Applications of Hydraulics-Pneumatics

-

Upload

oezguer-dal -

Category

Documents

-

view

126 -

download

11

description

Transcript of Applications of Hydraulics-Pneumatics

1

Applications ofHydraulics

Pneumatics

&

By: Alireza Safikhani

3

2

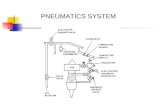

General Concept

3

Animation4

Directional Control Valve

5

Directional Control Valves

•• Identification of the component Identification of the component parts of a typical solenoid valve parts of a typical solenoid valve with spring return: with spring return:

•• (1) Solenoid (15mm)(1) Solenoid (15mm)•• (2) Piston(2) Piston•• (3) Spool with disc seals(3) Spool with disc seals•• (4) Valve body (4) Valve body •• (5) Return spring(5) Return spring•• (6) Alternative ports 2, 4(6) Alternative ports 2, 4•• (7) Pressure indicator(7) Pressure indicator•• (8) Manual override(8) Manual override•• (9) Electric connectors(9) Electric connectors 34

5

6

7 8

2

1

9

6

Directional Control Valves

11

22

7

Directional Control Valves

•• change, open or close flow paths in hydraulic and pneumatic change, open or close flow paths in hydraulic and pneumatic systems. systems.

•• They are used to control the direction of motion of power They are used to control the direction of motion of power components and the manner in which these stop. components and the manner in which these stop.

•• Directional control valves are shown as defined in DIN ISO 1219.Directional control valves are shown as defined in DIN ISO 1219.

2/2 DCV2/2 DCV

8

Representation of DCV

The following rules apply to the representation of directional The following rules apply to the representation of directional control valves (DCV):control valves (DCV):–– Each different switching position is shown by a square.Each different switching position is shown by a square.–– Flow directions are indicated by arrows.Flow directions are indicated by arrows.–– Blocked ports are shown by horizontal lines.Blocked ports are shown by horizontal lines.–– Ports are shown in the appropriate flow direction with line Ports are shown in the appropriate flow direction with line

arrows.arrows.–– Drain ports are drawn as a broken line and labeled (L) to Drain ports are drawn as a broken line and labeled (L) to

distinguish them from control ports.distinguish them from control ports.

9

kind of Connections10

Representation of DCV

11

4/2 DCV

The left box of the symbol shows the connections for the normal position. The right box shows the connections when the spool is moved to the left. The identification tags A, B, P and T are placed against the normal position of the valve. Note this particular valve has a push button to operate it and a spring to return it to the normal position.

12

Types of directional control valve

•• Continually operatingContinually operatingIn addition to two end positions, these valves can have In addition to two end positions, these valves can have any number of intermediate switching positions with any number of intermediate switching positions with varying throttle effect. Proportional and servo valves varying throttle effect. Proportional and servo valves which are discussed later are examples of this type of which are discussed later are examples of this type of valve.valve.

•• Digitally or Binary operatingDigitally or Binary operatingThese always have a fixed number (2, 3, 4, ...) of These always have a fixed number (2, 3, 4, ...) of switching positions. In practice, they are known simply switching positions. In practice, they are known simply as directional control valves. as directional control valves.

13

Classifications of DCV

•• Number of Number of spool positionsspool positions..–– Two PositionTwo Position–– Three PositionThree Position

•• Number of Number of flow pathsflow paths in the extreme positions.in the extreme positions.–– 2,3,4,5 2,3,4,5

22 33 44 55

14

Position type

•• Flow Flow pattern in the centerpattern in the center or crossover position. or crossover position.

15

Type of Actuatoin

•• Method of Method of shifting a spoolshifting a spool•• Method of providing Method of providing spool returnspool return

16

Manual Actuation

17

Pilot-Operated, three and Four-Way Valve

The pressure port (1) is normally open The pressure port (1) is normally open to the cylinder port (2) and the valve to the cylinder port (2) and the valve must be operated to turn the pressure must be operated to turn the pressure off. This valve is said to be off. This valve is said to be Normally Normally Open. Open.

By simply reversing ports (1) and (3) By simply reversing ports (1) and (3) the pressure port is normally closed the pressure port is normally closed and the valve is operated to obtain and the valve is operated to obtain pressure at port (2). This valve is pressure at port (2). This valve is Normally Closed.Normally Closed.

18

Solenoid

•• A solenoid is a coil with an iron plunger inside it. A solenoid is a coil with an iron plunger inside it. •• When current flows in the coil, the plunger becomes When current flows in the coil, the plunger becomes

magnetized and tries to move out of the coil. If a spring is magnetized and tries to move out of the coil. If a spring is used to resist the movement, the distance moved is directly used to resist the movement, the distance moved is directly proportional to the current in the coil. proportional to the current in the coil.

19

Solenoid-Operated, Four-Way Valves

•• When a solenoid is When a solenoid is energizedenergized, it forces a push rod against the , it forces a push rod against the end of a spool. A spool shifts away from the solenoid and end of a spool. A spool shifts away from the solenoid and toward the opposite end of the valve body.toward the opposite end of the valve body.

connectorconnector

20

Solenoid-Operated, Four-Way Valves

• In a spring-offset model, a single solenoid shifts a spring-loaded spool. When a solenoid is deenergized, a spring returns a spool to its original position.

21

Solenoid and pilot operated valve

•• X and Y are the pressure and tank connections for the pilot valvX and Y are the pressure and tank connections for the pilot valve which e which are brought through the main body to the underside. The pilot are brought through the main body to the underside. The pilot connections are made via end plates. The pilot valve is most likconnections are made via end plates. The pilot valve is most likely to be ely to be solenoid operated with solenoid assemblies on one or both ends.solenoid operated with solenoid assemblies on one or both ends.

22

DCV Applications: 2/2 way

Triggering a single acting cylinderTriggering a single acting cylinder

23

DCV Applications: 2/2 way

•• As a byAs a by--pass, e.g. rapid traverse pass, e.g. rapid traverse feed circuit, pressurizes pump feed circuit, pressurizes pump byby--pass;pass;

24

DCV Applications: 2/2 way

•• Switching on or off various flow or Switching on or off various flow or pressure pressure valves;(pressurevalves;(pressure stage stage circuit)circuit)

25

DCV Applications: 2/2 way

Triggering a motor in a single direction.Triggering a motor in a single direction.

26

DCV Applications: 3/2 way

Triggering a single acting cylinder.Triggering a single acting cylinder.

27

3/2 way: Use as Shunt28

DCV Applications: 4/2 way

Triggering a double acting cylinderTriggering a double acting cylinder

Possible applications of the 4/2Possible applications of the 4/2--way way valve:valve:

•• Triggering of doubleTriggering of double--acting cylinders;acting cylinders;

•• Triggering of motors with either Triggering of motors with either clockwise or anticlockwise or anti--clockwise rotation;clockwise rotation;

•• Triggering of two circuits.Triggering of two circuits.

29

DCV Applications: 4/3 way30

DCV Applications: 4/3 way

Triggering a double acting cylinderTriggering a double acting cylinder

31

Functional Symbols32

Overrides

Mechanical overridesMechanical overrides enable the valve to be operated enable the valve to be operated without without electrical switchingelectrical switching. This is useful in . This is useful in fault tracing fault tracing asas makes it possible to tell straight away whether the makes it possible to tell straight away whether the fault is electrical or mechanical.fault is electrical or mechanical.On direct operating solenoidsOn direct operating solenoids this may take the form of this may take the form of

pushing the plunger with a pushing the plunger with a screw driverscrew driver..

33

Valve Bases

Directional and other valves are usually designed to be mounted on a separate base. The external pipe work is connected to the base. The advantage of this is standardization of designs and it allows the valve to be removed without disconnecting the pipe work. Hydraulic bases to ISO size 6 and 10 are shown below.

34

Valve sizes

D10101011/4

D080883/4

D070771/2

D050553/8

D030331/8

_NFPA__ISO_CETOPsize_

CETOP (Comite Des Transmissions Oleohydrauliques et Pneumatiques or European Hydraulic and Pneumatics Committee).

35

Selector Valves

(1)(1) directional control devices directional control devices to insure the movement of to insure the movement of the hydraulic fluid flow in the hydraulic fluid flow in the proper direction, the proper direction,

(2)(2) stopstop--lockslocks to lock the to lock the selector switch in a certain selector switch in a certain position. position.

36

Cartridge Valves These are forms of poppet valve designed to fit into a These are forms of poppet valve designed to fit into a manifold block.manifold block.The basic function of a cartridge valve is to The basic function of a cartridge valve is to open or close open or close

the connectionthe connection between it's between it's A & BA & B portsportsJust about Just about all valve types all valve types can be designed as a cartridge can be designed as a cartridge

to fit into a block specially machined to accept it. In this to fit into a block specially machined to accept it. In this way a bank of valves may be way a bank of valves may be built into one blockbuilt into one block. The . The block might contain block might contain directional valvesdirectional valves, relief valves, flow , relief valves, flow dividers, one way valves dividers, one way valves ……

37

Cartridge Valves38

Cartridge Valves

39

Advantages•• Short switching times Short switching times -- 20% lower because of smaller parts and 20% lower because of smaller parts and

smaller stroke. smaller stroke. •• Gentle operation Gentle operation -- operates without pressure peaks hence low operates without pressure peaks hence low

noise. noise. •• Substantially reduced valve leakages. Substantially reduced valve leakages. •• Low electrical power, low voltage peaks. Low electrical power, low voltage peaks. •• Reduced sensitivity to contamination. Reduced sensitivity to contamination. •• Low thermal losses because of larger flow cross section. Low thermal losses because of larger flow cross section. •• Compact in size because number of different functions can be Compact in size because number of different functions can be

combined in single cartridge valve and combined in single cartridge valve and monoblockmonoblock becomes the becomes the housing for number of cartridge valves. housing for number of cartridge valves.

•• High flexibility. High flexibility. •• Ease of maintenance and servicing. Ease of maintenance and servicing.

40

Disadvantages

•• With out training it is difficult to maintain. With out training it is difficult to maintain. •• Trouble shooting becomes difficult. Trouble shooting becomes difficult.

41

• Proportional Solenoid gives displacement of spool proportionalto the current through the solenoid. As the spool moves the flow path between P & A gradually opens allowing flow to take place. To get good metering characteristics, notches are machined into edges of the spool lands. Therefore, it is able to control direction as well as flow to the circuit.

Proportional Hydraulics42

Proportional Hydraulics

• Proportional solenoid gives variable force to hold the poppet against a seat. Force would be proportional to the current passing through solenoid. Therefore, varying current through solenoid can vary pressure setting.

43

Proportional Solenoid

• A current through coilgenerates magnetic force which pulls armature towards pole piece. magnitude of force transmitted through pin to spool/poppet is proportional to the current.

44

Proportional Valves

45

Servo Valves46

Servo Valves

•• Control motor:Control motor:Change signal current to distance.Change signal current to distance.

•• Hydraulics Amplifier:Hydraulics Amplifier:Change distance to Pressure drop.Change distance to Pressure drop.

•• Second Stage:Second Stage:Changes pressure drop to FlowChanges pressure drop to Flow

47

Comparison

.1 %.1 %11--5 %5 %HysteresisHysteresis

100 Hz100 Hz10 Hz10 HzMaximum operating Maximum operating frequencyfrequency

55--10 ms10 ms4040-- 60 ms60 msResponse time for Response time for

valve spool to move valve spool to move fully overfully over

Zero or Zero or underlapunderlapvalve spool. No dead valve spool. No dead

zonezone

Overlap spool, Overlap spool, causing a dead zone causing a dead zone on either side of the on either side of the

null pointnull point

Valve lapValve lap

Servo ValvesServo ValvesProportional ValvesProportional ValvesParameter Parameter

48

Close Loop Example

49

Close Loop Example