13. EthanolSCC

Transcript of 13. EthanolSCC

-

7/28/2019 13. EthanolSCC

1/18

Ethanol Stress Corrosion Cracking

Presented by: Mark Baker, P.E.

-

7/28/2019 13. EthanolSCC

2/18

http://images.google.com/imgres?imgurl=http://www.thewhiskystore.de/experte/images/etohh2o_6.jpg&imgrefurl=http://www.thewhiskystore.de/experts/alcohol.htm&h=337&w=400&sz=5&hl=en&start=14&tbnid=1tivTt-GU6P2sM:&tbnh=101&tbnw=120&prev=/images%3Fq%3Dethanol%2Bmolecule%26svnum%3D10%26hl%3Den%26lr%3D%26sa%3DG -

7/28/2019 13. EthanolSCC

3/18

-

7/28/2019 13. EthanolSCC

4/18

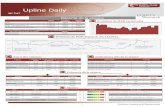

Increasing Domestic Use of EthanolRenewable Fuels Standard

Could change completely due to finding an enzyme that will break downcellulose like starches and sugars for fermentation possibilities.

-

7/28/2019 13. EthanolSCC

5/18

What Is SCC? Rapid cracking of steels through transgrannular

or intergrannular corrosion Duration of hours or months, but much shorter

than typical corrosion; ethanol appears to occur

in periods ranging from months to several years SCC not new (amine, carbonate, chloride), but

new for ethanol. Closest relative is methanol

SCC First known case in 1995 at Chevrons Willbridge

Terminal (2 tanks completely destroyed)

-

7/28/2019 13. EthanolSCC

6/18

Figure 16CC in Steel Tank Bottom Showing Highly Branched, Intergranular

Cracks at 100Source: API 939D

-

7/28/2019 13. EthanolSCC

7/18

API 939D Current Results SCC in fuel grade ethanol is not just a West Coast

problem limited to a few users that deal with foreign

sources of ethanol. End users should not consider fuel grade ethanol a

commodity. Fuel ethanol varies widely in composition.

SCC in fuel grade ethanol does not take years todevelop. Based on preliminary laboratory studies, the factorsthat increase corrosivity of fuel ethanol appear to be

increased water content and decreased pHe. Based on preliminary laboratory studies, SCC hasbeen produced in a sample of fuel ethanol that apparently

does not contain denaturants or inhibitors

-

7/28/2019 13. EthanolSCC

8/18

API 939D Results SCC in fuel grade ethanol has been reproduced

in laboratory tests in fuel ethanol samplesobtained from the field.

Some evidence has been generated based on

laboratory results, which indicates that materialfrom the near weld region in the base metal mayhave a greater susceptibility to SCC than base

metal. The economic impact of SCC in fuel grade

ethanol service in end user facilities has beenwell over $1 million in direct costs in the last fewyears.

-

7/28/2019 13. EthanolSCC

9/18

Slow Strain Rate Testing forScreening Ethanol SCC

Machining of SSR

Tension Specimen

Ethanol SCC inSSR Specimen

Slow strain rate

Testing machine

-

7/28/2019 13. EthanolSCC

10/18

SCC Crack Growth Testsin MTS Machine

Load frame &crosshead

Environment Cell& fracture fixtures

Hydraulic

Actuator &control

-

7/28/2019 13. EthanolSCC

11/18

Schematic of CT Specimen usedfor SCC Crack Growth Testing

Can be used for wedge loading or for testing in MTS orSlow Strain Rate (rising load) loading

-

7/28/2019 13. EthanolSCC

12/18

SCC on CT specimen followingtesting in fuel ethanol

SCC Crack growthin Fuel Ethanol

Mixed mode SCCIntergranular/TransgranularCT Specimen after testing in fuel ethanol

-

7/28/2019 13. EthanolSCC

13/18

Further Results

API 939D research continues

New factors have been found

Some factors eliminated or roles clarified

-

7/28/2019 13. EthanolSCC

14/18

Further Results

Primarily occurs for middle to end producer

No known cases for the producer

Occurs near weld HAZ

-

7/28/2019 13. EthanolSCC

15/18

Further Results

Factors found to be:Dissolved O2Secondary Coupling to rusted steel

Secondary Stress levels

Transportation Introduces O2Loading and unloading

-

7/28/2019 13. EthanolSCC

16/18

API 939D Revision Recommendations

Tank cleanliness is critical Wet MT needed to find cracks

Use ethanol fuel compatible coatings Leak detection for tank bottoms

Leak detection for piping systems

Minimize O2 exposure

No current analytical procedure

-

7/28/2019 13. EthanolSCC

17/18

API 939EGuidelines for Identification, Repair,and Mitigation of Cracking of Steel

Equipment in Fuel Ethanol Service

API RECOMMENDED PRACTICE 939-EFIRST EDITION, XXXXX

Laundry list of best practices such as:

PWHT

Coating

It is up to companies to do a risk assessment and to evaluate the

choices available to them using a ration method such as decisionanalysis.

-

7/28/2019 13. EthanolSCC

18/18

Questions