Annexure - 7 60MW Data Sheets

-

Upload

hari-krishnam -

Category

Documents

-

view

220 -

download

0

Transcript of Annexure - 7 60MW Data Sheets

-

8/12/2019 Annexure - 7 60MW Data Sheets

1/161 of 16

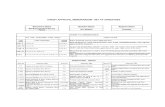

60 M.W STG & AUXILARIES TECHNICAL DATA SHEET

S.No Description NANJING

1.00 Performance Guarantee Parameters

Inlet steam pressure (Ata) 90

Inlet steam flow (TPH) 222

Inlet steam temperature (Deg.C) 535

Feed water flow (TPH) 222Feed water temperature (Deg.C) 223.48

No. of extractions 6

Exhaust pressure (Ata) 0.1

Exhaust flow (TPH) 158

Exhaust Temperature (Deg.C) 45

Cooling water Temperature (Deg.C) 33

Specific steam consumption 3.684

Auxilarie Power Consumption

Electrical out ut (KW) 60000Turbine Heat Rate(k.cal/kwh) 2210

delivery FOB 12months

Commissioning 17 months

2.00 Steam Turbine:

Make NANJING

Type Impulse Reaction

Duty continuous

Manufacturer Model No. N60-8.83

Rated Power(Design) 60000Maximum Continuous Rating of Power 63000

Rated Speed & its permitted variation 3000

Direction of Rotation

Clockwise lokking down

strem

Noise level 85dba

Dimensions of Turbine 7451x7090x3260

Casing split horizontal

Rotor type built-up

Shaft seal labyrinth seal

No. of governing valves 4

Bearing support pedastal

No.of.stages 22

2.01 Turbine Bearings

a)Journal Bearings YES

Make NTC

Type SLEEVE

Material Babbit lined

b)Thrust Bearings YES

Make NTCType Tilting pad type

Material Babbit lined

2.02 Material of construction of Major components:

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

http://www.docudesk.com/http://www.docudesk.com/ -

8/12/2019 Annexure - 7 60MW Data Sheets

2/162 of 16

S.No Description NANJING

1.outer casings 21/2Cr-1Mo

2.inner casing 21/2Cr-1Mo

3.guide blabe carrier Cast steel

4.rotar Cr.Mo.V Forged steel

5.exhaust hood fabrication

6.sealing strips SS7.caulking wire SS

8.steam strainer SS

9.nozzle SS

10.rotar blade SS

11.stator blade SS

12.valve spindle SS

13.valve cone SS

14.valve seat SS

15.bearing housing CS16.bearing lining Babbit

17.gland rings 11/2 Cr-Mo

18.balance piston gland 11/1 Cr-Mo

19 .inlet valve block 21/2 Cr-1Mo

2.03 Weights(KGS)

Weight of rotor 18700

Weight of upper half casing 25000

Wei ht of lower half casin 35000

Weight of Front base plate 2491

Weight of Rear base plate 4061

Weight of Turbine with base plate (Total weight) 127000

2.04 Details of Insulation and Clading Site Insulated

2.05 Turbine Connections

A Inlet steam

Number Four

Size 150 NB

Rating 2500

2.06 Turbine Accessories:

A Emergency Stop Valve

Quantity 1

size 250 NB

Material of body 21/2 Cr-1 Mo

Weights(KGS) 3271

B Governing Valves

Quantity 4

Size 100 NB

C Barring gear :

Type ElectricDrive details Motor

Motor Rating 22KW

D QCNRV:

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

-

8/12/2019 Annexure - 7 60MW Data Sheets

3/163 of 16

S.No Description NANJING

Qty 6

Type water operated

Operation By.Water

G Other valves details, if any :

H Gland sealing system :

Details of valves, strainers and inter connectingpiping

Sealing control valve&desuperheater

Gland Steem condensor:

Design code AZY-09.81-016.0-01

Type shell and Tube

Condensate Flow 240 TPH

Condensate Pressure 14 Kg/cm2.G

Heatin surface area 46m2

Test pressure Water side 22.44 Kg/cm2

Test pressure Tube side 2.0Kg/cm2Tube material SS

Shell & end cover material Carbon steel

Tube sheet material Carbon steel

Accessory Fan provided

Driver for air blower Motor

2.07Mating flanges with fastners and gaskets for therelated equipments.

Provided

2.08 Set of foundation bolts Provided

3.00 Lube Oil System:

3.01 Lube oil & its tank details :

Governing oil pressure 1.6MPa

Lube oil pressure 0.1MPa

Oil type ISO VG-46

Oil quantity for initial fill and flushing 15m3

Oil reservoir capacity 21m3

Retention time(Min) 5

Material of Oil reservoir Carbon steel Fabr.

Material of oil piping from pumps to filters S.S

O.H.T.capacity 5 m3

O.H.T. material S.S

Material of oil piping from filters to bearings S.S

Material of oil piping from bearings to reservoir S.S

3.02 Main oil pump(MOP) :/SHAFT DRIVEN

Make NTC

Type Centrifugal

O eratin s eed 3000

Capacity(flow-m3/h) 180delivery presure(kg/cm2) 16

Drive details Shaft Driven

Material of body HT250-7

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

-

8/12/2019 Annexure - 7 60MW Data Sheets

4/164 of 16

S.No Description NANJING

Material of end cover ZQSn6-6-3

3.03 Auxiliary oil pump(AOP):

Make NTC

Type Centrifugal

Operating speed 2950rpm

Capacity(flow-m3/h) 180delivery presure(kg/cm2) 16

Drive details AC Motor driven

3.04 Emergency oil pump(EOP)- AC :

Model 80Y60A

Make NTC

Type Centrifugal

O eratin s eed 2950

Capacity(flow-m3/h) 45delivery presure(kg/cm2) 4.9

Drive details YB160M2-2

Power AC Motor-15kw

Material of body Cast Iron

Material of end cover Cast Iron

Total weight 0.85 Ton

3.05 Emergency oil pump(EOP)- DC:

Make NTC

Type Centrifugal

Operating speed 3000

Capacity(flow-m3/h) 45

delivery presure(kg/cm2) 4.9

Drive details Z2 - 52

Power DC Motor-13kw

Material of body Cast Iron

Material of end cover Cast Iron

Total weight 0.85 Ton

3.06 Jacking Oil Pump - AC

Quantity 2 x 100%

Make NTC

T e Vane um

Operating speed RPM 1500

Capacity(flow-m3/h) 25

delivery presure(kg/cm2) 80-100

Drive details AC Motor driven

Power (KW) 15 KW

Material of body Cast steel

Material of end cover

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

-

8/12/2019 Annexure - 7 60MW Data Sheets

5/165 of 16

S.No Description NANJING

3.07 Jacking Oil Pump - DC

Quantity 1x 100%

Make NTC

Type Vane Pump

O eratin s eed 1460

Capacity(flow-m3/h) 25 LPM

delivery presure(kg/cm2) 80-120

3.08 Oil coolers :

Quantity 3 X 50%

Make NTC

Design code Chinese design insitute

Type Shell and Tube Type

Oil inlet temperature 65

Oil outlet temperature 45

Tube material Admirality Brass

Tube sheet material Carbon steel

Oil flow capacity 730

Mounting Vertical

Plugging margin 20%

3.09 Lube oil filter:

Quantit 2 X100%

Make NTCElement type Catridge

Oil flow ca acit (L.P.M) 730

Oil filtration capacity(Microns) 40

Mountin Vertical

3.10 Control oil filter:

Quantit 2 X100%

Make NTC

Element type Catridge

Oil flow ca acit (L.P.M)

Oil filtration capacity(Microns) 20

Mountin Vertical

3.11 Oil vapour extractor :

Quantity 2 X100%

Make NTC

Capacity(m3/h) 420

Total Pressure 4.2 Kpa

Driver AC Motor driven

Model YB100L - 2

Speed ( RPM) 2880Power (KW) 3 KW

Mounting top of the tank

3.12 Oil centrifuge :

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

-

8/12/2019 Annexure - 7 60MW Data Sheets

6/166 of 16

S.No Description NANJING

Model MMB 305S

Quantity 1

Make ALFA LAVAL

Oil flow capacity(L.P.H) 1000

Oil filtration capacity(Microns) 5

Centrifuge/boster pump rating 1Type of oil heater direct

Heater rating 12

3.13 Pressure regulating valves details :

3.14 Pressure relief valves details :

4 Inter connecting piping and accessories Included

5.00 Governing System:

5.01 Governor :

Make WOOD WARD

Type 505Inputs (critical) 1400-1800rpm

Control range 0-3360rpm

Control accuracy 1rpm

Speed droop 3-6%

Power supply DC 24V

Accessories non

5.02 Interconnecting control oil piping Local Supply

5.03 Other accessories details, If any O.H.T & ACC

6.00 Condensing system:6.01 Steam surface condenser with hotwell:

Design code chinese/HEI equi

T e Shell & Tube

Capacity 180 TPH

Cooling Surface Area 5100 m2

Number of passes 2

Cleanliness factor 0.8

velocity of water in Tubes 2.3 m/sec

MOC & Thickness of tubes in condensing zone Stainless steelMOC & Thickness of tubes in air cooling zone Stainless steel

MOC for Tube sheets TP 304 + Q235 B

Vertical expansion taken by Springs or Expansion Bell Springs

Temperature of condensate at hot well 45

Make up water Quantity 10 Tph

Make up water Temperature 33

Pressure drop on tube side as measured across CW

inlet and Outlet52.83 KPa

Tube plugging margin 5%Tube size OD X Thickness 22 x 0.7 thk

Cooling water flow T/h 11500

Coolin water tem erature I/L & O/L 33 & 410C

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

-

8/12/2019 Annexure - 7 60MW Data Sheets

7/167 of 16

S.No Description NANJING

Cleanliness factor 0.85

Tube plugging margin 5%

Hotwell retention time(Min) 3

Tube fixing Roller Expanded

Tube size OD X Thickness 1" 22 BWG

Tube sheet material Carbon steelWater box & Shell material Carbon steel

6.02 Water jet air Ejector

Quantity 2 x 100%

Type water Ejector

Design code chinese

Suction medium Water ejector

Material of nozzle

Material of shell & diffuserPump Details:-

Capacity (m3/h) 506

Head (M) 42

Min Flow (m3/h) 140

Efficiency 78.50%

T e of seal Mechanical

Drive details:-

Power (KW) 75

Speed ( RPM) 1480

6.03 Condensate Extraction Pumps

Make KSB

Quantity 2 x 100%

Type vertical cannister type

Mounting vertical cannister type

Suction pressure 0.098

NPSH required2.1 at eye ofSuction impeller

Flow capacity 240 TPH

Discharge pressure 14 kg/cm2.G

Operating speed 1480

No of Stages 5

Complete Drive details AC motor

Type of bearings Antifriction

type of seal Mechanical

Type of coupling lovjoy

Type of lubrication Oilcup

Material of casing CarbonsteelMaterial of impeller CF8M

Material of shaft Forged

Material of shaft sleeve Later

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

-

8/12/2019 Annexure - 7 60MW Data Sheets

8/168 of 16

S.No Description NANJING

Motor Rating 160 KW

6.04 Relief Valves for Condensor protection provided

6.05Interconnecting piping, strainers, steam traps,drains, vents and Isolation provisions. out of scope

6.06 Dry air/vapor line (Air removal from con to ejector) out of scope

6.07 Other accessories details, If any

7.0 HP.Heater -1 Local Supply

1.1 Type of Heater Vertical

1.2 Orientation Vertical

1.3 Location Below operating floor

1.4 Tube Type U-Tube Type

1.5 No.of.Tube Passes 4 pass

1.6 No.of.Zones (shell side) 22.0 DESIGN DATA SHELL SIDE

2.1 Extraction steam

Flow Rate 14.77 TPH

Inlet Temp 348.05

Operating Pressure 1.545 MPa

2.2 Drains Leaving

Flow Rate 26.07 TPH

Temperature 199.68

Enthalpy 851.042.3 Design Pressure

2.4 Design Vacuum FV

2.5 Design Temp

Main Shell

Skitr Shell

2.6 Test Pressure

3.0 DESIGN DATA TUBE SIDE

Feed water Flow Rate 240 TPH

In let Temp 160.08

Out let Tem 200.37

Operating Pressure

Design Pressure

Design Temp

TestPressure

4 Heat Duty

Total Heat Duty

5 Heat Transfer surface area 260 M2

6 GAURANTEE PERFORMANCE DATA

Terminal Temp DifferenceDrain cooler approach

Over all pressure drop on tube side

side at the average operating

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

-

8/12/2019 Annexure - 7 60MW Data Sheets

9/169 of 16

S.No Description NANJING

7 CONSTRUCTION FEATURES

7.1 Shell

Shell ID 1000 mm

Shell Thickness 14 mm

Overall length of Heater 7300

Shell side corrossion allowance 1 mm

7.4 Nozzle Type / End connection

Feed water inlet zone Butt Weld

Feed water outlet zone Butt Weld

Steam inlet nozzle on the shell side Butt Weld

Drain out let nozzle type on the shell side Flange

8 MATERIAL OF CONSTRUCTION

Main shell & shell side "D"

Shell skirt

Support plates

Tube sheet (Forging)

Tubes

Channel / Manway.cover (forging)

Channel Nozzles

Gasket on water side

9 WEIGHT 15389 Kg

10 SPARES

Start up and commissioning Included

11 TERMINAL POINTS

Steam inlet nozzle on the shell side

Steam pipe, root valve for instrument connection

Drain inlet nozzle (if any)

Drain out let nozzle type on the shell side

Feed water Inlet Nozzle

Feed water out let Nozzle

Air vent outlet nozzle

12 ACCESSERIES

Stand pipe IncludedStand pipe isolation valves Included

Stand pipe vent drain valve Included

Local level au e with isolation valves Included

Safety valve - shell side Included

Safety valve - channel side Included

Globe valve for vent and drain Included

Isolation valves for transmitters Included

Dial thrmometers Included

Pressure gauge with isolation gate valve Included

Shell drain valves Included

8.0 HP.Heaters- 4

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

-

8/12/2019 Annexure - 7 60MW Data Sheets

10/1610 of 16

S.No Description NANJING

1.1 Type of Heater Shell & Tube

1.2 Orientation Vertical

1.3 Location Later

1.4 Tube Type

1.5 No.of.Tube Passes

1.6 No.of.Zones (shell side)2.0 DESIGN DATA SHELL SIDE

2.1 Extraction steam

Flow Rate 13.28 TPH

Inlet Temp 395.41

Operating Pressure 2.841 Mpa

2.2 Drains Leaving

Flow Rate 13.28 TPH

Temperature 230.81

Enthalpy 994.04

2.3 Design Pressure

2.4 Design Vacuum

2.5 Design Temp

Main Shell

Skitr Shell

2.6 Test Pressure

3.0 DESIGN DATA TUBE SIDE

Feed water Flow Rate 222 TPH

In let Temp 196.6

Out let Tem 223.48

Operating Pressure

Design Pressure

Design Temp

TestPressure

4 Heat Duty

Total Heat Duty

5 Heat Transfer surface area 260 M2

6 GAURANTEE PERFORMANCE DATA

Terminal Temp DifferenceDrain cooler approach

Over all pressure drop on tube side

side at the avera e o eratin

7 CONSTRUCTION FEATURES

7.1 Shell

Shell ID 1000 mm

Shell Thickness 20 mm

Overall len th of Heater 7300

Shell side corrossion allowance 1 mm

7.4 Nozzle Type / End connection

Feed water inlet zone Butt Weld

Feed water outlet zone Butt Weld

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

-

8/12/2019 Annexure - 7 60MW Data Sheets

11/1611 of 16

S.No Description NANJING

Steam inlet nozzle on the shell side Butt Weld

Drain out let nozzle type on the shell side Flanged

8 MATERIAL OF CONSTRUCTION

Main shell & shell side "D"

Shell skirt

Support platesTube sheet (Forging)

Tubes

Channel / Manway.cover (forging)

Channel Nozzles

9 WEIGHT 16618 Kgs

10 SPARES

Start up and commissioning Included

11 TERMINAL POINTS

Steam inlet nozzle on the shell side

Steam pipe, root valve for instrument connection

Drain inlet nozzle (if any)

Drain out let nozzle type on the shell side

Feed water Inlet Nozzle

Feed water out let Nozzle

Air vent outlet nozzle

12 ACCESSERIES

Stand pipe Included

Stand pipe isolation valves Included

Stand pipe vent drain valve Included

Local level gauge with isolation valves Included

Safety valve - shell side Included

Safety valve - channel side Included

Globe valve for vent and drain Included

Isolation valves for transmitters Included

Dial thrmometers Included

Pressure au e with isolation ate valve Included

Shell drain valves Included

9.0 LP.Heater-1

1.1 T e of Heater Shell & Tube

1.2 Orientation Vertical

1.5 No.of.Tube Passes 2

1.6 No.of.Zones (shell side) 3

2 Extraction steam

Flow Rate (Kg/hr) 10.03 TPH

Inlet Temp 79.25

Operating Pressure (Mpa) 0.0459 MPa2.1 Drains Leaving

Flow Rate (Kg/hr) 31.19 TPH

Temperature 79.25

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

-

8/12/2019 Annexure - 7 60MW Data Sheets

12/1612 of 16

S.No Description NANJING

Terminal Temp Difference

Enthalpy (Kj/ kg) 331.37

side at the average operating (Kg/cm2)

22 Design Pressure (Kg/cm2) 2.5 Mpa

2.3 Design Vacuum

2.4 Design Temp

Main Shell /Skirt 95 / 85

2.5 Test Pressure 3.125 Mpa

3.0 DESIGN DATA TUBE SIDE

Feed water Flow Rate (Kg/hr) 201.97

In let Temp 45 .60

Out let Tem 74.25

Operating Pressure 14 kg/cm2.G

Design Pressure 2.5 Mpa

Design Temp 85

TestPressure 3.125 M a

Feed water velocity at sp.gravity 1.0

Plugging Margin

4.00 Heat Duty

Total Heat Duty

5.00 Heat Transfer surface area 185 M2

6.00 GAURANTEE PERFORMANCE DATA

Terminal Temp Difference

Drain cooler a roach

Over all pressure drop on tube side

side at the average operating

7.00 CONSTRUCTION FEATURES

7.10 Shell

Overall length of Heater 5862 mm

Shell ID 1020 mm

Shell Thickness 10 mm

Shell side corrossion allowance 1 mm

Total Weight 5457 Kgs

10.0 LP.Heater-2

1.1 Type of Heater Shell & Tube

1.2 Orientation Vertical

1.3 Location T Buildin 5 M LVL

1.4 Tube Type

1.5 No.of.Tube Passes 2

1.6 No.of.Zones (shell side) 32.0 DESIGN DATA SHELL SIDE

2.1 Extraction steam

Flow Rate (Kg/hr) 11.17 TPH

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

-

8/12/2019 Annexure - 7 60MW Data Sheets

13/1613 of 16

S.No Description NANJING

Inlet Temp 109.27

Operating Pressure 0.1398 MPa

2.2 Drains Leaving

Flow Rate 21.16 TPH

Temperature 107.05

Terminal Tem Difference

2.3 Design Pressure

2.4 Design Vacuum

2.5 Design Temp

Main Shell /Skirt 180 / 135

2.6 Test Pressure

2.7 Fouling Factor

3.0 DESIGN DATA TUBE SIDE

Feed water Flow Rate 222 TPH

In let Temp 72.51

Out let Tem 102.05

Operating Pressure 2.0 Mpa

Design Pressure 2.5 Mpa

Design Temp 135

TestPressure 3.125 Mpa

Feed water velocity at sp.gravity 1.0

Plu in Mar in

4 Heat Duty

Total Heat Duty

5 Heat Transfer surface area 170 m2

6 GAURANTEE PERFORMANCE DATA

Terminal Temp Difference

Drain cooler approach

Over all pressure drop on tube side

side at the avera e o eratin

7 CONSTRUCTION FEATURES

Shell ID 1000 mm

Shell Thickness 10

Overall length of Heater 5537 mm

Shell side corrossion allowance 1 mm

Total weight 5200 Kgs

11.0 LP.Heater-3

1.1 Type of Heater Shell & Tube

1.2 Orientation Vertical

1.3 Location Tg Building 5 M LVL1.4 Tube Type Bundle

1.5 No.of.Tube Passes 2

1.6 No.of.Zones (shell side) 3

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

-

8/12/2019 Annexure - 7 60MW Data Sheets

14/1614 of 16

S.No Description NANJING

2.0 DESIGN DATA SHELL SIDE

2.1 Extraction steam

Flow Rate 9.990 TPH

Inlet Temp 197.81

Operating Pressure 0.3222 MPa

2.2 Drains Leaving

Flow Rate 9.990 TPH

Temperature 136

Terminal Temp Difference

2.3 Design Pressure 0.8 Mpa

2.4 Design Vacuum

2.5 Design Temp 260

2.6 Test Pressure 3.125 Mpa

2.7 Foulin Factor

2.8 Minimum cladding thickness

2.9 Corrosion allowance(mm) 1

3.0 DESIGN DATA TUBE SIDE

Feed water Flow Rate 201 Tph

In let Temp 105

Out let Temp 134

Operating Pressure 2.0 Mpa

Desi n Pressure 2.5 M a

Design Temp 165

Feed water velocity at sp.gravity 1.0

Plugging Margin

4.00 Heat Duty

Total Heat Duty

5.00 Heat Transfer surface area 170 m2

6.00 GAURANTEE PERFORMANCE DATA

Terminal Tem Difference

Drain cooler approach

Over all pressure drop on tube side

side at the average operating

7.00 CONSTRUCTION FEATURES

7.10 Shell

Shell ID 1000 mm

Shell thickness 10 mm

Overall length of Heater 5537 mm

Total Weight 5254 Kgs

FOR ALL HEATERS :-SPARES

Start up and commissioning spares Included

7.20 Material of Construction

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

-

8/12/2019 Annexure - 7 60MW Data Sheets

15/1615 of 16

S.No Description NANJING

Water Chamber 16MnR

Dish End 16MnR

Tube sheet 20MnMoII

Flange 16MnII

ACCESSERIES

Stand pipe 100 NB Included

Stand pipe isolation valves Included

Stand pipe vent drain valve Included

Local level gauge with isolation valves Included

Level Transmitter Included

Safety valve - shell side Included

Safety valve - channel side Included

Globe valve for vent and drain Included

Isolation valves for transmitters Included

Dial thermometers Included

Pressure gauge with isolation gate valve Included

Shell drain valves Included

11.00 T.G.Intergrial piping

Condensate piping Included

Drain piping Included

oil piping Included

12.00 Control valves

H.P heater 2 level control valve Self Adjustable CV

H.P.heater 1 level control valve Self Adjustable CV

Deaerator presure control valve ExCLUDED

L.P.heater 3 level control valve Self Adjustable CV

L.P.heater 2level control valve Self Ad ustable CV

L.P heater 1 level control valve Self Adjustable CV

CEP recirculation control valve Included

Main condensate control valve IncludedHood spray Attemperation Included

PRDS control valve for Glands Included

PRDS control valve for Flange Heating Included

Vaccume break valve Included

13.00 T.G. Building Elevations

Overall Dimensions L x B x H 90 X 45 X 22

Auxiliries Floor 5.0 M LVL

Operating Floor 10.0 M LVLEOT Crane Girider 22 M LVL

PDF Created with deskPDF PDF Writer - Trial :: http://www.docudesk.com

-

8/12/2019 Annexure - 7 60MW Data Sheets

16/16

S.No Description NANJING

Data sheet to be filled by vendor : (A C Generator and other Equipment):

1.00 Rating And Performance

Type QFW-65-2

Capacity 65000 kWEfficiency 98.20%

Standard GB/T 7064-2002

Rated voltage 11000V

Rated current 4264.5A

Power factor 0.8

Connection Y

Speed 3000 r/min

Frequency 50 Hz

Phase 3Insulation class F

D.c resistance of stator winding 20 0.00147

D.c resistance of excitation winding 20 0.2609

Stator leakage reactance xe (p.u) 0.154

Direct-axis synchronous reactance xd (p.u) 1.702

Direct-axis transient reactance xd (p.u) 0.174

Direct-axis sub-transient reactance xD(p.u) 0.1313

Negative phase-requence reactance x2(p.u) 0.147

Zero phase-sequence reactance xo(p.u) 0.069

Transient time constant tdo 10.6 s

Sub-transient time constant tDo 0.06 s

Short-circuit ratio fk0 0.66

Excitation system AC. BRUSHLESS

Rated excitation current on full load 660 A

Rated excitation voltage on full load 246 V

Excitation current on no-load 282 A

Excitation voltage on no-load 82 V

Air cooler power 1240 kW

Air flow (for two fans) 22 m3/s

Water flow 331 m3/h

Water inlet temperature 33

Air temperature after cooled 40

Max working water pressure 0.196 MPa

Water pressure drop 0.0182 MPa