Introduction of Pneumatics -...

Transcript of Introduction of Pneumatics -...

Fluid Power Control & Design Laboratory

2

Contents

1. Introduction2. Fundamentals3. Air generation4. Pneumatic actuators5. Pneumatic valves6. Vacuum technology7. Typical circuit

Fluid Power Control & Design Laboratory

3

Contents

1. Introduction2. Fundamentals3. Air generation4. Pneumatic actuators5. Pneumatic valves6. Vacuum technology7. Typical circuit

Fluid Power Control & Design Laboratory

4

Concept

Pneumatics — use compressed air as a working medium to implement transfer, transition, distribution, and control of energy.Industrial applications:

Automobile manufacture, automatic industry, food industry…General methods of material handling

clamping, shifting, positioning, orienting…General applications

packaging, filling, locking, sorting of parts…Machining and working operations

drilling, turning, milling, sawing…

Fluid Power Control & Design Laboratory

6

Advantages of Compressed AirAvailability Air is available practically everywhere in unlimited quantities.

Transport Air can be easily transported in pipelines, even over long distance.

Storage Compressed air can be stored in a reservoir. In addition, the reservoir can be transportable.

Temperature Compressed air is relatively insensitive to temperature fluctuations.

Explosion proof

Compressed air offers no risk of explosion or fire.

Cleanliness Unlubricated exhaust air is clean, which does not cause contamination.

Components The operating components are of simple construction and therefore relatively inexpensive.

Speed Compressed air is a very fast working medium.

Overload safe Pneumatic tools and operating components can be loaded to the point of stopping and are therefore overload safe.

Fluid Power Control & Design Laboratory

7

Disadvantages of Compressed Air

Preparation Compressed air required good preparation. Dirt and condensate should not be present.

Compressibility It is not always possible to achieve uniform and constant pistonspeeds with compressed air.

Force requirement

Compressed air is economical only up to a certain force requirement. Under the normal working pressure of 6 to 7 bar, the output limit is between 40,000 and 50,000 Newtons.

Noise levelThe exhaust air is loud. This problem has now been largely solved due to the development of sound absorption material and silencers.

Fluid Power Control & Design Laboratory

8

Comparison of Various Control Methods

Mechanic Electric Electronic Hydraulic Pneumatic

Output force Normal Normal Very smallVery big

(>10 Ton)Big

(<3 Ton)

Drive speed Small High High High (~1m/s) High (>10m/s)

Signal response Normal Very fast Very fast High Slow

Influence by load Hardly Hardly Hardly Small Big

Structure Normal Little complicated Complicated Little

complicated Simple

Influence by temperature Normal Big Big <70℃ <100℃

Position control Very good Very good Very good Good Normal

Maintenance Easy Complicated Complicated Normal Easy

Signal change Difficult Simple Simple Difficult Difficult

Remote operation Difficult Very good Very good Good Good

Fluid Power Control & Design Laboratory

9

Contents

1. Introduction2. Fundamentals3. Air generation4. Pneumatic actuators5. Pneumatic valves6. Vacuum technology7. Typical circuit

Fluid Power Control & Design Laboratory

10

PressureAbsolute pressure and gauge pressureThe pressure of pneumatic system can be lower than atmosphere (vacuum).

Fluid Power Control & Design Laboratory

11

Characteristics of AirIdeal gas equation

Temperature =constantIsothermal changes

Pressure=constantIsobar changes

Volume=constantIsochore changes

Boyle-Mariotte’s Law

Gay-Lussac’s Law

Charles’s Law

constant=PV

constant=TV

constant=TP

RTPV ρ=

Polytropic process

constant=kPV

Fluid Power Control & Design Laboratory

13

Symbols in PneumaticsDirectional control valves: symbol development

Directional control valves: ports and positions (ways)

Fluid Power Control & Design Laboratory

16

Symbols in PneumaticsNon-return valve (check valve)and derivatives

Flow control valves

Pressure control valves

Fluid Power Control & Design Laboratory

20

Contents

1. Introduction2. Fundamentals3. Air generation4. Pneumatic actuators5. Pneumatic valves6. Vacuum technology7. Typical circuit

Fluid Power Control & Design Laboratory

21

Air Generation SystemThe air supply should be

at the required pressure,dry andclean.

The air generation system includes:

Inlet filterAir compressorAir reservoirAir dryerAir filter with water separatorPressure regulatorAir lubricator as requiredDrainage points

Generally, the maximum operating pressure is 8-10 bar.Recommended pressure is 5-6 bar for economic use.

Fluid Power Control & Design Laboratory

23

ReservoirsA reservoir compensates the pressure fluctuations.The large surface of the reservoir cools the air. Thus, portion of the moisture in the air is separated directly from reservoir as water.

Fluid Power Control & Design Laboratory

24

Air DryersDamage of condensate (water) is to corrode pipes, valves, cylinders and other components.If temperature is below 0℃, water becomes to ice and blocks valves.

Low temperature dryer

Adsorption dryer

Absorption dryer

Fluid Power Control & Design Laboratory

25

Service Unit

Compressed air filter

Lubricator

Pressure regulator

Service unit

Fluid Power Control & Design Laboratory

26

Contents

1. Introduction2. Fundamentals3. Air generation4. Pneumatic actuators5. Pneumatic valves6. Vacuum technology7. Typical circuit

Fluid Power Control & Design Laboratory

31

Contents

1. Introduction2. Fundamentals3. Air generation4. Pneumatic actuators5. Pneumatic valves6. Vacuum technology7. Typical circuit

Fluid Power Control & Design Laboratory

37

Contents

1. Introduction2. Fundamentals3. Air generation4. Pneumatic actuators5. Pneumatic valves6. Vacuum technology7. Typical circuit

Fluid Power Control & Design Laboratory

38

Vacuum SystemOperating pressure of vacuum system is below atmosphere pressure.Generally, vacuum system is used to hold workpieces by suction cups, which is a simple, low-cost and reliable solution.Vacuum system is suitable for workpieces with smooth surface, such as glass, paper.

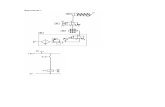

Typical vacuum circuit1-filter 2-refined filter 3-reducing valve4-pressure gauge 5-solenoid valve6-vacuum generator 7-silencer8-vacuum filter 9-vacuum pressure switch10-vacuum pressure gauge 12-suction cup12-workpiece

Fluid Power Control & Design Laboratory

39

Vacuum GeneratorIt uses Venturi tube to generate vacuum.

1-nozzle2-inducing zone3-mixing zone4-diffusing zone

Fluid Power Control & Design Laboratory

40

Vacuum Suction Cups

Flat suction cups Bellows suction cups

Fluid Power Control & Design Laboratory

41

Contents

1. Introduction2. Fundamentals3. Air generation4. Pneumatic actuators5. Pneumatic valves6. Vacuum technology7. Typical circuit

Fluid Power Control & Design Laboratory

42

Example 1:Direct/Indirect Control of a Double-acting Cylinder

A double-acting cylinder is to extent when a push button is operated.Upon release of the push button the cylinder is to retract.

The cylinder is of small bore (25 mm diameter) requiring a small flow rate to operate at correct speed.

The cylinder is 250 mm in diameter and consumes a large volume of air.

Fluid Power Control & Design Laboratory

43

Example 2:Memory Circuit and Speed Control of a Cylinder

The cylinder is to fully advance when a push button is operated and then retract automatically.Full extension is confirmed by a roller lever valve.The cylinder is to continue forward even if the push button is released before full extension is reached.The speed of the cylinder is to be adjustable in both directions of motion.

Fluid Power Control & Design Laboratory

44

Example 3:Pressure Dependent Control; Embossing of Plastic Components

A plastic component is embossed using a die powered by a double-acting cylinder.The return of the die is to be effected when the cylinder rod has fully extended to the embossing position and the preset pressure is reached.A roller lever valve is to be used to confirm full extension.The signal for retracting must only be generated when the piston rod has reached the embossing position.The pressure in the piston chamber is indicated by a pressure gauge.