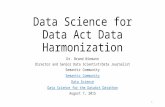

Data Pemsis

-

Upload

amalia-kis -

Category

Documents

-

view

33 -

download

0

description

Transcript of Data Pemsis

2000 1 402001 1 Tahun Jumlah2002 1 2000 12003 3 2001 12004 1 2002 12005 2 2 2003 32006 4 1 1 2004 12007 4 1 2 2005 42008 5 2006 52009 5 2007 62010 5 2 2008 52011 4 ADA BANYAK 2009 52012 11 2010 7

46 7 2011 42012 11

5453

2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 20120

2

4

6

8

10

12

1 1 1

3

1

4

5

6

5 5

7

4

11

2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 20120

2

4

6

8

10

12

1 1 1

3

1

4

5

6

5 5

7

4

11

Tahun Judul Nama

2006 Xin Li

2008

2007

2002

Multi-agent based modeling and analysis of collaboration strategies in supply chain

Agent.Hospital – Health Care Applications of Intelligent Agents1

Stefan Kirn, Christian Anhalt, Helmut Krcmar, Andreas Schweiger

Collaborative Agent-Based Negotiation in Supply Chain Planning Using Multi Behavior Agents

Pascal Forget, thibaud monteiro, sophie D'amours dan jean-marc frayret

agent-based simulation for distributed supply chain planning: conceptual modeling, analysis and illustration

Luis-Antonio Santa-Eulalia, Jean-Marc Frayret, Sophie D'Amours

Agent-based supply chain management*/1: framework

Nirupam Julka 1, Rajagopalan Srinivasan *, I. Karimi

2006

2003

2004

AGENT-BASED MODELING OF SUPPLY CHAINS FOR DISTRIBUTEDSCHEDULING

Jason LAU, George Q Huang (Corresponding Author) and K L Mak

Emergent Structures in Supply Chains—A Study Integrating Agent-Based and System Dynamics Modeling

Nadine Schieritz and Andreas Größler

Agent-Based Framework for Dynamic Supply ChainConfiguration

Denise Emerson, Selwyn Piramuthu

2011

2011 AGENT BASED SIMULATION OUTPUT ANALYSIS

2003 Agent-Based Applications in Health Care

AGENT BASED SIMULATION DESIGN FOR AGGREGATION AND DISAGGREGATION

Tiffany J. HarperJohn O. MillerRaymond R. Hill, J. Robert Wirthlin

Lee SchrubenDashi Singham

John Nealon1 and Antonio Moreno2

2012 Agent-based Model of Parcel Logistics Jirí Starý

2010

AGENT-BASED SUPPLY CHAIN SIMULATION: TOWARDS ANORGANIZATION-ORIENTED METHODOLOGICAL FRAMEWORK

Karam MUSTAPHA, Erwan TRANVOUEZ, Bernard ESPINASSE, Alain FERRARINI

An Agent-based framework for cooperation in SupplyChain

Benaissa Ezzeddine, Benabdelhafid Abdellatif, Benaissa Mounir

2012

2009 R. Brent Ross, PhD

Sharing Breakdown Information in Supply Chain Systems:An Agent-Based Modelling Approach

Yasser Ibrahim1, 2 Ghada Deghedi2*

Entrepreneurial Behavior in Agri-Food Supply Chains:The Role of Supply Chain Partners

2012 Dimitris Kremmydas

Agent based modeling foragricultural policy evaluation: Areview

An Agent Based Model for the Evolving Supply Chain of Jatropha Biofuel

Ahu Soylu, Derek Bunn, William McKenzie

An Agent-based Simulation System for Concert-event Emergency Management Support

2010

An Agent-Based Formal Framework forModeling and Simulating Supply Chains

Li Tan1, Shenghan Xu2, Benjamin Meyer1, and Brock Erwin1

Agent-based simulation of competitive and collaborative mechanismsfor mobile service chains

Guoyin Jiang a,b, Bin Hu a,*, Youtian Wang a

2008

2001 Dr. Thomas Berger

2008

Agent-based Discrete Event Simulation Modeling forDisaster Responses

Shengnan Wu, Larry Shuman, Bopaya Bidanda, Matthew Kelley, Ken Sochats, Carey Balaban

Dissecting and Understanding Supply Chainsthrough Simulation: an Agent-based Approach

Gian Paolo Jesi1 and Guido Fioretti1

Agent-based Spatial Models Applied to Agriculture:A Simulation Tool for Technology Diffusion, Resource Use Changes and Policy Analysis

Toward a conceptual agent-based framework for modeling and simulation of distributed healthcare delivery systems

Moez Charfeddine, Benoit Montreuil

2009

2012

2005

An agent-based retail location model on a supply chainnetwork

Arthur Huang and David Levinson†

Agent-based simuation to anticipate impacts of tactical supply chain decision-Making in the lumber industry

Sebastirn Lamieux, Sophie D'amours, Jonatham Gaudreault, Jean-Marc Frayret

MODELING FOOD SUPPLY CHAINS USING MULTI-AGENT SIMULATION

Caroline C. KrejciBenita M. Beamon

multi-agent modelling for simulation of customer-centric supply chain

Oliver Labarthe, Alain Ferrarini, Bernard Espinasse dan Benoit Montreuil

2008

Design and Optimization of Agent-Based Emergency SupplyChains

Ozlem Ergun, Pinar Keskinocak, and Julie L. Swann

Exploring policy interventions for rural sustainabledevelopment

Ruud Kempener, Peter Kaufmann, Sigrid Stagl

2012 Jakub Dyntar1, Jan Škvor2

Integrated Multi-agent-based Supply Chain Management

This paper appears in:Enabling Technologies: Infrastructure for Collaborative Enterprises, 2003. WET ICE 2003. Proceedings. Twelfth IEEE International Workshops onDate of Conference: 9-11 June 2003Author(s): Frey, D. Inst. of Process Control & Robotics, Univ. Karlsruhe, Germany Woelk, P.-O.; Stockheim, T.; Zimmermann, R. Page(s): 24 - 29

AN AGENT-BASED COLLABORATIVE MODEL FOR SUPPLY CHAINMANAGEMENT SIMULATION

C. M. Vieira, A. P. Barbosa-Póvoa, C. Martinho

Oil Refinery Supply Chain Modelling Using Pipe TransportationSimulator

2012 Akansha Mishra, Ramaa.A

2008 Güven Demirel

2007

Agent Based Simulation for Measuring Performance of Supply chain network – A case study of Cable wires Manufacturing Company

SUPPLY CHAIN MODELING AND ANALYSIS AT ALTERNATIVE LEVELS OF AGGREGATION

An agent-based approach for supply chain retrofitting under uncertain

Fernando D. Mele, Gonzalo Guill´en, Antonio Espu˜na, Luis Puigjaner ∗

Modeling of supply chain: a multi-agent approach

2005

Surya Dev Pathak, Greg Nordstrom, Susumu Kurokawa

Robust Agent-based Optimisation for Supply Chain Configuration to Copewith Risks and Uncertainties

Zheng Ren and David Z Zhang

WILLINGNESS TO COOPERATE IN THE SUPPLY CHAINA PRELIMINARY AGENT-BASED MODELING APPROACH

Timea TörökJon H. Hanf

A novel combined approach for supply chain modeling and analysis

Fernando D. Mele, Carlos A.Méndez, Antonio Espuña, Luis Puigjaner

2010 M. S. Uppin

Distributed Agent-Based Air Traffic Flow Management

Multi Agent System Model of SupplyChain for Information Sharing

SCAMM-CPA: A supply chain agent-basedmodelling methodology that supports acollaborative planning process

Jorge E. Hernández*, M.M.E. Alemany, Francisco C. Lario & Raúl Poler

Kagan Tumer, Adrian Agogino

2009

A Multi-Agent Simulation of Collaborative Air Traffic FlowManagement

Shawn R. Wolfe Peter A. JarvisFrancis Y. EnomotoMaarten SierhuisBart-Jan van PuttenKapil S. Sheth

Agent-Based Modeling and Simulation of Collaborative Air Traffic FlowManagement Using Brahms

Peter A. Jarvis1, Shawn R. Wolfe, Maarten Sierhuis2, Robert A. Nado3, Francis Y. EnomotoNASA Ames Research Center, Moffett Field, CA 94035

ANALYZING AIR TRAFFIC MANAGEMENT SYSTEMS USINGAGENT-BASED MODELING AND SIMULATION

A.P. Shah, A.R. Pritchett, K.M. Feigh and S.A. Kalaver, A. Jadhav and K.M. Corker, D.M. Holl and R.C. Bea,

Agent-Based Modeling of Culture’sConsequences for Trade

2007 Adaptive Planning for Supply Chain Networks

2010 Yee Ming Chen

Michael Andreev , George Rzevski , Petr Skobelev , Peter Shveykin , Er Tsarev , Andrew Tugashev

Improving Supply Chain Coordination by Linking Dynamic ProcurementDecision to Multi-Agent System

2007What differentiates a winning agent: An information gain based analysis of TAC-SCM

James Andrews , Michael Benisch , Alberto Sardinha , Norman Sadeh

Using Information Gain to Analyze and Fine Tune the Performance of Supply Chain Trading Agents

James Andrews , Michael Benisch , Alberto Sardinha , Norman Sadeh

2006

2005

The CrocodileAgent: research for efficient agent-based cross-enterprise processes”

Vedran Podobnik , Ana Petric , Gordan Jezic

An analysis of the 2004 supply chain management trading agent competition

Christopher Kiekintveld , Yevgeniy Vorobeychik , Michael P. Wellman

Keterangan

Cirrelt-54

Cirrelt-11

share information, pake 4 skenario investigasi untuk mengukur inventory cost dan cust servide levels

Multiagent EngineeringInternational Handbooks on Information Systems 2006, pp 199-220\

In SPP 1083 the Hospital Logistics group studies the applicability of agent-based information systemsin health care business scenarios by identifying problems, analyzing requirements, elaborating the state of the artof conventional and agent-based systems, specifying and designing multiagent applications, and evaluating theirapplication. This chapter includes a survey of both the projects forming the group and their collaboration in orderto integrate the systems designed by them into the agent testbed named Agent.Hospital.

automated negotiation, simulation, lumber industry

advanced planning and scheduling, lumber suplly chain

elsvier, Computers and Chemical Engineering 26 (2002) 1755 /1769

Software agents; Grafcets, entreprise supply chain

This paper appears in:Systems, Man and Cybernetics, Part A: Systems and Humans, IEEE Transactions onDate of Publication: Sept. 2006Author(s): Lau, J.S.K. Dept. of Ind. & Manuf. Syst. Eng., Univ. of Hong Kong Huang, G.Q.; Mak, K.L.; Liang, L. Volume: 36 , Issue: 5 Page(s): 847 - 861

Project scheduling, Agent-based modeling, Distributed scheduling,Information sharing,

Proceedings of the 36th Hawaii International Conference on System Sciences

An integration of systemdynamics and discrete agent-based modeling is apromising combination of methods for reducing the apriori complexity of the model. The paper discusses thestrengths and weaknesses of system dynamics anddiscrete agent-based modeling. An approach forintegration of the two modeling methodologies ispresented.

Proceedings of the 37th Hawaii International Conference on System Sciences

In this paper we develop a framework,with machine learning, for automated supply chain configuration

Proceedings of the 2011 Winter Simulation ConferenceS. Jain, R.R. Creasey, J. Himmelspach, K.P. White, and M.

This work ties together a general framework for using ABMS for supply chain risk management, which includes the use of software agents, for data mining, integrated with agent-based simulation platforms.

Proceedings of the 2011 Winter Simulation Conference

In most realistic simulations there are multiple outputs of interest and the overall performance of the sys-tem can only be estimated in terms of these multiple outputs. We propose a method that uses agent-based modeling to determine a truncation point to remove significant initialization bias. Mapping the output of multiple replications into agent paths that traverse the sample space helps determine when a near steady state has been reached.

in Applications of Software Agent Technology in the Health Care Domain , Whitestein Series in Software Agent Technologies, Birkhäuser Verlag

A distributed decision support system based onthe multi-agent paradigm can monitor the status of a hospitalised patientand help to diagnose the state of the patient [28], or support co-operativemedical decision- making [29], [30].

Master’s Thesis, Czech Technical University in PragueFaculty of Electrical EngineeringDepartment of Cybernetics

Inside,the vehicles move on a graph representation of the streets. Using the A* planner andwith the estimated distance as a cost, they compete for the deliveries. Later, on the cityof Prague, several allocation strategies are attempted, while an insight into the interactionsbetween agents is gained and the results discussed. Two variants of the allocation algorithmwere measured, each performing better under different conditions and metrics.

8th International Conference of Modeling and Simulation - MOSIM’10

a new methodologicalframework, organizationally oriented, which permits modeling and simulation of such SC organizational aspects, allowingobservables of different levels of details while reproducing the SC behavior according to desired observables.

Multi-Agent System, Cooperation, Ontologies,Supply Chain, Semantic Web Services, intelligent agents.

Information and Knowledge Management www.iiste.orgISSN 2224-5758 (Paper) ISSN 2224-896X (Online)Vol 2, No.4, 2012

Reverse Information Sharing, Beer Game, Agent-Based Modeling, Supply Chain Risk.

Submitted for consideration to the 19th Annual World Forum and Symposium of theInternational Food and Agribusiness Management Association in Budapest, Hungary

AUA Working Paper Series No.2012-3

Agent based modeling, Agricultural policy evaluation, Agripolis, Reg-MAS,MP-MAS, SWISSland

Plantations of Jatropha and production of biofuel can create new job opportunities and an economic resource for people living in subsistence areas and these places can greatly benefit from further development of Jatropha. However, its success will depend on construction of a successful infrastructure for its supply chain.

Modeling and Simulation, Agent-based System, Emergency Management, Disaster Mitigation

This paper appears in:Information Reuse & Integration, 2009. IRI '09. IEEE International Conference onDate of Conference: 10-12 Aug. 2009Author(s): Li Tan Sch. of Electr. Eng. & Comput. Sci., Washington State Univ., Richland, WA, USA Shenghan Xu; Meyer, B.; Erwin, B. Page(s): 224 - 229 Product Type: Conference Publications

elsevier, Information Sciences 180 (2010) 225–240

cirrelt-09

Proceedings of the 2008 Industrial Engineering Research Conference

Emergency response, agent-based simulation, discrete event simulation, geographical information system, rulebasedsystem

In this ongoing work, we focus on supply chain; in particular, as ourultimate goal, we focus on food mass purchasing consortium (MPC)market because of the availability of literature and data on this speci ctopic.

Agricultural Economics 25 (2/3),245-260.

spatial multi-agent programming model which has been developed forassessing policy options in the diffusion of innovations and resource use changes

patient flow modelling, health service, multi-agent systems, simulation, modelling framework and methodology, distributed healtcare delivery systems, logistics

Cirrelt-51

clustering, supply chain network, location choice, distribution pattern

distributed simulation, value creation network, advanced planning system, multi agent, lumber

Proceedings of the 2012 Winter Simulation Conference

In light of the pressures of increasing demands on earth’s resources, society faces serious challenges infood production and distribution. Food supply chain (FSC) models are critically important, providing decision-makers with tools that allow for the evaluation and design of FSCs, en route to ensuring sustainableFSC productivity. Multi-agent simulation (MAS) is well-suited to modeling FSCs for this purpose,enabling capture of decision-making, interactions, and adaptations of autonomous FSC actors.

International Journal of Simulation and Process Modelling

customer-centric supply chain, multi agent, agents-oriented simulation

http://nexus.umn.edu/Papers/Cluster.pdf Paper provided by University of Minnesota: Nexus Research Group in its series Working Papers with number 000037.

Emergency Management (EM)organizations need to have highly functioning logistics networks as key towards supporting andaiding a®ected populations in disasters or con°icts.

rural development, agent-based modeling, scenario analysis, supplychains, diversity

The aim of the methodology is to contribute to theanalysis, evaluation and development of robust policy instruments thatimprove and stimulate rural sustainable development over a range ofpotential future scenarios.

Daniel Frey, Peer-Oliver Woelk, Tim Stockheim, Roland Zimmermann

Their structure inherently meets the requirementsof decentralised supply chains, whereas conventionalSCM systems are often restricted in terms of dynamicbehaviour, handling severe disturbances at supplier sitesas well as dealing with highly customised or complexproducts.

Supply Chain Management, Multi-Agent System,Simulation.

IJCSI International Journal of Computer Science Issues, Vol. 9, Issue 2, No 1,

Discrete Event Simulation, Supply ChainManagement, Oil Refinery Supply Chain, Agent-Based Modelling.

ISCIAgent Based Modeling, Supply chain, cable manufacturing

Master of Science, Industrial Engineering, Boğaziçi University

The analysis focuses especially on inventory/order variability and the bullwhip effect, which is the increase in variability as one moves up in a supply chain. On the other hand, demand forecasting, order batching, and dynamic pricing are shown to be the causes of variability and bullwhip effect in aggregate orders and inventories.

elsevier, Computers and Chemical Engineering 31 (2007) 722–735

Supply chain management; Uncertainty; Multi-agent system

Elsevier

development of an agent-based software system for assisting in decision-making regarding supply chain management and the efficient and effective use of Electronic Data Interchange (EDI) in the automobile industry.

Supply chain configuration optimisation, supply chain risks and uncertainties, multi-objectiveoptimisation, robustness in supply chains

Leibniz Institute for Agricultural Development in Central and Eastern EuropeTheodor-Lieser-Str. 206120 Halle (Saale)Germany

Supply Chain Management, software agents, mixed-integer linear programming.

innovar

Contemporary Engineering Sciences, Vol. 3, 2010, no. 1, 1 - 16

Supply chain, Agent Technology, Multi Agent System and Informationsharing

multi-agent system (MAS), collaborative planning (CP), collaborative operational planning (COP), modelling methodology, supplychain management (SCM), distribution and supply chains and networks (DSC-N), literature review

Air Traffic Control, Multiagent Systems, Reinforcement Learning, Optimization

SAE International

NASA Ames Research CenterUnited States of America

agent-based modeling and simulation, air traffic flow management,collaboration, competition

In this paper, wedescribe an agent-based simulation of the newconcept of operations and our plannedexperimentation to determine if the newconcept of operations will lead to betterutilization of the national airspace.

As a result, this paper proposesagent-based simulation as a method of predicting theimpact of revolutionary changes to an airtransportation system. Agent based simulation canintegrate cognitive models of human performance,physical models of technology behavior anddescription of their operating environment.

Abstract. This paper describes methodology, toolset and case studies of adaptive planning for supply chain networks based on the holistic approach, multi-agent technology and ontological modeling. The set of tools for the development of adaptive planners can be used for a wide range of applications. Case studies are included describing applications inr adaptive airport logistics, factory planning, laundry scheduling and pharmaceutical logistics.

JOURNAL OF COMPUTING, VOLUME 2, ISSUE 4, APRIL 2010, ISSN 2151-9617

—Multi-Agent System、Bullwhip effect、 Fill rate 、NYOP(Name Your Own Price)

In Proceedings of Trading Agent Design and Analysis Workshop

During the course of each year’s competition historical data is logged describing more than 800 games played by different agents from around the world. In this paper, we present analysis that is focused on determining which features of agent behavior, such as the average lead time requested for supplies or the average selling price offered on finished products, tend to differentiate agents that win from those that do not. We present a visual inspection of data from 16 games played in one bracket of the 2006 TAC SCM semi-final rounds. Plots of data from these games help isolate behavioral features that distinguish top performing agents in this bracket.

Lecture Notes in Computer Science

The Trading Agent Competition (TAC) is an international forum which promotes high-quality research regarding the trading agent problem. One of the TAC competitive scenarios is Supply Chain Management (SCM) where six agents compete by buying components, assembling PCs from these components and selling the manufactured PCs to customers. The idea of TAC SCM is the development of agent-based architectures that implement wideapplicable business strategies which efficiently manage cross-enterprise processes. In this paper, we analyze the TAC SCM environment and describe the main features of the CrocodileAgent, our entry in the TAC SCM Competition.

In IJCAI 2005 Workshop on Trading Agent Design and Analysis

Goal Area

Healthcare

mengetahui behavior negosiasi manufacturing

manufaktur

manufacturing

investigate information sharing as a basic supply chain collaboration strategy through the application of the multi agent approach to model and simulate the supply chain sehingga dapat mereduce bullwhip effect dan menurunkan inventory

The main goal is the construction of an agent-based simulation system that simulates processesrelevant to the implementation of clinical trials [HHPA2003].

investigating this aspect of supply chain planning through the use of theoretical contributions found in the field of simulation, system theory and distributed decision making

The framework helps to analyze the business policies with respect to differentsituations arising in the supply chain. We illustrate the framework by means of two case studies

automated supply chain

In order to maketheoretical investigations of supply chains feasible andto support decision-making in real world supply chains,simulation models are used.

This is primarily due tothe availability of timely information across the various stages ofthe supply chain, and therefore the need to effectively utilize theinformation for improved performance -----

Aircraft Supply Chain Example

This paper proposes a framework for designing an agent based simulation to allow for easy aggregation and/or disaggregation of agent characteristics, behaviors, and interactions using a supply chain modeling context.

By viewing these paths in reversed time, qualitative and quantitative methods can be used to determine when the multivariate output is leaving its near-steady state regime as the paths coa-lesce back towards their common initialization state. The methodology is more efficient and general than typical approaches for finding a truncation point for scalar outputs of individual replicates. Artificial bootstrap-like re-sampling of simulation runs is proposed for expensive simulations to estimate system performance sensitivity.

The knowledge required to solve the problem is spatially distributed in differentlocations.

Vehicle

manufacturing

The purpose of this work is to leverage the agent-based modeling onto the process of parceldelivery. F

Our current work aims to take into account the impact anSC’s organizational structure has on its performances byproviding a methodological framework which supportranges from the domain model analysis to running thesimulation.

We propose in particular solutionsthat focus on cooperation between actors in the Supply Chain.

beergame

agri-food system

agent-based representation of the Beer Game Model (BGM) is used to demonstratehow disruptions, occurring to the factory of a SC, can negatively affect its overall performance, and how sharing thefactory disruption information can effectively help blocking the evolution of risk in the SC and improve itsperformance. The BGM is extended in this research to include two factories. The concept of Reverse InformationSharing (RIS) is introduced as a mechanism for sharing the breakdown information. The results show a significantreduction in the cost of the SC and each of its agents due to the RIS. In addition, the analysis shows that the RISsignificance is getting larger with the increase of the disruption frequency.

The objective of this study is to investigate the role of supply chain partners inthe entrepreneurial process. In particular, we will examine the differences inentrepreneurial performance between firms that discover and exploit new wealthcreation opportunities within existing supply chains as opposed to those that decide toestablish the supply chain themselves. In doing so, we introduce an agent-basedmodel that explicitly simulates entrepreneurial discovery, rent appropriation and thedissipation of those rents via competition and resource depletion in the presence ofsupply chain partners.

agriculture

energy

In this paper we initially do a short presentation of the principles of modeling economicsystems with the ABM approach quoting its features, the advantages and disadvantages.

The main aim in supply chain management is to satisfy production requirements, while optimizing the economic objectives. In traditional fossil fuel supply chains, huge amounts of fossil fuels are transported via pipelines or tankers with very small costs. These fuels can be transformed into other sources of energy or transportation fuels at their destination points. This supply chain structure results in creation of global energy markets and has made the fossil fuel based energy systems the dominating energy technologies in the world. Unfortunately, the consumption of fossil fuels now represents the major cause of climate change, and as a consequence, the viability of the fossil fuel supply chain is becoming increasingly questioned.

This paper presents aprototype of a computer simulation system that uses agent-based modeling to simulate an emergencyenvironment with crowd evacuation and provides for testing of multiple disaster scenarios at virtually nocost. The prototype is unique in the current literature as it is designed to simulate a concert-event settingsuch as a stadium or auditorium and is highly configurable allowing for user definition of twodimensionalenclosed areas with any arrangement of seats, pathways, stages, exits, and people as well asthe definition of multiple fire/bombs with fire and smoke dynamics included.

To improveextensibility, a distinctive feature of our approach is thatit separates the functionalities of an element from its roleand handles interactions among elements in an agent-basedframework: elements are modeled as agents and their interactionsdecide the behavior of a supply chain. Our frameworkprovides formal definitions for the syntax and semanticsof an element. The framework separates internal behaviorsof an element from its interface. These features make iteasier to define new types of elements and customize theirbehaviors for a variety of supply-chain applications.

A new paradigm for a mobile service chain’s competitive and collaborative mechanism isproposed in this study.

Byanalyzing the expectations and variances (or risks) of each player’s profit, the interactionbetween and among entities in the chain is well understood. It is found that in the situationwhere a collaborative mechanism is applied, the performance of players is better as comparedto the other two situations where a competitive mechanism is implemented. If someconstraints are applied, the risk will be kept at a low level.

food

We develop a comprehensive simulation model for civilian emergency/disaster responses. In order to incorporate thedetailed interactions among various responders and victims, we integrate the agent-based modeling ideas into thediscrete-event simulation framework and hybrid several components such as GIS.

simulasi disaster di pitterseiburg

We propose an agent based modeling (ABM) approach to study andidentify the supply chain weaknesses by modeling its structural evolu-tion over time. Our approach can provide answers to the previous ques-tions. We believe this approach is promising since it could represent avaluable tool in (i) understanding supply chain processes and (ii) in test-ing social, economical and political strategies in order to achieve bettersustainability models.

Simulationresults show that agent-based spatial modelling constitutes a powerful approach to betterunderstanding processes of innovation and resource use change.

softwood lumber industry

golf club industry

This paper investigates the emergence of clusters of business locations ona supply chain network comprised of suppliers, retailers, and, consumers.

This research thus finds that the centripetalforce attracts retailers to supplier locations; with even more retailers entering the market, thecentrifugal force disperses them. The sensitivity results on model parameters and consumers’demand elasticity are also discussed.

making the integaration of an advanced planning and scheduling system in multi-agent based simulation in lumber industry

However,certain characteristics of FSCs are particularly difficult to model in detail, as data requirements can be intensive.In this paper we highlight some of the challenges modelers face in deciding the most appropriatemethods for representing the elements of an FSC in an MAS model. We provide examples from the literaturethat show how other modelers have chosen to address these challenges. Finally, we discuss benefitsand limitations of each example’s approach, in terms of realism and data requirements.

estimasi demand per market per personalization so allows a satisfactory representation of a structure and behavior of SC

Optimization has made immense strides towards improving logistics costs and services. How-ever, most optimization has been designed to operate in a centralized environment, while manysystems actually operate in a decentralized way, with individuals making decisions that impactthe entire system, especially in emergency management. EM operations can be linked with mobilecomputing, but new methods are needed to operate across the decentralized network.

The Home Depot and Wa²e House for hurricanes and other disasters; supplychain design and interventions for in°uenza pandemic in Georgia and with the American Red Cross;and debris collection post-disaster with FEMA and USACE.

Common AgriculturalPolicy (CAP) increasingly place agriculture in a wider multifunctionalcontext taking into account their role in the rural economy, the qualityof the environment and food safety. This expanded perspective requiresan understanding of agricultural activities beyond farming, includingfood and energy processing, transport, retail and other land use relatedactivities like tourism.

MANUFACTURING

Since necessary data are not available withinthe whole supply chain, an integrated approach forproduction planning and control taking into account allthe partners involved is not feasible. In this paper a MASarchitecture integrating various intelligent agent systemsis presented to address the problem.

COMPARING EXISTING SCM DENGAN MAS IN manufacturer of agricultural equipment

The proposed model allows modellingdifferent SCs with multi-products and differentoperational policies considering information asymmetryand distributed/decentralized mode of control.

The aim of this paper is to describe an application of PipeTransportation Simulator (PTS) in oil refinery supplychain modelling.

manufacturing

MANUFACTURING

manufacturing

This paper proposes a supply chain management model allowing performance measurement in a cable wire manufacturing company. This paper specifically highlights the components and key parameters involved in the same and define the performance indicators. The proposed work focuses in showcasing the multiple agent interactions in the cable wire making industry and benefits of operating supply chains as an integral part of the manufacturing enterprise. It also discusses the importance of information sharing for the effective functioning of supply chains and multi- agent interactions.

The proposed methodology allows to address the design of complex SCs which are hard to be modelled otherwise, for example by means ofstandard mathematical programming tools. Specifically, the multi-agent system is suitable for SCs that are either driven by pull strategies or operateunder uncertain environments, in which the mathematical programming approaches are likely to be inferior due to the high computational effortrequired. The advantages of our approach are highlighted through a case study comprising several plants, warehouses and retailers.

manufacturing

agri-food business

manufacturing

We are developing a MIC-based supply chain management-modeling environment. This environment will allow domain experts to create models of the software agents to simulate, and control, the actual on-line negotiation processes. The modeling environment will allow modeling of agent behavior, as well as defining agent-to-agent interaction scenarios.

This paper examines the risks and uncertainties in supplychains and identifies the key factors included in supply chain optimisation. The paper also proposes amethodology to introduce the key risks and uncertainties into modelling in an agent-based supply chainoptimisation algorithm, with the aim of minimising cost and maximising reliability and robustness.

The aim of the paperis to introduce ideas regarding the ABMS implementation and to build a model which capturesthe change of willingness to cooperate within a first simplified supply chain model of anagricultural market.

The hybrid approach proposed in this work offers the advantages of the multi-agent system to model the SC together with the optimization capabilities of local not so large mathematical programming models to solve in an efficient manner the decision problems that the central agent faces along one simulation run. The results so far obtained are very promising.

The proposed work focus on the significance and benefits of operating supply chainsas an integral part of the modern manufacturing enterprises and also the importanceof information sharing as the major requirement for the effective functioning ofsupply chains.

Finding reliable and adaptivesolutions to the flow management problem is of paramountimportance if the Next Generation Air Transportation Systemsare to achieve the stated goal of accommodating threetimes the current traffic volume. This problem is particularlycomplex as it requires the integration and/or coordinationof many factors including: new data (e.g., changingweather info), potentially conflicting priorities (e.g., differentairlines), limited resources (e.g., air traffic controllers)and very heavy traffic volume (e.g., over 40,000 flights overthe US airspace).

Our FACET based results show that agents receivingpersonalized rewards reduce congestion by up to 45%over agents receiving a global reward and by up to 67% overa current industry approach (Monte Carlo estimation).

Wesummarize a new concept that has been proposed for collaborative air traffic flowmanagement, the problems it is meant to address, and our approach to evaluating theconcept. We present our initial simulation design and experimental results, using severalsimple route selection strategies and traffic flow management approaches.

mengantar penumpang dalam pesawat

Case studies are included describing applications inr adaptive airport logistics, factory planning, laundry scheduling and pharmaceutical logistics.

Using NYOP(Name Your Own Price) to be the core of dynamic procurement negotiation algorithm sets up multi-agent dynamic supply chain system, to present the DSINs(Dynamic Supply Chain Information Networks) by JADE, and to present the dynamic supply chain logistic simulation by eM-Plant. Finally, evaluating supply chain performance with supply chain performance metrics (such as bullwhip, fill rate), to be the reference of enterprise making deciding in the future.

The Supply Chain Trading Agent Competition (TAC SCM) was designed to explore approaches to dynamic supply chain trading. During the course of each year’s competition historical data is logged describing more than 800 games played by different agents from around the world. In this paper, we present analysis that is focused on determining which features of agent behavior, such as average lead time or selling price, tend to differentiate agents that win from those that don’t. We begin with a visual inspection of games from one bracket of the 2006 semi-final rounds. Plots from these games allow us to isolate behavioral features which do, in fact, distinguish top performing agents in this bracket. We introduce an information gain based metric that we use to provide a more complete analysis of all the games from the 2006 quarter-final, semi-final and final rounds.

Using this metric we find that, in the final rounds of the 2006 competition, winning agents distinguished themselves by their procurement decisions, rather than their customer bidding decisions. We also discuss how we used the analysis presented in this paper to improve our entry for the 2007 competition, which was one of the six finalists that year.

pake Future

skenario

simulasi scm

prototype model dari supply chain menggunakan java --> simulasi skenaio

efek stokastik harus dianalisis lebih lanjut

simulationmodels were implemented, which map necessary and participating actors. These models were based onan actor-centered view and were implemented by an agent-oriented approach. The developed prototypesupports medical personnel and other staff of participating

Software agents are used to emulate the entities i.e. various enterprises and their internal departments. Flows*/material and information*/are modeled as objects. .

This paper considers a supply chain which comprises multiple independent and autonomousenterprises (project managers) which seek and select various contractors to complete operationsof their projects. Both the project managers and contractors jointly determine the schedules oftheir operations while no single enterprise has complete information of other enterprises. Thecentralized scheduling approach that can usually obtain good global performance but mustshare nearly complete information sharing is difficult or even impractical due to the distributednature of real- life supply chains. This paper proposes an agent-based supply chain model tosupport distributed scheduling.

Vensim® andeM-Plant® in a hierarchical model.

Automated Supply Chain Configurer (ASCC) Framework

The design methodology is based on combining hierarchical model-ing with data-driven modeling.

The next model we consider is a simple tool bank with M machines and N workers. This example is a simplified version of the model in Schruben (1981), that still illustrates an unconventional initial transient and has what might be viewed as a conventional steady-state in the scalar output of total work in the pro-cess queue. The system being modeled is a set of parts presses with workers who do degating (trimming the flange) of finished parts. When the parts queue is too long a “start” light signals the workers, who as soon as they are free, degate the parts in the queue until they reach a “free” limit. Afterwards, they can take a break if there are no parts above their “start” limit.

An allocation algorithm based on the definition isformed. The model of the problem is built and described. The implementation is constructedover an event-based agent simulation platform for the urban environment, AgentPolis.

Methodological for the modeling andsimulation oriented agents, The software designer details the CAOM by associating aconceptual agent with a software agent architecture (forexample BDI (Believe, Desire, Intention) [Rao et al.1991]) and specifying their behaviors (for example aUML2, state chart for a reactive agent) and interactions(AUML3 sequence diagram [Odell et al., 2001]), resultingin an Operational Agent Model (OPAM). T

We covet to propose solutions related to informationsystems and Supply Chains through an intelligentplatform (i-SEEC) that allows different companies tohave the ability to best meet customer demands.

The proposed topology addresses manyissues where future research could yield interestingresults.

skenario

Agripolis, Reg-MAS, MP-MAS,SWISSland

Theframework also gives rigid simulation-based semantics fora supply-chain model. The formalism it introduced helps ananalyst understand and validate simulation results preciselyand rigorously. The formal framework also facilitates automatedformal analysis of a supply chain [7]. We discuss theimplementation of our framework in context of SIMRISK, asupply chain simulation and analysis tool we developed.

The main idea of the proposed approach is based on a multi-agentsystem with optimal profit of the pull, push, and collaborative models among the portalaccess service provider (PASP), the product service provider (PSP), and the mobile serviceprovider (MSP). To address the running mechanism for the multi-agent system, an integratedsystem framework is proposed based on the agent evolution algorithm (AEA), whichcould resolve all these modes. To examine the feasibility of the framework, a prototype systembased on Java-Repast is implemented. The simulation experiments show that this systemcan help decision makers take the appropriate strategies with higher profits.

D4S2

AOE2 framework

The individual choice ofthe farm-household among available production, consumption, investment and marketingalternatives is represented in recursive linear programming models.

We introduce research that explicitly integrates the decentralized decision-makers into the opti-mization of the entire supply chain by incorporating their behavior with mathematical models so asto improve the overall system outcomes.

The methodology is developed to assist DGAgriculture in implementing the newly orientated CAP, RuralDevelopment Policy and the Lisbon Strategy over a period of 15 years1

Witness simulation softwareenvironment using MS Excel for input data loading and outputsupgrading. PTS is particularly suitable for “what-if” analysis inthe crude oil, fuels or gas supply chains where the products aretransported among warehouses and refineries through the pipelines

Model matematis

The scheduling systems generally have different objectives and constraints, and operate in an environment where there is enough Information related to production failures, supplier information, and order processing and customer requests. Each process is assigned to an agent who works according to the information received from other agents. Henceforth, we discuss here the various aspects of agent interactions in supply chain management.

Model matematis

Model Integrated Computing dan ZEUS Agent Building Toolkit

Deliberative agents take into account not only the present situations but also the history of its past interactions. All such interactions can be stored and can be considered as a very large history space, theoretically infinite, limited by the hardware resources.

With the increased importance of an efficient and robust supply chain in business success, most firmsneed to optimise their supply chain configurations not only to meet customer demands with minimum cost butalso to satisfy customer requirements in a dynamically changing operational environment. As such risks anduncertainties should be included in supply chain configuration design and optimisation.

model matematis menggunakan Matlab®: Stateflow and Simulink

air trafic

In this paper we use FACET – an air traffic flow simulatordeveloped at NASA and used extensively by the FAA andindustry – to test a multi-agent algorithm for traffic flowmanagement.

Experiment on a Local Traffic Scenario - Though our modelis still in an early stage of development, these results have revealed interesting properties ofthe proposed concept that will guide our continued development, refinement of the model,and possibly influence other studies of traffic management elsewhere. Finally, we concludewith the challenges of validating the proposed concept through simulation and future work.

Simulation of these individual models acting togethercan predict the result of completely newtransformations in procedures and technologies.While agent-based simulations cannot include everyaspect of system behavior, they can provide quick,cost-effective insights that can supplement otherforms of analysis.

. The technique involves calculating the amount of information gained about an agent’s performance by knowing its value for each of 20 different features. Our analysis helps identify features that differentiated winning agents. In particular we find that, in the final rounds of the 2006 competition, winning agents distinguished themselves by their procurement decisions, rather than their customer bidding decisions. We also discuss how the information gain analysis could be extended by agent developers to identify potential weaknesses in their entry.

123456789

101112131415161718192021222324252627282930313233343536373839

404142434445464748495051525354555657585960616263646566676869707172737475767778798081828384858687

888990919293949596979899

100101102103104105106107108109110111112113114115116117118119120121122123124125126127128129130131132133134135

136137138139140141142143144145146147148149150151152153154155156157158159160161162163164165166167168169170171172173174175176177178179180181182183

184185186187188189190191192193194195196197198199

Area Pengarang

1 Umum

2 Umum

3 Umum Lau et al. (2006)

4 Umum

5 Umum(automated SC)

6 Umum Xin Li (2006)

7 Umum

8 Umum Lau et al. (2007)

9 Umum Jetly et al. (2012)

Santa-Eulalia et al. (2011)

Akanle dan Zhang (2008)

Schieritz dan Größler (2003)

Emerson dan Piramuthu (2004)

Andrews et al. (2007)

11 Umum

12 Umum

13 Umum

14 Umum Karimi et al. (2007)

15 Umum Kovalchuk (2008)

16 Umum Zhang dan

Wuhan (2008)17 Umum Kumar et al. (2009)

18 Umum Tan et al. (2009)

19 Umum Chen (2010)

20 Umum Mustapha (2010)

21 Umum Jahani et al. (2011)

22 Umum Harper et al. (2011)

Carvalho dan Custódio (2005)

Sardinha et al. (2006)

Huang dan Levinson (2006)

23 Umum (automated SC)

24 Manufaktur Forget et al. (2008)

10 Manufaktur

25 Manufaktur Aslam et al. (2010)

26 Manufaktur Goel et al. (2011)

27 Manufaktur

28 Manufaktur (inddstri kayu)

29

30 Manufaktur Al-zu’bi (2010)

31 Manufaktur

32 Manufaktur Verdicchio danColombetti (2001)

33 Manufaktur

34 Manufaktur

Ameri dan McArthur (2013)

Santa-Eulalia et al. (2002)

Kaur dan Pandey (2012)

Santa-Eulalia et al (2008)

Manufaktur (industri otomotif dan semi konduktor)

Azevedo et al. (2007)

Souza dan Khong (1999)

Ulieru dan Cobzaru (2005)

Monostori et al. (2006)

34 Manufaktur

35 Manufaktur

36 Manufaktur

37 Manufaktur (kayu)

38 Manufaktur(Golf)

39 Manufaktur Frey et al. (2003)

40 Manufaktur Vieira et al. (2012)

41 Manufaktur Demirel (2008)

42 Manufaktur Mele et al. (2007)

43 Manufaktur Pathak et al. (

44 Manufaktur Mele et al. (2005)

45 Bisnis Lin et al. (2002)

Monostori et al. (2006)

Frayret et al. (2011)

Ibrahim dan Deghedi (2012)

Lamieux et al. (2009)

Labarthe et al. (2005)

45 Bisnis Lin et al. (2002)

46 Bisnis Jiang et al. (2010)

47 Bisnis (Koran)

48 Bisnis (logistic)

49 Bisnis Starý (2012)(Logistik parcel)

50 Kesehatan

51 Kesehatan Kirn et al. (2006)

52 Kesehatan

53 Kesehatan Gasmelseid (2012)

54 Agrikultur Ross (2009)

Böhnlein et al. (2011)

Rani dan Srinivasan (2012)

Nealon dan Moreno (2003)

Charfeddine dan Montreuil (2008)

55 Agrikultural Chen (2011)

56 Agrikultur

57 Energi Kremmydas (2012)

58 Energi

59 Bencana Wu et al. (2008)

60 Bencana Ergun et al. (2008)

1999 1 umum2000 0 manufaktur2001 1 Bisnis2002 2 Kesehatan2003 3 Agrikultural2004 1 Energi2005 4 Bencana2006 62007 52008 92009 42010 52011 72012 102013 1

1 Co-evolutionary 12 Ggeographical information system (GIS) 13 Desain e-Supply Chain Management 14 Procurement auctation 15 Desain pricing 1

Krejci dan Beamon (2012)

Dyntar dan Škvor (2012)

19992000

20012002

20032004

20052006

20072008

20092010

20112012

20130

2

4

6

8

10

12

10

12

3

1

4

65

9

45

7

10

1

umum

manufak

turBisn

is

Kesehata

n

Agriku

ltural

Energ

i

Bencan

a0

5

10

15

20

25

22 22

5 4 3 2 2

Chart Title

Column E

6 Pemilihan distributor 17 Resiko SC 19 Pola distribusi 1

10 Lokasi setiap agen 111 Pergerakan dan rute kendaraaan 212 Perbandingan kontraktor 213 Bullwhip effect 214 Pengendalian sumber daya 215 Peranan partner 216 Emergency Management (EM) 217 Ketidakpastian 318 Automatisasi konfigurasi SC 319 SC competition 320 Pengaturan harga jual 321 Biaya operasi 322 Penjadwalan 523 Alat pengambilan keputusan 524 Kebijakan dan kontrol inventory 625 Pengendalian dan desain order 6

Kerangka kerja SC 8Planning SC 9Desain jaringan SC 9Negosiasi 10Information sharing 12

Kata Kuci dalam Konten

-FAMASS

- Kombinasi sumber daya untuk order individual.

Sentralisasi penjadwalan proyekMelihat penyebaran infromasi-Perbandingan Kontraktor

-Model integrasi

-Pembahasan 2 model

- Konfigurasi SC yang terautomasi

- Information Sharing

- Pendekatan multi agent Untuk memodelkan dan mensimulasikan SC.- Supply Chain Trading Agent Competition (TAC SCM)

-sharing information

- biaya operasi,

-tingkat persediaan

obat dalam lingkungan yang tidak pasti.

-Integrasi SC dengan Advanced Planning and Scheduling (APS)

Model analitis yang unik, yaitu dengan framework FAMASS (FORAC Architecture for Modelling Agent-based Simulations for SC planning)

- Konfigurasi optimisasi dari penawaran iteratif agen dalam

Melihat dan memilih beragam kontrektor yang dapat menyelesaikan proyek.

Untuk menurunkan kompleksitas dari model dengan integrasi antara system dynamic dan diskrit agent based.

Menganalisis kekuatan dan kelemahan 2 model dalam Emergent Structures dalam SC.

Menginvestigasi penyebaran informasi sebagai sebagai dasar dari strategi kolaborasi SC

-tingkat backlog dari retailer, distributor, produsen dan seluruh komponen SC

-SC dalam beberapa perusahaan farmasi yang berinteraksi untuk memproduksi dan mendistribusikan

-Simulasi dari jumlah agen yang hampir tak terbatas

heuristik untuk pengambilan keputusan,

-evaluasi yang berbeda terhadap kriteria dan fungsi-Urutan order yang berbeda-beda, -Prilaku stokastik atau deterministik-intelligent agent-SCM competitionpenerapan desain Trading Agent Competition.-Mengklusterkan- Pemilihan lokasi retail-Pola dari distribusi-jaringan SC- procurement auction

-Selain SCM, solusinya adalah forecasting financial markets dan berpartisipasi dalam online auctions.

-kinerja, dan kebijakan sharing information-negosiasi bilateral, -Pemantauan sistem order dan produksi-Perencanaan dan penjadwalan sistem multiagen.

-Pemecahan masalah komunikasi- MAS-Bullwhip effect-Fill rate-NYOP(Name Your Own Price)-Dinamika negosiasi-Dinamika keputusan pembelian

- intelligent platform (i-SEEC)untuk mencari permintaan konsumen- Pawaran bahan

- agregasi atau disagregasi

-kemungkinan untuk memilih strategi keputusan diantara alternatif dan taktik,

-Jenis informasi dengan dampaknya terhadap rantai pasokan

-MAS merupakan pemecah masalah melampaui kapasitas individu dari setiap problem solver.

- Sebuah metodologi kerangka kerja yang baru dan berorientasi organisasi

-Negosiasi dengan pemasok dan pelanggan pada harga, volume, kualitas, dan tanggal pengiriman bahan supplier.

- data mining yang terintegrasi dengan landasan simulasi agent-based

-Negosiasi automasi

-Framework SC perusahaan-Kebijakan perusahaan-Optimisasi dalam SCM- Intelligent agentspemasok, produsen, distributor dan retailer.

-Pengembangan MAS-Negosiasi antar komponen SC-Pemilihan yang intelegen pada distributor- Negosiasi antara makelar dan distributor- Perancangan, kofigurasi dan desain SC

-Jaringan perusahaanJaringan pasok yang terintegrasi-DSS (Decision support systems)-Production planning and control-E-business-E-Supply Chain Management- Teknanan ekonomi SC klasik

- information sharing sebagai kunci dalam penentuan level dalam jaringan SC- inter-agent stateantara 2 perusahaan

-Studi kasus Industri Manufaktur Telepon-Negosiasiadalah kegiatan interaksi agen akan sistem harga.

-Perkenalan software agents dan sistem multi-agent-ketidakpastian-sharing information

- Menyelesaikan masalah SC dengan kerangka kerja Digital Manufacturing Market (DMM).

-Aplikasi pertama dari teknologi agen didasarkan pada ontologi formal yang mengkodekan kemampuan manufaktur dari supplier.

Negosiasi dalam perencanaan SC menggunakan multi-behavior-agents

-Model perusahaan holonic dengan Foundation for Intelligent Physical Agents (FIPA)

- customer-centric SC

-Perusahaan Canadian forest product-Reverse Information Sharing

-Beer Game-SC risk-Nilai penciptaan jaringan -Advanced planning system- perencanaan lanjutan -sistem penjadwalan-customer-centric supply chain, -MAS dengan simulasi agents-oriented -Desentralisasi SC- Penanganan gangguan yang parah pada supplier- pendekatan terpadu -perencanaan dan pengendalian produksi -Pertimbangan retailer-MAS- information asymmetry

-Mode kontrol yang terdistribusi atau terdesentralisasi.-Variabilitas dari inventory atau order variability -Bullwhip effect-Forecasting-Order batching-Dynamic pricing-MAS-Ketidakpastian-Pengambilan keputusan

-Industri otomotif-Negosiasi online- SCM-Mixed-integer linear programming- Pendekatan hybrid-MAS-Sharing information-tingkat pemenuhan in-time order

-Cara mengaplikasikan advanced planning dan scheduling tool.

-Kombinasi dari teknologi agent-based dan operations research-based tools.

berbagi informasi mengenai breakdown (kerusakan)

-Penggunaan yang efektif dan efisiern dari Electronic Data Interchange (EDI)

-waktu siklus agar lebih pendek

provider (MSP).- Interaksi antara entitas dalam rantai

- Menyelesaiakn permasalahan rute kendaraan.-Memperhitungkan pungutan dalam SC

-Bisnis logistik logistik-shipping- Pergerakan kendaraan dalam bentuk grafik

- Agent.Hospital

Didesain sebagai ntegrasi supply chain dari sistem

-Distribusi dari bahan medis

-Model aliran pasein-Pelayanan kesehatan-MAS-Sistem delivery healthcare yang terdistribusi

-Mengadopsi konsep co-evolutionary

- Agri-Food SC-Peranan partner dalam SC

-Paradigma baru dalam untuk mekanisme kompetitif dan kolaboratif dari rantai layanan mobile

- laba yang optimal dari portal access service provider (PASP), product service provider (PSP), dan mobile service

-Pendekatan Multi-agent dalam sistem produksi dan distribusi industri Koran.

- Kontrol persediaan dan Minimasi total cost dari SC dengan sharing information dan forecasting, menggunakan mekanisme negosiasi.

- DSS (Decision Support system) berlandaskan pada paradigma multi-agent paradigm

dengan permintaan yang tinggi dalam sistem informasi yang dijadikan automasi.

- pengembangan referensi model dari multi-agen Pharmacoinformatics.

-SC dari Produk Agrikultural-ASCTS-SIstem keamanan produk Agrikultural

produksi dan distribusi makanan.-Pembangunan ifrastruktur untuk SC

- Oil refinery SCM

-Discrete Event Simulation, -Agent-Based Modelling.- Respon darurat -Ggeographical information system (GIS)-Emergency Management (EM)Fungsi jaringan logistic yang kuat adalah kunci utama

2222

54322

-Food supply chain (FSC)

-Pengangkutan hasil produksi biofuel pada Perkebunan Jatropha dengan kapal tanker dan pipa

SC pada crude oil, cairan atau gas yang ditransportasikan menggunakan pipa.

Co-evolutionaryGgeographical information system (GIS)

Desain e-Supply Chain ManagementProcurement auctation

Desain pricingPemilihan distributor

Resiko SCPola distribusi

Lokasi setiap agenPergerakan dan rute kendaraaan

Perbandingan kontraktorBullwhip effect

Pengendalian sumber dayaPeranan partner

Emergency Management (EM)Ketidakpastian

Automatisasi konfigurasi SCSC competition

Pengaturan harga jualBiaya operasiPenjadwalan

Alat pengambilan keputusanKebijakan dan kontrol inventoryPengendalian dan desain order

Kerangka kerja SCPlanning SC

Desain jaringan SCNegosiasi

Information sharing

0 2 4 6 8 10 12 14111111111

222222

33333

55

66

899

1012

umum

manufak

turBisn

is

Kesehata

n

Agriku

ltural

Energ

i

Bencan

a0

5

10

15

20

25

22 22

5 4 3 2 2

Chart Title

Column E

Co-evolutionaryGgeographical information system (GIS)

Desain e-Supply Chain ManagementProcurement auctation

Desain pricingPemilihan distributor

Resiko SCPola distribusi

Lokasi setiap agenPergerakan dan rute kendaraaan

Perbandingan kontraktorBullwhip effect

Pengendalian sumber dayaPeranan partner

Emergency Management (EM)Ketidakpastian

Automatisasi konfigurasi SCSC competition

Pengaturan harga jualBiaya operasiPenjadwalan

Alat pengambilan keputusanKebijakan dan kontrol inventoryPengendalian dan desain order

Kerangka kerja SCPlanning SC

Desain jaringan SCNegosiasi

Information sharing

0 2 4 6 8 10 12 14111111111

222222

33333

55

66

899

1012

Goal Metodologi

Framework

Seluruh siklus simulasi.

Mengoptimasi konfigurasi SCM Metode Optimasi

Vensim® daneM-Plant®

-Menurunkan bullwhip effect-Menurunkan inventory

-

Simulasi multi-agents

Memberikan kerangka terpadu untuk menganalisis, menentukan,

merancang dan mengimplementasikan percobaan simulasi meliputi

Mempertimbangkan SC sehingga dapat memilih kontraktor.

model agent-based SC model untuk membantu penjadwalan distribusi.

Menciptakan integrasi model dengan menurunnya kompleksitas dari model antara system dynamic dan diskrit agent based.

Mengetahui availability dari informasi dalam beragam tingkatan SC dan mengefektifkan utitiitas dari informasi sehingga meningkatkan

Kombinasi model hierarchical dengan driven modeling.Penggunaan model prototype dari supply chain sehingga menghasilkan beberapa skenario.

Menentukan fitur dari perilaku agen, seperti rata-rata lead time atau harga jual untuk membedakan agen yang menang dan tidak.

-Mengkaji dampak dari berbagai tingkat penyebaran informasi tentang penambahan inventory perusahaan dan tingkat backlog.

Skenario dalam simulasi eksperimental.

-Mempelajari tingkat penyebaran informasi mana yang paling optimal.

Mengembangkan dan memvalidasi simulasi SC dengan multi-agen,sehingga dapat akurat diwakili untuk menciptakan model yang spesifik.

Simulasi

-

Simulasi

-

-

informasi operasional SCJava

SIMRISK (simulasi)

JADE

-

-

Software agents

Manajemen masalah SC, sehingga memperoleh hasil dengan

tingkat stok stok untuk setiap produk dari material.

untuk menangani sub masalah dari dinamiika SCM

Meneliti munculnya kelompok lokasi bisnis pada jaringan SC.

Mengendalikan kendala dan mendefinisikan procurement auction yang baru.

Model matematis dan simulasi

Memprediksi harga penawaran dalam konteks dinamika lingkungan yang kompetitif.

Memberikan review koordinasi

Konstruksi, arsitektur, koordinasi dan perancangan agen.

Menciptakan sistem yang dikembangkan secara terpisah interkoneksi memebangun agen, jadi memungkinkan harmonisasi yang berfungsi di luar kemampuan dari agen Mengevaluasi kinerja rantai pasokan dengan metrik kinerja rantai pasok, sehingga menjadi acuan perusahaan untuk membuat keputusan di masa depan.

Menghasilkan solusi yang fokus pada kooperasi antara agen-agen dalam SC.

Menyajikan kerangka kerja berbasis agen yang sistematis untuk pemilihan supplier berdasarkan pendekatan kasus.

Menciptakan kerangka kerja untuk merancang sebuah simulasi agent-based untuk memungkinkan adannya agregasi atau disagregasi pada karakteristik agen, perilaku,

skenario

Software agents

Simulasi

Software agent-based

-

Model yang kompleks

Software Agents

JADE

seluruh holarchy SC.

software agents

-Membuat kerangka agent-based untuk menciptakan konfigurasi CS yang tangkas.

Java Agent DEvelopment Framework (JADE).

-Hasilnya buka SC yang optimal, namun kelayakan teknologi SC yang dihasilkan.

mengetahui behavior negosiasi

Framework digunakan untuk membantu menganalisis kebijakan bisnis dengan situasi yang berbeda-beda.Untuk menyajikan kerangka kerja baru dalam penerapan ABS dan teknik optimasi berbasis simulasi.

Rancangan kerangka sistem dapat menghilangkan masalah komunikasi dan pengambilan keputusan untuk sistem Untuk pemilihan distributor yang cocok untuk manufaktur.

Java Application Development Environment (Jade)-Mengusulkan suatu erangka simulasi yang

berbasis agen untuk pemodelan sistem SC dalam tahap analisis.

-Mengusulkan suatu metode formal untuk mengubah model analisis menjadi spesifikasi dan desain dari model.

Meningkatkan visibilitas informasi, peringatan dini gangguan, disinkronisasi produksi dan perencanaan kolaboratif dalam SC.

Menciptakan alat yang dapat menghadapi globalisasi, inovasi produk, hambatan organisasi, dan penyebaran informasi yang

MAS+SCM dengan MAS untuk mendukung Electronic SCMUntuk menghadapi tekanan dalam industri

disk drive, yaitu nilai, waktu, pasokan, permintaan dan pengembangan teknologi Menyajikan struktur data untuk komitmen yang dapat digunakan dalam kerangka komunikasi berbasis agen untuk pengelolaan rantai pasokan

untuk mengakomodasi diferensiasi kepentingan dan menyediakan alokasi sumber daya

Menangani masalah ketidakpastian dan dinamika temporal, sharing information dan operasi terdistribusi atau koordinasi dan kerjasama entitas yang otonom.

software agents

Software

Beer Game

Simulasi

Simulasi

Memungkinkan pemodelan Simulasi

Model matematis

Mengatasi desain yang kompleks dari SC Model matematis

Mensimulasikan -

Menangani masalah ketidakpastian dan dinamika temporal, sharing information dan operasi terdistribusi atau koordinasi dan kerjasama entitas yang otonom.

Mendukung koordinasi perencanaan dan upaya pengendalian dalam lingkungan yang berpusat pada pelanggan dengan cara perencanaan lanjutan dan sistem penjadwalan.

Mengetahui bagaimana gangguan dapat mempengaruhi kinerja secara keseluruhan dan cara penyebaran informasi pabrik secara efektif dapat membantu menghalangi evolusi risiko di SC dan meningkatkan kinerja.Membuat integrasi dari perencanaan lanjutan dan sistem penjadwalan dalam simulasi berbasis multi-agent dalam industri kayu

Mengestimasi permintaan per market per personalisasi, sehingga merepresentasikan kepuasan dari so struktur dan perilaku dalam Mengintegrasikan berbagai sistem intelegent agents untuk mengatasi masalah yang ada

Perbandingan SCM lama dan MAS

SC yang berbeda-beda dengan multi-produk dan kebijakan operasional yang berbeda-beda.

Mengagregatkan jumlah pesanan dan persediaan dengan menurunkan variabilitas bullwhip effect.

Menciptakan model dari agen perangkat lunak untuk mensimulasikan dan mengontrol proses negosiasi online.

Simulasi dengan Model Integrated Computing dan ZEUS Agent Building Toolkit

Memperoleh keuntungan dari sistem multi-agen untuk model SC bersama-sama dengan kemampuan optimasi untuk memecahkan masalah secara efisien.

Model matematis dan simulasi

dan menganalisa korelasi pembeli dan penjual dalam sharing information antara para mitra bisnis SC.

-

Java-Repast

Metode Optimasi

Software agents

-

-Menganalisis kebutuhan

Simulasi

software agents

menyelidiki peran partner di SC. -

Untuk menguji kelayakan kerangka kerja suatu pengimplementasian sistem prototype berbasis Java-Repast yang dapat membantu pengambil keputusan mengambil strategi yang tepat dengan keuntungan yang lebih tinggi.

Optimasi jadwal transportasi yang berhubungan erat dengan jadwal produksi

Merancang biaya subsistem menggunakan teknologi multi-agen yang berkaitan dengan perhitungan pada barang dalam logistic SC.

Memperkirakan jarak sebagai biaya dengan persaingan untuk pengiriman parcel.

Simulasi bernama AgentPolis.

Mengetahui persyarata yang diperlukan untuk memecahkan masalah yang secara spasial terdistribusi dalam berbagai lokasi.

-Mencari proses yang relevan untuk dapat diterapkan pada klinik.

Sistem informasi dengan agent-based indalam skenario-skenario bisnis kesehatan.

-Mengidentifikasikan masalah dalam bisnis healthcare

Membantu memodelkan sistem delivery bahan kesehatan dan meminimasi resiko dari melewatkan elemen dan interaksi yang penting.

Untuk meningkatkan komunikasi,, melaporkan reaksi obat yang merugikan dan memfasilitasinya

berbasis skenario, sehingga meningkatkan kualitas pelayanan farmasi.

-

Simulasi (MS. Excel)

D4S2 (Software Simulasi)

Model matematis

2048

32

Untuk mengatasi kecacatan pada sistem ASCTS (Agricultural Supply Chain Traceability System).

Metode kualitatif dan analisis algoritma pada model fisik.

Memungkinkan penangkapan interaksi dari pengambilan keputusan, dan adaptasi agen FSC yang bersifat otonomMemenuhi kebutuhan produksi dan mengoptimalkan tujuan ekonomi.

Menggambarkan penerapan Pipe Transportation Simulator (PTS) dalam model rantai pasok kilang minyak.

Membuat Model simulasi komprehensif untuk darurat atau bencana tanggapan sipil, sehingga mengintegrasikan ide-ide pemodelan Merancang ME yang paling optimasi dengan dihubungkan dengan mobile komputasi dan metode baru yang diperlukan untuk beroperasi

Co-evolutionaryGgeographical information system (GIS)

Desain e-Supply Chain ManagementProcurement auctation

Desain pricingPemilihan distributor

Resiko SCPola distribusi

Lokasi setiap agenPergerakan dan rute kendaraaan

Perbandingan kontraktorBullwhip effect

Pengendalian sumber dayaPeranan partner

Emergency Management (EM)Ketidakpastian

Automatisasi konfigurasi SCSC competition

Pengaturan harga jualBiaya operasiPenjadwalan

Alat pengambilan keputusanKebijakan dan kontrol inventoryPengendalian dan desain order

Kerangka kerja SCPlanning SC

Desain jaringan SCNegosiasi

Information sharing

0 2 4 6 8 10 12 14111111111

222222

33333

55

66

899

1012

umum

manufak

turBisn

is

Kesehata

n

Agriku

ltural

Energ

i

Bencan

a0

5

10

15

20

25

22 22

5 4 3 2 2

Chart Title

Column E

Co-evolutionaryGgeographical information system (GIS)

Desain e-Supply Chain ManagementProcurement auctation

Desain pricingPemilihan distributor

Resiko SCPola distribusi

Lokasi setiap agenPergerakan dan rute kendaraaan

Perbandingan kontraktorBullwhip effect

Pengendalian sumber dayaPeranan partner

Emergency Management (EM)Ketidakpastian

Automatisasi konfigurasi SCSC competition

Pengaturan harga jualBiaya operasiPenjadwalan

Alat pengambilan keputusanKebijakan dan kontrol inventoryPengendalian dan desain order

Kerangka kerja SCPlanning SC

Desain jaringan SCNegosiasi

Information sharing

0 2 4 6 8 10 12 14111111111

222222

33333

55

66

899

1012

Software 9 D4S2 1

UmumManufaktur

Bisnis Lin et al. (2002)

Bisnis Jiang et al. (2010)

Bisnis

Bisnis (Koran) Böhnlein et al. (2011)

Bisnis (logistic) Rani dan Srinivasan (2012)

Bisnis Starý (2012)(Logistik parcel)

Kesehatan Nealon dan Moreno (2003)Kesehatan Kirn et al. (2006)

Kesehatan

19992000

20012002

20032004

20052006

20072008

20092010

20112012

20130

0.5

1

1.5

2

2.5

3

3.5

4

4.5

Umum

1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 20130

0.5

1

1.5

2

2.5

3

3.5

Manufaktur

Column E

1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 20130

0.5

1

1.5

2

2.5

Bisnis

Kesehatan Kirn et al. (2006)

Kesehatan Charfeddine dan Montreuil (2008)

Kesehatan Gasmelseid (2012)

Agrikultur Ross (2009)

Agrikultural Chen (2011) Agrikultur

Agrikultur Krejci dan Beamon (2012)

Energi Kremmydas (2012)Energi

Energi Dyntar dan Škvor (2012)

Bencana Wu et al. (2008)

Bencana Ergun et al. (2008)

Bencana

1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 20130

0.5

1

1.5

2

2.5

Bisnis

1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 20130

0.2

0.4

0.6

0.8

1

1.2

Kesehatan

1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 20130

0.2

0.4

0.6

0.8

1

1.2

Agrikultur

1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 20130

0.5

1

1.5

2

2.5

Chart Title

Column E

1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 20130

0.5

1

1.5

2

2.5

Chart Title

Column E

1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 20130

0.5

1

1.5

2

2.5

Bencana

Column E

199920002001 12002 12003 220042005 12006 22007 42008 32009 22010 22011 32012 12013 11999 120002001 12002 12003 120042005 32006 12007 22008 32009 12010 22011 22012 320131999200020012002 120032004200520062007200820092010 12011 12012 220131999

2000200120022003 1200420052006 120072008 12009201020112012 1201319992000200120022003200420052006200720082009 120102011 12012 1201319992000200120022003200420052006200720082009201020112012 2201319992000

20012002200320042005200620072008 220092010201120122013

Pengarang Kata Kuci dalam Konten

-FAMASS

- Kombinasi sumber daya untuk order individual.

Lau et al. (2006) Sentralisasi penjadwalan proyekMelihat penyebaran infromasi-Perbandingan Kontraktor

-Model integrasi

-Pembahasan 2 model

- Konfigurasi SC yang terautomasi

Xin Li (2006) - Information Sharing

- Pendekatan multi agent Untuk memodelkan dan mensimulasikan SC.

Lau et al. (2007) -sharing information

-tingkat persediaan

Jetly et al. (2012)

obat dalam lingkungan yang tidak pasti.

heuristik untuk pengambilan keputusan,

-evaluasi yang berbeda terhadap kriteria dan fungsi-Urutan order yang berbeda-beda,

Santa-Eulalia et al. (2011)

-Integrasi SC dengan Advanced Planning and Scheduling (APS)

Model analitis yang unik, yaitu dengan framework FAMASS (FORAC Architecture for Modelling Agent-based Simulations for SC planning)

Akanle dan Zhang (2008) - Konfigurasi optimisasi dari penawaran iteratif agen

dalam

Melihat dan memilih beragam kontrektor yang dapat menyelesaikan proyek.

Schieritz dan Größler (2003) Untuk menurunkan kompleksitas dari model dengan

integrasi antara system dynamic dan diskrit agent based.

Menganalisis kekuatan dan kelemahan 2 model dalam Emergent Structures dalam SC.

Emerson dan Piramuthu (2004)

Menginvestigasi penyebaran informasi sebagai sebagai dasar dari strategi kolaborasi SC

Andrews et al. (2007)

- Supply Chain Trading Agent Competition (TAC SCM)

- biaya operasi,

-tingkat backlog dari retailer, distributor, produsen dan seluruh komponen SC

-SC dalam beberapa perusahaan farmasi yang berinteraksi untuk memproduksi dan mendistribusikan

Carvalho dan Custódio (2005)

-Simulasi dari jumlah agen yang hampir tak terbatas

-kemungkinan untuk memilih strategi keputusan diantara alternatif dan taktik,

2005 2007 2008 2009 2010 2011 20120

0.5

1

1.5

2

2.5

Multi Agent-based Simulition

-Prilaku stokastik atau deterministik-intelligent agent-SCM competitionpenerapan desain Trading Agent Competition.-Mengklusterkan

-Pola dari distribusi-jaringan SC

Karimi et al. (2007)

Kovalchuk (2008) -Selain SCM, solusinya adalah forecasting financial markets dan berpartisipasi dalam online auctions.

Zhang dan

Wuhan (2008) -kinerja, dan kebijakan sharing informationKumar et al. (2009) -negosiasi bilateral,

-Pemantauan sistem order dan produksi-Perencanaan dan penjadwalan sistem multiagen.

Tan et al. (2009)

-Pemecahan masalah komunikasiChen (2010)

-Fill rate-NYOP(Name Your Own Price)-Dinamika negosiasi-Dinamika keputusan pembelian

Mustapha (2010)

untuk mencari permintaan konsumenJahani et al. (2011) - Pawaran bahan

Harper et al. (2011)

- agregasi atau disagregasi

Forget et al. (2008) -Negosiasi automasi

-Framework SC perusahaan

Carvalho dan Custódio (2005)

Sardinha et al. (2006)

Huang dan Levinson (2006) - Pemilihan lokasi retail

- procurement auction

-Jenis informasi dengan dampaknya terhadap rantai pasokan

-MAS merupakan pemecah masalah melampaui kapasitas individu dari setiap problem solver.

- MAS-Bullwhip effect

- Sebuah metodologi kerangka kerja yang baru dan berorientasi organisasi

- intelligent platform (i-SEEC)

-Negosiasi dengan pemasok dan pelanggan pada harga, volume, kualitas, dan tanggal pengiriman bahan supplier.

- data mining yang terintegrasi dengan landasan simulasi agent-based

Ameri dan McArthur (2013)

- Menyelesaikan masalah SC dengan kerangka kerja Digital Manufacturing Market (DMM).

-Aplikasi pertama dari teknologi agen didasarkan pada ontologi formal yang mengkodekan kemampuan manufaktur dari supplier.

Negosiasi dalam perencanaan SC menggunakan multi-behavior-agents

Santa-Eulalia et al. (2002)

-Kebijakan perusahaanAslam et al. (2010) -Optimisasi dalam SCM

pemasok, produsen, distributor dan retailer.

Goel et al. (2011) -Pengembangan MAS-Negosiasi antar komponen SC-Pemilihan yang intelegen pada distributor

-Jaringan perusahaanJaringan pasok yang terintegrasi-DSS (Decision support systems)-Production planning and control

Al-zu’bi (2010) -E-business-E-Supply Chain Management

Verdicchio danColombetti (2001) sebagai kunci dalam penentuan level dalam jaringan SC

antara 2 perusahaan

-Studi kasus Industri Manufaktur Telepon-Negosiasiadalah kegiatan interaksi agen akan sistem harga.

-Perkenalan software agents dan sistem multi-agent-ketidakpastian-sharing information

-Perusahaan Canadian forest product-Reverse Information Sharing

-Beer Game-SC risk-Nilai penciptaan jaringan -Advanced planning system- perencanaan lanjutan -sistem penjadwalan

Santa-Eulalia et al. (2002)

- Intelligent agents

Kaur dan Pandey (2012) - Negosiasi antara makelar dan distributorSanta-Eulalia et al (2008)

- Perancangan, kofigurasi dan desain SC

Azevedo et al. (2007)

Souza dan Khong (1999)

- Teknanan ekonomi SC klasik

- information sharing

- inter-agent state

Ulieru dan Cobzaru (2005)

-Model perusahaan holonic dengan Foundation for Intelligent Physical Agents (FIPA)

Monostori et al. (2006)

- customer-centric SCFrayret et al. (2011)

-Cara mengaplikasikan advanced planning dan scheduling tool.

-Kombinasi dari teknologi agent-based dan operations research-based tools.

Ibrahim dan Deghedi (2012) berbagi informasi mengenai breakdown (kerusakan)

Lamieux et al. (2009)

-customer-centric supply chain, -MAS dengan simulasi agents-oriented

Frey et al. (2003) -Desentralisasi SC

-perencanaan dan pengendalian produksi -Pertimbangan retailer

Vieira et al. (2012) -MAS

-Mode kontrol yang terdistribusi atau terdesentralisasi.Demirel (2008)

-Bullwhip effect-Forecasting-Order batching-Dynamic pricing

Mele et al. (2007) -MAS-Ketidakpastian

Pathak et al. ( -Pengambilan keputusan

-Industri otomotif-Negosiasi online

Mele et al. (2005)-Mixed-integer linear programming

-MASLin et al. (2002) -Sharing information

-tingkat pemenuhan in-time order-waktu siklus agar lebih pendek

Jiang et al. (2010)

provider (MSP).

- Menyelesaiakn permasalahan rute kendaraan.-Memperhitungkan pungutan dalam SC

-Bisnis logistik logistik-shipping

Labarthe et al. (2005)

- Penanganan gangguan yang parah pada supplier- pendekatan terpadu

- information asymmetry

-Variabilitas dari inventory atau order variability

-Penggunaan yang efektif dan efisiern dari Electronic Data Interchange (EDI)

- SCM

- Pendekatan hybrid