Cu07821 7 culverts new

-

Upload

henk-massink -

Category

Education

-

view

1.265 -

download

1

Transcript of Cu07821 7 culverts new

Definition Civil Engineering work for the passage of water. Sometimes lockable, for example related to safety.

Top view

Longitudal sectionCulvert between two waters1

Types and Materials

Tubes of concrete, reinforced concrete or pretensioned concrete

Rectangular culvert element In situ poured concrete

Steel sheet piling Section corrugated sheeting

Side view

Masonry

Tube, NEN 7031

Mouth-profile,

Fiber reinforced cement tube, glasfiberreinforced polyesther tube

Oversight of the most important culvert forms and materials

1

Socket and wedge connection

thickening

Wedge WedgeSocket Socket

Groove in wedge

Rolling connection with an unprofiled wedge Sliding connection of a tube with a profiled wedge

1

Round tubes

www.dehamer.nlwww.wacolingen.nl

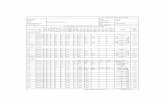

Dimensions Mass

Working length

Reinforced and non-reinforced Waco SW-tubes

1

Shallow foundation(fundering op staal)(foundation on sand / gravel)

Bottom of trench free of rocks

Shallow foundation1

Laying of tubes

Tube horizontally !

Lifting sling

Rubber ring

Shallow foundation

Deepen trench bottom at location of socket

Pull in with winch or tirfor (handwinch)

Push in with shovel

Working direction

1

Foundation on improved soilGrondverbetering

Carrying layer

Dig out and fill in with sand

Foundation on improved soil1

Foundation on gratingRoosterwerk

Bolt for wood

Ongoing girder (carrying in longitudal direction)

Girder (carrying in cross direction)

Block (between tubeside and ongoing girder)

Foundation on grating1

Foundation on poles with girder

Block; wedge formed

Girder

Large bolt

Poles

2 layers of ruberoid between tubeside and block

Hollows block

Bolt, head in wood on topside

Foundation on poles with hollows blocks (carrying in cross direction)1

Foundation on poles with wooden girders and purlins

BlockCarrying girder

Purlin at the location of the sockets

Tubesides free of blocks!

Foundation on poles (carrying cross- and longitudally)1

Foundation on poles with wooden girders and purlins

carrying girder

long (length)

Girder

Slanting (interface carrying wood/ tube)

Block connection by means of 2 bolts for wood

Purlin Poles

long (length)

Foundation of a culvert of round concrete tubes

1

Rectangular culvert elements

Loose placed elements

Void for longitudal coupling

Mutually coupled elements

Void for aftertensioning

After tensioned elements

Void for aftertensioning

Double culvert elements Hanging culvert elements

Foundation on poles

In situ poured concrete slab

Working layer

Portal culvert elements

Oversight of prefab rectangular culvert elements1

Shallow foundation on improved soil

San

d-ce

men

t st

abili

satio

n

dig out and refill with sand, compress!

Foundation on improved soil with a sand-cement stabilisation1

Foundation on concrete polesImposition

In situ poured concrete (longitudal girder)Punch slab

Cable canal

Concrete pole

Hanging culvert1

Rectangular culverts with interlocking

Coupling canal

Lifting hole

Interlocking ends

Large bolt

Poles

Girder

Carrying wood 100x180

Detail interlocking connection

Wedge type endSocket type end Filler

Taping

Mass of cross section of the culvert element 4350 kg; scale 1:40

1

Hanging culvert

Imposition on fur felt

Longitudal tensioning/cable void

punch- or passage slab

longitudal girder (poured in situ)

poles (reinforced concrete)

1

Portal culverts

Lifting facility

Levelling floor (poured in situ)

Working layer

View Section

Mass of element

Detail interlocking element

Fill joint with sand-cement

Outside measurementTaping

Culvert build of (reversed) U-shaped elements1

Pushing through of culverts

Pressure frameCulvert elements

Pressure spreading HE-profilesJack beamJacks

Oil pressure tube

Support frame for jacks

Support of conduitConduit beam

Heavy wooden slabs

Soil reversal construction Steel sheet piling (dead weight)

Cutting head

Principle of a push through facility1

Pulled through culverts

jacks

Culvert elements R3

Steel frame

Steel level frame

Steel cutting headPull bars

Pressure girders

Steel sheet piling (dead weight)

Level beams

Pressure frame

Principle of the construction of a pulled through culvert

1

Special facilityIron cast pit top with cover

Cone piece

Top pieceVoid in culvert element

Other facilities:- reinforcement ends- screw shells- various concrete socket

connections- anchor rails- rubber bands for joints- pvc connections

Special facilities in a culvert element

Socket connection for round tubes

1

Connection with metal sheeting

Reminder: slab reinforcement is not drawn

Sheet piling Working layer

With bitumen impregnated sheet of cork, width 350

Connection of steel sheeting with a construction on a shallow foundation1

Duikersluis

Impregnated sharp pointed poles, length 1600

Deposit on geo textile

Concrete blocks 400/400/150On coarse gravel

Bitumen joint sheet

Surrounds of hatch

Top view and horizontal cross section at level 0

INSIDE OUTSIDEGroove for a level scale

Climbing irons

Beam slotsLevel

Longitudal sectionCork slab thick 40

CULVERT SLUICE

SCALE1

Culvert with sluiceSurrounds hatch

INSIDE

Groove for

level scale

Slide slot

Drawing scale

Opened up drawing of the culvert sluice of the previous slide

Joint

1

Culvert made of metal sheeting

Cross section

Front view without earthing

Front view with earthing

Railing is not drawn

Impregnated sharp pointed poles

1

Culvert made of metal sheeting

Top view with earthing Top view without earthing

Punch slabs

Ramming plan steel sheet piling

Steel sheet piling

Longitudal section

Concrete blocks on gravel Rubble (broken concrete and masonry) on polyetheen fabric1

Culvert made of masonry

Special layer

Segment curve

Pla

ster

ed s

ides

poles

girdersflooring

Sliding woods

Bottom levelled Bottom curved

Cross section of a culvert made of masonry1

Floating“concrete” anchors Anchor blocks

“concrete” anchors Prefab anchor block

Tensioning rods

Tensioning rods

Polyetheen plating1

Dilatation joints

Dilatation joint width 300

Culvert floor slabSealer or glue

Bitumen joint sheeting or EPS

2xbituminateShallow foundation

Foundation on poles

2xbituminateBitumen joint sheeting or EPS

Culvert floor slab

Dilatation joints with sealed joints1

Receiving- and gravel beds

Ground water level fall

Dumping bed Receiving bed

General: σsoil = σgrain + σwater

Ground level

Ground water level

Water over pressure

turbulence

excavation

Scheme of weights/pressures working on the bottom defence1

Receiving- and gravel bedsrubble (broken concrete/ broken masonry) or broken natural stone dump

Rubble or natural stone dump

Willow branches

planks clay

poles

long

Situational a synthetic fabric

sand

Azobe (tropical wood) twined mat

Concrete layer Broken natural stone dump

Sand or clay Sand or clayplanks

poles

long

Variant: row of closely rowed poles

Doubled layer

Nicolon polyetheen fabric thick 0,6 mmm

1

Receiving- and gravel bedsConcrete blocks

gravelclay

Stone masonryRubble dump (filling layers)

Layed layers

Sand or clay

Sheeting thick 72 long 2000Creosoted pine

Sheeting thick 72 long 2300

Reinforced concrete

Azobe sheeting

Stone masonry

Rubble dump

Reed on 0,3 m clayWillow branches

sand

sheeting

sand

1