Amkor Portfolio

-

Upload

lindsey-larson -

Category

Documents

-

view

178 -

download

2

Transcript of Amkor Portfolio

Envision. Invent.Enable.

Leading-Edge Packaging Solutions for Current & Next Generation Applications

Innovative IC packaging and test solutions for today’s advanced microelectronics.

Visit Amkor Technology online for current product information and locations.

AutomotivefcBGA | fcCSP

MEMS | QFN | SiP

CommunicationsfcCSP | MEMS

MLF® | SiP | WLCSP

ComputingfcBGA | fcCSP

MEMS | QFN | SiP

ConsumerfcBGA | fcCSP

MLF® | SiP | SSOP

IoTCABGA | MEMS

QFN | SiP | WLCSP

NetworkingCABGA | fcBGA

PBGA | QFN | SiP

CONNECTINGPeople and Technology

© 2016 Amkor Technology, Inc.amkor.com

Visit Amkor Technology online for current product information and locations.

Mobilize Your ProductsAdvanced portfolio for thinner, higher-performance devices

Key Packaging & Technology for Mobile & Tablet Devices

Smart phones and tablets provide gateways for managing our connected lives. Amkor’s robust advanced packaging portfolio provides a complete solution for mobile connectivity.

CABGA | fcBGA | fcCSP | MEMS | MLF® PBGA | QFP | SiP | SOIC | SSOP | WLCSP

CONNECTINGPeople and Technology

© 2016 Amkor Technology, Inc.amkor.com

Visit Amkor Technology online for current product information and locations.

MEMS and Sensor Packaging

Leading the Industry in Advanced MEMS DevicesThe roadmaps for smart cars, homes and consumer mobile/tablet products require advanced MEMS and sensors – Amkor Technology is answering that call with sensor fusion technology.

Enabling a Smarter World

Next Generation Packages for Sensor Fusion

MLF®/QFN

ChipArray® BGA

Cavity Package Hybrid Cavity Package

CONNECTINGPeople and Technology

© 2016 Amkor Technology, Inc.amkor.com

Advanced SiPPacked with performance

We pack more functionality into a smaller space while increasing system performance and lowering system power consumption of today’s mobile devices.

SiP TechnologyCombining different package form factors and interconnect technologies

■ Wirebond CSP■ Flip Chip CSP■ PBGA & FCBGA■ Leadframe■ Bumps, copper pillars, F2F■ Cavity packages■ Molded and unmolded packages■ IPD, conformal shielding, embedded technology

CONNECTINGPeople and Technology

© 2016 Amkor Technology, Inc.amkor.com

Visit Amkor Technology online for current product information and locations.

Amkor Confidential 1

8,00

0,00

0+Sq

. Ft.

Man

ufac

turin

g Sp

ace 16

Sales & Customer Support Centers

Assembly &Test Facilities

22

Amkor Technology by the Numbers

2,464Number Of Patents

Number of Employees

26,700+ $3.70BNET SALES

$3.70BSALES

Founded1968Founded196848

26,700+

3,000+Package Portfolio 10

CountriesFootp

rint In

Assembly

Top Turnkey Services3Test Design

(Amkor + J-Devices)

Strategically L ocated Asia F actories and Customer Support Centers

w w w .amkor.com

Asia

J apan

SALES OFFICEShanghai, C hinaB eij ing, C hinaShenz hen, C hinaTokyo, J apanSeoul, K oreaSingapore Z hubei C ity, Taiwan

ASSEMBLY AND TESTShanghai, C hinaI ncheon, K oreaG wangj u, K oreaSeoul, K oreaSelangor, MalaysiaB inan L aguna, P hilippinesMuntinlupa C ity, P hilippinesH ukou Township, TaiwanL ungtan Township, Taiwan

J-DEVICES LOCATIONSF ukui, J apanF ukuoka, J apanH akodate, J apanK itsuki, J apanK umamoto, J apanMiyagi, J apanU suki, J apan

Amkor Technology, Inc.Audit Committee Conference Call

Q3 2015 10-Q

Date: Date

Time: 1:30pm Eastern

10:30am Arizona

Dial In Number: Numbers

Passcode: Numbers

POWER PRODUCTSD ata Sheet

Q uestions? Contact us: marketing@ amkor.com

Visit Amkor Technology online for locations andto view the most current product information.

D S612B R ev D ate: 2/16

TSON8-FL

Process Highlights• B are copper leadframe with no plating• D ie attach: 5 5 um thin die pick up capability• I nterconnect: C u clips technology for better electrical and thermal

performance. Also available on Al strap + wire option.• P lating: 1 0 0 % matte Sn• Marking: P en type laser

Standard Materials• L eadframe: B are copper• D ie attach: Solder paste*• I nterconnect: 3 options,

– D ual C u clips– Al strap + C u wire– Multiple C u wires

• Mold compound: H alogen free* Apply to option dual C u clips.

Reliability QualificationAmkor devices are assembled with proven reliable semiconductor materials. • All test include pre- condition of: Ta = 8 5 °

Ta = 2 6 5 °C , 2 X• H igh Temperature Storage, Ta = 1 5 0 °C , 1 0 0 0 hrs• P ressure C ooker, Ta = 1 2 1 °C /R h = 1 0 0 %/ P = 2 atm, 9 6 hrs• Temperature C ycle, - 6 5 ~1 5 0 °C , 3 0 0 cycles

Test ServiceAmkor offers full turnkey business for all power discrete products. W e have the capability to test various type of power devices including MO SF ETs, bipolar transistors, I G B Ts, diodes, regulator I C s/intelligent power devices, etc.• Amkor power discrete test capability:

– Static test ( D C )– D ynamic test ( AC , Switching/Trr, C apacitance/R g)– D estruction test ( I nductive load/V SU S, I L atch, Surge, I solation/V I L )–

• P rogram generation/conversion• F ailure analysis• Available test/handling technology• I ntegrated marking, vision inspection and tape & reel services

IntroductionTSO N 8 - F L ( F lat L ead) is a smaller package ( 3 .3 x 3 .3 mm) with thermally enhanced that gives a 6 4 % reduction in footprint area compared with standard SO I C 8 ld package, yet an eq uivalent max imum permissible power dissipation capability.This package may also be know as:• TSO N - Adv• P owerF L AT™ 3 .3 x 3 .3• TSD SO N• miniH V SO N• P owerP AK ® 1 2 1 2 - 8• J ED EC : MO 2 4 0 B A

ApplicationTSO N 8 - F L is suitable for medium- power applications, designed for low on- resistance and high- speed- switching MO SF ETs:• B attery protection circuits• N otebook P C s• P ortable electronic devices• D C - D C converters

F eatures• Small and thermally enhanced package with the same

power dissipation but 6 4 % less footprint area thanSO I C 8 ld

• D ual C u C lip interconnect for better heat dissipation

• Al strap + wire option is also available• Turnkey with test and packing services• G reen materials: P b- free plating & halogen free mold

compound

New D evelopments• D ual ex posed pad for better thermal performance• Thin wafer dicing with narrow saw streets• L arger/higher density leadframe strips• Environmentally friendly P b- free solder paste

POWER PRODUCTSD ata Sheet

Q uestions? Contact us: marketing@ amkor.com

With respect to the information in this document, Amkor makes no guarantee or warranty of its accuracy or that the use of such information will not infringe upon the intellectual rights of third parties. Amkor shall not be responsible for any loss or damage of whatev er nature resulting from the use of, or reliance upon it and no patent or other license is implied hereby. This document does not in any way extend or modify Amkor’ s warranty on any product beyond that set forth in its standard terms and conditions of sale. Amkor reserv es the right to make changes in its product and specifications at any time and without notice. The Amkor name and logo are registered trademarks of Amkor Technology, Inc. All other trademarks mentioned are property of their respectiv e companies. © 2016, Amkor Technology Incorporated. All R ights R eserv ed.

Visit Amkor Technology online for locations andto view the most current product information.

D S612BR ev D ate: 2/16

Shipping• Tape and reel packing

– 3 0 0 0 pcs or 5 0 0 0 pcs per reel– Tape width 1 2 mm–

• B arcode packing label• D rop ship

TSON8-FL

Package Outline D raw ing TSON8 - F L

Cross- section – Option 1 : D ual Cu Clip

Cross- section – Option 2 : Al Strap + W ire

Cross- section – Option 3 : Multiple Cu W ires

Electrical Characteriz ation

ServiceSolutions

Q uestions? Contact us: marketing@ amkor.com

Visit Amkor Technology online for locations andto view the most current product information.

SS03 HR ev D ate: 11/15

Electrical Co- D esign and ModelingAmkor’ s electrical team members are ex perienced in the latest simulation tools and packaging technology. This allows our world class electrical team to reduce design cycle times and provide ex pert advice and services to customers.Amkor plays a leading role in supporting customers in the development of nex t generation packages and electronic technology for ex isting and emerging products. O ur unparalleled level of electrical design ex pertise provides the following “ best in class” electrical services:• H ighly trained and ex perienced staff members• H igh q uality, reliable and accurate designs• D esign for P erformance ( D F P ) , D esign for C ost ( D F C ) and D esign

for Manufacturing ( D F M)• Ex cellent customer design collaboration to meet electrical, thermal

and mechanical req uirements

Going B eyond the B asicsW ith rapidly increasing data transfer rates, the need to optimiz e package layout and electrical performance is ever more crucial. D elivering an optimum package design req uires more than j ust a robust layout and post- layout electrical simulation; it req uires close interaction with customers and substantial engineering support during the entire layout phase. Amkor’ s electrical engineering team works closely with customers and package designers to make sure the package layout meets the req uired signal integrity ( SI ) and power integrity ( P I ) performance specifications. O ur electrical analysis tools are tightly integrated with package layout tools and the assistance of our design automation team. As a result, electrical constraints can be passed to the design team during the design process, thus minimiz ing electrical design rule violations. This allows for q uicker design turnaround times while delivering a reliable and cost effective solution.C omprehensive design optimiz ation is possible by using electrical, thermal and mechanical characteriz ation. W ith Amkor’ s co- design methodology, signal and power integrity issues can be predicted in a timely manner and fix ed well before ex pensive prototypes are built. Amkor’ s ex perts can also help identify and optimiz e cost- effective thermal and mechanical solutions that satisfy our customers’ operating conditions and reliability ex pectations.

D esign MechanicalElectrical Thermal

mechanical solutions that satisfy our customers’ operating conditions and reliabilityexpectations.

Signal and Pow er IntegrityWith ev ery shrinking silicon node, faster I/O buffers and decreasing operating margins,signal and power integrity is a critical element of package design. V oltage fluctuations in the power distribution network due to IR drop, Ldi/dt noise, or LC resonance seriouslyimpact package performance. At Amkor, we hav e highly integrated signal and powerintegrity analysis capabilities. Packages are characteriz ed with multiple simulations byexercising v arious buss/signal channels with their respectiv e driv er/receiv er and associated power/ground domains. Amkor uses highly accurate, industry- standard 2D ,3 D , q uasi- static and full- wav e field solv ers.

Package L ayout, Electrical Modeling and Simulation ToolsCadence APD and SiP

Cadence/Sigrity U PD

Mentor xPedition

AutoCAD

Ansys Q3 D

Ansys H FSS

Ansys SIwav e

Ansys D esigner

Ansys Sentinel- NPE

K eysight AD S

mechanical solutions that satisfy our customers’ operating conditions and reliabilityexpectations.

Signal and Pow er IntegrityWith ev ery shrinking silicon node, faster I/O buffers and decreasing operating margins,signal and power integrity is a critical element of package design. V oltage fluctuations in the power distribution network due to IR drop, Ldi/dt noise, or LC resonance seriouslyimpact package performance. At Amkor, we hav e highly integrated signal and powerintegrity analysis capabilities. Packages are characteriz ed with multiple simulations byexercising v arious buss/signal channels with their respectiv e driv er/receiv er and associated power/ground domains. Amkor uses highly accurate, industry- standard 2D ,3 D , q uasi- static and full- wav e field solv ers.

Package L ayout, Electrical Modeling and Simulation ToolsCadence APD and SiP

Cadence/Sigrity U PD

Mentor xPedition

AutoCAD

Ansys Q3 D

Ansys H FSS

Ansys SIwav e

Ansys D esigner

Ansys Sentinel- NPE

K eysight AD S

mechanical solutions that satisfy our customers’ operating conditions and reliabilityexpectations.

Signal and Pow er IntegrityWith ev ery shrinking silicon node, faster I/O buffers and decreasing operating margins,signal and power integrity is a critical element of package design. V oltage fluctuations in the power distribution network due to IR drop, Ldi/dt noise, or LC resonance seriouslyimpact package performance. At Amkor, we hav e highly integrated signal and powerintegrity analysis capabilities. Packages are characteriz ed with multiple simulations byexercising v arious buss/signal channels with their respectiv e driv er/receiv er and associated power/ground domains. Amkor uses highly accurate, industry- standard 2D ,3 D , q uasi- static and full- wav e field solv ers.

Package L ayout, Electrical Modeling and Simulation ToolsCadence APD and SiP

Cadence/Sigrity U PD

Mentor xPedition

AutoCAD

Ansys Q3 D

Ansys H FSS

Ansys SIwav e

Ansys D esigner

Ansys Sentinel- NPE

K eysight AD S

mechanical solutions that satisfy our customers’ operating conditions and reliabilityexpectations.

Signal and Pow er IntegrityWith ev ery shrinking silicon node, faster I/O buffers and decreasing operating margins,signal and power integrity is a critical element of package design. V oltage fluctuations in the power distribution network due to IR drop, Ldi/dt noise, or LC resonance seriouslyimpact package performance. At Amkor, we hav e highly integrated signal and powerintegrity analysis capabilities. Packages are characteriz ed with multiple simulations byexercising v arious buss/signal channels with their respectiv e driv er/receiv er and associated power/ground domains. Amkor uses highly accurate, industry- standard 2D ,3 D , q uasi- static and full- wav e field solv ers.

Package L ayout, Electrical Modeling and Simulation ToolsCadence APD and SiP

Cadence/Sigrity U PD

Mentor xPedition

AutoCAD

Ansys Q3 D

Ansys H FSS

Ansys SIwav e

Ansys D esigner

Ansys Sentinel- NPE

K eysight AD S

Electrical Characteriz ationService

Solutions

Q uestions? Contact us: marketing@ amkor.com

With respect to the information in this document, Amkor makes no guarantee or warranty of its accuracy or that the use of such information will not infringe upon the intellectual rights of third parties. Amkor shall not be responsible for any loss or damage of whatev er nature resulting from the use of, or reliance upon it and no patent or other license is implied hereby. This document does not in any way extend or modify Amkor’ s warranty on any product beyond that set forth in its standard terms and conditions of sale. Amkor reserv es the right to make changes in its product and specifications at any time and without notice. The Amkor name and logo are registered trademarks of Amkor Technology, Inc. All other trademarks mentioned are property of their respectiv e companies. © 2015 , Amkor Technology Incorporated. All R ights R eserv ed.

Visit Amkor Technology online for locations andto view the most current product information.

Simultaneous Switching Noise

3

2

1

0

0 2

4Vo

ltage

(V)

4 6 8Time (ns)

Power Bounce

Switching Signal

Ground Bounce

I/O Supply

SS03 HR ev D ate: 11/15

Signal and Pow er IntegrityW ith every shrinking silicon node, faster I /O buffers and decreasing operating margins, signal and power integrity is a critical element of package design. V oltage fluctuations in the power distribution network due to I R drop, L di/dt noise or L C resonance seriously impact package performance. At Amkor, we have highly integrated signal and power integrity analysis capabilities. P ackages are characteriz ed with multiple simulations by ex ercising various bus/signal channels with their respective driver/receiver and associated power/ground domains. Amkor uses highly accurate, industry- standard 2 D , 3 D , q uasi- static and full- wave field solvers.

Package L ayout, Electrical Modeling and Simulation Tools• C adence AP D and SiP• C adence/Sigrity U P D• Mentor x P edition• AutoC AD• Ansys Q 3 D • Ansys H F SS• Ansys SI wave• Ansys D esigner• Ansys Sentinel- N P E• K eysight AD S• K eysight Momentum• C adence/Sigrity Tool Suite - P owerSI , B B Spice, Speed2 0 0 0 ,

P owerD C , X tractI M, 3 D - EM, T2 B , System SI• Synopsys H SP I C E

Eye Diagram

System in Package ( SiP)

TechnologySolutions

Questions? Contact us: [email protected]

Visit Amkor Technology online for locations andto view the most current product information.

Semiconductor industry demands for higher levels of integration and lower costs coupled with a growing awareness of complete system configuration have continued to drive the popularity of System in P ackage ( SiP ) solutions. Amkor' s SiP technology is an ideal solution in markets that demand smaller siz e with

increased functionality. B y assembling, testing and shipping more than one million SiP devices per day, Amkor Technology has a proven track record as the industry leader in SiP design, assembly and test. C ontact us today and let us add you to our growing list of customers who have been successful with System in P ackage technology.

What is System in Package?System- in- P ackage technology is more than j ust an I C package containing multiple die. A SiP is characteriz ed by any combination of one or more I C s of different functionality, which may include passive components and/or MEMS assembled into a single package that performs as a system or sub- system. U sing wirebonding or flip chip technology or a combination of both for the I C s, the SiP can contain components that are traditionally found on a P C board. Amkor' s emphasis is on functional integration and siz e reduction by using different package form factors and interconnect technologies, including:

TS101NRev Date: 11/15

• SiP Solutions ( side by side, P O SSU M™ , stacked die, package on package ( P oP ) , package in package ( P iP ) , cavity, face- to- face ( F 2 F ) and others)

• Surface mount discrete passive ( any common format including 0 1 0 0 5 siz e)

• I ntegrated passive devices ( I P D ) , either glass or silicon ( Si) type • P assives embedded inside or patterned on the substrate • D ie embedded in the package substrate • Surface acoustic wave ( SAW ) /bulk acoustic wave ( B AW ) filters,

crystals, oscillators, antennas • Sputtering conformal shielding and compartmental conformal

shielding• C ore and coreless substrate• R ecessed and cavity substrate• D oubled side mold• D ouble- sided assembly ( P O SSU M™ )• Strip grinding fine pitch ultra- thin package• D ifferent I C s integrations ( Silicon, G aAs, SiG e) • P re- packaged I C s • C onnectors • Mechanical partsThe power of SiP technology is the ability to bring together many I C and package assembly and test techniq ues to create highly integrated products with optimiz ed cost, siz e and performance.

SiP Module Design Options

System in Package ( SiP)Technology

Solutions

Questions? Contact us: [email protected]

Visit Amkor Technology online for locations andto view the most current product information.

TS101NRev Date: 11/15

Total System in Package SolutionsI n a SiP approach, one must consider not only the traditional elements of package assembly, but also design aspects relative to the overall system functional req uirements and manufacturing process, as well as supply chain management and test.System design becomes paramount to the overall success of developing an effective SiP product. Early in the overall system design, the customer and Amkor discuss and agree upon all elements of the system req uirements to ensure design success. W ith this in mind, Amkor has significantly ex panded its design capability to combine traditional layout ex pertise with digital and R F circuit design and system modeling. Amkor can also translate a customer' s reference designs for use in SiP development. W orking closely with the customer, Amkor can model circuits electrically, mechanically and thermally, which reduces design iterations and minimiz es time- to-market.

Manufacturing ExcellenceAmkor’ s “ C enter of Ex cellence” for substrate- based SiP technology is located in our largest volume manufacturing facility in K 4 K wangj u, South K orea. The large- scale manufacturing capabilities in this factory can achieve significant volume production support with very short cycle times. The manufacturing eq uipment is the latest advanced technology that supports high speed, high accuracy chip and component placement. Amkor’ s SiP design rules are the most advanced in the industry and are available to customers through a web portal access system. Amkor production lines have full automation, in- line inspection, R F I D control and other process control methods to ensure the highest yields and q uality while minimiz ing any potential loss of bill of material ( B O M) components.

Amkor SiP factories are eq uipped with the latest generation surface mount eq uipment to provide these attributes: 1 . U ltra- high- speed SMT placement machines which have leading-

edge component placement accuracy – best q uality and lowest cost.

2 . F lex ible placement machines which are better suited for odd- form component placement.

3 . C apable of placing any common component format available in tape and reel format down to and including the smallest 0 1 0 0 5 siz e.

4 . C apable of mounting bumped die directly from wafer tape.5 . Support for solder paste stencil printing, flux stencil printing, flux

j etting or flux dipping processes. 6 . Automated 1 0 0 % in- line optical inspection of solder paste to

reduce B O M component loss. 7 . Support for all common R oH S/G reen compliant solder alloys.After modeling, Amkor supports Engineering B uild R eq uests ( EB R s) on dedicated rapid- turn “ N ew P roduct I ntroduction” lines. These lines are ex actly the same as the high volume manufacturing lines so transfer to production is seamless and efficient. I n the R F market sector, Amkor often needs to support a large number of rapid- turn EB R s to facilitate R F tuning of the parts. F ast turn is critical to product success and time- to- market, our ex perts work closely with our customer’ s to facilitate this collaborative process. Supply chain considerations play a maj or factor in the success of SiP product realiz ation and impact both design and manufacturing. Amkor has ex panded its traditional supply chain ex pertise into passive components, and other parts not traditionally found in the package assembly environment. Amkor can manage the supply chain to ensure successful SiP development and production.

SiP Module Design Flow

System in Package ( SiP)Technology

Solutions

Questions? Contact us: [email protected]

Visit Amkor Technology online for locations andto view the most current product information.

Thermal & Mechanical Solutions for SiPI nevitably, higher levels of integration result in thermal challenges. As part of our co- design service, we capture not only electrical but also thermal constraints early on so that the package solution will meet all customer performance criteria. Amkor has a menu of thermal enhancement options to ensure that your die runs cool, including:1 . Thermal vias2 . Stacked C u- filled via structures3 . D irect- to- metal die attach pad structures4 . Enhanced thermal die attach compounds5 . Enhanced thermal mold compounds6 . D etailed mechanical test and simulations for mechanical SiP

integrity such as warpage improvement, solder j oint reliability, die strength and stress, flip chip bump fatigue, substrate trace cracking, temperature cycling, bend cycle, drop shock test, die strength, electromigration.

As part of the co- design service, Amkor helps identify the optimum and most cost- competitive thermal and mechanical enhancements req uired by a device to satisfy the end customer’ s operating conditions and field life ex pectations.

Markets for System in PackageEx isting market uses for SiP include:• R F and wireless devices

– P ower amplifiers, front end module, antenna switch, G P S/G N SS modules, cellular handset and cellular infrastructure, B luetooth® solutions

• Solid- state drives ( SSD s)– Storage for tablets, net books and computing applications where

typical SSD s include controller ASI C , N AN D , D D R , logic and power circuits

• Automotive applications– U nder- hood electronic control unit ( EC U ) , sensory modules and infotainment

• I oT for wearable and machine to machine ( M2 M) products – C onnectivity, MEMS, sensors, microcontroller, power

management and other mix ed- signal devices• P ower modules

– D C /D C converter, L D O , P MI C , battery management and othersSystem in P ackage technology allows multiple advanced packaging technologies to be combined to create solutions customiz ed to each end application.

Amkor is heavily involved in providing SiP solutions for R F , digital and mix ed- signal applications. W e have R F and high- speed digital design engineers on staff to assist customers in designing SiP s for their applications. Amkor is able to meet all design, material and manufacturing req uirements for R F and high- speed digital SiP s. Sputtering Conformal Shielding SolutionAmkor developed an ex cellent sputtering shielding technology to solve electromagnetic radiation effects among electronic components within SiP components and surrounding environment. C onformal shielding is used to replace bulky metal shielding. I t has z ero impact on package siz e and weight, with ex cellent electrical and magnetic shielding performance.

TS101NRev Date: 11/15

Unshielded SiP

SiP with Sputtering Conformal Shielding

Near Field Conformal Shielding Performance MeasurementsFrom 100 MHz to 6 GHz

Questions? Contact us: [email protected]

W i th r es p ec t to th e i n f o r m ati o n i n th i s d o c u m en t, A m k o r m ak es n o g u ar an tee o r w ar r an ty o f i ts ac c u r ac y o r th at th e u s e o f s u c h i n f o r m ati o n w i l l n o t i n f r i n g e u p o n th e i n tel l ec tu al r i g h ts o f th i r d p ar ti es . A m k o r s h al l n o t b e r es p o n s i b l e f o r an y l o s s o r d am ag e o f w h atever n atu r e r es u l ti n g f r o m th e u s e o f , o r r el i an c e u p o n i t an d n o p aten t o r o th er l i c en s e i s i m p l i ed h er eb y . Th i s d o c u m en t d o es n o t i n an y w ay ex ten d o r m o d i f y A m k o r ’ s w ar r an ty o n an y p r o d u c t b ey o n d th at s et f o r th i n i ts s tan d ar d ter m s an d c o n d i ti o n s o f s al e. A m k o r r es er ves th e r i g h t to m ak e c h an g es i n i ts p r o d u c t an d s p ec i f i c ati o n s at an y ti m e an d w i th o u t n o ti c e. Th e A m k o r n am e an d l o g o ar e r eg i s ter ed tr ad em ar k s o f A m k o r Tec h n o l o g y , I n c . A l l o th er tr ad em ar k s m en ti o n ed ar e p r o p er ty o f th ei r r es p ec ti ve c o m p an i es . © 2 015, A m k o r Tec h n o l o g y I n c o r p o r ated . A l l Ri g h ts Res er ved .

Visit Amkor Technology online for locations andto view the most current product information.

System in Package ( SiP)

TechnologySolutions

TS101NRev Date: 11/15

SiP TestingAmkor has developed ex pertise in R F and digital testing including test system software/hardware development and manufacturing test. O ur internally- developed, world- class test platform typically offers a 5 0 % to 8 0 % reduction in test time for common R F parts – P As, L N As and combinations in integrated front ends ( I F Es) .

System in Package BenefitsSimilar to a system on chip ( SoC ) approach, Amkor' s SiP technology is an ideal solution in markets that demand smaller siz e with increased functionality. H owever, SiP has the added benefit of compatibility with die design changes and integration of various die technologies ( e.g., Si, G aAs, SiG e, SO I , MEMS) without the high cost and lead time associated with SoC development and manufacturing.Additional Benefits of System in Package Approach• Smaller siz e solution than individually- packaged I C s• H igher performance through shorter interconnect paths, better

dimensional tolerances and local shielding• L ower overall cost of ownership

– Eliminate packaging ( multiple I C s now in one package)– R educed system board space and complex ity and layer count by

moving to a SiP solution– R educed overhead for the customer ( Amkor offers turnkey

solutions for assembly, test, supply chain management and value- added services)

– K nown good modules

• R educed time- to- market– Modules and main system assembly can be developed concurrently– C hanges can be made to the SiP without costly changes to the system board– D esign flex ibility and easy redesign versus complex SoC design– SiP allows plug- and- play insertion into one or multiple systems

• W ith proper consideration to design, Amkor’ s SiP packages are able to meet J ED EC L 3 /2 6 0 moisture resistance and are passing Amkor’ s internal SQ L b.

System in P ackage is the modular design approach offering unprecedented flex ibility in product development. The end user benefits from a faster time- to- market, reduced cycle times for system design, lower development risk compared to SoC I C development, flex ibility, tuned functional performance, and, in the end, a lower overall cost of ownership.

Site K4 GwangjuTotal L and: 1 ,4 9 0 K ft2Mfg F loor: 1 ,1 1 9 K ft2

B E C S D D CC S D S C D

B E C S D D CC S D S C D

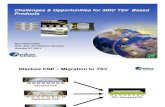

Amkor TSV Test Platform• Amkor supports optional test wafer and package socketing at strategic, interim assembly phases

Incoming Wafers

Active DiesOn Wafer

Front & BacksideProcessing

Test Partially Assembled Units (Various Formats)

Wafer Sort Know Good Die (Optional)

Backside Wafer ProbeGood Interposer

(Optional)

Assemble KnownGood Die & Interposer

Interposer

Final Test(Singulated)

Finished Goods

System Level Test

Fully AssembledUnit

QA – “x%”Samples

Know

nG

ood Parts

WSS Carrier

Probe Card

Wafer Probe During MEOL

Mem

oryP

rocesssor

Mixed S

ignal

RF

Baseband

KGD?

Probeat

Amkor

Yes

No

To Assembly

Wafer and Package Test at Assembly

Assy. 1

Proc

1

Test

Assy. 2

Mem

2

Test

Assy. 3

BB

3

Test

Assy. 4

MS

4

Test

Assy. 5

RF

8

SystemTest

Amkor TSV Test Platform• Amkor supports optional test wafer and package socketing at strategic, interim assembly phases

Incoming Wafers

Active DiesOn Wafer

Front & BacksideProcessing

Test Partially Assembled Units (Various Formats)

Wafer Sort Know Good Die (Optional)

Backside Wafer ProbeGood Interposer

(Optional)

Assemble KnownGood Die & Interposer

Interposer

Final Test(Singulated)

Finished Goods

System Level Test

Fully AssembledUnit

QA – “x%”Samples

Know

nG

ood Parts

WSS Carrier

Probe Card

Wafer Probe During MEOLM

emory

Processsor

Mixed S

ignal

RF

Baseband

KGD?

Probeat

Amkor

Yes

No

To Assembly

Wafer and Package Test at Assembly

Assy. 1

Proc

1

Test

Assy. 2

Mem

2

Test

Assy. 3

BB

3

Test

Assy. 4

MS

4

Test

Assy. 5

RF

8

SystemTest