことも示さ

れた。そこでは従来の採算性や効率性という開発指標に、「サステイナビリティー」とい

う指標が加わっただけで、最終プロセスにいたるアルゴリズムは変わっていない。言い換

-7-

えれば、官学の研究者がGSCの新手法を「選択肢」として提示しておくことこそが重要

である。

誤解を恐れずに論じるならば、企業では「効率性・採算性を重視するイノベーション」、

大学では「方法論として挑戦すべき新しいハードル(=基礎的イノベーション)」として

GSCを捉えている。両者の一層の協調が、真に完成された次世代GSCプロセスの完成を

促すことは自明であろう。

2.3 21世紀におけるGSC(グリーン&サステイナビリティー・ケミストリー)

(1)多元的化学研究推進とインタラクション

今回のワークショップでも示された我が国の幾つかの化学プロセスの成功例において

は、採算性と環境調和性がともに高度に達成されているが、それらは長期に亘る基礎研究

や改良研究の果実そのものである。「サステイナビリティー」が強く求められる21世紀に

おいては、一部の研究者の「ガンバリ」や「良心」に期待するのみではなく、GSC研究

を促進する枠組み作りが急務であろう。そのためには、GSC研究の土台となる基礎科学

研究に加えて、基礎合成化学研究-実践合成プロセス研究、新物質開発(シーズ)-新材料

開発(ニーズ)、化学反応研究-反応装置開発、触媒開発研究-新反応媒体研究、精密合成

研究-材料開発、さらには安全性専門家、エンジニア(新たな媒体や装置に対応)、分析化

学者などの異分野化学者間のインタラクティブな協力体制が不可欠である。このような多

様な組み合わせからなるインタラクティブな連携は、各々の領域の研究者個人が連絡を取

り合うだけでは成立しにくい。各研究成果、シーズ、ニーズ、またそれらの安全性確認な

どを議論できる「インタラクティブ・ショーケース」的な枠組みが望まれる。すなわち、

GSCを目指した基礎、応用、装置、評価等の個別領域や個別研究課題を強力に推進しつ

つ、その成果を共有できる融合拠点を形成し、世界標準の確立に日本が主導的役割を果た

すことが重要であろう。

(2)社会との協調

2日間の討論に加え個別に持たれた情報交換や議論では、GSCは単なる「化学研究上

の挑戦課題」や「効率性、採算性の新ファクター」に留まらず、より根元的に社会全体で

理解し取り組んで行かねばならない、大きな命題であるという共通認識があると感じられ

た。1gの新薬によって一人の命を救うには、時には1kgの「ゴミ」を産み出すこともあ

る。そのゴミを産み出している根源は化学産業ではなく消費者である。すなわち、人類社

会の活動そのものが化学ゴミを産出する根源であるということを再確認し、人類社会全体

や各個人が地球環境への責任を認識することが重要である。現在の文化レベル・生活レベ

ルを損なうことなく発展を持続させ、しかも未来世代に良好な地球環境を残していくため

には、GSC研究の推進が不可欠であることを共通理解とする必要がある。すなわち、社

会がST(サステイナビリティー・テクノロジー)やGSCに必要なコストを払うという自

覚と意識を醸成することが必要となる。そのためには、各種啓蒙活動、報道、教育などを

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-8-

通じた積極的な共通理解の土壌育成が、実際のGSC研究とともに車の両輪として推進さ

れるべきであろう。

研究開発効率の重視により十分な取り組みがなされにくい企業研究におけるGSC研究

の奨励、大学基礎研究を中心としたGSC指向の新方法論開発研究の推進、教育・報道・

PRなどの社会活動 の三位一体の枠組み作りも視野に入れるべきではなかろうか。

-9-

[3]ワークショップの総括と提案

3.1 プレゼンテーションのまとめ

本ワークショップにおけるプレゼンテーションは、大きくは以下のようにまとめること

ができる。

①触媒

固定化:リサイクル触媒への展開(魚住)

ナノ触媒設計:触媒機能の精密化(林、辰巳)

有機触媒:有害触媒の代替(Rovis、石原)

バイオ触媒:有害触媒の代替(古川、八十原)

②反応媒体

水:有機溶媒の代替(魚住)

イオン性流体:有機溶媒の代替(Rogers)

フルオラス媒体:有機溶媒の代替(Yu)

③プロセス設計

マイクロリアクター:低エネルギープロセス(吉田、立松)

原子効率:省資源(Grabowski、茶谷、Kraft)

安全プロセス:非毒性原料への転換(府川)

④環境負荷低減

バイオマス:ポリ乳酸(Babcok)

環境浄化:金属錯体による廃棄物浄化(Collins)

プロセス評価・データベース:コンピューターの活用

(Meier, Beckman、Brooks)

3.2 ワークショップの総括

環境問題はその包含する領域が多岐にわたるため、ある専門分野では常識的な事項が他

分野では全く知られていないというような事態がしばしば見受けられる。たとえば無機錯

体の専門家の用いる配位子が発癌可能性原料を使用している、あるいはコンピューターに

よる評価が現場では実際に役に立ちそうもない形になっているなどの例が見られた。環境

化学を効率的に発展させるためには異なる専門分野を多次元的に融合し、初期の段階か

ら、お互いの情報のフィードバックを繰り返しながら研究を推進する必要がある。

同様のことが主要化学工業の一つである有機化学品製造プロセスについても認められ、

お互いの専門分野が近くてコミュニケーションギャップが少ないと思われる実験室での合

成化学者と製造プロセスでの化学者の間ですら、完全に相互理解が得られているとは言い

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-10-

難い。通常は、実験室で合成ルートを確立したのち、プロセス化学者が製造プロセスへの

応用を検討するという二段構えの開発過程が採用される。当然、後段での検討により、実

験室での結果の全面的見直しという事態が発生することもある。この様な迂遠な手法をあ

らため、実験室レベルと製造プロセスレベルの研究者がプロジェクト立案の段階から協力

することが、開発を効率的にするのみならず真に環境化学的に有効なプロセスの創出に必

要である。以下この問題に焦点を絞って研究課題を提言する。

3.3 ワークショップからの研究課題提案

①触媒化学とプロセス化学の融合

新規触媒の開発はこれまでと同様にあるいはより一層その重要性を増すであろう。一方、

これらの触媒は環境化学的見地から持続可能なプロセスに適用可能であることが必須であ

る。たとえば、医薬品やファインケミカル製造の最終工程に遷移金属触媒を用いると、そ

の残渣の除去に反応工程自体の数倍のエネルギーと労力を費やすことになる。今後、この

様なプロセス化学を踏まえた視座からの触媒開拓研究が必要となろう。(魚住:触媒固定

化;Rovis、石原:有機触媒)

②反応媒体の統一的検討

有機溶媒の大量使用は化学品製造プロセスの一大弱点である。この問題の解決法として

種々の新規反応媒体が提案されているがそれぞれの長所・短所についての統一的な評価が

なされていない。各種媒体を包括的に比較検討し、最適化のための指針を確立することが

必要である。さらに無溶媒反応のプロセス化も重要な検討課題である。(魚住、Rogers、

Yu)

③安全プロセスの開拓

化学工業は重大な事故を幾度となく繰り返してきた。これまでの事故は現場におけるエ

ンジニアリングの問題として扱われがちであったが、根元的には、原料、反応剤、溶媒、

触媒などを含む反応プロセスに起因するものである。ややもするとプロセス化学は単なる

スケールアップの技術でありそこにサイエンスはないものとして基礎研究部門では軽んじ

られてきた。今後は、一部製薬会社等ですでに行われているように、反応設計の初期段階

から、化学工学専門家を含むすべての研究開発関係者が協調して安全プロセス開発に取り

組むシステム構築のためのノウハウを国レベルで確立することが肝要である。(吉田:マ

イクロリアクター;府川:ホスゲンから二酸化炭素への原料転換)

④バイオマス

化石資源の枯渇、および価格の高騰は深刻な問題であり、バイオマスへの転換が叫ばれ

て久しい。米国でのポリ乳酸の開発、ブラジルでのエタノール自動車エンジンの使用など

外国では限定的ではあるがバイオマス技術は着実に根付きつつある。一方、我が国では関

-11-

連する研究に進展が殆どみられず事実上停滞している。この際、先行諸国に追いつき世界

のトップに立つことが今からでも可能かどうか、真剣に再検討することが急務である。

(Babcock)

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-12-

[4]各講演の要旨

4.1 Kenneth M. Doxsee

Identifying Achievable Research Objectives in Green Chemistry

Kenneth M. DoxseeDepartment of Chemistry

University of OregonEugene, OR 97403

National Science Foundation4201 Wilson Boulevard

Arlington, VA [email protected]

As Green Chemistry moves beyond the stages of initial recognition and early development, there is a need for the definition of both broadlydefined and specific research priorities and agendas. When establishing achievable research objectives, it is important to recognize thatidentifying goals does not necessarily help us to identify what is needed to achieve them. Disagreement about relative merits of various goals canfurther erode the impact of such analyses.

The complexity of Green chemical issues – chemical, environmental, economic, legal, societal – is daunting, and we run the risk of writing offpotentially significant approaches because of unanswered questions regarding health and environmental hazards or other issues. It is important not to close the doors on new aspirants to the field, recognizing that unanswered questions are indicators of essential research objectives. As we raisethese questions, we should appreciate that we don’t have to know the answers in order to ask questions.

By considering a set of technologies, including those generally recognized as highlighting “green” principles – e.g., renewable feedstocks, ionicliquids – and those clearly needing to be made greener – e.g., dyes and pigments – we can begin identifying both global goals and well-definedresearch problems. By bringing our green knowledge to these various technologies, we can both define an achievable research agenda and,hopefully, avoid making serious mistakes due to unforeseen health or environmental impacts.

Identification of Research Priorities

CRITICAL BUILDING BLOCKS AND TOOLS FOR SUSTAINABILITY IN THE CHEMICAL INDUSTRY:Identifying an Agenda for National Research

A WORKSHOPMonday and Tuesday, February 7-8, 2005

-13-

Disagreements Highlight Research Questions & Needs

• Identification of a problem.• Proposal of a solution to the problem.• Recognizing the complexity of Green Chemistry, raise

objections to the proposed solution, which is “not reallygreen.”

• Interpret the objections in terms of research objectives that need to be addressed – achievable researchobjectives.

Evolution of Green Chemistry

Some General Observations

We don’t have to know the answer in order to ask the question.

Chemistry alone may not be able to answer the question.

We might make mistakes. How can we minimize them while atthe same time make progress?

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-14-

Definable Research Objectives:Renewable Feedstocks

Develop ways to enhance crop yields without use of conventional fertilizers

Localizable fertilizer technologies?Genetic engineering?

Economic analysis Qty. of corn(bu/acre)

Qty. of fertilizer(lbs/acre)

Qty. of labor(hrs/acre)

Qty. of herbicide(liters/acre)

runoff costs addedto farmer’s cost

slope= (Pf+runoff)/Pcslope= Pf/Pc slope= -(Ph+runoff/Pl)

slope= -Ph/Pl

http://www.agecon.purdue.edu/academic/agec340/week9.ppt

Definable Research Objectives:Ionic Liquids

Biological activity?

Environmental mobility and fate?

Product isolation without need for conventional solvents?

Ionic liquid recovery, purification, reuse?

Jastorff, B., Störmann, R., Ranke, J., Mölter, K., Stock, F., Oberheitmann, B.,Hoffmann, W., Hoffmann, J., Nüchter, M., Ondruschka, B. and Filser, J.:How sustainable are ionic liquids? Structure-activity relationships andbiological testing as important elements for sustainability evaluation. GreenChem. 2003, 5, 136-142.

-15-

Definable Research Objectives:Nanomaterials

Biological activity / bioaccumulation?

Environmental mobility and fate?

Heavy metal leaching?

Green synthesis and processing?

Definable Research Objectives:Dyes and Pigments

Safer dyes and pigments?

Safer technologies for dyeing?

Analysis of outsourcing technologies?

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-16-

Aquacatalysis with Polymeric Palladium Complexestoward Ideal Organic Synthesis

UOZUMI, Yasuhiro @ Institute for Molecular Science

We have recently developed palladium and rhodium complexes of amphiphilicpolystyrene-poly(ethylene glycol) (PS-PEG) resin-supported phosphine ligands whichpromote various catalytic transformations smoothly in water under heterogeneousconditions. The palladium-catalyzed -allylic substitution, carbonylation, Heck reaction,Suzuki-Miyaura coupling, Sonogashira coupling, cycloisomerization, and rhodium-catalyzed alkyne-cyclotrimerization, hydroformylation, and Michael addition arerepresentatives where the advantages of both aqueous- and heterogeneous-switchingwere combined in one system to achieve high level of chemical greenness. A fullyenvironmentally benign multi-step asymmetric organic synthesis of a hydrindaneframework was achieved in water under mild conditions with recyclable polymericcatalysts to represent what may be considered an ideal chemical process. Thus, ahydrindane framework was prepared via palladium-catalyzed asymmetric -allylicalkylation, propargylation, and cycloisomerization of 1,6-enynes, where all three stepswere performed in water with recyclable polymeric catalysts.

UOZUMI, 1997-2005

4.2 Yasuhiro Uozumi (魚住泰広)

-17-

Polymeric Phosphine Ligands

Amphiphilic Resin-Dispersion of Nano-Pd

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-23-

2005 Presidential Green Chemistry Challenge Award (Academic)(A Platform Strategy Using Ionic Liquids to Dissolve and Process

Cellulose for Advanced New Materials)

The Next StepsThe Next Steps……..

BASF takes out exclusive license for use of ionicliquids to dissolve cellulose

Personnel and FundingPersonnel and FundingGraduate Students

Melanie L. MoodyKeith E. GutowskiNicholas J. BridgesViolina A. CocaliaMeghna DilipMarcin SmiglakMozhgan Bagheri-dermani(Visiting Scholar)C. Corey HinesMirela MaximNing SunDavid M. Drab

Undergraduate StudentsJane-Holly PoplinWhitney L. HoughTimothy WilsonMegan Suggs

AIME PersonnelRobert Wells-Executive DirectorDaniel Daly-DirectorScott K. SpearPam Wells

FundingNational Science FoundationEnvironmental Protection AgencyDepartment of Energy-Basic EnergySciences and Environmental ManagementScience ProgramAir Force OSRMerck/EMD

Staff ScientistsScott T. GriffinW. Matthew Reichert

525 SolutionsRichard P. Swatloski

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-24-

Process Research & Green Chemistry: A Natural PartnershipEdward Grabowski, Process Research, Merck Research Labs

The traditional goals of Process Research typically reflect the principals of GreenChemistry that have evolved over the past decade. This will be illustrated by recentwork that has been done in developing a manufacturing process for Merck’s newdiabetes candidate sitagliptin (MK-0431) which is in Phase III clinical trials.Structurally sitagliptin is a -amino acid amide in which the amine is located at a chiral center. Although there has been previous work on the design of enantiospecific syntheses of -amino acid derivatives, none of it was considered suitable with regard to the goals of this program. In searching for a direct method forthe synthesis of this general entity, we have discovered that enamines derived from

-ketoesters and amides by treatment with ammonium acetate can be enantiospecifically reduced employing a rhodium catalyst and t-butyl josiphos, aproprietary ligand of the Solvias Corporation. The talk will trace the development ofthe manufacturing process from initial research concepts and laboratory studiesthrough reduction to practice at the 1000 kg scale. In September 2005 this programwas awarded the Astra Zeneca Award for Excellence in Green Chemistry and Engineering in London, England.

MK-0431

F

FF

NH2 O

NN

NN

CF3The Retro-Synthesis

-amino acid derivative Triazole

F

FF

NH2 O

X

HNN

NN

CF3

+

4.4 Edward Grabowski

-25-

Enamine Amide Through-Process

HCl• HNN

NN

CF3

O

FF

FOH

OH

FF

FO

O

O

O

O

F

F

O

NN

NN

CF3

FNH2

FF

F

O

NN

NN

CF3

NH4OAc, 5.5 eqMeOH

tBuCOClMeldrum's acid

Hunig basecat. DMAPMeCN

assay, 95 %

TFAA50 °C, 5h

98 % assay82 % isolated yield from TFPPA>99.6 w% purity

-keto amideassay: 89%

TFPPA

>2000 Kg prepared F. Xu, et. al. JACS 2004

Asymmetric Hydrogenation

• Over 80 ligands screened• 6 different metal precursors screened, all Rh complexes were similar• Over 40 acid, base, salt additives screened, some acids showed dramatic

rate enhancement, but side reactions occurred• 19 different solvents screened, MeOH was by far the best.• Best performers:

Collaborative effort between project team, CRDD, and Solvias

0.3 mol%

95 %ee98 % conv.

NH2

FF

F

O

NN

NN

CF3

NH2

FF

F

O

NN

NN

CF3

MK-0431enamine amide

Rh(cod)Cl + V

50 °C, 100psiMeOH, 18 h

97%ee 97%ee -98%ee 98%ee V: 95%ee

P(Ph)2P(t-Bu)2

FeP(p-CF3-Ph)2

P(t-Bu)2

Fe

PPh2

PFePCy2

P(p-tol)2

S

S

PPh2

PPh2

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-26-

The Ultimate Synthesis

NH2

FF

F

O

NN

NN

CF3

>99.6 w% purity

[RhCl(cod)]2(R,S)-PPF-PtBu0.3 mol%100 psi H250 °C, 18 h

NH2

FF

F

O

NN

NN

CF3

98 % conv.95 %ee

1. Ecosorb 941

2. IPA/Heptane,ee upgrade>99.7 %ee85 % recovery

IPA-H2O, H3PO4

96 % yield>99.9 LCAP100 %eeRh <3 ppm

partical size 61-62 u

NH2

FF

F

O

NN

NN

CF3

•H3PO4 •H2O

> 1500 kg has been made

outsourced

Asymmetric Hydrogenation of Unprotected Enamines

R X

NH2 O

R X

NH2 ORh–L*

H2 *

P(4-CF3-Ph)2

PtBu2

Fe

I

II

PPh2

PtBu2

Fe

R X Ligand yield,% ee%Ph4-MeOPh4-F-PhBn3-PyPh4-MeOPh4-F-PhBn

OMeOMeOMeOMeOMeNHPhNHPhNHPhNHPh

IIIIIIIIIIIII

97.687.585.494.490.575.682.074.394.0

96.195.096.193.395.795.696.396.097.1

Yi Hsiao, S. Krska, N. Rivera et al, JACS 2004, 126, 9918

-27-

Development of sustainable technologyin Asahi Kasei

Isaburo Fukawa, Asahi Kasei Corporation

Asahi Kasei has developed several sustainable technology such as theproduction process of cyclohexanol MMA TBA, PTMG and N O cracking processSince then our company has been cont nuously improving these processes and catalystssuch as precious metals zeolites, mixed oxides, heteropolyacids, etc

The recent topic is the development of non-phosgene polycarbonate productionprocess with CO as a starting material This process is the green sustainableprocess because it does not use any toxic materials, and produces neither wastes norwastewater. The reactive distillation method for production of diphenyl carbonateand the gravity utilized-non agitation polymerization method are the key technologyof the processAsahi Kasei is challenging new sustainable processes such as fluorous biphasicsystem for the production of fine chemicals and direct production of alkylcarbonatefrom carbon dioxide and alcohol.

Chemical Technology as the Base Technology of Sustainable Development

CHEMICAL

TECHNOLOGY

MATERIAL

PROCESS

CATALYST

ENVIRONMENT FRIENDLY

PRODUCTS

ENVIRONMENT FRIENDLY

PROCESSES

LOW CONSUMPTION

OF RESOURCES

LOW CONSUMPTION

OF ENERGY

R.Yumikura The 4th Forum of World Chemical Industry April 1996

4.5 Isaburo Fukawa (府川伊三郎)

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-28-

Sustainable Technology developed by Asahi Kasei (1)

C(1999)

C(1987)

C(1990)

C(1998)

C(1984)

C(2002)

C(2002)

Simple processTwo phase reactionHeteropolyacid cat.

Mixed-Butylene TBAH2O

TBA(t-Butyl alchol)

High selectivityMixed oxide cat.Pd/Pb cat.

TBA Macr MMAO2 MeOH & O2

MMA

Low waste(Carbon yield 100%)

Multiphase ReactionRu cat. Zeolite cat.

BZ cyclohexene CHH2 H2O

CH(cyclohexanol)

No toxic catalystTwo phase reactionHeteropolyacid cat.

THF PTMGPTMG(polytetramethyl-ene glycol)

Reduction of green housegas(N2O)

The mal Cracking(recovery of nitric acidfrom NO)

N2O N2+NO+O2

(CH+HNO3 adipicacid+N2O)

Cracking of N2O

Non-phosgeneNo-waste

Gravity utilized polym.DPC+BisA PCPC(Polycarbonate)

Non-phosgeneHigh selectivity and nowaste

ReactiveDistillation

EO/CO2 EC DMC DPCDPC(Diphenylcarbonate)

SustainabilityProcess & Catalyst(C:Commercialized : year)(D:under Development)

ReactionProduct/Process

Sustainable Technology developed by Asahi Kasei(2)

Replacement of AlCl3,BF3DTwo phase reactionFluorous Lewis acid

Ex. Esterification, Bayer-Villiger Oxidation,Transesterification

Fluorousbiphasic system

D

D

C(1963)

D

C(1993)

Saving of resource(improvement ofselectivity)

Fluidized bed reactorMixed oxide cat.

Propylene/NH3/O2 ANANAcrylonitrile)

Alternative resourceFluidized bed reactorMixed oxide cat.

Propane/ NH3/O2 ANAN from propane

Direct conversion of CO2 tocarbonate

Organometal cat.Reactive distillation

CO2/ROH DRC DPCDPC

Saving of resourceZeolite cat.

Unused C4,C5 fractionpropylene

process

Saving of resourceZeolite cat .

Unused C4,C5fraction aromatics

process

SustainabilityProcess & Catalyst(C:Comme cialized : year)(D:under Development)

ReactionProduct/Process

-29-

Asahi Kasei’s New Non-Phosgene PC Process

E GCO2

CO2 forms PC Main Chain : World’s First

Material-Saving : High Yield & Selec. (>99%) , Intermediates : Full-Recycling

High Performance PC : Purity, Transparency, Mold- Processing

High Purity EG : No By-production of Dimer & Trimer

Energy-Saving EG Process : No Use and No Distillation of H2O

Totally Cost-Saving Process : Both Construction & Raw Materials

E C

:Raw Material : Intermediate : Product

Characteristics

EO

P CDMC

MeOH

PhOH

DPC Bis-A

Asahi Kasei PC Melt Polymerization Process

High Purity PC (Ice Color, No ‘Cl’)

High Performance PC

- - - - Good Mold- Processability

- - - - Less Mold-Deposit

Advantages in PC Product

No Mechanical Agitation

- - - - Energy-Saving

Direct Pelletization from Reactor

- - - - Energy-Saving

Advantages in Polymerization

AmorphousPC

Prepolymer

‘Gravity-Utilized’ Non-Agitated Vertical TypeMelt Polymn. Reactor

PC Pellet

ASAHI Patents : World’s FirstUSP 5,840,826 etc.

Commercial Production(PC50KT/Y)

Started from June 2002

Vac. 240270

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-30-

· High activity due to the strongelectron-withdrawing groups

· High affinity to fluorous solvents

MLn M = YbIII, ScIII, SnIV, HfIV

L = -N(SO2C8F17)2

-N(SO2C10HF20O3)2

(n = 3, 4)

Sn[N(SO2C8F17)2]

OS

CF

N

substrate

organic phase

Cat.fluorous phase

recycled

stirring

catalyticreaction

product

organic phase

Cat.fluorous phase

FluorousFluorous LewisLewis AcidAcid CatalystsCatalysts

SuitableSuitable forfor FluorousFluorousBiphasicBiphasic System(FBS)System(FBS)

+ CO2

O OO

R R

ROH

OH

O O

OR O O

O

O O

OR R

ROHH2O

DRCDPC

SnOR

Bu

Bu

ORCO2 adduct ofBu2Sn(OR)2

tin alkoxideresidue

-36-

Reversing Aldehyde Reactivity in Asymmetric Catalysis Using ChiralNucleophilic Carbenes

Tomislav Rovis

Carbon-carbon bond-forming reactions are one of the cornerstones of organic chemistry,a key requirement in the formation of complex molecules. Efficiency in these reactionsis predicated on the rapid assembly of the molecules, excellent control of both relativeand absolute stereochemistry, and minimization of waste. Addition reactions, where theproducts contain all elements of the reaction partners, are particularly attractive as is theuse of catalysts to induce the event. We have been interested in the use of chiraltriazolium salts as precursors to organic catalysts that mediate the addition of aldehydesto Michael acceptors in umpolung fashion. The reactions are efficient andstereoselective, have the capability of forming quaternary and contiguous stereocentersand proceed under exceedingly mild conditions.In considering new reactivity of these catalysts, we envisioned that an appropriatelyplaced leaving group might result in an oxidation state change at the aldehyde carbon andwould allow us to form acid derivatives by nucleophilic attack of alcohols and amines.We have reduced this concept to practice, with the result that a mild, environmentallyfriendly oxidation occurs under non-oxidative conditions. The full scope of this study aswell as its application to an asymmetric protonation reaction will be discussed.

4.7 Tomislav Rovis

-41-

Design of Dehydrative Ester CondensationCatalysts

Kazuaki IshiharaGraduate School of Engineering, Nagoya University, Furo-cho, Chikusa,

Nagoya 464-8603, Japan

Abstract: Esterification is one of the most fundamental and importantreactions in organic synthesis. In order to promote atom efficiency andreduce E-factor, the use of stoichiometric amounts of condensingreagents and excess substrates should be avoided. This lecture willfocus on the design of esterification catalysts directed towards greenand sustainable chemistry. The first topic is the direct esterificationreaction catalyzed by homogeneous but reusable hafnium(IV) andzirconium(IV) salts. Ionic liquid was very effective to extracthafnium(IV)- or zirconium(IV)–iron(III) complex in the reaction mixture.And the second is the direct esterification catalyzed by bulkydiarylammonium arenesulfonates which do not include any metalspecies.

The Direct Ester Condensation Catalyzed byHf(IV) or Zr(IV) Salts

R1CO2H + R2OH R1CO2R2 + H2O

2. Use of excess substrates

1. Use of Condensing Reagents

R2OH

–HX

cat.

3. Catalytic direct condensation using equimolaramounts of substrates

R1CO2H + R2OHcat. Hf(IV) or Zr(IV)

–H2O

AX

–AOHR1CO2H R1COX R1CO2R2

R1CO2R2

Science 2000, 290, 1140.

4.8 Kazuaki Ishihara (石原一彰)

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-42-

Recovery and Reuse of Direct Esterification Catalysts

+

Zr(Oi-Pr)4(1 mol% )

Fe(Oi-Pr)3(1 mol% )

5 mmol 5 mmol

Run 1

99999999

2

>99999884

3

>99989612

BnOH

R1CO2R2

Organic phase

R1CO2H + R2OH

cool to rt

1. decantation

2. concentrationazeotropic

reflux (–H2O)

R1CO2R2

Table. Conversion (%) to Ester

R1CO2HR2OH

heptane

>99 – – –

4

Ph CO2H

Zr(IV)–Fe(III)

[BPY][NTf2]

Ph CO2Bn

••••

>99 – – –

15

Zr(IV)–Fe(III)Zr(IV)–Ga(III)Zr(IV)–Sn(IV)

Zr(IV)

heptane (2.5 mL)[BPY][NTf2] (1.0 mL)azeotropic reflux(115 °C), 8 h

[BPY][NTf2] –NTf2N+ Bu

MeO CO2C8H17 Ph CO2C8H17

OMe

MeO CO2MeO CO2Me

CO2Me

O CO2C8H17

Ph CO2Me

24h, 70%

Direct Ester Condensation Reaction at Room Temperature

R1CO2H + R2OHCatalyst (1 mol%)

no solvent, rtR1CO2R2 + H2O

48h, 69% 24h, 74%

3h, 81% 11h, 91% 24h, 91% 24h, 95%

NH2O3S

F

F F

F

F

-43-

Practical Synthesis Practical Synthesis of Fine Chemicals of Fine Chemicals Using Catalysts and EnzymesUsing Catalysts and Enzymes

Yoshiro FurukawaResearch Laboratories, DAISO CO., LTD.

9 Otakasu Amagasaki Hyogo 660-0842, JAPANAbstract:

Catalyst and enzyme play a very important role for sustainable organic synthesis.We have been developing enantiomerically pure building blocks such asepichlorohydrin and 3-chloro-1,2-propanediol based on microbial resolutions andcatalytic asymmetric reactions. And we produce almost 70 enantiomerically purepharmaceutical intermediates on an industrial scale and supply them worldwide.

In this presentation, the process development of these enantiomerically purepharmaceutical intermediates will be discussed as well as the direct preparation ofanhydrous sodium polysulfide from metal sodium and elemental sulfur. Anhydroussodium polysulfide is used as the starting material for silane coupling agent forenergy saving tire.

HO ClOH

HO Cl

HO ClOH

(S)

(R)

Pseudomonas sp.DS-K-2D1

Alcaligenes sp.DS-S-7G

> 98 %ee

> 98 %ee

Cl OHCl

Cl OHCl

Cl OHCl

(R)

(S)

Pseudomonas sp.OS-K-29

Alcaligenes sp.DS-K-S38

> 98% ee

Cl O

Cl O

> 98% ee

> 98% ee

base

base

OHHO O

HOO

base

base

> 98% ee(R)

(S)

(S)

(R)

(R, S)-

(R, S)-

(Daiso)Agric. Biol. Chem., 54, 3185 (1990); J. Indust. Microbiol. 10, 37 (1992);J. Ferment. Bioeng. 73, 443 (1992);Appl. Microbiol. Biotechnol. 40, 273 (1993).

Production of Chiral Epichlorohydrin and Chloropropanediol

Dec. 1994 Production Start

4.9 Yoshiro Furukawa (古川喜朗)

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-44-

Kinetic Resolution with Salen-Co Catalyst

ClO

N

t-Bu

t-Bu t-Bu

t-BuO OCo

N

OAc

ClOHO Cl

OH+(S,S)-salen-Co(OAc)

42%, >99% ee 52%, 89% ee

H2Ono solvent

(R, S)-

E. N. Jacobsen et. al., Science, 227, 936 (1997).

Oct. 2000 Production Start

Core Products

Chiral Derivatives

Daiso’s Line-up of Chiral Building Blocks

N

O

O

O

O OX X

OO

O

ONR

X

O

OHOH

OHOHCl

RO

ClOH

CN

OHR

O

HO

X

RNO

R

O

ORO

OArSO3 NH

HO

X

Cl O

X = H, Cl, OMeX = H, Cl, OMeR = H, Ar

X = O, H2

R = Ar, Me, Bn,

*X = Cl, OH

X = O, H2Ar = 4-Me-C6H43-O2N-C6H4

n-PrCO2

R = Alkyl

R = Alkyl

* *

*

*

* **

*

*

** *

* *

-45-

Silane coupling agent is necessary for silica tire.Silane coupling agent is necessary for silica tire.

Saving energy and resources (ISaving energy and resources (Improvement of 5mprovement of 5--6% mileage)6% mileage)Environmental protection (REnvironmental protection (Reduction of 1.2%eduction of 1.2% ccarbon dioxidearbon dioxide emissionemission ))

Necessity of Silane Coupling Agent

One-pot Reaction of Silane Coupling Agent

(Daiso) US Patent 6,066,752 (2000);JP Patent 3501008 (2003).

Na

(EtO)3Si Cl(EtO)3Si Sn Si(OEt)3

ether solvent80oC, 3h

S

n = 1-4

Na2Sn

2 steps, 98% Yield

April, 2001 Production Start

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-46-

2

Sustainable Chemical Synthesis Within the US

Specialty Chemicals IndustryIngrid K. Meier, Ph.D., Air Products and Chemicals, Inc.

NSF Workshop on Sustainable Chemical Synthesis13-14 December 2005

© Air Products and Chemicals, Inc., 2005

One of the key challenges within the US Specialty Chemicals Industry is todevelop new chemicals that positively contribute to the sustainability of anindividual company, the Chemical Industry and the world. Air Products andChemicals, Inc.'s Performance Solutions business has found that the discoveryof new environmentally-friendly surfactants can be expedited by using toolssuch as EPIWIN modeling and structure-ecotoxicity relationships to aid in thedesign of "greener" chemicals. Moreover, the introduction of relevantecotoxicological testing early in the Concept Stage can help to identify topcandidates for further development. This presentation describes the use ofthese learnings to develop the EnviroGem AE Series Surfactants and nextgeneration "green" surfactants.

3

Sustainability for the Performance Solutions Business

Economic– Provide long-term economic advantage toour customers, our company and ourinvestors

Environmental– Reduce our customers’ and our ownenvironmental footprints

–Minimizing hazards– “Greener” alternatives

4.10 Ingrid Meier

-47-

4

Surfactants Can Adversely Affect the Environment

Widely used in many applications– Can reach levels of 2 mg/L in waterways

Can harm or kill aquatic organisms– Possible aquatic toxicity at ≥ 0.025 mg/L

Can persist in the environment– Ready biodegradation to CO2 and water

is idealMust be chosen carefully to minimizeenvironmental impact

5

New Surfactants: Mastering the Sustainability Balancing Act

Speed toMarket

Superior Environmental Profile

ProductRegistrationHurdles

Superior Performance vs. Competition

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-48-

6

Our Approach to Designing New Surfactants

Set Concept Stage EH&S and PerformanceTargetsShared Knowledge Between Idea Generators– Structure-performance relationships– Structure-biodegradation/aquatic toxicity effects

Used Modeling to Help Design MoleculesSynthesized Best Predictions of ModelScreened for Performance– Fundamental surfactant screens– Meaningful EH&S tests

Iterated on Learnings

7

EPIWINTM Calculations Were Run Before Syntheses

Estimations Programs Interface forWindows– Interface program for ten stand-alone property

estimation programs– Developed by EPA and Syracuse Research

Corporation– Can be downloaded from the web– Input = chemical structure (SMILES notation)– Output:

• Estimated physical properties• Estimated chemical and environmental properties

– Ko/w, biodegradability, aquatic toxicities, etc.

-49-

8

Concept Stage EH&S Screens

OECD 306 Marine Biodegradation Test

Respirometry Biodegradation Test– Freshwater biodegradation, done internally– If predictions looked bad, this was done first

Marine Algae Toxicity Test

Skin, Eye Irritation Tests

Oral Toxicity Test

<$6000 per compound

9

Learnings for Designing More Environmentally-FriendlyChemicals

Put EH&S Criteria in the Product Concept– Run meaningful EH&S tests early

Use Modeling to Aid in Designing MoleculesConsider New Chemistries and ChallengeTraditional Assumptions– Not all sugar-based molecules are

biodegradable– Hydrophobic species are not always

aquatically toxic

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-50-

Green Chemical Product Design: TheNeed for Collaboration between Chemists

and Engineers

E.J. BeckmanMascaro Sustainability Initiative

Chemical Engineering DepartmentUniversity of Pittsburgh

Abstract• Creating greener products through incremental

improvement of existing technologies is not likely to reapthe savings in cost or increase in performance needed toencourage investment in such improvements. Byadopting a customer-oriented focus, however, one canfind ways to break through the incremental improvementbarrier, finding ways to achieve both dramaticenvironmental improvement and broad customeracceptance. However, large company structures may notallow for this type of “E++” thinking, and hence suchdisruptive technology may arise from unexpected places.Examples include finding ways to displace PVC andacrylamide from their current applications. Finally, thecurrent chemistry and chemical engineering curricula donot include the fundamentals of product design, potentially relegating our students to the sidelines in the important first stages of product realization.

4.11 Eric Beckman

-51-

Sustainable Product Design [from Fuller &Ottman, J. Business Res. (2004)]

• Eco-redesign (E-); short term, modify current design,reduce waste, preserve business as usual – the “lowhanging fruit”.

• Eco-innovation (E+); longer term, re-invent ways andmeans by which to provide benefits to customers.

• Sustainable technology innovations (E++); emerging or unproven technology to provide through inherentlydifferent mechanisms; radical technology change.

How can we promote E++ thinking?

E- E+ E++

More disciplines required,business opportunity & riskincrease.

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-52-

O

H

+ HCNH+ CN

OH

O

NH2

CN

NH

O

H

+ H2O

HCN +

NHO

H

Heat

BASF Process

NVF Production

HCN, an inherent hazard, raises costs; atom efficiencynominally (assuming full HCN recycle) of 80%

$1/kg

O

H H

O

NH2

+H+ OH

NH

HO

+

O

O

O

R

O

NH

HO

O

O

OH

RNHO

H

R

O

OH

O

OH

Heat- H2O

+

1. Water generated “off-line”

2. Choose R to renderseparation of diacidand NVF easy.

3. Reaction of HEF withanhydride “pulls” firststep equilibrium.

4. 3rd step crackingtemperature 80C orlower.

5. Potential for singlereactor operation withT-ramp.

But…we’re still fightingagainst an atom efficiencyof 80% (versus 100% foracrylamide) and the lowprice of acrylonitrile.

-53-

A 2nd Case Study: the Chlorine Problem

~ 45 million tons ofCl2 producedannually, many applications

Chlorinated byproductsenter the environment

Chlorine is dangerous totransport

Chlorine is energyintensive to produce (viathe electrochemicalchloralkali process)

Why is PVC Cost-effective?

Because pipe thickness is set by operating pressureand the strength of the material, cost/length of pipe canbe derived as follows:

Cost/length ~ ρCw/S

Materialdensity

Material costper mass

Materialstrength

What is desired: Low cost, low density, high strength

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-54-

Design of Alternatives To PVC

MineralReinforcement Copolymer

GlassNatural Fibers

Synthetic Fibers

Strengthen a Polyolefin

We also need todesign a “fastening”system; could be a glueor could bemechanical…requiringsupport from our MEcolleagues

Can we create a composite with increased strength, while minimizingIncreases to density and cost.

-55-

Sustainable Chemical Synthesisthrough Microreactors

Jun-ichi YoshidaDepartment of Synthetic & Biological Chemistry

Graduate School of Engineering, Kyoto UniversityChemical processes using micro-structured reactors (micro chemical processes) have

received significant interest in the stream of downsizing of chemistry, and they are expected tomake an innovative and revolutionary change for chemical synthesis.

In addition to the safety and environmental benefits of dealing with smaller quantities ofmaterial, micro-structured flow reactors have several advantages over conventional systemsstemming from the high surface-to-volume ratio; for example, precise temperature control andhigh efficiency of heterogeneous mass transfer. Short residence times in reactors may also beadvantageous from a viewpoint of the control of highly reactive intermediates. These advantageslead to significant improvement of reaction efficiency and product selectivity in micro chemicalprocesses. The advantages of micro-structured flow reactors of easy modulation and thepossibility of combining reactors in parallel promising a quick means for scale-up (microchemical plants) also warrant comment.

Some examples of micro chemical processes including micro flow electrochemical organicsynthesis and highly selective organic reactions using micro mixers, and their advantages from aview point of sustainable chemistry will be discussed in the presentation.

The objectives of this presentation

• Part 1: to demonstrate an example that selectivity of somechemical reactions can be dramatically increased using amicromixer.

• Part 2: to demonstrate an example that electrochemicalmicroreactor serve as a powerful tool for integratedsynthesis.

4.12 Jun-ichi Yoshida (吉田潤一)

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-56-

How microreactors improve selectivityof chemical reactions?

• Minimizing local deviation of concentrationsof reaction components (micromixer)

• Minimizing local deviation of temperature(micro heat exchanger)

Improve selectivity of chemicalreactions by fast mixing

• Mixing is extremely important forvery fast reactions in which reactiontime is comparable to mixing time.

• Such reactions are often conductedunder mixing-controlled conditions.

• Efficient and fast mixing using amicromixer is expected to improvethe selectivities of such reactions. 25 µm

A

B

A+B

-57-

Electrochemical Reactions

• Advantages– Avoiding use of hazardous chemical reagent– Easy control of the reactivity of electrodes– Generation of reactive intermediates under mild

conditions• Disadvantages

– Use of supporting electrolyte– Inefficiency of surface reaction– Loss of energy by ohmic resistance

Microreactors solve the problems ofelectrochemical reactions

• High surface to volumeratio of the reactor facilitates the mass transfer on the surface of theelectrode.

• Short distance between twoelectrodes diminishes theohmic resistance andminimizes the loss of energy and heat formation.

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-58-

US-Japan Workshop on Sustainable Chemical SynthesisDecember 13-14, 2005

Polylactic Acid – Challenges in Developing Functional, Sustainable Materials

Laura M. BabcockNatureWorks LLCPO Box 5830, MS 114Minneapolis, MN 55440-5830USA

Abstract

Polylactic acid is a biodegradable polymer produced from biorenewable resources byNatureWorks LLC, a company owned by Cargill. Current markets for PLA includeNatureWorks® PLA packaging and Ingeo™ fibers. Many performance attributes of PLAare the result of polymerization conditions, lactide monomer composition and initiatorlevel. Other performance properties, such as impact resistance, require additives toeffectively modify the polymer. This work addresses the challenges faced when utilizingtraditional formulation technologies with a fundamentally sustainable polymer such asPLA. Results describe formulation requirements and considerations that must be madewhen developing sustainable products with commercial performance requirements.

Several options for impact modification of PLA are presented spanning a range ofperformance attributes. Grafted rubber composite and other core shell type impactmodifiers offer good impact performance at moderate loading in PLA for opaqueapplications. In addition, low Tg, biodegradable polyesters are shown to improve theimpact performance of PLA. This screening work can serve as a starting point for thedevelopment of PLA formulations meeting target impact performance requirementsestablished for specific market applications.

4.13 Laura Babcock

-59-

7

Melt Polymerization-Lactide Ring Opening

•Molecular weight control by initiator concentration

•Viscosity and melt flow

•Optical composition control through lactide feed

•Melt temperature and crystallization

1. Initiator: Initiator

2. Stepwise Addition

O

O

H CH3

n

PLA

Catalyst

O

O

CH3

O

O

LL--LactideLactide

H3C

poly((S,S)-3,6-dimethyl-1,4-dioxan-2,5-dione)(S,S)-3,6-dimethyl-1,4-dioxan-2,5-dione

Solvent Free Process

14

Impact Modified PLAGoal: Meet target impact performance using additives

PLAImpact

Resistant

Cost Regulatory

Sustainability

Performance

Food ContactChem. Inventory

Impact, Clarity, Thermal

BiorenewableCompostable

Low cost, CommercialSpeed to market

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-60-

15

Improvement of PLA Impact Performance

0.00

0.50

1.00

1.50

2.00Break Stress

Ultimate Elongation

Energy to Break

Modulus

Notched Izod

Dart Impact

PET PLA Additive 1

Impact performance at or better than target can be achieved

16

Range of PLA Impact Performance with Additives

0

2

4

6

8

10

12

14

16

1

DartDropImpact

Commercial and semi-commercial optionsfound to improve impact performanceof PLA.

Target

PLA

-61-

20

Impact Modifier Additives Performance

--++-TPU

SustainableRegulatoryPerformanceCost

-

+/-

+/-+

Commercial

+*

+/-

+*+/-

Compliant

-

+

+/-+

Cost

+/-+NaturalRubber

++InternalDevelop

+/-+Esters

-++Core Shell 1

ConsistentImpactAdditive

*Requires testing

No additive meets all target criteria

17

Commercial Impact Modifiers in PLA

Dart Impact based on ASTM 1709-98 on 6x6” sheets 15 mil thicknessTensile based on ASTM D882 on 4” dogbone samples cut from 15 mil thickness sheet, 2”/min elongation rate*Test equipment maximum

Additive LoadingDart Impact(ft.lb)

Energy toBreak(in-lb)

Elongation(%)

Modulus(kpsi)

Blendex 338 5 13.7* 37.6 198 128Clearstrength 320 5 10.6 17.4 97 119Paraloid BTA 753 5 10.6 24 153 119Ecoflex F 15 2.6 7.1 220 115PLA 0 0.2 4.9 17 131

Tensile

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-62-

23

Challenge – DevelopingFunctional, Sustainable Materials

• The advent of biobased, sustainable materials ishappening now– Increasing customer interest – environmental, economic– Variety of supplier and material options

• “Green” technology alone is not enough todevelop a sustainable market position– Competitive cost structure– Comparable functional performance – minimum

24

Challenge – Engage Entire Supply Chain• Engage suppliers– Expand options for sustainable additives– Develop biodegradable formulation options frombiorenewable resources

• Drive internal development– Deliver functional performance improvement– Continuously drive costs down– Maintain technology leadership

• End Users– Design for the advantages of sustainable materials– Educate on value proposition of sustainable materials

-63-

Biocatalytic Reduction System for the Production of Chiral Compounds

Yoshihiko YasoharaFine Chemicals Research Laboratories,

Kaneka Corporation1-8 Miyamae, Takasago, Hyogo 676-8688, Japan

The importance of optically active compounds has been increasingly recognized in thepharmaceutical field. The asymmetric reduction of prochiral carbonyl compound is one of theattractive methods for synthesis of optically active alcohol. Many trials were done fordevelopment of the effective methodologies in the filed of both organic chemistry and biologicalchemistry. But coenzyme regeneration and insufficient stereoselectivity have interfered industrialapplication in biological methodology.

A novel NADPH-dependent carbonyl reductase S1 from Candida magnoliae can reduce ethyl4-chloro-3-oxobutyrate to ethyl (S)-4-chloro-3-hydroxybutyrate (CHBE) with a highstereoselectivity. The Escherichia coli transformant co-producing S1 and glucose dehydrogenaseregenerating coenzyme was constructed. This microbe is the useful catalyst for the synthesis of(S)-CHBE which is important intermediate of the pharmaceutical synthesis. This recombinanttechnique for the enzymatic reduction can be applied to other carbonyl reductases for thesynthesis of various kinds of chiral alcohols.

Biological Stereoselective Reduction of CarbonylCompounds

R1 R2

OR1 R2

OHBaker’s yeast

Carbonyl compoundsOptically active

hydroxyl compounds

Useful chiral compounds

C. Neuberg et al., Biochem. Z., 91, 257 (1918).

R. Noyori et al., J. Am. Chem. Soc., 102, 7932 (1980).

vs Chemical Catalytic Stereoselective Reduction

BINAP-Ru complex

Complex mechanismLow productivityInsufficient steroselectivity

4.14 Yoshihiko Yasohara (八十原良彦)

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-64-

S1 S3 S4 RSubunit MW (SDS-PAGE) 33,000 30,000 29,000 36,000Number of subunit 2 2 2 1Thermal stability <45oC N.D.* < 45oC <40oCOptimum pH 5.5 N.D. 6.0 7.0Stereoselectivity for COBE >99%e.e. 53%e.e. 51%e.e. >99%e.e.

(S ) (S ) (S ) (R )Enzyme family SDR SDR SDR AKR* Not dererminedSDR: short-chain alcohol dehydrogenase/reductaseAKR: aldo-keto reductase

Stereoselective Reduction of COBE by Carbonyl Reductase of Candida magnoliase

Cl COOEt

O

Cl COOEt

OH

Cl COOEt

OH

(S)-CHBE

(R)-CHBE

COBE

S1, S3, S4

R

pNTS1G(4.4 kb)

Ampr

oriPlac

E. coli HB101 (pNTS1G)

GDH gene

Bacillus sp.

Transformation

Reductase S1gene

Construction of Reductase S1 and GlucoseDehydrogenase Co-producing Recombinant E. coli

ClOH

COORClO

COOR

Candida magnoliae

-65-

Gluconolactone

Glucose

NADPH

NADP+

E.coliGDH S1

Enzymatic Asymmetric Reduction of Halo-ketone

Bio-Reduction System

R1 R2

O

R1 R2

OHReductase

Carbonyl compoundsOptically active hydroxyl

compoundsNADH NAD+

Gluconolactone GlucoseGlucose Dehydrogenase

Enzymatic NADH Regeneration System

Formate DehydrogenaseCO2 + H2 etamroFO

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-66-

Comparison of Catalytic Activities and Kinetic Parameters ofDesigned Mutants

S1 (NADPH) S1M1 (NADH) SIM4 (NADH)41-43 / 63-66 SSS / WYNS AAQ / IDIN AAR / IDIN

Thermal stability < 45 OC < 45 OC < 45 OC

Optimum pH 5.5 5.0 5.0

Specific Activities (U/mg) 27.8 2.8 9.9

Km for COBE (mM) 3.0-4.6 3.9 2.6

Km for cofactor 16.7-23.5 160 62

Vmax (mmol/min/mg) 157-273 11.6 21.8

-67-

Evolution Toward Simplicity:Green Chemistry in the ProcessDevelopment of a SelectivePPARgamma Agonist

Dawn A. Brooks, Ph.D.Pacfichem, December 13-16, 2005

5002mehcificaP5002,61-31rebmeceDCopyright © 2005 Eli Lilly and Company

2

Green Chemistry – Evolution toward simplicity

Abstract: Non-insulin dependent diabetes mellitus (NIDDM) is amajor progressive metabolic disorder that affects 5-10% of adultsover the age of 30 in most populations. In our discoveryinvestigations, we sought PPARg agonists outside the knownglitazone class that would produce improved glycemic and lipidcontrol in animal models of diabetes that could be translated toman. Compound 1b (LY519818) was selected from our SARstudies to be advanced to clinical evaluation for the treatment oftype 2 diabetes. This talk will outline the laboratory to pilot plantscale evolution of the synthetic route for this molecule, which wasdeveloped with the goal of providing a commercially-viable,environmentally green process for long-term manufacture. E-factor assessment of the current synthetic process will beincluded.

4.15 Dawn Brooks

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-68-

5002mehcificaP5002,61-31rebmeceDCopyright © 2005 Eli Lilly and Company

3

Green Chemistry – Evolution toward simplicity

Topics

• Why Green Chemistry in thePharmaceutical Industry?

• Strategies

• PPARgamma example

• Measuring success,understanding challenges

5002mehcificaP5002,61-31rebmeceDCopyright © 2005 Eli Lilly and Company

4

Green Chemistry – Evolution toward simplicity

BnO

O

OMeOMe

O

OMe

HOOMe

O

THFOMe

BnOOMe

OOH

1) CLEC®-CR

eMOAAFT

BnOOMe

OO

O

CF3C

O

OH

ONa

HOOMe

O

ONa

OOMe

O

O

O Aq. HCl/IPA

O

O Cl

OH

OOMe

O

O

O

5) NaOH(aq)/DMSO

+

Step 1a

Step 1b

1) H2, Pd/C, THF

Step 1c

2) NaOH (aq), TBAH3) Azeotropic Distill.

Step 4

Toluene2) H2O, NaHCO3

Toluene, KH2PO42) 4 N HCl

3) Isopropyl Acetate/NaOAc/MeOHStep 2

1) 1,3-dichloropropane 4) 543758 Na (VI)

Step 3a

t-BuOK

Process Improvements:1) Replace NaHMDS with KO-t-Bu2) Decrease TFAA Equivalents from 5 to 23) Remove cinchonidine recrystallization4) Couple directly with the acid (eliminate ester formation)5) One-pot process to prepare the API sodium salt

Improved Process to Prepare LY519818

-69-

5002mehcificaP5002,61-31rebmeceDCopyright © 2005 Eli Lilly and Company

5

Green Chemistry – Evolution toward simplicity

Process Chemistry* Operational simpilicity* Combination of steps (only two intermediates isolated)* Good carbon economy* Robust, Scaleable* No chromatography* Crystalline intermediates* Purification by simple washes and recrystallizations* Good control strategy for impurity rejection

Process Economics* Inexpensive reagents and raw materials* Raw materials available in bulk quantities* Minimal tank/equipment use* Enzyme can be recycled* Excess 1,3-dichloropropane recovered by distillation

Process Ecology* Environmentally friendly reagents/solvents* Chemoenzymatic process* Aqueous based reactions using PTC* Minimal waste/carbon economy

Overview of the Final Process

5002mehcificaP5002,61-31rebmeceDCopyright © 2005 Eli Lilly and Company

6

Green Chemistry – Evolution toward simplicity

PPAR gamma Process ComparisonMaterial Use kg/kg API

0

100

200

300

400

500

600

700

800

2070RSD1010SRDTRI Use Water Use All Other Material Use

TRI - US EPA's Toxics Release Inventory List

E-Factor: “kg materialused for each kg APImanufactured”•only materials used aspart of the syntheticchemical process (no cleaning)•determination includes allmaterials used startingfrom commerciallyavailable raws•useful to comparesynthetic routes of thesame molecule

Pre route design Post route design

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-70-

Greener Process and Products Developed by Asahi Glass Shin Tatematsu

December, 2005The Japan-US Workshop on Sustainable Chemical Synthesis

Corporate Planning, Asahi Glass Co. Ltd.1-12-1 Yurakucho Chiyoda-ku TOKYO 100-8405e-mail: [email protected]

Asahi Glass has been manufacturing halogenated organic compounds for more than40 years. As for greener products, we have developed CFC alternatives to prevent ozonelayer destruction and to suppress the global warming. Since then, we always considerthe environmental issues for the development of new chemical process and products.As some examples, three topics will be presented in this workshop.

I) Catalytic hydrodechlorination of Carbon tetrachlorideII) “PERFECT” process to synthesize tailor made fluorinated compoundsIII) Applying microreactors for safer synthesis of peroxides

Hydrodechlorination of Carbon tetrachloride

CHCl3CCl4 CH3ClCH2Cl2 CH4-HCl+H2 +H2 +H2 +H2

-HCl -HCl -HCl

Gas phase reaction : difficult to prolong the catalyst life time due to theformation of heaviesLiquid phase reaction : easy to remove the heavies from the catalystsurface, but difficult to supply hydrogen to the catalyst surface

Trickle bed(down flow)

HCl+MethaneCCl4

hydrogenSlurry bed

Granular carboncatalyst

hydrogen

CCl4HCl+Methane

Chloroform etc.

Filter

4.16 Shin Tatematsu (立松伸)

-71-

H3C CHORH

H2C OH

H3C CHORH

H2C O

CFOCF3

ORF

F2/N2F3CCF

ORF

F2C O

CFOCF3

ORF

F3C CFORF

COF

CF2=CFORF

Esterification

Fluorination

(180%/cyclewhen R=propyl)

Hydrocarbon Compound

Thermal Elimination

Organic Synthesis

Liquid-phase Fluorination

Fluorine Chemistry

Adv. Synth. Catal., 2001, 343, 215

Perfluoroacyl fluoride is multiplied by repeating the cycle.

“PERFECT”ProcessPERFluorination of an Esterified Compound then Thermal elimination

Perfluorination By-product = HF H2 + F2recycle)

Clean

Non-solvent (products = solvent)Clean & Simple

Multiplication process

Hydrocarbon component

Chlorination Fluorination

Multi-step processCl containing by-products posing threat to the environment .

F2 gas

Recycle

Product

Product

Methane

Conventional Fluorination Process

Raw materials are inexpensive hydrocarbonsThe synthesis of hydrocarbon components makes it possible

to create new fluorinated compounds at will.

Features

PERFECT: Solutions for customers with tailor-made functionalized materials

Green Process

EsterificationThermal

elimination

“PERFECT”as a Green Synthetic Process

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-72-

Safer synthesis for PerfluoroperoxidesHigher Yield: Microreactor>>Batch and Tube reactorEasy on-site synthesis for the polymerization

Batchreactor

Tubereactor

Tube reactorwith sonicator Microreactor

Yield(%) 50 18 66 92

Synthesis of perfluoroperoxides using Microreactors

2 HFPO 3COF+H2O2+2KOH HFPO)3COO 2+2KF+2H2O

multi laminar flow microreactor

10h t1/2 16.4

-73-

Solvent Tuning for Fluorous BiphasicReactions

JOINT US-JAPAN WORKSHOP ON SUSTAINABLE CHEMICALSYNTHESIS

Marvin S. Yu, Ph.DFluorous Technologies, Inc.

Abstract: Fluorous biphasic reactions have been used in a number of interesting andcommercially important transformations. The ability to recover and recycle catalysts or reagents is a cornerstone of green chemistry and fluorous techniques represent a potentially attractive method to achieve this goal. Unfortunately, the theoretical attractiveness of fluorous methods is marred bysome practical limitations, including the inefficient recover, need for large numbers of fluorous ponytails, and the use of environmentally persistent solvents. These problems are generally theresult of poor partition coefficients for fluorous molecules between fluorous and organic solvents.The research described here increases the partition coefficient of fluorous molecules throughsolvent tuning. A new qualitative model for biphasic separations is presented based on the results.Potential applications in fluorous triphasic techniques are also presented.

Fluorous Liquid-Liquid Extraction (FLLE)

Advantages:• Highly selective for fluorous tagged

components• Ease of scale-up• Fluorous solvents readily available

in bulk

organic

fluorous

aqueousDisadvantages:• Poor atom economy• Partition coefficients for single fluorous

tagged molecules are low.

• Multiple fluorous chains necessary• Environmental persistance issues• Cost and complexity of synthesis

4.17 Marvin Yu

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-74-

Fluorous Liquid-Liquid Extraction

Current Strategy: Increase number of fluorous ponytails until desired fluorous partitioning is obtained. In other words, asubstrate tuning model.

Result: Fluorous reagents, tags, and scavengers have very highMWs increasing cost and complexity and limiting the useof fluorous LLE separations.

Hypothesis: Solvent tuning can be used to influence fluorous partitioncoeffcients.

Desired Result: Useful partition coefficients leading to fluorouscomponents with lower MWs, lower comsumption offluorous solvents, use of more benign solvents.

Alternative Fluorous Solvents

F3CC3F7

CF3 F

OEtF

OF13C6

CF3F F

FFFF F F F

FF

C6F14

C4F9-OMe

Non-ozone depleting

VOC exempt

Unrestricted use under theEPA Significant New AlternativesProgram (SNAP)

FC-72 PFMCH

HFE-7500 HFE-7100

F-626

-75-

Solvent Tuning StudiesPPh

F13C6

A

2

8911HFE-7100 / 5% H2O in DMFPPh39

>99.5<0.5FC-72 / 5% H2O in DMFPPh38

>99.5<0.5FC-72 / DMFPPh37

<0.5>99.5FC-72:HFE-7100/5% H2O in DMFA6

694FC-72 / 5% H2O in DMFA5

1090FC-72 / 5% H2O in CH3CNA4

8911FC-72 / DMFA3

2971FC-72 / CH3CNA2

>99.5<0.5FC-72 / THFA1

% Organic% FluorousSolvent systemCompoundEntry

FC-72 = C6F14 HFE-7100 = MeOC4F9

Qualitative Model for Liquid-Liquid Extractions

cilihpordyhcilihpopil

fluorophobic

fluorophilic

hexane

toluene

FC-72 FC-72 / HFE-7100

HFE-7100

5% H2O in DMF

H2O

THF

• Solvent miscibilityproportional to distance

• P is inversely proportional tosubstrate distance to twosolvents

• Traditional substrate tuningmoves fluorous compoundup and to the left

fluorouscompound

• Solvent tuning movessolvents relative to substrate

DMF

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-76-

Conclusions

• Solvent tuning is an alternative approach to substrate tuningto increase partitioning coefficients in LLE processes.

• Fluorous reagents and scavengers suitable for LLEapplications can contain as little as two C6F13 tags.

• New qualitative model for fluorous and polar/non-polar basedliquid separations proposed.

• New FLLE processes using substrates and catalysts withlower fluorous content are envisioned for fluorous biphasic and triphasic processes, fluorous supported chemistry, and scavenging.

-77-

Selective Oxidation overSupported Nano Gold Catalyst

Nippon Shokubai Co., Ltd. Strategic Technology Research Laboratory, Osaka, Japan

Toshio HAYASHI

Abstract: Nippon Shokubai Co., Ltd. has successively developed new and“green” production processes of various important chemicals based oncatalyst technology. Recently, we have focused on a unique catalysis ofsupported nano gold catalysts and developed two progressive oxidationprocesses, (1) one step vapor-phase oxidation of propylene to propyleneoxide and (2) selective liquid-phase oxidation of ethylene glycol to glycolicester.

Supported Nano Gold Catalyst

Au particles with nm size supported on carrier

In 1980’s, Prof. Haruta made thediscovery of highly-active supportednano gold catalysts for CO oxidation.

Gold is rapidly recognized to be anextremely unique catalytic metalwhen prepared as supported nanoparticles.

4.18 Toshio Hayashi (林利生)

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-78-

One Step Oxidation ofPropylene to Propylene Oxide

Au-TiO2 catalyst

T. Hayashi, et al, J. Catal., 178 (1998) 566; US 5,932,750; US 6,124,505; US 6,252,095.

Vapor-Phase One Step Oxidation

Reductive Activation of Molecular Oxygen by Hydrogen

High Selectivity to PO (over 90%)

+ O2 + H2O

+ H2O

Selective Oxidative Esterificationof Ethylene Glycol (EG)

to Methyl Glycolates (MGC)

HO OH HO COOMe+ + 2 H2OMeOH + O2

JP 2003-93876; JP 2004-43385; EP 1516619; etc.The Chemical Daily, July 16, 2004; Chemical Engineering Magazine, Sept., 2004.

Liquid-Phase One Step Oxidation

High Substrate-Selectivities (EG>>MeOH)

Pilot-Scale Demonstration in 2004 Spring

Au based catalyst

-79-

New Life for an Old Reaction; Unprecedented

Reactivity in the Morita-Baylis-Hillman Reaction

Krafft Research GroupFlorida State University

The Morita-Baylis-Hillman reaction is an organomediatedreaction which gives rise to the formation of carbon-carbonbonds at the alpha carbon of an enone. Traditionally, onlyaldehydes have been used as the electrophile. We haveextended the process to include allylic halides, alkyl halidesand epoxides (homo-MBH reaction) as electrophilic partnersfor the carbon-carbon bond forming process. An intermediatefrom the MBH alkylation has been isolated and characterizedby X-ray crystallography.

4.19 Marie Kraff t

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-80-

Sustainable Chemical Synthesis

Some Reaction CharacteristicsAtom EfficientCatalyticAqueous or non-traditional solventsSolvent freeOrganocatalysis

Requirements to achieve Sustainable Chemical Synthesis:C-C bond formation

Development of efficient new methodsor

Refinement of older, well-known methodsUnderstanding reaction mechanismsIsolation of reaction intermediatesKinetic studies for mechanism elucidation

R'

O

R'

OLv Gp

Organocatalyst

( )n ( )n

RR

R = Me, Ph, HR' = Ph, alkyl, H, OR

Our Plan - Allylic Leaving Groups

-81-

ClO

O(i) Bu3P (1 eq), t-BuOHr.t. 5 h

(ii) KOH, Et3NBnClCH2Cl2–H2O (1:1)r.t. 2 h0.1-0.5 M

80%

Ph

O O

Ph Ph

O

82% 84% 75%, Me3P used

One-pot MBH cycloallylation

RX

O

R

O

i. organocatalyst

ii. base

R = alkyl, aryl; X = leaving group

( )n ( )n

Morita-Baylis-Hillman Alkylation

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-82-

E

E

O

H3C

E

E

O

E

E

O

Ph

CH3

O

H

O

99

90

79

90

83

O

H3C

O

O

H3C

O

80 (PMe3)

99

81 (PMe3) 95 (PMe3)

RBr

O

R

O

( )n( )n

i. Bu3P (1 equiv),t-BuOH (0.5M)

ii. KOH, BnEt3NCl,CH2Cl2:H2O (1:1)rtn=1,2

MBH-Alkylation examples

Catalytic MBH Alkylation

Br

EE

O

RE

E

O

R0* 99

91 90

1 eq0.2 eq

O

R

90 90

O

RBr O

R

BrO

R

O

R

84 8188 95

0* 8045* 99

Yield (%)

R = CH3

R = Ph

R = CH3

R = Ph

R = CH3R = Ph

R = CH3

*A 1M solution of tert-butyl alcohol/methylene chloride (1:1) was used.

R = NaphthR = p-NO2C6H4

R = NaphthR = p-NO2C6H4

94* 9597 99

97 9699 97

Br

O

R

20 mol% Bu3PKOH, BnClEt3N

0.5 M t-BuOH/DCMH2O

-83-

Homologous MBH Reaction - Epoxide opening

R

O

R

O

O

OH

R

O

OH

PR3 exo

endo

( )n

( )n

( )n

O

R R

OHO

O t-BuOH, rt, 72 h

PMe3 (0.10 eq.)

41%0.10

R = Me PhYield

Concentration (M)

0.05 48%

43%

52%

_____________________________

_____________________________0.025 65% 64%

6-endo5-exo

ORO

H

P

O

R

O

P H

ONLY

Epoxide examples

開催概要

各講演の要旨

ワークショップの総括と提案

討議の内容

-84-

Novel large space zeolite catalysts extremely activein the oxidation with H2O2 as a green oxidant

Takashi TATSUMIChemical Resources Laboratory, Tokyo Institute of Technology, Nagatsuta, Yokohama, 226-8503