COMMUNAL LIVING

Transcript of COMMUNAL LIVING

15WWW.CEN-ONLINE.ORG JUNE 9, 2008

can be made up of a multitude of bacterial species, some of which may have never been studied in a lab. They make for a for-midable adversary.

But researchers are starting to accu-mulate enough knowledge about how bio-films form to think seriously about how to control them. “In the past 10 or 15 years, we’ve seen the techniques and approaches of modern biology and genetic and mo-lecular tools applied to biofilms,” says Phil Stewart, director of the Center for Biofilm Engineering (CBE) at Montana State University. “That has helped change the biofilm from an amorphous primitive slab of slime into a biologically sophisticated,

HA

RV

AR

D U

NIV

ER

SIT

Y

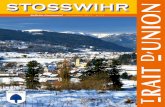

CAREFUL GROWTH

This clean room will be used to generate and study biofilms as part of the BASF Advanced Research Initiative at Harvard University.

through which nutrients are distributed. In the end, they are better off living as a colony than going it alone.

That safety in numbers poses a chal-lenge for anyone trying to get rid of a biofilm, which can plant itself virtually any-where. Bacteria are tricky enough to deal with on their own; they’ve spent billions of years learning to overcome whatever envi-ronmental threats come their way.

So imagine the power of bacteria banded together, living under something akin to a force field, and acting in unison in ways scientists have only recently begun to un-derstand. In addition to being able to thrive in pretty much any environment, biofilms

IT WAS LONG ASSUMED that bacteria were loners that floated through their single-celled existence without need of companionship. That simple, independent lifestyle made it pretty easy to study them in a test tube or grow them in a petri dish.

But it turns out that bacteria are actu-ally social creatures. They congregate and chemically communicate, working together to stay alive. More often than not, they exist in complex communities called biofilms, started up when one cell sticks to a surface in an aqueous environ-ment and somehow signals others to join in. Those recruits, along with descendents of that first cell, create a protective matrix

COVER STORY

Imagine the power of bacteria banded together, living under

something akin to a force field, and acting in unison.

COMMUNAL LIVINGScientists across academia and industry are making a concerted effort

to understand and control BACTERIA THAT FORM BIOFILMS

LISA M. JARVIS, C&EN NORTHEAST NEWS BUREAU

16WWW.CEN-ONLINE.ORG JUNE 9, 2008

BIOFILM TOPOGRAPHY Weibel’s lab uses

interferometry to create two-dimensional

arrays of Pseudomonas biofilms.

differentiated, and regulated community.”Indeed, academic researchers are in-

trigued and industry executives seem ready to devote money to real-world methods of manipulating biofilms. Everyone involved believes it is going to take a coordinated effort across the biological and physical sciences to better understand and harness these bacterial communities.

Biofilms’ ubiquity makes them a ripe subject for both academia and industry. If you have ever slipped on a rock while walking in a stream, you’ve encountered a biofilm. Run your tongue across the surface of your teeth; that plaque buildup you feel is actually a biofilm. When you’re standing over your sink wondering why the water refuses to drain, blame a biofilm.

But biofilms can have a more costly im-

pact. Bacteria like to freeload on the hulls of ships. Biofouling, or the accumula-tion of bacteria and other material on an underwater surface, exacts hefty fuel costs on the shipping industry. Antifouling paints can delay the process, but eventually bacteria will glom on. And removing the films takes a toll on the environment; those bacterial communities adhere to the sur-face so strongly that it takes chlorine and heavy-duty scraping to remove them.

Meanwhile, biofilms also have a major impact on human health. Hospital-ac-quired infections are now the fourth-lead-ing cause of death in the U.S. behind heart disease, cancer, and stroke. The culprit behind most of those infections? Biofilms. Bacteria can thrive for months on hospital surfaces—floors, instruments, gloves—and be passed on to open wounds or to implanted devices such as catheters, heart valves, and artificial hips where biofilms can form.

YET BIOFILMS can also be useful. Indus-trial wastewater treatment centers have long exploited bacteria’s propensity to suck in anything that looks tasty. Biofilms are incorporated into water treatment sys-tems to filter out organic compounds and pathogens.

Despite the prevalence of biofilms, the discovery that bacteria like to form their own gated communities was discounted for years. Most scientists finally took no-tice of biofilms in the mid-1990s. Since then, the number of journal articles about the topic has risen exponentially, CBE’s Stewart says.

Several underlying developments are spurring interest in biofilms. For one, ideas about bacteria are changing. “It used to be that we thought of microorganisms as being these little things that were all roughly the same clonal descendents of some maternal line who talked to one another, if at all, dis-tantly,” says George M. Whitesides, profes-sor of chemistry at Harvard University and surface science expert.

Now, scientists are beginning to under-stand that bacteria have a complex commu-nication system, the properties of which are dictated, at least in part, by biofilms. In a film, there’s no circulation or blood flow,

no con-vective mass transport, Whitesides notes. “Concentrations of a chemical can build up to higher levels; there’s an efficiency of chemical commu-nication that occurs in a biofilm that would not occur otherwise.”

And importantly, more people—be they scientists or members of the public—understand that “biofilms actually mat-ter,” Stewart says. “When you go out into nature, or in engineered systems, and increasingly in the medical context, the microorganisms really are banded together in aggregate.”

The human health threat, in particular, has attracted attention to the problem. Al-though ships have long dragged and pipes have forever clogged, those problems never seemed urgent, notes Roberto Kolter, pro-fessor of microbiology and molecular ge-netics at Harvard Medical School. But the proliferation of implants and other medical devices means more and more pernicious infections caused by the biofilms that love to call the devices home. Antibiotics are perplexingly ineffective against bacteria contained within a biofilm.

Once a few geneticists started point-ing out that bacteria like to spend most of their time on surfaces, “interest really ex-ploded,” Kolter says. Advanced microscopy and other scientific tools have aided both in convincing people that bacteria like the communal lifestyle and in facilitating re-searchers’ ability to study and understand how biofilms form.

One sure sign that biofilms are ripe for exploration is industry involvement. After all, the ultimate goal is learning to control the films in the real world. Last fall, BASF formed the BASF Advanced Research Ini-tiative at Harvard University, a partnership that brings together researchers from both organizations to tackle scientific chal-lenges. BASF put up $20 million to fund the

COVER STORYB

AS

F

Greenberg

Kolter

BA

SF

CO

UR

TE

SY

OF

DO

UG

LA

S W

EIB

EL

17WWW.CEN-ONLINE.ORG JUNE 9, 2008

five-year program, and biofilms are the first project on tap.

“Biofilms on surfaces cause multi-billion-dollar

losses each year,” Franz Brandstetter, head of BASF’s

Polymer Research Competence Center, told reporters at a sym-

posium on biofilms held in April to mark the launch of the partner-

ship. Montana State’s CBE also works closely with industry on biofilms. It has

32 member companies and ran projects aimed at solving biofilm-related problems

for 43 companies last year.Because biofilms are magnificently com-

plex systems, it will take a concerted effort by academia and industry to unravel the details of their formation and function.

SCIENTISTS ARE also weighing a chicken-or-egg question: Should they first develop a better understanding of biofilm forma-tion and makeup, or is it possible to head straight to products and methods to con-trol bacteria and then work backward to glean knowledge about how the systems work?

CBE’s Stewart wants to charge ahead. “If we try to wait until we have every gene in the circuit figured out, we’re not going to get there,” he says. “We need to do some fundamental science and build the infor-mation base, but this is the right time to begin actually exploring technologies.”

Biofilms’ complexity is daunting, but it also lends itself to myriad methods of attack. Scientists can imagine many ways to prevent or control a biofilm. One route is to create surfaces that don’t let bacteria stick at all. There are also multiple oppor-tunities for intercession during the forma-tion of a biofilm or after it has matured; researchers are considering everything from how the film feeds itself to how its composition changes over time. Scientists are even considering how they might en-courage a benign biofilm to grow on a sur-face, thereby preventing a more pernicious one from attaching itself.

Many scientists are working to find the overarching principles to which, despite their diversity, all biofilms subscribe. Find-ing those commonalities could accelerate the search for broad means of control. Thus, the hunt is on for general themes, such as how surface properties affect bio-film formation and how a change in the en-vironment affects the destiny of a colony.

The varying perspectives of the chem-

ists, biologists, medical doctors, and physi-cists involved in the field means a wide range of scientific approaches. Harvard’s Kolter, for example, is trying to understand the cellular changes that occur during biofilm formation and how different cell types organize themselves within the film matrix. By monitoring the gene expression of three important cell types—those re-

sponsible for motility, matrix production, and sporulation within a Bacillus subtilisbiofilm—scientists in Kolter’s lab found that the population of each type changed over time and was distributed based on the architecture of the colony.

Kolter also uncovered evidence of a developmental pathway by which the mo-tile cells transition to matrix production

RE

QU

ES

T M

OR

E A

T A

DIN

FO

NO

W.O

RG

All Masses Great and Small.Size matters, and so does mass. That’s why Wyatt instru-

ments measure the absolute molar masses of polymers

and biopolymers, from less than a thousand to hun-

dreds of millions of grams per mole. In fact, the DAWN®

HELEOS,TM with 18 photo-detectors, is the only instrument

that directly measures macromolecules without calibra-

tion routines or reference standards. With an unprece-

dented dynamic range, the DAWN virtually never goes off

scale, resulting in faster sample runs and a wider range of

sample concentrations. You can even view performance

in real time on the stunning LCD color display. For more

information, contact us at

805.681.9009 or www.wyatt.com. We’ll help

you think big, and small.

©2008 Wyatt Technology.

DAWN®HELEOS.TMLight scat-tering for macromolecular characterization.

Optilab®rEX.The RI with the greatest sensitivity and range.

DynaProTMPlate Reader. High throughput dynamic light scattering.

CORPORATION

18WWW.CEN-ONLINE.ORG JUNE 9, 2008

and then to sporulation. Furthermore, he found checkpoints during biofilm forma-tion when interrupting the development of a cell will change its fate. “If you arrest normal development by having a mutation that does not make the matrix, the bacte-ria don’t progress to the next stage; they somehow get stuck,” Kolter says.

These checkpoints are something scien-tists previously wouldn’t have associated with bacterial communities, Kolter says, and could eventually provide the means to control or mediate them.

Whitesides’ lab, meanwhile, is bring-

ing its expertise in shaping and defining the mechanical properties of gels—a good proxy for slimy biofilms—to help elucidate the interface between a biofilm and a sur-face. The goal is to learn which properties of the biofilm are molecular and which are mechanical. “We don’t know whether the characteristics of the biofilm are intimately connected to the properties of the mol-ecules that are there or primarily a result of the gel and its influence on mass trans-port,” Whitesides says.

Biofilm formation occurs in two stages, Whitesides points out. The first is when a

bacterial cell has to stick to a surface—be it steel, Teflon, or bone—and form a gel-like matrix. The second is when subsequent parts of the biofilm stick to that matrix. Whitesides is interested in building gels to understand those two interfaces—one be-tween a surface and a microbial gel and one between two gels.

RESEARCHERS IN Whitesides’ lab are taking several tacks to explore those inter-actions. For example, they are using self-assembled monolayers (SAMs) to build structured molecular interfaces that have

COVER STORY

A lot of time and effort is

spent trying to rid the world

of biofilms, those slicks of

bacteria that cling to the

inside of pipes, the bottom

of ships, and the surface of

medical devices. But what if

the sticky, stubborn nature

of biofilms could be put to

good use? Biofilms have

long been applied as natural

filters in industrial wastewa-

ter treatment systems, and

researchers are now contem-

plating other ways they could

be exploited.

“We know biofilms can

be very stable, effective

systems. In fact, a lot of

conventional wastewater

treatment systems use them,

and they’re very robust and

efficient,” says Phil Stewart,

director of the Center for

Biofilm Engineering at Mon-

tana State University.

BASF, the world’s largest

chemical company, is at-

tempting to exploit biofilms

to make key compounds via

biocatalytic means. A biofilm

can be seen as nothing more

than a thin-film catalyst, says

Bernhard Hauer, the firm’s

vice president of biocatalysis

research. Hauer’s group is

trying to make viable reac-

tors in which a chemical

substrate is pumped over a

support coated with a biofilm

that converts the substrate

into a product. Scientists

at BASF hope to replace

conventional fermentation

processes and suspension-

based cultures with reactors

containing biofilms.

The process could offer

several advantages over

conventional fermentation.

A biofilm is relatively stable,

whereas batch fermentation

requires starting or inoculat-

ing a reactor every other day,

Hauer notes. Biofilms can

offer high cell density, Stew-

art adds, resulting in a lot of

reactivity in a small volume.

Because of the fixed nature

of biofilms, another advan-

tage is that the solution

coming out the other end of

the reactor is relatively free

of biomass. Moreover, the

biofilm can be immediately

reused as a catalyst.

So far, Hauer’s group has

constructed reactors filled

with rings made of several

materials—metals, glass, and

ceramics—as a support on

which the biofilms grow. After

experimenting with more

than 70 strains of bacteria,

the scientists found that

some thrived on specific sup-

ports, while others planted

themselves on whatever was

around. The fact that the

films grow so easily on a wide

variety of materials also cre-

ates complications; BASF has

to use special filters on either

end of the reactor to keep the

bacteria from growing back-

wards into the feedstock.

In the end, Hauer says,

steel rings proved to be a

suitable support for these

early systems, although BASF

will revisit the support ques-

tion if the systems are ex-

panded to commercial scale.

The trials also showed that

the biofilm systems are sta-

ble for more than 100 days.

Once a system was worked

out, Hauer’s group first at-

tempted catalytic conver-

sion by trying to create

R-2-butanol from a racemic

mixture of 2-butanol. The

group was able to isolate

R-2-butanol using a biofilm

but had trouble working at

high concentrations. Still,

the experiment proved the

system was viable, and the

researchers moved on to use

a biofilm to oxidize ethylene

glycol to glycoxylic acid.

Other groups have tried this

oxidation using Escherichia

coli without success. BASF

found a Pseudomonas-based

biofilm that proved to be

highly effective at turning

out the desired product.

Currently, BASF scientists

are working to increase the

concentration of starting

material while maintaining a

stable system. They are also

trying to identify the genes

that metabolize glycoxylic

acid and then use proteom-

ics to block that process and

improve the yield to 90%.

“Biofilms look promising,”

Hauer says. “Most industrial

strains form them, they are

metabolically active for a long

time, there isn’t fouling in

the reactor, and the specific

investment seems to be lower

than batch fermentation.”

BA

SF

EXPLOITING BIOFILMS

BASF Explores Using Bacterial Surfaces To Its Advantage

Hauer

REQUEST MORE AT ADINFONOW.ORG

New Chemical Entity is within your reach!Shorten your route to clinic

with ChemDiv’s Discovery outSource TM

Shared risk, services and licensing business models

Chemistry Systems On- DemandTM

World’s broadest portfolio of over

12,000 chemical library designs

MedChem driven, IP rich

Largest commercial collection of

1.2m lead-like molecules

Biology On-DemandTM

Assay development and screening

DMPK/Tox and pre-clinical profiling

Efficacy models and formulation

Leads and candidates inoncology, inflammation, metabolic disease and virology

Advanced animal testing systems: oncology, metabolic disease, viral and infectious disease

Preclinical and Phase I support for

IND submission

20WWW.CEN-ONLINE.ORG JUNE 9, 2008

both adsorbing and nonadsorbing surfaces and are then studying how well compounds attach to them. One goal is to understand how biofilm formation correlates with hydrophilicity, hydrophobicity, and other surface properties.

By screening for nonfouling surfaces, his group has been successful in finding a handful of SAMs that resist protein ad-sorption. Whitesides is also trying to build three-dimensional microfluidic devices—systems of micrometer-scale channels and wells that mimic the chemistry and physics of biological systems. Those 3-D approaches could help scientists build lay-ered biofilm systems that contain different organisms and closely replicate what is go-ing on in nature.

Rustem F. Ismagilov, a chemist at the University of Chicago, is using microfluid-ics to understand biofilms’ spatial struc-ture, which dictates the flow of nutrients, environmental signals, and how cells with-in the film chemically talk to each other. The structure also influences metabolic interactions within films, including the breakdown of molecules.

“We can’t understand biofilms until we understand the spatial structure,” Is-magilov says. This means determining the main bacterial players, how those players function depending on their location, and how that function changes as the biofilm matures and the external environment varies.

THE GOAL is to better understand how the highly organized structure enables cells within biofilms to act in concert. Such an un-derstanding could provide new ideas about how to break the structure down or recreate it in synthetic systems that mimic some of the functions performed by biofilms.

Douglas B. Weibel, a biochemist at the University of Wisconsin, Madison, is studying the point in biofilm development when that first bacterial cell adheres to a surface. His lab is trying to understand how a cell senses it is on a surface—a seemingly basic step that is well understood in mam-malian cells but is a mystery in bacterial cells.

Weibel first wants to figure out the en-vironmental trigger that tells the cell it is in contact with a surface and next to deter-

RE

QU

ES

T M

OR

E A

T A

DIN

FO

NO

W.O

RG

mine the transcrip-tional change that tells it to abandon its solitary lifestyle. Although scientists have yet to prove whether that change is chemical or physi-

cal, Weibel, like Whitesides, is looking at a host of physical phenomena including sur-face stiffness, surface tension, hydropho-bicity, hydrophilicity, viscosity, and osmo-lality. The idea is that, despite differences between bacteria, commonalities based on physical phenomena could provide starting points for controlling bacterial behavior.

Others are diving directly into real-world problems by tapping general knowl-edge about bacteria and human biology and then extrapolating to how biofilms distrib-ute nutrients. For example, microbiology professors E. Peter Greenberg and Pradeep Singh, both at the University of Washing-ton, Seattle, are exploiting basic informa-tion about bacteria’s dependence on iron, which is required for biofilm development, to develop drugs that treat biofilm-related infections.

Singh found that lactoferrin, an iron-binding antimicrobial factor present in hu-man tears, sweat, mucus, and other bodily

#(%-"2)$'%� #/20/2!4)/.� )3� !� ,%!$).'�',/"!,� $)3#/6%29� #(%-)3429� #2/� !.$�02/6)$%2� /&� !$6!.#%$� 3#2%%.).'�,)"2!2)%3� &/2� 3-!,,� -/,%#5,%� $25'�$)3#/6%29�

3%44).'�4(%'/,$�34!.$!2$).�$)3#/6%29#(%-)3429

777�#(%-"2)$'%�#/-

0/24&/,)/s���������3CREENING�� #OMPOUNDS

s�$ISCOVERY�� CHEMISTRY�� RESEARCH�SERVICES

%80%2)%.#%s����YEARS�EXCELLENCE�� IN�CHEMISTRY

s�4OP�TIER�CHEMISTS��� LEAD�DISCOVERY�� LIBRARIES���MED�� CHEM�SUPPORT

35##%33s�����INTERNATIONAL�� CLIENTS��BIOTECH�� INDUSTRY���ACADEMIC

s�-AJOR��MULTI YEAR�� ALLIANCES�WITH�TOP�� PHARMA

s�0ROVEN�RESULTS����IN�LITERATURE�� CITATIONS

#(%-"2)$'%�#/20/24)/.3AN�$IEGO��#ALIFORNIA

� ��� ��� ������\��SALES CHEMBRIDGE�COM

SURFACE STUDY

Ye Jin (Jenna) Eun, a graduate student in Weibel’s lab, works on a biofilm experiment.

CO

UR

TE

SY

OF

DO

UG

LA

S W

EIB

EL

Scientists need to recognize the enormous

diversity contained in a biofilm.

21WWW.CEN-ONLINE.ORG JUNE 9, 2008

fluids, sends a signal to bacteria that iron in the area is low, prompting them to move on rather than squat and form a biofilm. Ehud Banin, of Israel’s Bar Ilan University, and Greenberg showed that normal bio-film development needs a threshold level of cellular iron. Putting those concepts together led to the idea that the efficacy of antibiotics, which are notoriously bad at killing bacteria within a biofilm, could be increased by somehow limiting iron in the cell.

Singh decided to take a Trojan horse strategy and gain access to the cell using the ironlike element gallium, which inter-feres with bacterial iron metabolism. Banin and Greenberg combined efforts with Mottie Chevion, a chemist at Hebrew Uni-versity of Jerusalem, to make gallium-con-taining compounds that look like a source of iron to bacteria. In the lab, several com-pounds seem to enhance the efficacy of an-tibiotics, and early experiments in animals are validating the gallium approach.

IN ADDITION to potentially yielding new drugs, the research by Greenberg and Singh could explain why antibiotics are unable to kill bacteria living in a biofilm. They have shown that the combination of a gallium-containing compound with the antibiotic gentamicin is more effective against bio-films than either treatment on its own. Greenberg hypothesizes that the antibiotic is killing the bacteria on the surface of the biofilm, which is well fed and therefore susceptible to treatment, while the gallium compound is killing the bacteria in the middle of the biofilm, which is starved and scavenging for iron or ironlike compounds.

Despite the wide range of approaches to unraveling the complexity of biofilms and inventing ways of controlling them, there are some basic housekeeping issues that need to be resolved before any product can make it to market.

Wisconsin’s Weibel points to the issue of reproducibility. At present, the tech-niques for generating biofilms in the lab are not very precise, to the detriment of me-thodical study. For example, researchers would like to be able to make a whole slew of identical biofilms and then study each one under different conditions to decide which conditions are important and which are not.

“This is one area where I think chemists can have a big impact,” Weibel says. “We know how to control surface chemistry, which means we know how to control

where cells get seeded on a surface. We can take those concepts and extend them into techniques to make reproducible biofilms.”

Being able to generate reproducible films could also ease the registration of antibiofilm products, mainly disinfectants, with the Environmental Protection Agen-cy. “The test EPA uses to register disin-fectants is from the 1950s,” CBE’s Stewart

says. CBE is working with EPA, the Food & Drug Administration, and a number of companies to develop standardized meth-ods for testing biofilms.

The lack of agreed-upon standards for making biofilms also extends into the medical arena. The first drug to combat a biofilm “is going to be a hard one,” Uni-versity of Washington’s Greenberg says.

RE

QU

ES

T M

OR

E A

T A

DIN

FO

NO

W.O

RG

COVER STORY

Products are also available from VWR International, ThermoFisher Scientific, Regional and International distributors. Order your FREE catalog today.

The Must-Have CatalogOver 2,000 USP/NF/FCC grade chemicals and DEA

controlled substances – the industry’s most

comprehensive collection.

Our Integrated QualitySM program is based on industry-standard best practices: cGMP, ISO and governmental regulations plus enhanced testing, documentation and change control. The result: a quality product with documentation to simplify your compliance efforts.

www.spectrumchemical.com • 800.813.7782

CPhI Worldwide 2008

At the forefront of the rapidly expanding pharmaceutical market, CPhI Worldwide is renowned for showcasing the latest

technology and innovations in this industry. In 2008, professionals from all over the world will gather in Frankfurt to discuss

the most recent trends and developments.

Meet new customers, forge partnerships and benefit from the multitude of networking opportunities to support your business

needs. Don’t miss your chance to exhibit at CPhI Worldwide 2008 – the perfect environment for growth.

30 September – 2 October 2008

Messe Frankfurt, Germany

www.cphi.com

The source of new growthin networking opportunities

23WWW.CEN-ONLINE.ORG JUNE 9, 2008

RE

QU

ES

T M

OR

E A

T A

DIN

FO

NO

W.O

RG

“Whoever does this is going to have to work closely with FDA.”

Meanwhile, the Harvard and BASF re-searchers have ambitious goals for their biofilms collaboration. Andreas Kreimeyer, executive director for research at BASF, figures it will take about three years to parse through the general understanding of biofilms to decide which product opportu-nities are most viable. The approaches for tackling biofilms are vast, and the scientists at BASF and Harvard are likely to first con-sider how to develop controlled surfaces, adds David Weitz, a physicist at Harvard.

REAL-LIFE SOLUTIONS—new medical materials or ship coatings that can resist biofilms—are still years away. While work in the lab has largely focused on simple systems combining one surface and one strain of bacteria, the real world is never so simple. Most biofilm systems comprise multiple species of bacteria, including many organisms that have never been char-acterized, Kolter cautions. It’s a big leap to get from studying the basic mechanisms of a single cell to understanding what’s hap-pening on a ship’s hull, he says.

Scientists need to recognize the enor-mous diversity contained in a biofilm and consider that there may not be a single solution or even a set of them, Kolter says. Still, researchers are optimistic that a con-certed push across many disciplines will accelerate efforts to control biofilms. “This is an area where we think the problem is both complicated enough to be interest-ing, but simple enough that well-defined approaches will lead to good results,” Har-vard’s Whitesides says. ■

800.228.4373 • 402.464.0231

www.isco.com • [email protected]

Request your copy of the new

CombiFlash Rf brochure today!

www.combiflash.com

Speed • Performance • ReliabilitySpeed • Performance • Reliability

Never worry about lost compounds again.

We understand your need to conserve compounds as well as time and

space – so we designed the new CombiFlash® Rf to be smart and

small. Advanced automation using RFID (Radio Frequency Identification)

technology is just one of the ways this sleek, compact purification system

will fast-forward your Flash Chromatography toward a more productive

and error-free future.

RiskManagement.

ÂÂ

• Up to 200 psi rating for purification of tough compounds

• Avoids tube overfills by using RFID-enabled “smart” racks

• Detects accidental leaks or spills to enhance safety

• Actively measures solvent level during runs, so columns don’t run dry

• Automatically selects optimal purification method to ensure

successful first run

Whitesides

BA

SF