Advances of Fuel Cell and Battery Development in...

Transcript of Advances of Fuel Cell and Battery Development in...

-

Advances of Fuel Cell and Battery Development

inTaiwan詹世弘

校聘教授(University Professor)

及

遠東能源講座教授

元智大學

海峽兩岸新能源技術研討會2011年10月8日至17日 湖北 武漢

-

OUTLINE

INTRODUCTIONFUEL CELL Development

Key components --元智大學HYDROGEN DevelopmentBATTERY DevelopmentEV DevelopmentENERGY STORAGE Development

大型儲電能系統之研發---元智大學CONCLUSIONS

-

Introduction

Taiwan’s New Energy Policy

-

“A PLACE THAT MAY BE ASIA’S BEST KEPT SECRET.”

National Geographic Traveler November/December 2007

-

No.2 talliest building in the world

World’s largest solar BIPV roof on stadium

-

Comparison of COComparison of CO 22 Emission IndicatorsEmission IndicatorsTaiwa

n Korea JapanGerman

y OECD WorldTaiwan – Worldrankin

g %

CO2 Emission(Mt of CO2 )

245.21 448.37 1201.3 7 854.29 12794 24983 220.98 %

Population(millions) 22.61 47.93 127.62 82.52 1154 6268

0.36 %

GDP per capita (2000 US$) 13559 12221 38208 22845 23216 5327 29

CO2 Emission per capita

(t CO2 per capita)10.85 9.36 9.41 10.35 11.08 3.99 19

CO2 per GDP(kg CO2 per 2000

US$)0.80 0.77 0.25 0.45 0.48 0.75 71

CO2 per GDP(kg CO2 per 2000

US$ PPP)0.53 0.51 0.35 0.41 0.45 0.51 46

CO2 per energy demand

(kg CO2 / tLOE)2.49 2.18 2.32 2.46 2.37 2.36 32

Reference:IEA key world energy Statistic (data for 2003)

-

GHG Policy & Target of TaiwanGHG Policy & Target of Taiwan1. Taiwan is willing to share responsibility in addressing the

problem of global climate change under the principle of fairness and justice.

2. Any GHG emission reduction approach should consider the global competitiveness of Taiwan’s industries.

3. By 2016~2020, CO2 emission reduces to that of 2008 By 2025, reduces to that of 2000

By 2050, reduces to 1/2 of 2000

Reference: Conclusion from Executive Yuan Energy Policy and S&T Development Steering Committee

-

Executive Yuan 2009.04 ~ six new industries

"Six new industries" includes:high-quality agriculturehealth carecultural and creative industryTourismgreen energy industrybiotech

Source: Council for Economic Planning Website

-

Green energy industryGreen energy industry

The main force industry (energy optical planes)

Solar, LED lighting

Industry has a good foundation, with a jump of energy

General industry with potential (energy wind, fire round)

Wind power, biomass fuels, hydrogen and Fuel Cell, Energy information and communication, electric vehicles

Technology under development, with industrial development

Source: Bureau of Energy Web site, the green energy industry Xusheng program action plan

-

Renewable Energy Development Act –passed on 2009.07.08

Renewable Energy:Solar, biomass, geothermal, ocean energy, wind power, non-pumped storage hydraulic, domestic general waste and general industrial waste or processed by direct use of energy generated, or other by the central competent authority may be sustainable use of energy.

Government to ensure the acquisition, profits and cost recovery in the next20 years, awards a total generation capacity from 6.5 to 10 million kWRenewable energy equipment be connected to grid and power generated be purchased by utilitySubsidy renewable energy equipment in the early period

Source: Renewable Energy Development Act

2009.07.08

-

Ministry of Economic Affairs Bureau - fuel cell demonstration & verification Guidelines

System demonstration - max subsidy be 50% of cost

Fuel cell systems subsidy:Pure hydrogen system:

100 million NT (US$33K) first KW70 million NT per additional KW

Reformer + FC system:200 million NT (US$66K) first KW150 million NT per additional KW

Hydrogen infrastructure:80% of cost

Fuel cost subsidy during demonstration:5% of system cost

Source: Energy Authority website

2009.01.07

-

By Air Photo Service

福島第一核電站,1,2,3 & 4號機 外牆爆炸/損壞

日本福島核電廠事故(日本3/11/2011地震)

ECCS 全面喪失移除餘熱功能→爐心溫度↑→氫氣→氫氣爆炸

-

Japan’s Fukushima Nuclear Crisis 3/11/2011(日本311地震及福島核災)

“Change in Energy Policy in Japan”:Nuclear power- keeps minimum operation

No new constructionsNo retrofit to extend their operation life.

Renewable energy-toward maximum effort (20% by 2020)Fossil fuels- increase natural gas useIntensive energy saving & control

Energy saving,new life/work styleDistributed power system(fuel cell), etc.

-

Taiwan New Energy Policy— Post Japan’s Fukushima Nuclear CrisisMinistry of Economy,8/2011: Policy Plan to 2030 assuming 5% annual economic growthTaiwan’s Nuclear Power Plants:

All existing plants (sites 1,2&3) will not be retrofitted to extend their lifeSite 1: Plant 1 ends 2018

Plant 2 ends 2019Site 2 & 3 Plants will follow the sameSite 4, New plants will be operational

Nature gas power plants --- 40%Renewable energy – 16%(triple)

Off-shore wind mills—600MW(2020)Million PV roofs—420MW(2015); 1020MW(2020)

Raise reserve electricity to 25% (from 23.5%) due to instability of renewable energy

-

S H Chan Fuel Cell Ct. YZU

STATUS OF FUEL CELL DEVELOPMENT

-

Research Institutes of Fuel Cell and Hydrogen Technology in Taiwan

Energy and Environment Laboratories (EEL), Industrial Technology Research Institute (ITRI)

PEMFC 、3kW prototype PEMFC power generation system using reformate gas.

Material and Chemical Laboratories (MCL),Industrial Technology Research Institute (ITRI)

DMFC portable power, fuel cell compoments.

Institute of Nuclear Energy Research (INER), Atomic Energy Council, Executive Yuan

SOFC、DMFC、hydrogen storage by CNT、hydrogen reforming from nature gas as feedstock

Fuel Cell Center, Yuan Ze UniversityKey component development, mostly on PEMFC and minor on DMFC, URFC & SOFC

Chung-shan Institute of Science and Technology (CSIST)Hydrogen Storage Tank 、Portable Power

-

Asia Pacific Fuel Cell Technology (APFCT)PEMFC 、 Fuel Cell Hybrid System (scooters、electric wheelchairs) 、Hydrogen Storage、

DeltaEngineering Integration of Delta for Fuel Cell Engineering Integration of Delta for Fuel Cell Development,converterDevelopment,converter etc.etc.

ZTEK TechnologySOFC Power Generation 、Hydrogen Refueling Station 、SOFC-MT Hybrid System

Tatung System Technology1kW Fuel Cell Power System 、 2kW mobile methanol fuel cell system 、Converter & Inverter 、Reformer

Enerage Inc.Dedicate to develop key components that make mass fabrication of DOFC, PEMFC, and Micro-SOFC

Antig TechnologyDMFC to power portable electronics 、“Component-like” DMFC Solution

Emerging Industries of Fuel Cell and Hydrogen Technology in Taiwan

-

Emerging Industries of Fuel Cell and Hydrogen Technology in Taiwan(continue)

Nan YaMEA

Chung Hsin Electric & Machinerary Co.PEMFC stack, UPS, Direct Methanol Reformer

Jemmytech Int. Co.UPS

Toplus Energy Co.Stack, UPS

Green Hydrotec Inc. (GHT)3-in-1 Hydrogen Generator 、 3-in-1 Steam reformer

HBank Technology Inc.The metal-hydride based AB5-type alloys absorb hydrogen

-

Asia Pacific Fuel Cell TechnologyFuel Cell Hybrid System

SpecificationDimension 1576 ×

440 ×

1087 mm

Power type PEMFC + Ultra-capacitor hybrid

PEMFC Nominal output: 24V, 2kW

Ultra-capacitor 32V, 27F

Fuel Hydrogen gas

Fuel consumption ≦1.6 g H2/km

Climbing 15km/hr@12 degree

Max speed 52 km/hr

Riding Range 60 km@ 30km/hr (est.)

Refuel Canister swapSpecificationDimension 1180mm(L) ×630mm(W) ×940mm(H)

Power type PEMFC + Ni-MH Battery

PEMFC Nominal output: 24V, 250W

Ni-MH Battery 12 Ah

Fuel Hydrogen gas

Fuel consumption ≦3.5 NL/min

Max speed 6 km/hr

Continuous operating time/distance

≧10 hours/60km

Refuel Canister swap

-

Tatung’s 1kW Fuel Cell Power System

(including methanol reformer)

Front View Back View

-

南亞(Nan Ya PCB Corp.)

南亞公司與杜邦(DuPont) 購買技術設備,生產MEA 並開始發展小型可攜式

DMFC 系統。Manufacturing PEMFC’s MEA using DuPont’s technology and facilityAlso developing small portable DMFC system

膜電極組

(Membrane Electrode Assembly, MEA)

DMFC Stack

DMFC system 85W

-

中興電工 Chung Hsin Electric & Machineray Co

2/5KW UPS Direct Methanol Reformer

PEMFC Stack

Converter

-

Jemmytech Int. Co Uninterrupted power supply

10 KW UPS:

PEMFC System

5 KW AC

5 KW DC

-

Toplus Energy Co.鼎佳6 KW testing station

100-400W for mobil stack

5KW UPS

-

Fuel Cell Center Yuan Ze University (元智大學)

Background:

In January 2000, the Fuel Cell Center was established by S. H. Chan, the former president of Yuan Ze University, and selected by

• Energy Commission,• Ministry of Economy and • Ministry of Education

as the university fuel cell center of the nation in Taiwan, focusing on

• Key components R& D• Educate Fuel Cell talents

-

26

Key Component R & D :Key Component R & D :1.Membrane

3.Bipolar plate4.Hydrogen

2.MEA

5.Micro sensor

Fuel Cell Center Yuan Ze University(元智大學)

-

27

120~200℃ (HTRHFC) versus 60~80℃ (LTRHFC)

Smaller heat exchanger

Potential to eliminate water management

Higher power density and lower cost

Better anode kinetics in the presence of CO

Low Cost, High Efficiency

元智High temperature membrane Advantage of HT reformate H2 PEM Fuel Cells

-

Membrane 元智High temperature membrane

(PBI-PTFE membrane patent)

PBI

-

Table 2. Conductivities σ and resistances per unit area rof membranes (Relative humidity 18+2%)

-----------------------------------------------------------------------------membrane σ (10-3 Scm-1) r (cm2S-1)

-----------------------------------------------------------------------------Nafion-117 (175 μm)150oC 1.03 5.42180oC 1.62 3.44

PBI (100 μm) 150oC 14.4 0.183180oC 18.6 0.153PBI/PTFE-2 (22 μm)150oC 4.76 0.133180oC 7.54 0.081

-----------------------------------------------------------------------------

PBI/PTFE composite membrane

-

Cell and Stacks

Inverter and Converter

Nano-structure TechnolgyMEA Failure Mode

Substitutes for Bipolar Plate MEMS Micro-sensor

Flow Field DesignWater and Heat Management

Numerical Simulation

Bureau of Energy(2000~2004Y, 2005-2009Y, 2010-

2013Y)

Industrial Technology Department

(2002~2005Y, 2007-2009Y)

MEA Manufacturing Technology

Key components by 元智大學

Technical Data Bank, Property Policy

PTFE-Nafion(LT-PEM) 、

PTFE/Nafion-TEOS(MT-PEM) 、PBI/H3PO4(HT-PEM)

PTFE/ Nafion-TEOS(x2500)

PBI/H3PO4 film

Treated (L), Original(R)Bio-cell

-

STATUS OF HYDROGEN DEVELOPMENT

-

HBank Technology Inc.

The metal-hydride based AB5-type alloys absorb hydrogen 1.65wt%(same type commercial alloys having reversible capacities

-

Taiwan H2 & fuel cell industrial supply chainsHydrogen companies Fuel Cell companiesHydrogen

supplier Metal hydride catalyst Membrane MEA stack FCsystem

中油聯華亞東三福氣體

亞太漢氫旭陽世界氫能

安炬科技 光騰安炬南亞電遠茂

亞太大同台達電中興電工南亞電世界氫能盛英鼎佳台全博研繼茂

台達電大同中興電工能碩中強光電亞太真敏台電加百裕博研新普揚光綠能鼎佳思柏科技

Natural gas reformer Zinc-air

中油 大同碧氫信通北瑞

異能科技

methanol electrolyzer GDL Bipolar plate BOP parts

李長榮公司伊墨克(進口商)

光騰友荃

源沛能碳能科技

鼎旭恩良盛英新永裕

大同台達電高力茂迪捷豹瓦特飛瑞

DMFC

奇鋐

資料來源:工研院

*法人與學界未列入*南亞電MEA技術轉自DuPont

-

EV,s Battery Industry Roadmap-Taiwan

Anode material

康普、鋰科、長園、

鐵研、立凱、尚志

Cathode materials

中碳、台松

Battery Assembly

能元、新普、達振、

統量、台達電

Battery managing system

致茂、光寶科(敦

陽)、台達電、瑞薩

Battery Electrolyte

台塑

Battery system

能元、新普、有量、

必翔、達振、瑞德、

銓陽、宇泉、喬信

Current inveter/converter

致茂、東元、台達電

Battery Separator

高銀化學

Battery Cells

能元、有量、必用、

昇陽、動能、瑞能

資料來源:工研院,圖片來源:PSI

e.g.新普, SIMPLO, one of the world largest battery packing co.

-

Battery,s Industrial Clusters-TaiwanLead acid / Solar energy / Fuel/Zinc air battery

台灣湯淺

(YUASA,Taiwan)

統一工業(ZTONG YEE)

台灣神戶(CSB)

廣隆光電(KLB)

茂迪(MOTECH)

異能(eVionyx

Taiwan )

亞太(APFCT)

百樂、正懋、光華、

南亞 、台灣杜邦、世

鋅

NI-MH

湯淺科技

(YUASA,Taiwan)

智弘(JHT)

耐能 、勁華、量威

Li-ion/Lipolymer

必翔電能(PHET)

能元科技(E-ONE)

動能(EXA)

科技興能高科技

(SYNST)

有量(AMITA)

普詮(Powertronics)

威力(PSE)

精極科技(LION-TECH)

威力仕(FeLis)

昇陽(PSI)

蘭陽(Lanyang)

特創、立澄、台灣超

能、金山實業

Battery assembly

新普(SMP)

順達(DynaPack)

天宇(FEII)

正崴(FOXLINK)

台灣松下能源(PECTW)

統振(WELLDONE)

宇泉(WIZ Energy)

漢達(FSP)

車王電子(MORE)

加百裕(Celxpert)

西勝(C-TECH)

德臻(GLW)

信音(Singatron)

統用、首能、異象、

台灣盛力、所羅門、

信邦電子

Standard/Certification

優力(UL)

電檢中心(ETC)

世界通(CGC)

快特電波(QuieTek)

E-bicycle

必翔電能(PHET)

捷安特(GIANT)

美利達(MERIDA)

愛地雅(IDEAL)

六逸、中廣、吉安、

永祺

E-scooter

光陽(KYMCO)

三陽(SYM)

摩特動力(PGO)

台灣山葉(YAMAHA)

台鈴(SUZUKI) 易維特、 台灣易立

歐、卡洛林 、飛寶

UPS

台達(DELTA)

飛瑞(PHOENITEC)

科風、烜翊、杰輝

PDA

Digital camera

Notebook

Cellular phone

Anode material

中鋼碳素(CSCC)

莊鏵

Cathode material

康普(CoreMax)

鋰科(LICO)

鐵研(TAK)

淡水河谷英可(VALE INCO)

尚志(TFC)

歐恩畝(OMG)

長園、亞獵士

Substrate(Li)

金居

Facility

亞泰金屬(AMI)

友煜(Unitronic)

崇越、固緯、鑫鴻

Battery

components

宏全(THC)

佳優(Acu

Tech)

勝昱(SUNVIC)

承德(CTEM)

海金(Flash)

翊高(iComforce)

立上電器、和勤

Materials

3M

緯利(LeadinWay)

Research

工研院材化所(MCL)

交通部運輸所(IOT)

台科大奈米電化學實

驗室

Electrolyte(Li)

台塑

Additive

ICI

Separator

高銀化學

資料來源:台灣電池協會網站

-

Taiwan’s EV Development

-

S H Chan Fuel Cell Ct. YZU 37

元智Hybrid power tourist car Metallic Fuel cell and LiFePo4 battery

(Yulan Car company )

-

EV Companies inTaiwanAC Power(鎰福電子)All Win Green Power(皆盈綠動能)Amita Tech.(有量科技)Asia Pacific Fuel Cell(亞太燃料電池)Avc Industrial Co.(全冠企業)Bei Li Electric Motion Enterprise Co.(貝力科技)C.C.P. Contact Probes. Co.(中國探針)Chen Chi Automation Co.(誠企企業)Chen Tech Electric MFG. Co.(承德科技)Chroma Ate INC.(致茂電子)Chumpower Machinery Co.(銓寶工業)C-Life Technologies, INC.(長利科技)Dijiya Energy Saving Tech.(迪吉亞節能科技)DJK (Taiwan) Corp.(一實股份)Empire Energy Co.(金和能源)E-Ton Power Tech Co.(益通動能科技)Formosan United Co.(福桑聯合企業)Forsen Motor Co.(卡洛琳國際)Free Power Energy Co.(飛寶動能)Fukuta Elec. % Mach. Co.(富田電機)Giorgial International Co.(喬吉歐企業)Goldmark Electric Vehicle Co.(金牌電動車)Green Diamond Power INC.(綠鑽公司)GWA Energy, INC.(統量電能)Heng Sheng Precision Tech. Co.(恆陞精密科技)Hirate Energy Tech.(海灣超能源科技)Honlin Heavy Industries Co.(紅菱重工)Hirose Tech Corp.(宏瀨科技)Intellect Battery Co.Jackfame International Corp.(永泰動力)Jin Hua Mtl Vehicle Co.Jordan Green Tech. Co.(東莞喬登節能)K.S. Terminals INC.(健和興端子)Kentfa Advanced Tech. Corp.(見發先進科技)

KOC Industry Corp.(台純工業)Kuann Dah Industry Co.(鑛達工業)Kwang Yang Motor Co.(光陽工業)Kyotathu Tech. Co.(協達科技)Lanyang Energy Tech. Co.(蘭陽能源科技)Lico Tech. Corp.(鋰科科技)Life Power Tech. Co.(台灣鋰鐵科技)Lifetech Energy INC.(強德電能)Long Time Tech. Co.(榮炭科技)Longwin Tech. Co.(長楹科技)Luanda Green Tech. Co.(路安達綠能)Luxgen Moteor Co.(納智捷汽車)Masterhold INT’L Co.(菲凡能源科技)Munich Expo veranstaltungs GMBHNoveltek Industrial Manufacturing INC.(恆智重機)Pantec Tech. Co.(捷豹聯合科技)Phoenix Silicon INC.(昇陽國際半導體)Pihsiang Electric Vehicle MFG.Co.(必翔電動汽車)Pitotech Co.(皮托科技)Power Source Energy Co.(威力能源)Seventeam Electronics Co.(七盟電子)Simplo Tech. Co.(新普科技)Sino-American Electronics Co.(華美電子)Stars Co.(群星科技)TARC(電灣車輛研發聯盟)Taiwan Electric Propulsion system Co.(台灣動能系統)Taiwan Precision Gear Corp.(台灣精密齒輪工業)Three-E Energy Tech Corp.(神錡能源)Tung Keng Enterprise Co.(東庚企業)Universal-Well Industry Co.(宇瑞工業)Well Shin Tech. Co.(維熹科技)Wu-Tsuen Co.(梧村公司)Yonyu Applied Tech. Material Co.(新永裕應科技科材料)Yulon Tobe Motor Co.(裕隆酷比汽車)

資料來源:台灣國際電動車展

-

Energy Storage

大型儲電能系統之研發---元智大學

-

S H Chan Fuel Cell Ct. YZU

40

大型儲電能系統之研發---元智大學

背景:儲電能之關鍵瓶頸突破,有賴於發展大型儲電能系統

目的:研發均一化再生型固態氧化物燃料電池系統

(Unitized Regenerative Solid Oxide Fuel Cell, URSOFC) ,提供大型儲電使用。

預期成果:

URSOFC之電極材料與電池製作研析

URSOFC之結構設計與微觀模式建立

URSOFC之熱能管理與電能轉換技術

團隊:跨領域團隊及完整軟硬體研發環境

-

URSOFC(續)41

URSOFC與SOFC差異

結合SOE與SOFC→URSOFC

高溫核電廠 ,

聚焦太陽熱能

固態電解器(SOE),

800℃氫(氧)儲存

固態氧化物燃料

電池(SOFC)

800℃

離峰儲電

高溫蒸汽

(800℃)

22

2

22

OHOH SOE

+⎯⎯→⎯

OH

OHSOFC

2

22

2

2

⎯⎯ →⎯

+

尖峰發電

SOFC(釋電)SOE(儲電)

H2

H2

-

URSOFC 之優點利用高溫URSOFC產生電力及氫氣之系統優勢包括:

減少電力-藉用核能高溫蒸氣,降低電解時所需電 力(下頁圖)

儲存電力-儲存核能及再生能源(如太陽熱能等) 離峰時段過剩能源

提供電力-提供尖峰時段電力

URSOFC:供電及儲電

傳統SOFC:僅供電!!

URSOFC(續)42

-

43

氧氣極//電解質//氫氣極

→

O2-

←

H2 (SOFC)

H2 (SOE)H2 O

H2

O

ZrO2

Ni

NiO

釋電

儲電

URSOFCURSOFC核心技術核心技術--自製自製““膜電極組膜電極組”” ((先用現有商業化材料先用現有商業化材料))

膜電極組

現況問題(電極不穩定):

Ni/ZrO2於水電解過程(SOE)氧化成NiO/ZrO2,增加阻抗 (Ni +O2- →NiO + 2e-)

創新核心技術-自製膜電極組(商業化材 料):

以現行SOFC材料完成膜電極組(氫極/電解質/氧氣極),進行電解/電池實測後,分析其真正不穩定成因。

-

44

燒結還原後之胚片

成功開發出水系(環保)刮刀技術,

燒結平整度佳-分別為4%(小面積)、7%(大面積)。

具有相當多的連通孔洞。

大面積燒結之胚片

8.5 cm ×

8.5 cm

NiO-YSZ表面型態

直徑2.4cm

以以環保製程環保製程製備製備氫氫氣極支撐材之成果氣極支撐材之成果

-

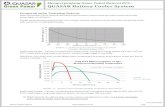

S H Chan Fuel Cell Ct. YZU

自製膜電極組自製膜電極組--電池及電解成果電池及電解成果 MEA Manufacture Ability

Fig. 1 Voltage-current density curves of five MEA samples operated under SOEC and SOFC modes with a humidity of 60% RH and at a temperature of 800 ℃

We concluded that the success of the firing process developed in this study was 80% ( four samples out of five).

We concluded that the success of the firing process developed in this study was 80% ( four samples out of five).

電解←∣→

電池

-

S H Chan Fuel Cell Ct. YZU

海峽兩岸 ECFA 兩岸 “Free Trade” – Significant Economic Development

Economic Cooperation Framework Agreement (ECFA)a preferential trade agreement between the governments of China and Taiwanaims to reduce tariffs and commercial barriers between the two sides. Effective 1/1/2011 , the most significant agreement since the two sides split in 1949. To greatly boost the bilateral trade ( currently US$110 billion) Many products from Taiwan to China free/reduced tarriff

http://en.wikipedia.org/wiki/Preferential_trade_agreementhttp://en.wikipedia.org/wiki/Mainland_China

-

S H Chan Fuel Cell Ct. YZU

ConclusionsConclusionsTaiwan has boosted its R & D funding for fuel cell, H2 , battery & EV technology development. Many research institutes and companies are active these technologies and many prototypes/commercial units are available.

With its success in manufacturing capability and high market share in 3C products, Taiwan is conducive to 海峽兩岸/international collaboration to apply its manufacturing experience to bring down the cost and to help the earlier realization of fuel cell/EV commercialization.

幻灯片编号 1OUTLINEIntroduction幻灯片编号 4幻灯片编号 5Comparison of CO2 Emission IndicatorsGHG Policy & Target of TaiwanExecutive Yuan 2009.04 ~ six new industries 幻灯片编号 9Renewable Energy Development Act –passed on 2009.07.08Ministry of Economic Affairs Bureau - fuel cell demonstration & verification Guidelines 幻灯片编号 12Japan’s Fukushima Nuclear Crisis�3/11/2011(日本311地震及福島核災)Taiwan New Energy Policy—�Post Japan’s Fukushima Nuclear Crisis幻灯片编号 15Research Institutes of Fuel Cell and Hydrogen Technology in TaiwanEmerging Industries of Fuel Cell and Hydrogen Technology in TaiwanEmerging Industries of Fuel Cell and Hydrogen Technology in Taiwan(continue)幻灯片编号 19幻灯片编号 20南亞(Nan Ya PCB Corp.)中興電工 Chung Hsin Electric & Machineray CoJemmytech Int. Co�Uninterrupted power supplyToplus Energy Co.鼎佳 幻灯片编号 25幻灯片编号 26元智High temperature membrane �Advantage of HT reformate H2 PEM Fuel CellsMembrane�元智High temperature membrane �(PBI-PTFE membrane patent)幻灯片编号 29幻灯片编号 30STATUS OF HYDROGEN DEVELOPMENTHBank Technology Inc.Taiwan H2 & fuel cell industrial supply chainsEV,s Battery Industry Roadmap-TaiwanBattery,s Industrial Clusters-TaiwanTaiwan’s EV Development元智Hybrid power tourist car�Metallic Fuel cell and LiFePo4 battery� (Yulan Car company )EV Companies inTaiwanEnergy Storage大型儲電能系統之研發---元智大學幻灯片编号 41幻灯片编号 42幻灯片编号 43幻灯片编号 44自製膜電極組-電池及電解成果�MEA Manufacture Ability海峽兩岸 ECFA� 兩岸 “Free Trade” – Significant Economic DevelopmentConclusions