Conectore Para RF

-

Upload

jovares2099 -

Category

Documents

-

view

232 -

download

0

description

Transcript of Conectore Para RF

-

2003

25 September 2003

-

1Connector Care

2003/09/25

Jason Chien

2

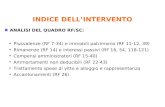

Agenda

-59-

-

31. Fundamentals of

Connectors

4

Type F

BNC

SMC

Type N

APC 7

SMA

3.5 mm

2.92 mm or K

2.4 mm

MaleFemale FemaleMale

-60-

-

5

Test Port

Mating Plane

Cable

6

-61-

-

7Outer Conductors

Outer conductor mating surfaces definemeasurement reference plane

8

Center pin

-62-

-

9Connector Considerations

zA significant factor in repeatabilityand accuracyzConnectors are consumables

limited lifetime,frequency use.damaged connectors are costlyproper care maximizes lifetime

10

2. Commonly used connectors

-63-

-

11

APC 3.5 mm

12

APC 3.5 mm

-64-

-

13

Sma,smb,smc

SMA SMB SMC

14

SMA

-65-

-

15

SMA and APC 3.5 mm

16

MATING SMA WITH PRECISION 3.5 mm

SMA/SMAConventionalMated Pair

APC-3,5/SMAConventionalJunction

FREQUENCY in GHz2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

1.05

1.10

1.15

SWR

APC-3.5MatedPair

-66-

-

17

18

-67-

-

19

20

N connector

-68-

-

21

22

-69-

-

23

24

Type N Connector

-70-

-

25

SPC 3.5

26

APC 7 mm

-71-

-

27

COLLET

28

APC 7mm

-72-

-

29

Tri-Axial connector

30

-73-

-

31

32

-74-

-

33

34

-75-

-

35

36

3. Impedance, Frequency

range, Connector Grades

-76-

-

37

1. Impedance, 2. frequency range, 3. Connector Grades

3.5 mmType

-N 2.4 mm

TNCK-type

Production Grade

7 mm

Instrument Grade

4-Slotted

Collet

SMABNC

Co-Planar

Slot Less Contacts

6-Slotted Collet

Metrology Grade Sexed vs Sexless

V-typeBulkhead Cable

1.0 mm

APC 3.5

1.85 mm

38

Model for Characteristic Impedance, Z

(Low-Loss Case)

Z =o 2SDP1

H dn

DdD = 7.0 mmd = 3.04 mmZ = 50 ohmso

D = Inner diameter of outer conductor

d = Outer diameter of inner conductor

1. Impedance Characteristic

-77-

-

39

2. Frequency range

z

z

z

max

40

Type N 18 GHz

BNC 3-4 GHz

Precision 7 mm 20GHz

SMA 23 GHz

Precision 3.5 34 GHz

Precision 2.4 50 GHz

-78-

-

41

3. Connector Grades

zMetrology

zInstrument

zProduction (Field)

42

Metrology Grade

zUsed on calibration standards

zHighest performance slotless contacts

zTightest tolerances

zAir dielectric interface

zLong life

zHighest manufacturing cost

-79-

-

43

Instrument Grade

zUsed for test ports

zEconomy calibration kits

zGood performance

zTight tolerances

zDielectric supported interface

zLong life

44

Production (Field) Grade

zSystems and device connector

zLow performance

zLoose tolerances

zDielectric supported interface

zLimited number of connections

zLowest Cost

Always Inspect Before Connecting

-80-

-

45

27

46

-81-

-

47

48

Connector Summary

Reference: Agilent Microwave Test Accessories Catalog, 1999-2000 pp. 15,16,17.

Connector Metrology Instrument Production Cutoff Freq (GHz) SexedPrecision Slotted

Connector

Type F(75) N N Y 1 Y N

BNC (50 & 75) N N Y 2 Y N

SMC N Y N 7 Y N

Type N (50 & 75) Y Y Y 18 Y Y

APC-7 or 7 mm Y Y Y 18 N N

SMA (4.14 mm) N N Y 22 Y N

3.55 mm Y Y Y 34 Y Y

2.92 mm or "K" 1

N Y Y 44 Y N

2.4 mm 2

Y Y Y 52 Y Y

1.85 mm 2,3

N Y Y 70 Y N

1.0 mm N Y Y 110 Y N

123

Compatible with SMA and 3.5 mm ConnectorsNot Compatible with SMA, 3.5 mm, or 2.92 mm Connectors1.85 mm IS Compatible with 2.4 mm Connector

.

-82-

-

49

4. How to making

Connections

50

Making connections

Align connectors carefully

Make a preliminary connection lightly.

Turn the connector nut ONLY in making

connections.

Do not rotate devices in making

connections.

Use a torque wrench for the final

connection.

-83-

-

51

52

-84-

-

53

Typical Connector Cross Section

Male Female

Center Conductor

Outer Conductor

54

-85-

-

55

APC 7 mm Connection

56

APC 7 mm Connection

-86-

-

57Type N-connector

58

Torque wrench

-87-

-

59

.

Hold the torque wrench perpendicular to the connector center line

axis(within +/- 10 deg)

60

.

-88-

-

61

Recommended Torque Values for Connectors

62

The outter mating plane was damage

by incorrect operation.

-89-

-

63

64

-90-

-

65

66

Return Loss

* = _________V

VIncident

Reflected= TU

Return Loss RL= -20 log 10U

SWR =

1+ U

1- U_________

SWR= standing wave ratio

= reflection coefficientU

U = _________SWR-1

SWR+1

Reflection coefficient* =

Characteristic Impedance

Z = (1+ * ) / (1- * )T

-91-

-

67

68

Add the depth between inner conductor plane

each others.

A bump occurred due to the d become smaller

indicate high impedance .

-92-

-

69

Test with vendors SMA adapter

70

-93-

-

71

Test with a Agilents SMA to BNC adapter

72

5. Maintaining

Visual Inspection

Mechanical Inspection

-94-

-

73

74

-95-

-

75

Slotted Female Centre Conductor

76

Slotless Female Centre Conductor

-96-

-

77

Example Connector Problems

78

-97-

-

79

80

-98-

-

81

Cost of Connector Damage

APC 3.5(m) to APC-7 1250-1746 205

APC-3.5(m) to N9m) 1250-1743 140

2.4 mm(m) to 2.4 mm(m) 11900A 575

Cost

82

Gauge Test Ports

Gauge All Devices Under Test

-99-

-

83

Gauge 3.5 mm

84

Gauge

Before first use

When the connector has been used by

someone else

After any evidence of damage-visual

Or electrical

After 100 connections

-100-

-

85

Using Connector gauges

x Inspect and clean before each usex Zero the gaugex Use multiple measurements

86

Connecting the gauge Master

x Screw on the gauge master and hand-tighten

x Use correct torque wrench

x Settle the gaugex Adjust the zero knob to zero the gauge

-101-

-

87

Example

88

-102-

-

89

Measure the connector

x Connect the devicex Settle the gaugex Read recession or x protrusion

Recession:Protrusion:

90

-103-

-

91

92

-104-

-

93

94

-105-

-

95

Connector specification.

3.5 mm recession 0.0 to 0.003 inch

7 mm recession 0.0 to 0.003 inch

(collet remove)

The thickness of 500 sheets of copy plain papers are 50 mm.

equal to 0.003937 inch 39 lines

1 line == 0.0001 inch (Gauge scale )

96

Apply a mild blast of dry compressed air or Nitrogen

Use the minimum amount of pure alcohol

Use lint-free cleaning tools (swab or brush)

Do not use acetone, methanol, or CFCs (Freon).

6. Cleaning & protection

-106-

-

97

Cleaning

98

Cleaning Procedure

Use Compressed Air or Nitrigen

Clean the connector threads

Clean the mating plane surfaces

Clean the interior surfaces

-107-

-

99

kit

100

.

-108-

-

101

Lint free Swab

102

-109-

-

103

WRONG

CIRCULAR STROKES LEAVE TORNFIBERS SNAGGED ON EDGES OFCENTER COLLET

CORRECT

RADIAL STROKES DO NOT LEAVEFIBERS

USE CIRCULAR STROKES FOR OUTERCONDUCTOR FACE ONLY

104

Using Adapters as Connector Savers

z Protect Connectors on test set or cablez Saversz ESDz Use plastic end caps when not in usez Never store loosely in a box or drawerz Store in foam-lined storage case

z LubricationNo conductive and dirt issue.

protection

-110-

-

105

Connect a SAVERS into the input connector

SAVER : APC 3.5(F)-APC 3.5(F), p/n:5016-0015saver

106

ESD

-111-

-

107

108

coverPut a cover to prevent scratch or damage.

-112-

-

109

Dont put connectors

mixed in a box.

110

-113-

-

111

Summary

zInspect

zClean

zGage

zConnect

zDisconnect

zProtect

112

End

-114-

-

(Agilent Service Note)

www.agilent.com.tw/find/tm_servicenotes

-

: www.agilent.com.tw/find/handout

Agilent www.agilent.com.tw

0800-047-669

2003 Printed in Taiwan 9/25/2003 5988-0098ZHA